Professional Documents

Culture Documents

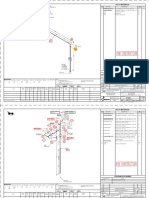

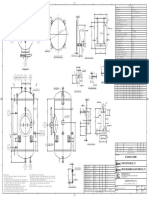

Susunan Butterfly Valve Ø900 Bendungan Sermo: Yogyakarta

Uploaded by

silviOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Susunan Butterfly Valve Ø900 Bendungan Sermo: Yogyakarta

Uploaded by

silviCopyright:

Available Formats

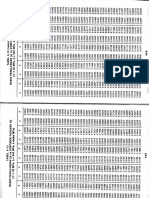

COMB No. DRAWING No.

/

NAME OF PART No. SPEC

30 20 10 REMARK

1 B / F VALVE ASSY 1 ASSY _

_ _ 2 _ _ _

_ _ 1 BODY ASEMBLY 3 MILD STEEL A1 - 212 - 0168 AS 3678 - 250

_ _ 4 _ _ _

1 END CAP 5 MILD STEEL A3 - 213 - 0500 AS 3678 - 250

25 66 1 GLAND RING

_ _

6 ST / STEEL

_

A2 - 216 - 017 - 9

_

AS 1449 - 316

_

26 7

170 (4 HOLES Ø 25)

