Professional Documents

Culture Documents

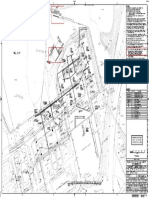

GERB Foundation 72328 02E Rev0

Uploaded by

Omprakash SinghCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GERB Foundation 72328 02E Rev0

Uploaded by

Omprakash SinghCopyright:

Available Formats

1 2 3 4 5 6 7 8 9 10 11 12

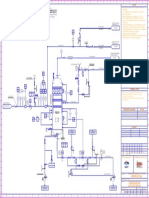

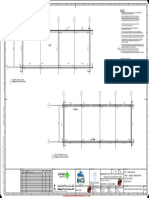

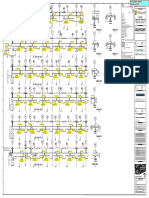

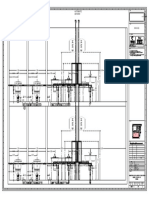

MOUNTING INSTRUCTIONS FOR SPRING ELEMENTS NOTES

ANVIL ALL DIMENSIONS ARE SUBJECT TO VERIFICATION AGAINST THE

TYPE:

SECTION A-A SECTION B-B B

TYPE E-72328-01

FINAL DRAWING OF THE MACHINE MANUFACTURER AND THE ACTUAL

ON-SITE SITUATION.

L ATTENTION ! SPRING ELEMENTS ARE SHIPPED EX POSITIONING OF FOUNDATION RESP. MACHINE AXES RELATIVE TO L

HEIGHT OF HAMMER FOOT DIMENSIONS ACC. TO CUSTOMER WORKS READY FOR INSTALLATION AND THE BUILDING AXES BY OTHERS.

*

490

BELOW FLOOR LEVEL ACC. TO 300 3350 300 3980 C PREFILLED WITH THE VISCOLIQUID.

MACHINE MANUFACTURER'S D A THE CORRECT HEIGHT OF THE FORMWORK FOR THE FOUNDATION

DRAWING. 150 150 1675 1675 150 150 300 1690 1690 300 BLOCK MUST BE RESPONSIBLY CHECKED BY THE SUPERVISOR ON

TO BE CONFIRMED BY CUSTOMER 20 mm JOINT, PERIPHERALLY ACCESSORIES FOR MOUNTING AND FIXING SITE. ELEVATIONS REFER TO OPERATING CONDITION.

1520 * 1520* 600* 600* THE SPRING ELEMENTS, GERB SUPPLIES :

(e.g. POLYSTYRENE)

-Z- FOLLOW GERB CONSTRUCTION MANUAL !

FLOOR LEVEL ±0.000

-M- GROUNDWATER LEVEL

±0.000 ±0.000

A) SELF-ADHESIVE RESILIENT PAD

(1 PCS./ELEMENT)

CONCRETE TOLERANCES:

GENERAL: ±10 mm

B) STOPPERS BOLTED TO ELEMENT

620

CONCRETE SURFACES AT SPRING ELEMENT LOCATIONS TO BE

300

300

-0.300 C) ANCHOR BOLTS M20 (HILTI) CONSTRUCTED LEVEL

D) POSTS - DEVIATION FROM FLATNESS PER ELEMENT LENGTH ±2 mm

K 2800 (ANVIL) 1400 (ANVIL) K

- DEVIATION FROM PLAN ELEVATIONS ±2 mm

C 1470

C

1470

1400 1400 700 700 860

±2

1960 ±2

REGARDING PROTECTION OF GROUNDWATER THE CUSTOMER

L HAMMER

2980

2980

1960

-B- IS RESPONSIBLE FOR THE EXECUTION OF THE FOUNDATION PIT

2330

2330

250 450 450 250 INSTRUCTIONS IN ACCORDANCE WITH THE REGULATIONS OF THE LOCAL

2030

-1.470 -1.470 1. CHECK THE SURFACE BELOW THE SPRING ELEMENTS. ENVIRONMENT AUTHORITY.

2980

A LINER OR PROPER PAINTING MAY BECOME NECESSARY, INSIDE

C

2. THE SURFACES MUST BE LEVEL, CLEAN (BROOM-SWEPT) AND OIL-FREE.

3. MARK THE POSITION OF THE ELEMENTS ACCORDING TO THE SYSTEM DRAWING, AND/OR OUTSIDE AS THE CASE MAY BE. CONSTRUCTION JOINTS

490

490

AND MARK THE HOLES FOR THE ANCHOR BOLTS ACCORDING TO THE HOLE. ARE TO BE PREPARED ACCORDINGLY.

