Professional Documents

Culture Documents

Si-8050sd Ds en

Uploaded by

Anto PurwantoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Si-8050sd Ds en

Uploaded by

Anto PurwantoCopyright:

Available Formats

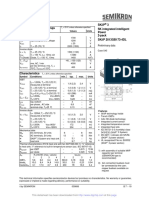

3 A, Buck Converter IC

SI-8000SD Series Data Sheet

Description Package

SI-8000SD series are buck converter ICs whose TO263-5L

maximum output current is 3 A.

These products have various functions including the

Soft Start Function, the Output On/Off Function, the

Overcurrent Protection and the Thermal Shutdown, and

achieve a buck converter circuit with few external

components.

Not to scale

Features

● High Efficiency 84% Selection Guide

(SI-8050SD: VIN = 20 V, IOUT = 1 A)

● Few Components Part Number Output Voltage

● Downsized Choke Coil SI-8033SD 3.3 V

(Switching Frequency 60 kHz (typ.)) SI-8050SD 5V

● Fixed Output Voltage

● Soft Start Function Applications

● On/Off Function

● Low Supply Current during Output Off For the systems requiring power supplies such as:

● Protection Functions ● Audio Visual Equipment

Overcurrent Protections (OCP): Drooping Type, ● Office Automation Equipment (e.g., Printer)

Auto-restart ● Onboard power supply

Thermal Shutdown (TSD): Auto-restart

Typical Application

SI-8000SD

GND

VOS

VIN

SW

SS

1 2 3 4 5

VIN L1 VOUT

CIN C3 D1

COUT

GND GND

SI-8000SD-DSE Rev.2.1 SANKEN ELECTRIC CO., LTD. 1

Aug. 25, 2020 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2011

SI-8000SD

Contents

Description ------------------------------------------------------------------------------------------------------ 1

Contents --------------------------------------------------------------------------------------------------------- 2

1. Absolute Maximum Ratings----------------------------------------------------------------------------- 3

2. Thermal Resistance Characteristics ------------------------------------------------------------------- 3

3. Recommended Operating Conditions ----------------------------------------------------------------- 4

4. Electrical Characteristics -------------------------------------------------------------------------------- 5

4.1. SI-8033SD --------------------------------------------------------------------------------------------- 5

4.2. SI-8050SD --------------------------------------------------------------------------------------------- 5

5. Block Diagram --------------------------------------------------------------------------------------------- 6

6. Pin Configuration Definitions --------------------------------------------------------------------------- 6

7. Typical Application --------------------------------------------------------------------------------------- 7

8. Physical Dimensions -------------------------------------------------------------------------------------- 8

8.1. Land Pattern Example ----------------------------------------------------------------------------- 8

9. Marking Diagram ----------------------------------------------------------------------------------------- 9

10. Operational Description ------------------------------------------------------------------------------- 10

10.1. PWM Output Voltage Control------------------------------------------------------------------ 10

10.2. Input/output Current and Inductor Current ------------------------------------------------ 10

10.3. Overcurrent Protection Function (OCP) ----------------------------------------------------- 11

10.4. Thermal Shutdown (TSD) ----------------------------------------------------------------------- 11

10.5. Soft Start Function -------------------------------------------------------------------------------- 11

10.6. Output On/Off Function ------------------------------------------------------------------------- 12

11. Design Notes ---------------------------------------------------------------------------------------------- 13

11.1. Selecting External Components ---------------------------------------------------------------- 13

11.1.1. Inductor, L1 ---------------------------------------------------------------------------------- 13

11.1.2. Input Capacitor, CIN ------------------------------------------------------------------------ 13

11.1.3. Output Capacitor, COUT -------------------------------------------------------------------- 14

11.1.4. Freewheeling Diode, D1 -------------------------------------------------------------------- 15

11.1.5. Spike Noise Reduction ---------------------------------------------------------------------- 15

11.1.6. Reverse Biasing Protection ---------------------------------------------------------------- 16

11.2. PCB Layout----------------------------------------------------------------------------------------- 16

11.2.1. High Current Line -------------------------------------------------------------------------- 16

11.2.2. Input/ Output Capacitor ------------------------------------------------------------------- 16

11.3. Operational Waveforms Confirmation ------------------------------------------------------- 17

11.4. Thermal Design ------------------------------------------------------------------------------------ 18

12. Pattern Layout Example ------------------------------------------------------------------------------- 19

13. Typical Characteristics --------------------------------------------------------------------------------- 20

13.1. SI-8033SD ------------------------------------------------------------------------------------------- 20

13.2. SI-8050SD ------------------------------------------------------------------------------------------- 21

13.3. Thermal Derating Curve------------------------------------------------------------------------- 23

Important Notes ---------------------------------------------------------------------------------------------- 24