1 DOOR 8 ST / STEEL A1 - 213 - 0152 AS 2074 - H6C

23 8 CLAMP RING 9 ST / STEEL A2 - 214 - 0275 AS 1449 - 316

17 25 SEE NOTE 11

_ _ 11 _ _ _

1 POSITION POINTER 12 ST / STEEL A4 - 216 - 0643 AS 1449 - 316

45 1 POSITION IND. PLATE 13 ST / STEEL A3 - 299 - 0176 AS 1449 - 304

59 28

SEE NOTE 7 1

_

ACT. MTG. PLATE

_

14 MILD STEEL

_

A3 - 216 - 0639

_

AS 3678 - 250

_

15

16 31 1 LOCKING PLATE 16 ST / STEEL A2 - 216 - 082 - 54 AS 1449 - 316

25 29 1

1

CLEVIS PIN

TRUNION - DRIVE

17

18

ST / STEEL

ST / STEEL

A2 - 215 - 033 - 24

A2 - 215 - 0499

AS 2837 - 431

AS 2837 - 431

1 TRUNION - NON DRIVE 19 ST / STEEL A2 - 215 - 0501 AS 2837 - 431

3 1 CENTERING RING 21 BRONZE A4 - 215 - 0430 AS 1565 C92610

_ _ 22 _ _ _

1 LOCK PIN ASSEMBLY 23 ST / STEEL A3 - 215 - 0508 AS 2837 - 431

_ _ 24 _ _ _

1 HYDRAULIC SYLINDER 25 _ A2 - 215 - 0502 _

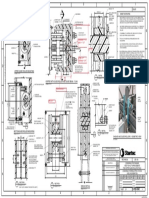

DETAIL H DETAIL F DETAIL E 1 LEVER ARM ASSY 26 _ A1 - 216 - 0637 AS 3678 - 250

ANCHOR BOLT DETAILS CLEVIS DETAIL LOCK PIN DETAIL 2 CYL TRUNN BEARING 27 PERMAGLIDE 1 3/4" X 1 15/16" X 2 PAP Z2832 P10

1 CLEVIS BEARING 28 ELGES GE 30 UK - 2 RS PAP Z2832 P10

4 LOCK PIN BEARING 29 PERMAGLIDE 20 I/D X 23 O/D X 25 LG PAP 202 P10

2 TRUNNION BEARING 31 PERMAGLIDE 110 I/D X 115 O/D X 100 LG PAP 110100 P11

2 SYLINDER COVER 32 ST / STEEL A4 - 215 - 0511 AS 2837 - 316

2 MTG STOOL 33 MILD STEEL A2 - 216 - 0638 AS 3678 - 250

_ _ 34 _ _ _

1 O'RING END CAP 35 LURENE 5 7/8" X 6 1/8" X 1/8" DASH No. 257

_ _ 36 _ _ _

32 SOC HD CAP SCREW 37 ST / STEEL M. 10 X 20 LG AS 2837 - 316

56 _ _ 38 _ _ _

1 _ 39 _ _ _

65 3 3 43 32 4 STOLL MTG STUDS 41 ST / STEEL A2 - 273 - 051 - 111 AS 2837 - 431

8 END CAP STUDS 42 ST / STEEL A2 - 273 - 051 - 89 AS 2837 - 431

55 6 8 GLAND SEAL STUDS 43 ST / STEEL A3 - 273 - 060 - 2 AS 2837 - 316

4 MTG PLATE STUDS 44 ST / STEEL A2 - 273 - 051 - 117 AS 2837 - 431

35 31 31 67 27 4 SCREW HEX HEAD 45 ST / STEEL M. 8 X 15 LG AS 2837 - 316

21 3 2 HEX - HD SET SCREW 46 ST / STEEL 1/4" - 20 UNC X 20 LG AS 2837 - 316

5 18 66 9 10 DRIVE SCREW 47 ST / STEEL BRAND U No. 6 X 10 AS 2837 - 304

3 14 1 NAME PLATE GEC 48 ST / STEEL A3 - 299 - 0159 AS 1449 - 302

19 37 1

6

SERIAL PLATE

GRUB SCREW

49

51

ST / STEEL

ST / STEEL

A4 - 299 - 0156

M. 6 X 12 LG

AS 1449 - 302

AS 2837 - 316

8 GANTI BARU 25 6

2

GRUB SCREW

MTG PLATE DOWEL

51

52

ST / STEEL

ST / STEEL

M. 6 X 12 LG

A2 - 273 - 013 - 43

AS 2837 - 316

AS 2837 - 431

3 LEVER ARM DOWEL 53 ST / STEEL A2 - 273 - 012 - 75 AS 2837 - 431

2 HEX - HD SET SCREW 54 ST / STEEL M. 12 X 30 LG AS 2837 - 316

8 NUT HEX - HD 55 ST / STEEL M. 16 AS 2837 - 304

8 NUT HEX - HD 56 ST / STEEL M. 10 AS 2837 - 304

DETAIL A DETAIL B DETAIL C DETAIL D _ _ 57 _ _ _

NON DRIVE END DETAIL DRIVE END DETAIL DOOR SEAL DETAIL 8 NUT HEX - HD 58 ST / STEEL M. 20 AS 2837 - 304

HYDRAULIC SYLINDER DETAIL 4 CAPSULE 59 HILTI HEA M. 20 X 170 _

4 BROOKER ROD 61 ST / STEEL M. 20 X 250 LG AS 2837 - 316

1 LIMIT SWITCH BLOCK 62 ST / STEEL A4 - 215 - 0485 AS 2837 - 316

1 LIMIT SWITCH 63 PROXIMINITY MODEL 44 ADO C / W SPRING YOKE

3 DOOR DOWEL 64 ST / STEEL A2 - 273 - 012 - 51 AS 1449 - 316

1 LIMIT SWITCH 65 ST / STEEL A3 - 216 - 0651 AS 1449 - 316

1 DOOR SEAL 66 70 ± 5 IRHD A3 - 214 - 0274 QLD RUBBER 4732

1 GLAND SEAL 67 55° - 65° IRHD A2 - 214 - 0320 - 9 ACRYLO NITRILE RUBBER

2 O'RING (FLANGE) 68 NITRILE Ø7 X 3285 LG _

FLANGE DRILING _

TO AS 2129 TABLE "C" 2 PAINT 69 REF ONLY SEE PAINT SPEC

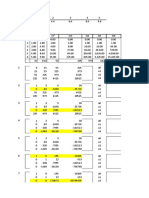

24 HOLES EQUISPACED DESIGN CONDITIONS SPECIFICATIONS

OFF CENTRE ON 1092 P.C.D

TEST PRESSURE - BODY 750 kPa

20 HOLES DRILL Ø 36

TEST PRESSURE - DOOR 750 kPa

B / FACE Ø 60 TEST PRESSURE - SEAL 750 kPa

4 HOLES DRILL AND TAP DESIGN PRESSURE

M. 33 X 60 DEEP (EACH FLANGE) FLOW RATES 9m / sec (NORMAL)

17m / sec (EMERGENCY)