-1.960 ±2 -1.960 ±2

PATTERN IN THE BASE PLATE OF THE SPRING ELEMENTS AND DRILL.

4. PLACE THE BOTTOM ADHESIVE PADS BELOW THE ELEMENTS. WHEN PLANING THE PIT, TAKE CARE FOR THE REGULATIONS

100

370

370

-2.330 -2.330 5. SET THE SPRING ELEMENTS, ON TOP OF THE ADHESIVE PADS. INSERT BOLTS OF THE LOCAL ENVIRONMENTAL OFFICE.

J J

AND TIGHTEN TO SNUG TIGHT, PLACE THE RUBBER PLATE ON THE TOP

WATERSTOP WATERSTOP EMBEDDED PARTS ARE NOT SUPPLIED BY MACHINE MANUFACTURER

OF THE SPRING ELEMENTS.

1125 1125 UNLESS OTHERWISE NOTED. EMBEDMENTS TO BE PLACED AND

650

650

650

6. REMOVE POSTS, WHICH SECURE THE SPRING ELEMENTS DURING TRANSPORT.

7. PLACE AND SECURE THE ANVIL/STEELPLATE ONTO THE TOP OF RUBBER PLATE CHECKED ACCORDING TO THIS DRAWING. THEY SHALL BE SECURED

-2.980 -2.980

SAFELY AGAINST SHIFTING.

CAUTION

THE ELEMENTS MUST STAND UPRIGHT DURING TRANSPORT AND INSTALLATION, NOT SHOWN CONDUITS OR OTHER OPENINGS (E.G. FOR POWER OR

1000 1000 LEAN CONCRETE min. 50mm LEAN CONCRETE min. 50mm AND WHEN STORED. TOP SIDES OF THE SPRING ELEMENTS ARE MARKED WITH OIL SUPPLY) WHEN NEEDED TO BE DEFINED BY CUSTOMER.

"THIS SIDE UP" AND / OR "DO NOT TILT".

IN CASE OF GROUNDWATER MAKE CONCRETE PIT WATERPROOF.

300 100 3150 100 300

-A- 300 750 1880 750 300

MAINTENANCE

THE FOUNDATION PIT SHOULD BE CLEANED PERIODICALLY TO ENSURE ALL CONCRETE EDGES TO BE CHAMFERED.

3950 3980 SPRING ELEMENTS ARE NOT BLOCKED BY SCALE OR DIRT.

H CONCRETE OF FOUNDATION PIT TO BE PLACED WITHOUT H

GERB SPRING ELEMENTS DO NOT REQUIRE ANY SPECIAL MAINTENANCE. HOWEVER, INTERRUPTION. FOR UNPLANNED CONSTRUCTION JOINTS, THE

CARE SHOULD BE TAKEN TO PREVENT CORROSION. DAMAGE TO THE PROTECTIVE FOLLOWING MEASURES HAVE TO BE TAKEN:

COATING SHOULD BE REPAIRED. -KEYING OF CONCRETE SURFACE

DO NOT PLACE THE SPRING ELEMENTS IN OR NEAR WATER. ESPECIALLY -SHRINKAGE REINFORCEMENT(INCL. CALCULATION)

DETAIL-B- VISCOLIQUID SHOULD NOT COME IN CONTACT WITH WATER OR OTHER LIQUIDS. -CONSTRUCTION JOINT TAPE...

NOT UNDER ANY CIRCUMSTANCES SHOULD WATER, OTHER LIQUIDS

SECTION C-C PROPOSAL COVERING SCALE 1 : 5 OR SCALE AND DIRT GET INTO THE VISCODAMPERS. CONCRETE SURFACES TO BE PROTECTED AGAINST DETRIMENTAL

OIL WHERE NECESSARY (ACC. TO MACHINE MANUFACTURE).