SI-8000SD-DSE Rev.2.1 SANKEN ELECTRIC CO., LTD. 2

Aug. 25, 2020 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2011

SI-8000SD

1. Absolute Maximum Ratings

Current polarities are defined as follows: current going into the IC (sinking) is positive current (+); current coming

out of the IC (sourcing) is negative current (−). Unless specifically noted, TA = 25 °C.

Parameter Symbol Conditions Rating Unit Remarks

35 V SI-8033SD

Input Voltage VIN

43 V SI-8050SD

Allowable Power Dissipation PD(1) (2)

3 W

Junction Temperature TJ 125 °C

Storage Temperature TSTG −40 to 125 °C

(1)

Limited by the thermal shutdown.

(2)

Glass-epoxy board (40 mm × 40 mm), copper area 100%

2. Thermal Resistance Characteristics

Parameter Symbol Conditions Min. Typ. Max. Unit

Thermal Resistance between Junction

θJ-A — — 33.3 °C/W

and Ambient Mounted on the board.*

Thermal Resistance between Junction See Figure 2-1.

θJ-L — — 3 °C/W

and Lead

TC

Figure 2-1. Case Temperature Measurement Point

*

Glass-epoxy board (40 mm × 40 mm), copper area 100%

SI-8000SD-DSE Rev.2.1 SANKEN ELECTRIC CO., LTD. 3

Aug. 25, 2020 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2011

SI-8000SD

3. Recommended Operating Conditions

Parameter Symbol Conditions Min. Max. Unit Remarks

5.5 28 V SI-8033SD

Input Voltage VIN

7 40 V SI-8050SD

*

Output Current IOUT 0 3 A

Operating Junction Temperature TJOP −30 125 °C

Operating Ambient Temperature TOP −30 125 °C

*

Must be used in the range of thermal derating (see Figure 13-13).

SI-8000SD-DSE Rev.2.1 SANKEN ELECTRIC CO., LTD. 4

Aug. 25, 2020 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2011

SI-8000SD

4. Electrical Characteristics

4.1. SI-8033SD

Current polarities are defined as follows: a current flow going into the IC (sinking) is positive current (+); and a

current flow coming out of the IC (sourcing) is negative current (−).

Unless otherwise specified, TA = 25 °C.

Parameter Symbol Conditions Min. Typ. Max. Unit

Output Voltage VOUT VIN = 15 V, IOUT = 1 A 3.17 3.30 3.43 V

Output Voltage Temperature

ΔVOUT/ΔT — ±0.5 — mV/°C

Coefficient

Efficiency *

η VIN = 15 V, IOUT = 1 A — 79 — %

Operating Frequency fO VIN = 15 V, IOUT = 1 A — 60 — kHz

VIN = 8 V to 20 V,

Line Regulation VLINE — 25 80 mV

IOUT = 1 A

VIN = 15 V,

Load Regulation VLOAD — 10 30 mV

IOUT = 0.5 A to 1.5 A

Overcurrent Protection Start

IS VIN = 15 V 3.1 — — A

Current

SS Pin Low Level Voltage VSSL — 0.2 — V

SS Pin Source Current at

ISSL VSSL = 0.2 V 15 25 35 μA

Low Level

4.2. SI-8050SD

Current polarities are defined as follows: a current flow going into the IC (sinking) is positive current (+); and a

current flow coming out of the IC (sourcing) is negative current (−).

Unless otherwise specified, TA = 25 °C.

Parameter Symbol Conditions Min. Typ. Max. Unit

Output Voltage VOUT VIN = 20 V, IOUT = 1 A 4.8 5.0 5.2 V

Output Voltage Temperature

ΔVOUT/ΔT — ±0.5 — mV/°C

Coefficient

Efficiency * η VIN = 20 V, IOUT = 1 A — 84 — %

Operating Frequency fO VIN = 20 V, IOUT = 1 A 48 60 72 kHz

VIN = 10 V to 30 V,

Line Regulation VLINE — 40 100 mV

IOUT = 1 A

VIN = 20 V,

Load Regulation VLOAD — 10 40 mV

IOUT = 0.5 A to 1.5 A

Overcurrent Protection Start

IS VIN = 20 V 3.1 — — A

Current

SS Pin Low Level Voltage VSSL — 0.2 — V

SS Pin Source Current at

ISSL VSSL = 0.2 V 20 30 40 μA

Low Level

*

Efficiency is calculated by the following equation.