DIRECTION

655 943 108 45 45 SURFACE TREATMENT

INTERNAL SURFACES : - DULUK AMERLOCK 400 GF, MINIMUM D.F.T. 450 um (2 COATS MINIMUM)

A

INTERNAL SURFACES : - DULUK AMERLOCK 400 GF, MINIMUM D.F.T. 160 um

68

OF FLOW

ASSEMBLY NOTES

860 NOM

SEE DETAIL "C" 1. TO SECURE PLATES (ITEM 13, 48 & 49) DRILL HOLES No. 31 (Ø3.05) TO SUIT ITEM 47 DRIVE SCREW

SEE DETAIL "E" 2. COAT ALL ST / STEEL TO ST / STEEL FASTENERS WITH DOW - CORNING SILICON COMPOUND III

3. LOCK ALL FASTENERS, EXCEPT SHAFT SEAL NUTS WITH LOCKTITE 262

SEE DETAIL "B"

47 REFER NO. 1 4. COAT FLANGE FACES WITH CRC SOFTSEAL

5. PARAREL DOWEL ITEM 52, DRILL AND REAM TO SUIT AT ASSEMBLY

REFER NOTE 6

26 48 6. USE TAPERED REAMER ST2 / 76 FOR TAPEREDE DOWEL - ITEM 64. THEN DRILL AND TAP M.6 X 15 DEEP

(HALF AND HALF IN ITEMS 8 & 64) TO SUIT ITEM 51

SEE DETAIL "A" 47 7. TAPERED DOWEL ITEM 53, WITH CYLINDER IN CLOSED POSITION, DOOR CLOSED AND CLEVIS

350 64 51 49 IN CENTRE OF ADJUSMENT, DRILL AND REAM 2 HOLES EQUALLY SPACED AS SHOWN IN EACH

Ø 100 REF

LEVER ARM. USE REAMER ST2 / 68. DRILL AND TAP 1 HOLE HALF AND HALF IN EACH DOWEL

13 47 AND TRUNNION TO SUIT GRUB SREW ITEM 51. DRILL AND REAM HOLE IN BODY (THROUGH LEVER ARM)

TO SUIT LOCK PIN BEARING ITEM 29.

Ø 1175

Ø 1045

REFER NOTE 1 IMPORTANT

SHOULDER ON INSIDE OF LEVER ARM MUST BE METAL TO METAL WITH

SEE NOTE 12 SHOULDER ON TRUNNION BEFORE FITTING DOWELS.

12 45 8. TEST COVER TO BE ADVISED

46 54 62 63 65 53 REFER NOTE 7

9. TERMINAL POINTS ARE ALL ITEM INCLUDED ON THIS DRAWING

310 70 10. VALVE TO BE PAINTED PRIOR TO HYDROSTATIC TEST

11. ITEM 23, LOCK PIN TO BE FIXED TO VALVE BODY ON ASSEMBLY

SEE DETAIL "F"

SEE DETAIL "D"

51 WEIGHT OF VALVE (INCLUDING C / WEIGHT & STOOLS) = 2000 Kg

670

58

44

41 58 52 REFER NOTE 5

30 GROUT

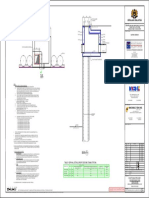

Nama Paket :

190

PENYUSUNAN INSPEKSI KHUSUS DAN

33 A LOCK PIN STOWAGE

MANUAL DI BENDUNGAN SEMPOR,

RL 89.700 58 WADASLINTANG DAN SERMO (DOISP II)

SEE DETAIL "H" JUDUL : Provinsi :

160 160 RL 89.600

255 YOGYAKARTA

SUSUNAN BUTTERFLY VALVE Ø900

296

BENDUNGAN SERMO Kabupaten :

KULON PROGO

496 484 866 300 MIN Digambar Andik Santosa No. Kontrak :