STEP IRON, HEA/HEB PROFILES, CHEQUERED PLATE, 0-5 mm 1)

B L-PROFILES AND ANCHOR ARE SUPPLIED BY CUSTOMER

MAX. LIVE LOAD = 50 kN/m²

ELECTRICAL GROUNDING OF THE BLOCK SHALL BE PROVIDED IN

ACCORDANCE WITH THE MACHINE MANUFACTURER'S INSTRUCTIONS.

G (370) 1030 1030 (370) SPRING ELEMENTS B LOCATION OF STEEL STAIRCASE BY CUSTOMER. G

0 0

SUMP 400x400x200 ±0.0

ALL MEASURES ARE "mm". FINISHED LEVEL ROUGH CONCRETE

DETAIL -Z- ELEVATIONS ARE "m".

SPRING ELEMENTS

300

300

SCALE 1:2.5

(350) COMPLEMENTARY

L HAMMER

DIMENSIONS

SLOPE TO SUMP 75 CHEQUERED PLATE

0

750

-0.30 t = 20mm 4

DEPENDING ON THE GROUND WATER LEVEL, THE FOUNDATION PIT

1) THE GAP BETWEEN MACHINE 5 10

180

±0.000 IS TO BE SECURED AGAINST UPLIFT.

20

1520* 1520* FOOT (OR STEEL PLATE) IS TO BE

C

1690

FILLED WITH STEEL SHEETS. THE SPRING ELEMENTS ARE ATTACHED BY ADHESIVE PADS AT BOTTOM.

HEB 240

60

OUTLINE ANVIL

STEEL SHEETS ARE TO BE FIXED

(250)

F F

700 +5/-0

AT THE STOPPERS OF THE MANUFACTURER OF THE VIBRATION ISOLATION SYSTEM: GERB

940

SPRING ELEMENTS

600*

SCOPE OF DELIVERY:

75

450

HEA 120

HEA 120

C - SPRING ELEMENTS

3980

3380

3980

1880

C

L HAMMER L HAMMER S

M ENT - ADHESIVE PADS

. IRE

ACC REQU

700 +5/-0

450

NIN

G - VISCODAMPERS WITH DAMPING LIQUID AND

600*

ER

OPE USTOM 1 L-PROFIL

TO C 75x75x7mm FIXING MATERIAL (ANCHOR BOLTS, TEMPLATES)

940

A A A A

(250)

- HILTI DOWELS

WELD: min. 2mm

60

ANCHOR

1690

OUTLINE ANVIL 2

HEB 240

180

5x20, L=150mm

0

L HAMMER

-0.30

SPACING= 500mm

60 -M- BUILDING MATERIALS:

115 1400 +5/-0 1400 +5/-0 60 115

E REINFORCEMENT Fe 500 E

-Z- CONCRETE M 30

1050

SLOPE TO SUMP

C

DETAIL -M- WEIGHTS

300

300

SCALE 1:2.5 MACHINE WEIGHT APPROX. 780 kN

STEP IRON 0

±0.00

5x GERB SPRING ELEMENTS 1575 1575 SUMP 400x400x200 LOCATION BY CUSTOMER

TYPE E-72328-01 75 LEGEND :

100 3150 100 150 150 1675 1675 150 150 -0.300

CONCRETE

300 3350 300 300 3350 300

DETAIL -M-

3950 3950

75

D D

DETAIL -Z-

B * DIMENSIONS ACC. TO CUSTOMER B CHEQUERED PLATE

PLAN - PILES 1 L-PROFIL

75x75x7mm

WELD: min. 2mm

B 2 ANCHOR

5x20, L=150mm

SPACING= 500mm

DETAIL-A-

NO SCALE EMBEDDED PARTS

C C

865

MATERIAL: E250-killed

REFERENCE DRAWINGS:

ITEM PCS. TITLE SINGLE TOTAL

kg/m kg/m² WEIGHT WEIGHT E-72328-01 DYNAMIC AND STATIC ANALYSIS (GERB)

-2.930 E-72328-03 REINFORCEMENT (GERB)

50

1 1 L-PROFIL 75x75x7, L=~21420mm 7.976 170.856 170.856

1990

50

(TOP OF PILE)

(BOTTOM OF 2 83 ANCHOR, FLAT STEEL 150x20x5 39.250 0.118 12.390 HO500-23-3471666-0 DATA SHEET HO-U500 (LASCO)