VOUT × IOUT

η(%) = × 100

VIN × IIN

SI-8000SD-DSE Rev.2.1 SANKEN ELECTRIC CO., LTD. 5

Aug. 25, 2020 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2011

SI-8000SD

5. Block Diagram

VIN 1 2 SW

Internal Overcurrent

Regulator Protection

Latch and

Reset

Driver

OSC

Comp. Thermal

Shutdown

Error amp. 4 VOS

Reference

Voltage

5 3

SS GND

6. Pin Configuration Definitions

Pin Pin

Description

Number Name

1 VIN Input pin

2 SW Output pin

GND

VOS

3 GND Ground

VIN

SW

SS

4 VOS Feedback Pin

1 2 3 4 5 Soft start period adjustment capacitor connection,

5 SS

on/off signal input

SI-8000SD-DSE Rev.2.1 SANKEN ELECTRIC CO., LTD. 6

Aug. 25, 2020 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2011

SI-8000SD

7. Typical Application

SI-8000SD

GND

VOS

VIN

SW

SS

1 2 3 4 5

L1

VIN VOUT

CIN C3 D1 COUT

GND GND

Figure 7-1. Typical Application

Table 7-1. Reference Value of External Components

Symbol Part Type Reference Value Remarks

CIN Electrolytic capacitor 50 V/1000 μF See Section 11.1.2.

COUT Electrolytic capacitor 50 V/1000 μF See Section 11.1.3.

C3 Ceramic capacitor 0.01 μF Soft start period adjustment capacitor. See Section 10.5.

D1 Schottky diode 60 V, 5 A See Section 11.1.4.

L1 Choke coil 150 μH See Section 11.1.1.

SI-8000SD-DSE Rev.2.1 SANKEN ELECTRIC CO., LTD. 7

Aug. 25, 2020 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2011

SI-8000SD

8. Physical Dimensions

● TO263-5L

Symbol Min. Nom. Max.

E A A 4.40 4.57 4.70

(E)

L1

C2

A1 0 0.10 0.25

(L1)

A2 2.59 2.69 2.79

b 0.77 — 0.90

L4

b1 0.76 0.81 0.86

D1

c 0.34 — 0.47

D

c1 0.33 0.38 0.43

C2 1.22 — 1.32

H

E1

A2 D 9.05 9.15 9.25

A1 D1 6.86 — 7.50

E 10.06 10.16 10.26

E1 7.50 — 8.30

c c

1.70

e

L

BSC

L3 H 14.70 15.10 15.50

b

e

b PLATING L 2.00 2.30 2.60

b1 L1 1.17 1.27 1.40

BASE METAL L3 0.25 BSC

c1

c

L4 2.00 REF

θ 0° — 8°

SECTION C-C θ1 5° 7° 9°

θ2 1° 3° 5°

NOTES:

● Dimensions in millimeters

● Bare lead frame: Pb-free (RoHS compliant)

● Dimensions do not include mold burrs.

8.1. Land Pattern Example

11 ±0.2

9 ±0.2

6.8 ±0.1

9 ±0.1 3.7 ±0.05

4 ±0.1

1.7 ±0.1 1 ±0.05

Dimensions in millimeters

SI-8000SD-DSE Rev.2.1 SANKEN ELECTRIC CO., LTD. 8

Aug. 25, 2020 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2011

SI-8000SD

9. Marking Diagram

Specific Device Code (See Table 9-1)

YMDXXX Lot Number

Y is the last digit of the year of manufacture (0 to 9)

M is the month of the year (1 to 9, O, N, or D)

D is the period of days represented by:

1: the first 10 days of the month (1st to 10th)

1 5 2: the second 10 days of the month (11th to 20th)

3: the last 10–11 days of the month (21st to 31st)