Ketua Tim Ir. Eko W., M. Tech. HK.02.03/PHLN/SRO-CS1/S.OPSDA.SO.01-2018/37

Diperiksa oleh Direksi Pekerjaan Antyarsa Ikana Dani, ST., M.Eng Tanggal : No Halaman :

PART SECTION A - A PART SECTION

Disetujui oleh PPK OPSDA I Eko Supriyanto, ST., M.PSDA

Mengetahui Ka Satker O&P SDA Tampang, S. ST., MT

You might also like

- Detail "A" Detail "B" Detail "C": Susunan Butterfly Valve Ø300 Bendungan SermoDocument1 pageDetail "A" Detail "B" Detail "C": Susunan Butterfly Valve Ø300 Bendungan SermosilviNo ratings yet

- Diagrama Hidraulico Del 980HDocument2 pagesDiagrama Hidraulico Del 980HMiguel GonzalezNo ratings yet

- Eep 000097 0102148005 3 ST Det 0669 R02Document1 pageEep 000097 0102148005 3 ST Det 0669 R02Vikram DalalNo ratings yet

- Bill of Materials: See Iso 10-P-1202 SHT 02Document2 pagesBill of Materials: See Iso 10-P-1202 SHT 02Junaid AdnanNo ratings yet

- Spreader Beam Drawings & MTODocument3 pagesSpreader Beam Drawings & MTOsales ntscompaniesNo ratings yet

- GERB Foundation 72328 02E Rev0Document1 pageGERB Foundation 72328 02E Rev0Omprakash SinghNo ratings yet

- Drawing No.: IssueDocument2 pagesDrawing No.: IssuevvkNo ratings yet

- 00 ASI 030s RepairedDocument67 pages00 ASI 030s RepairedMohamad HssanNo ratings yet

- Rev - 1 - Approved JK 5-27-21Document2 pagesRev - 1 - Approved JK 5-27-21stuart tomkinsNo ratings yet

- Hopper Guide Plate DWG - RDDocument1 pageHopper Guide Plate DWG - RDRaj KumarNo ratings yet

- Eep 000097 0102148005 3 ST Det 0682 R02Document1 pageEep 000097 0102148005 3 ST Det 0682 R02Vikram DalalNo ratings yet

- Kone 1-4Document133 pagesKone 1-4José luis CasimiroNo ratings yet

- Note Generale: Key NotesDocument1 pageNote Generale: Key NotesPablo BenedettoNo ratings yet

- KC-ME-EER-024 Rev.1Document16 pagesKC-ME-EER-024 Rev.1Daniel TuerosNo ratings yet

- Caterpillar Multiterreno 277CDocument4 pagesCaterpillar Multiterreno 277CAnonymous KOtSfT6qNo ratings yet

- Shougang Hierro Peru S.A.A.: Plano No. Plano NoDocument1 pageShougang Hierro Peru S.A.A.: Plano No. Plano NoFrank Jerry Aylas TejedaNo ratings yet

- Bloque "B2" Bloque "B2": Ministerio PublicoDocument1 pageBloque "B2" Bloque "B2": Ministerio PublicoChriss AlagónNo ratings yet

- 1C10 (KSS021-D-534) - Column-R1Document1 page1C10 (KSS021-D-534) - Column-R1mo3azNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- E S D 0 S D 2.1 S D 2.1: Equipment ListDocument1 pageE S D 0 S D 2.1 S D 2.1: Equipment ListJuan Manuel Gomez FigueroaNo ratings yet

- A-200 Reflected Ceiling Plan and Power LayoutDocument1 pageA-200 Reflected Ceiling Plan and Power LayoutProperty Engineer PENo ratings yet

- Foul Sewer Pumping Station - Category A: Vent PipeDocument2 pagesFoul Sewer Pumping Station - Category A: Vent PipeMohd HaroonNo ratings yet

- Plano Huidráulico Itm 324DDocument2 pagesPlano Huidráulico Itm 324DTONINo ratings yet

- CBP Wall - DWGDocument1 pageCBP Wall - DWGsambasivammeNo ratings yet

- Building 02 - Corridor Smoke Extraction Layout For 2nd FloorDocument1 pageBuilding 02 - Corridor Smoke Extraction Layout For 2nd FloorMTT VIETPRONo ratings yet