CONCRETE COVER

LEAN CONCRETE

FOUNDATION PIT) -2.980 HO500-23-3507378-0 DATA SHEET HO-U500

1125

3 1 STEEL PLATE 20x10, L=~14660mm 2.355 34.524 34.524

4 1 CHEQUERED PLATE 20mm

850 1125 1125 850

C

TOTAL WEIGHT: 217.77 kg

L HAMMER Ø750

L HAMMER

B B

REVISION DATE MODIFICATION DRAWN CHECKED

A A

1125

GERB Engineering GmbH PHONE

FAX

+049-(0)201-26604-20

+049-(0)201-26604-50

PILING SCHEDULE PROPOSAL

C

Ruhrallee 311 / 45136 Essen (Germany) E-MAIL eng@gerb.de

1990

CLIENT: DRAWING TITLE:

NO. TOP OF PILE MIN. SAFE

GROUP Req'd

PILE HEAD DIA LENGTH LOAD CAPACITY

LASCO UMFORMTECHNIK GmbH GEN. ARRANGEMENT

PROJECT: STRUCTURAL MEMBER:

1 4 -2.930 Ø750 mm 31.0m min.1030 KN/PILE *1 2024501J METAL & STEEL FACTORY, FOUNDATION PIT

865

ISHAPORE, INDIA

DIRECT SPRING SUPPORT OF A HAMMER

A *1 NOTE : SLS WITHOUT SAFETY FACTOR LASCO HO-U 500

1975 1975 ATTENTION : THIS DRAWING IS THE PROPERTY SCALE DATE NAME DRAWING NO.

OF GERB AND SUBJECT TO

PILE-DESIGN NOT INCLUDED IN SCOPE OF -GERB Engineering GmbH- COPYRIGHT PROTECTION. IT MUST

DRAWN

26.02.2021 Schürmann LOCATION - JOB NO. - DWG NO. REVISION

72328-02E-Rev0.dwg

NOT BE USED, ESPECIALLY COPIED

OR OTHERWISE REPRODUCED, 1 : 25 CHECKED 26.02.2021 Rauße

B EITHER WHOLLY OR PARTLY OR

TO BE MADE AVAILABLE TO THIRD

PARTIES WITHOUT PERMISSION.

RELEASED

26.02.2021 Bauer

72328-02 0

IF IN DOUBT PLEASE CONTACT GERB.

1 2 3 4 5 6 7 8 9 10 GERB A0 (1189.00 X 841.00 MM)

You might also like

- IT and Software Companies - GujaratDocument31 pagesIT and Software Companies - GujaratDishank100% (1)

- Rio Tinto Standard DetailsDocument34 pagesRio Tinto Standard DetailsHCStepNo ratings yet

- Buster Hernandez Aka Brian KilDocument38 pagesBuster Hernandez Aka Brian KilKyle BloydNo ratings yet

- A-402 - Cellar Reflected Ceiling PlanDocument1 pageA-402 - Cellar Reflected Ceiling PlanShweta KamatNo ratings yet

- Notes: Investor/Operator Engineering ContractorDocument1 pageNotes: Investor/Operator Engineering ContractorPerviz BabazadeNo ratings yet

- Epcc05 MDR 421 STR DWG 000 0072 05Document1 pageEpcc05 MDR 421 STR DWG 000 0072 05RANJEET PRATAP SINGHNo ratings yet

- 1824 322 PR Pid 1001 - 4 - IfcDocument1 page1824 322 PR Pid 1001 - 4 - IfcNils Ericsson Sánchez HuayanaNo ratings yet

- 4cx Master Site Electrical DiagramDocument34 pages4cx Master Site Electrical DiagramDean mark rey luzonNo ratings yet

- 1-ModelDocument1 page1-Modeljoselito navarroNo ratings yet

- XXXXXDocument1 pageXXXXXSanjoy SanyalNo ratings yet

- 1824 000 SS DST 0040 - 2 - IfcDocument1 page1824 000 SS DST 0040 - 2 - IfcAquiles MartinezNo ratings yet

- 1824 000 SS DST 0040 - 2 - IfcDocument1 page1824 000 SS DST 0040 - 2 - IfcAquiles MartinezNo ratings yet

- Notice The Complete Requirements For Procuring The Product Described Herein Shall Consist of This Document and The Latest Issue of As85049Document3 pagesNotice The Complete Requirements For Procuring The Product Described Herein Shall Consist of This Document and The Latest Issue of As85049daNo ratings yet

- MCC Schematics - Highlighted StartersDocument8 pagesMCC Schematics - Highlighted Startersshrikanth5singhNo ratings yet

- Ground Floor PlanDocument1 pageGround Floor PlanSadaf HzNo ratings yet

- Legend: 225Mw/337.5Mwp Ground Mounted Solar PV Project At, Vijayanagar KarnatakaDocument1 pageLegend: 225Mw/337.5Mwp Ground Mounted Solar PV Project At, Vijayanagar Karnatakaamit mitraNo ratings yet

- Petronas Carigali SDN BHD: Document Review StatusDocument1 pagePetronas Carigali SDN BHD: Document Review StatusMohd KhaidirNo ratings yet

- Final Design (Ifc) : Emergency LightingDocument1 pageFinal Design (Ifc) : Emergency LightingIbrahim AlqunoonNo ratings yet

- General Notes & Specifications Detail "A" Barrel Details Section "B-B"Document1 pageGeneral Notes & Specifications Detail "A" Barrel Details Section "B-B"ton carolinoNo ratings yet

- General Notes & Specifications Detail "A" Barrel Details Section "B-B"Document1 pageGeneral Notes & Specifications Detail "A" Barrel Details Section "B-B"ton carolinoNo ratings yet

- CB 1655 CombinedDocument3 pagesCB 1655 CombinedQuerubin RamirezNo ratings yet

- Safety gate installation drawingDocument1 pageSafety gate installation drawingMary DenizeNo ratings yet

- 15 Staircase Finishing DetailsDocument2 pages15 Staircase Finishing DetailsRenuka ChalikwarNo ratings yet

- Onshore Facilities FEED North Field Expansion Project: Qatargas OperatingDocument1 pageOnshore Facilities FEED North Field Expansion Project: Qatargas OperatingAbid AyubNo ratings yet

- A0 SWSC/KZG/WS/ - REV00: Interconsult ZimbabweDocument1 pageA0 SWSC/KZG/WS/ - REV00: Interconsult ZimbabweRoddy TeeNo ratings yet

- 00 ASI 030s RepairedDocument67 pages00 ASI 030s RepairedMohamad HssanNo ratings yet

- M BD2 100tu0 Ctli Edr 000116Document1 pageM BD2 100tu0 Ctli Edr 000116Sanjoy SanyalNo ratings yet

- M BD2 100tu0 Ctli Edr 000112Document1 pageM BD2 100tu0 Ctli Edr 000112Sanjoy SanyalNo ratings yet

- Sunday 7-11-Model - PDF Sara 1Document1 pageSunday 7-11-Model - PDF Sara 1Mariam Mohamed Abdo Morsy GhanemNo ratings yet

- Construction and wood technologies center project reviewDocument1 pageConstruction and wood technologies center project reviewRaul BarreroNo ratings yet

- Kone 1-4Document133 pagesKone 1-4José luis CasimiroNo ratings yet

- A102-R7 Ground Floor Plan-A102-r7 Revised Ground Floor PlanDocument1 pageA102-R7 Ground Floor Plan-A102-r7 Revised Ground Floor Planzubair khanNo ratings yet

- Note Generale: Key NotesDocument1 pageNote Generale: Key NotesPablo BenedettoNo ratings yet

- Legend: Project Name: LPIC EPC1 SCUDocument1 pageLegend: Project Name: LPIC EPC1 SCUjeswinNo ratings yet

- M BD3 1F8000 Cutl Edr 000301Document1 pageM BD3 1F8000 Cutl Edr 000301ahmed.abdelmegeed78No ratings yet

- B011 000 16 50 01205 - Rev 2Document1 pageB011 000 16 50 01205 - Rev 2GLOBUS ENGINEERSNo ratings yet

- Deep Sea Controller 5310 DrawingDocument1 pageDeep Sea Controller 5310 DrawingLeonel Cadenas HernandezNo ratings yet

- TECHNICALPart 5Document1,521 pagesTECHNICALPart 5সীমান্ত ছাড়িয়ে - Shemanto ChariyeNo ratings yet