- Hold Hold: 2"-0320-AP-00302-C1E2A 2"-0320-AP-00305-C1E2ADocument1 pageHold Hold: 2"-0320-AP-00302-C1E2A 2"-0320-AP-00305-C1E2ACristianJhonNo ratings yet

- 16 Mob-Bb-Ab-Sd-L14-100Document1 page16 Mob-Bb-Ab-Sd-L14-100ايفان ارميروNo ratings yet

- Hydraulic System Schematic 914-g PDFDocument2 pagesHydraulic System Schematic 914-g PDFpupoz100% (7)

- Tupi BV: Cosco (Dalian)Document4 pagesTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- RRPR-OPR-PRB-BR1-SB52 - Rev 1Document1 pageRRPR-OPR-PRB-BR1-SB52 - Rev 1sanjeev sharmaNo ratings yet

- Bleach and Bromine Skid LayoutDocument1 pageBleach and Bromine Skid LayouteegNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Group 2 Electrical Circuit: 25L/30L/33L (LC) - 7MDocument7 pagesGroup 2 Electrical Circuit: 25L/30L/33L (LC) - 7MCamilo TorresNo ratings yet

- 536E4525 Gen Arr. RWF-II-222 Screw Compress.Document1 page536E4525 Gen Arr. RWF-II-222 Screw Compress.Jose TorrezNo ratings yet

- Tupi BV: Cosco (Dalian)Document3 pagesTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- Primera Planta Segunda Planta: Detalle: Doblado de Estribos en Columnas Y VigasDocument1 pagePrimera Planta Segunda Planta: Detalle: Doblado de Estribos en Columnas Y VigasDiego CervantesNo ratings yet

- B Basden Steel Corp: Bill of MaterialDocument1 pageB Basden Steel Corp: Bill of MaterialsateeshdonkadaNo ratings yet

- 20 Gie 001 - M 1 2Document1 page20 Gie 001 - M 1 2fouad belalNo ratings yet

- Tupi BV: Cosco (Dalian)Document5 pagesTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- Linked PDFDocument4 pagesLinked PDFtruck diesel solutionNo ratings yet

- 4cx Master Site Electrical DiagramDocument34 pages4cx Master Site Electrical DiagramDean mark rey luzonNo ratings yet

- Hydraulic 992G - Azx PDFDocument2 pagesHydraulic 992G - Azx PDFGuztiNo ratings yet

- Hydraulic System 784C Tractor 785C Off-Highway Truck: Fluid Power SymbolsDocument2 pagesHydraulic System 784C Tractor 785C Off-Highway Truck: Fluid Power SymbolsGustavo Enrique fontalvoNo ratings yet

- Aa 036142 011Document1 pageAa 036142 011Mohamed RamadanNo ratings yet

- A102-R7 Ground Floor Plan-A102-r7 Revised Ground Floor PlanDocument1 pageA102-R7 Ground Floor Plan-A102-r7 Revised Ground Floor Planzubair khanNo ratings yet

- Produced by An Autodesk Educational Product: A B C D E F GDocument1 pageProduced by An Autodesk Educational Product: A B C D E F GManinder ChaudharyNo ratings yet

- D038 Evs Co000 1090 - 00Document1 pageD038 Evs Co000 1090 - 00Mussarat BabasahebNo ratings yet

- SX6 SchematicsDocument14 pagesSX6 SchematicsSugeng AriyadiNo ratings yet

- Slab Detailing of 1st Floor SlabDocument1 pageSlab Detailing of 1st Floor SlabManish AgrawalNo ratings yet

- Bukit Jelutong Lighting Switch Plan (Ground Floor) 20220319 (A2)Document3 pagesBukit Jelutong Lighting Switch Plan (Ground Floor) 20220319 (A2)danny chenNo ratings yet

- ZX200 225usr Eng eDocument1 pageZX200 225usr Eng eirawan jatmikaNo ratings yet

- DRG-OT-561 - R02 - L-Clamp Assy (Vedang)Document7 pagesDRG-OT-561 - R02 - L-Clamp Assy (Vedang)Puneet SharmaNo ratings yet

- 1 Key Notes: MECH (F-Viii)Document1 page1 Key Notes: MECH (F-Viii)Cristo BglezNo ratings yet

- 143H and 163H Motor Grader Hydraulic System Ripper AttachmentDocument2 pages143H and 163H Motor Grader Hydraulic System Ripper AttachmentMohamed Harb100% (1)

- R1 Donor Cut Tower: Hexane Drum Item No. D-755Document1 pageR1 Donor Cut Tower: Hexane Drum Item No. D-755NoppolNorasriNo ratings yet

- 102B24 - W21X68 - 29'-1 1/2" - ONE REQ'D CAMBER 3/4": Bill of MaterialDocument1 page102B24 - W21X68 - 29'-1 1/2" - ONE REQ'D CAMBER 3/4": Bill of Materialai ambaraNo ratings yet

- ST32 (KSS021-D-1477) - Stringer-R0 PDFDocument1 pageST32 (KSS021-D-1477) - Stringer-R0 PDFmo3azNo ratings yet

- Tdimmer Set 02 1Document2 pagesTdimmer Set 02 1LUCIANO MARTINNo ratings yet

- Uas DevanDocument8 pagesUas DevansilviNo ratings yet

- Perhitungan Balok Kirei FixDocument8 pagesPerhitungan Balok Kirei FixsilviNo ratings yet

- Tugas 1 - Devan Suwandi - 171222019150857Document31 pagesTugas 1 - Devan Suwandi - 171222019150857silviNo ratings yet

- Gauss JordanDocument1 pageGauss JordansilviNo ratings yet

- Table: Element Forces - Frames Frame Station Outputcase Casetype P V2 V3 TDocument11 pagesTable: Element Forces - Frames Frame Station Outputcase Casetype P V2 V3 TsilviNo ratings yet

- Susunan Butterfly Valve Ø900 Bendungan Sermo: YogyakartaDocument1 pageSusunan Butterfly Valve Ø900 Bendungan Sermo: YogyakartasilviNo ratings yet

- Titik BeratDocument13 pagesTitik BeratsilviNo ratings yet

- Desain Counterweight Bendungan Sermo: Elevasi Elevasi ElevasiDocument1 pageDesain Counterweight Bendungan Sermo: Elevasi Elevasi ElevasisilviNo ratings yet

- Img 0007 PDFDocument1 pageImg 0007 PDFsilviNo ratings yet

- Table 2.6. Climatological Data AvailibilityDocument1 pageTable 2.6. Climatological Data AvailibilitysilviNo ratings yet

- Img 0007 PDFDocument1 pageImg 0007 PDFsilviNo ratings yet

- Jenny Prischila Litha - 171222019150977 - Statika Ii PDFDocument9 pagesJenny Prischila Litha - 171222019150977 - Statika Ii PDFsilviNo ratings yet

- Relative Pronoun / Relative Adverb Contoh Kalimat Adjective Clause Who Kalimat SederhanaDocument2 pagesRelative Pronoun / Relative Adverb Contoh Kalimat Adjective Clause Who Kalimat SederhanasilviNo ratings yet

- UTS Beton%1Document7 pagesUTS Beton%1silviNo ratings yet

- Regresi PolinomialDocument9 pagesRegresi PolinomialsilviNo ratings yet

- Kata PengantarDocument8 pagesKata PengantarsilviNo ratings yet

- Kata Kerja V1, V2 & V3Document3 pagesKata Kerja V1, V2 & V3silviNo ratings yet

- Ach. Muhib Zainuri Kekuatan BahanDocument154 pagesAch. Muhib Zainuri Kekuatan BahanHeru SatryaNo ratings yet

- Relative Pronoun / Relative Adverb Contoh Kalimat Adjective Clause Who Kalimat SederhanaDocument2 pagesRelative Pronoun / Relative Adverb Contoh Kalimat Adjective Clause Who Kalimat SederhanasilviNo ratings yet

- Metric DIN 7349 SpecDocument6 pagesMetric DIN 7349 SpecANIRBANNo ratings yet

- Thread-Cutting Tools and ProceduresDocument31 pagesThread-Cutting Tools and ProcedureszaidoNo ratings yet