- J3BGDF02BR030 09 02Document1 pageJ3BGDF02BR030 09 02Nauman TahirNo ratings yet

- J3BGDF02BR030 07 02Document1 pageJ3BGDF02BR030 07 02Nauman TahirNo ratings yet

- 220 M6 0310 00032Document1 page220 M6 0310 00032nestor159357No ratings yet

- D038 Evs Co000 1091 - 00Document1 pageD038 Evs Co000 1091 - 00Mussarat BabasahebNo ratings yet

- A 0103 - Roof Deck Floor Plan 20 X 30 TBDocument1 pageA 0103 - Roof Deck Floor Plan 20 X 30 TBKimberly Crystel GorospeNo ratings yet

- 10083a 1X M6 Ab 00006 04Document1 page10083a 1X M6 Ab 00006 04wael zakariaNo ratings yet

- Porta Cabin For NGNDocument1 pagePorta Cabin For NGNRashmi Ranjan MohantyNo ratings yet

- Lines Variables Abbreviations Control Valve Bodies Self Actuated Devices Typical Connection-Any VariableDocument1 pageLines Variables Abbreviations Control Valve Bodies Self Actuated Devices Typical Connection-Any VariableALexis Arturo Godoy GarridoNo ratings yet

- Skid Weight Information and DimensionsDocument1 pageSkid Weight Information and DimensionsEnamul KhanNo ratings yet

- Review of Ramps and Stairs Drawings Shop DrawingDocument1 pageReview of Ramps and Stairs Drawings Shop DrawingPhạm Quốc ViệtNo ratings yet

- 11 620000 4800000621 Nap STR DRG 120104 01Document1 page11 620000 4800000621 Nap STR DRG 120104 01MOHAMEDNo ratings yet

- Pyramids Sections-Sec A-ADocument1 pagePyramids Sections-Sec A-AMAHMOUD HISHAMNo ratings yet

- Drawing DM1Document22 pagesDrawing DM1slamet haryadiNo ratings yet

- District 7 Townhouse Vietnam 2019-10-07Document6 pagesDistrict 7 Townhouse Vietnam 2019-10-07Hieu TranNo ratings yet

- DSE5310 DiagramsDocument1 pageDSE5310 DiagramsHenrik KunzkeNo ratings yet

- Corte Finalisimo 1 AmDocument1 pageCorte Finalisimo 1 AmJeison PedrazaNo ratings yet

- Manhole cover connection detailDocument1 pageManhole cover connection detailCivil Design EngineerNo ratings yet

- H047&H048-CMS-SD-04-12-2 - Cctv-General Position - As Built DrawingDocument1 pageH047&H048-CMS-SD-04-12-2 - Cctv-General Position - As Built DrawingDedeNazaludinNo ratings yet

- Hill Limit: Saudi Arabian Oil CompanyDocument1 pageHill Limit: Saudi Arabian Oil Companyzarrar malikNo ratings yet

- z3 Macc SV Con Abl ST SSC 020021 00Document1 pagez3 Macc SV Con Abl ST SSC 020021 00jafarNo ratings yet

- 1 Key Notes: MECH (F-Viii)Document1 page1 Key Notes: MECH (F-Viii)Cristo BglezNo ratings yet

- 20240131 UG FLOOR PLAN- INTERIOR (1)Document1 page20240131 UG FLOOR PLAN- INTERIOR (1)ranjeet.globalgreenNo ratings yet

- 220 M6 0330 00006Document1 page220 M6 0330 00006jhonNo ratings yet

- Soil Test Report Lasco HammerDocument14 pagesSoil Test Report Lasco HammerOmprakash SinghNo ratings yet

- GERB Foundation 72328 01C Rev0Document49 pagesGERB Foundation 72328 01C Rev0Omprakash SinghNo ratings yet

- GERB Foundation 72328 02E Rev0Document1 pageGERB Foundation 72328 02E Rev0Omprakash SinghNo ratings yet

- GERB Foundation 72328 03L Rev0Document5 pagesGERB Foundation 72328 03L Rev0Omprakash SinghNo ratings yet

- GERB Foundation 72328 01C Rev0Document49 pagesGERB Foundation 72328 01C Rev0Omprakash SinghNo ratings yet

- h13-623 Hcnp-Storage-Cdps v4.0 Mock ExamDocument3 pagesh13-623 Hcnp-Storage-Cdps v4.0 Mock ExamIki ArifNo ratings yet