- How To Install Track Lighting - For DummiesDocument5 pagesHow To Install Track Lighting - For DummiesJelaiNo ratings yet

- Matrix Extruder Assembly ManualDocument17 pagesMatrix Extruder Assembly ManualAlfonso BautistaNo ratings yet

- FLANGE JIS 16K SS304 & CS Rev 2Document2 pagesFLANGE JIS 16K SS304 & CS Rev 2Hendrias ari sujarwoNo ratings yet

- CH 10Document76 pagesCH 10Sky 6794No ratings yet

- XF Series 4.0t-X5.5t Mast Parts Catalog 2023.3Document127 pagesXF Series 4.0t-X5.5t Mast Parts Catalog 2023.3santiago medinaNo ratings yet

- Bodytobonnet Torque Values For Fluorocarboncoated FastenersDocument8 pagesBodytobonnet Torque Values For Fluorocarboncoated FastenersJoão Mendonça SantosNo ratings yet

- Automotive and Truck Specification ListDocument10 pagesAutomotive and Truck Specification List김동훈No ratings yet

- Catalog of Replacement Parts: CL44e AND CL54e Series DishwashersDocument40 pagesCatalog of Replacement Parts: CL44e AND CL54e Series DishwashersAndres RiveraNo ratings yet

- Control OperatorsDocument3 pagesControl OperatorsAnonymous cS9UMvhBqNo ratings yet

- S03 Drill FeedDocument48 pagesS03 Drill FeedrolandNo ratings yet

- Linde H30D1Document2 pagesLinde H30D1Ionut GrozaNo ratings yet

- 02 01 Byg ClassicDocument204 pages02 01 Byg ClassicEscuela EntrenamientoNo ratings yet

- Wa0013Document30 pagesWa0013Smc PowerNo ratings yet

- Heli-Coil Aerospace Standard Interchangeability List: Metric InsertsDocument2 pagesHeli-Coil Aerospace Standard Interchangeability List: Metric InsertsheewooNo ratings yet

- Remove - Install Center ConsoleDocument2 pagesRemove - Install Center ConsoleOsama Ben DawNo ratings yet

- ASME 1.20.1 1983 R 2006 Pipe Threads, General Purpose (Inch) - Revision and Redesignation of ASME ANSI B2.1-1968Document32 pagesASME 1.20.1 1983 R 2006 Pipe Threads, General Purpose (Inch) - Revision and Redesignation of ASME ANSI B2.1-1968DANIEL'S SERVICIOS INTEGRALES EN SOLDADURANo ratings yet

- 778 1984 Reff2020Document33 pages778 1984 Reff2020ocsspectroNo ratings yet

- Stripping Strength of Tapped HolesDocument4 pagesStripping Strength of Tapped HolesbennyfergusonNo ratings yet

- Kf6 Catalogo NuevoDocument18 pagesKf6 Catalogo NuevoMauro PerezNo ratings yet

- Fabory Screw Threads PDFDocument2 pagesFabory Screw Threads PDFalifuat duyguNo ratings yet

- Eye Bolts: Forged Eye Bolt Warning and Application InstructionsDocument5 pagesEye Bolts: Forged Eye Bolt Warning and Application InstructionsshamanthupadhyayaNo ratings yet

- Office Fit-OutsDocument2 pagesOffice Fit-OutsRoberto Jr ParagasNo ratings yet

- List of Parts Singer 31-15 and 31-20Document296 pagesList of Parts Singer 31-15 and 31-20Just4Him89% (9)

- BlackBook English PDFDocument2 pagesBlackBook English PDFeinsten77714% (7)

- Mathcad - Bolt Loading VDI M39 01Document10 pagesMathcad - Bolt Loading VDI M39 01Pete SwiftNo ratings yet

- F25DMH 2019 PiezasDocument54 pagesF25DMH 2019 PiezasDinora ArroyoNo ratings yet

- Gearbox UnitDocument1 pageGearbox UnitRiste RisteNo ratings yet

- Finetech Catlog 2022Document36 pagesFinetech Catlog 2022Neeraj VohraNo ratings yet