- TX2A/RX2A: UHF FM Data Transmitter and Receiver ModulesDocument10 pagesTX2A/RX2A: UHF FM Data Transmitter and Receiver ModulesMoisesNo ratings yet

- 1106A-70TG1 135-Kva Details PDFDocument10 pages1106A-70TG1 135-Kva Details PDFHải Nguyễn Hồng0% (1)

- Abb cs31Document67 pagesAbb cs31Cristobal Silva Sanhueza100% (1)

- Aircraft Landing Gear SystemDocument12 pagesAircraft Landing Gear SystemPaul Pipi OkonkwoNo ratings yet

- Electrical and Electronic Engineering Courses (Ay2013-2014) : EE0001 Effects of Electromagnetic Radiation On HumansDocument22 pagesElectrical and Electronic Engineering Courses (Ay2013-2014) : EE0001 Effects of Electromagnetic Radiation On HumansChris BarolasNo ratings yet

- SYS600 COM500i Users GuideDocument144 pagesSYS600 COM500i Users GuideJose Blanco RojasNo ratings yet

- Smart Campus UIMDocument1 pageSmart Campus UIMHadis AzNo ratings yet

- Zscaler Corporate Solution OverviewDocument12 pagesZscaler Corporate Solution Overviewsureshkumarv100% (1)

- Stm32f0xxx Cortexm0 Programming Manual StmicroelectronicsDocument91 pagesStm32f0xxx Cortexm0 Programming Manual Stmicroelectronicsnisaken634No ratings yet

- PressReleasePoint - eTOM - A Business Process Framework Implementer's Guide - 2009-04-29Document2 pagesPressReleasePoint - eTOM - A Business Process Framework Implementer's Guide - 2009-04-29jbdecorzent0% (1)

- McDonald's Extended HoursDocument6 pagesMcDonald's Extended Hoursjrom4444No ratings yet

- Human Computer Interaction BookDocument210 pagesHuman Computer Interaction BookTsegaye Andargie100% (1)

- Reduce Concrete Waste with Bubble Deck SlabsDocument11 pagesReduce Concrete Waste with Bubble Deck Slabsgpt krtlNo ratings yet

- Check Your ECDIS Uses Latest IHO S-52 StandardsDocument4 pagesCheck Your ECDIS Uses Latest IHO S-52 StandardsgongaxNo ratings yet

- Ar-One: Monitor Any Frequency From 10 KHZ To 3.3 GHZDocument2 pagesAr-One: Monitor Any Frequency From 10 KHZ To 3.3 GHZaliaj2No ratings yet

- Report Final Year Project 2Document65 pagesReport Final Year Project 2yew chunNo ratings yet

- Trane Pacu Voyager RT-PRC028AH-EN - 12152021Document156 pagesTrane Pacu Voyager RT-PRC028AH-EN - 12152021brian mmec2020No ratings yet

- SCE Training Curriculum TIADocument57 pagesSCE Training Curriculum TIAZoran100% (1)

- Combivert: Instruction Manual Power Supply Unit R5-C V1.1Document28 pagesCombivert: Instruction Manual Power Supply Unit R5-C V1.1ade izuanNo ratings yet

- VFVD MotorDocument11 pagesVFVD Motornhu@nhuNo ratings yet

- Petroleum Engineer Fernando MostajoDocument8 pagesPetroleum Engineer Fernando MostajoFernando Mostajo RocaNo ratings yet

- Earth Ground Resistance Testing Methods for Accurate Low-Voltage System EvaluationsDocument8 pagesEarth Ground Resistance Testing Methods for Accurate Low-Voltage System EvaluationsTana AzeezNo ratings yet

- Local literature on teaching with gamesDocument1 pageLocal literature on teaching with gameskimjay languitaNo ratings yet

- EMOSFET-Enhancement MOSFETDocument21 pagesEMOSFET-Enhancement MOSFETAnita DeshmukhNo ratings yet

- Lean Six Sigma - WikipediaDocument17 pagesLean Six Sigma - WikipediaSAIBAL JANANo ratings yet

- 700RB Indented Bill of MaterialsDocument23 pages700RB Indented Bill of MaterialsMaximiliano VanegasNo ratings yet

- HP Elite X2 1012 Service ManualDocument90 pagesHP Elite X2 1012 Service ManualHomer LarchNo ratings yet