XXX is the control number

Table 9-1. Specific Device Code

Specific Device Code Part Number

8033SD SI-8033SD

8050SD SI-8050SD

SI-8000SD-DSE Rev.2.1 SANKEN ELECTRIC CO., LTD. 9

Aug. 25, 2020 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2011

SI-8000SD

10. Operational Description 10.2. Input/output Current and Inductor

All the characteristic values given in this section are Current

typical values, unless they are specified as minimum or The square wave output generated by the switching

maximum. transistor built in the IC is smoothed by the LC filter

composed of the inductor and the output capacitor, and

converted to the DC output voltage. The operation of the

10.1. PWM Output Voltage Control LC filter significantly affects the stable operation of the

switching regulator. Figure 10-3 shows the schematic

The SI-8000SD series control the output voltage by the diagram of the current flowing through the circuit, and

PWM method and have a built-in PWM comparator, Figure 10-4 shows the waveforms of the current flowing

oscillator, error amplifier, reference voltage, output through each element.

transistor drive circuit, etc. The PWM comparator

outputs the switching transistor control signal as a square

wave by comparing the triangular wave output (≈60 kHz)

ITR IL = ITR + IDI

from the oscillator with the error amplifier output. The

PWM comparator controls the switching transistor to

turn on during the period when the error amplifier output TR L1

exceeds the oscillator output. When the output voltage VIN D1 IOUT

rises, the output of the error amplifier decreases because IDI COUT

the error amplifier is an inverting type. When the error

amplifier output decreases, the period below the

oscillator triangle wave level decreases. Thus, the turn-on

period of the switching transistor is shortened. In this Figure 10-3. Schematic Diagram of Circuit Current

way, the output voltage is regulated by changing the

turn-on time of the switching transistor with the

switching frequency fixed. The higher the V IN, the TON TOFF

shorter the turn-on period of the switching transistor. The TR

square wave output of the switching transistor is Emitter Voltage

smoothed by an LC low-pass filter consisting of an (Switching Output)

VIN

inductor and a capacitor. As a result, a regulated DC

voltage is supplied to the load.

VIN Switching L1 VOUT ITR

Transistor ILP

PWM IIN

Comparator 0

D1 COUT

Drive

IDI

Circuit

Oscillator ILP

Error Amplifier

0

Reference

Voltage IL

ΔIL

ILP

IOUT

Figure 10-1. Basic Structure of Switching Regulator

with PWM Control

0

Figure 10-4. Waveforms of Current through Each

Oscillator Output Element

Error Amplifier Output

As shown in Figure 10-3, the current, IL, flowing

through the inductor has a triangular waveform. This

triangular waveform is composed of two types of current

ON OFF Switching Transistor Output components, ITR and IDI. The current, ITR, is the current

supplied from the input side through the transistor at

transistor turn-on, and the average value is the input

Figure 10-2. PWM Comparator Operation Diagram current, IIN. The current, IDI, is the current that the energy

SI-8000SD-DSE Rev.2.1 SANKEN ELECTRIC CO., LTD. 10

Aug. 25, 2020 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2011

SI-8000SD

stored in the inductor is commutated through the 10.5. Soft Start Function

freewheeling diode at transistor turn-off.

The inductor current, IL, is the sum of ITR and IDI. When a capacitor, C3, is connected to the SS pin, soft

Moreover, the average IL is the DC output current, IOUT, start is activated at input voltage turned-on. The soft start

because the triangular wave component on which IL is time, tSS, until VOUT rises is calculated by the Equation

superimposed is smoothed by the capacitor, COUT. (1).

t SS = t d + t S (1)

10.3. Overcurrent Protection Function

(OCP)

0.7 × C3 (2)

The IC has the drooping type overcurrent protection td =

20 × 10−6

(OCP) circuit. The overcurrent protection circuit detects

the peak current of the switching transistor. When the

peak current exceeds the set value, the current is limited VOUT × 0.9 × C3

by forcibly shortening the on-time of the transistor and tS = (3)

VIN × 20 × 10−6

reducing the output voltage. When the output voltage

decreases further to 50% of the rated value, the switching

frequency is decreased to about 30 kHz. As a result, the Where:

current increase at the low output voltage is suppressed. td is delay time (s),

When the overcurrent state is released, the output voltage tS is rising time (s),

restarts automatically. VOUT is output voltage (V), and

VIN is input voltage (V).

Output Oscillation frequency

Voltage decreases at this point

VIN

VOUT

td tS

Output Current tSS

Figure 10-5. Overcurrent Protection Characteristics

Figure 10-7. Soft Start Waveform

10.4. Thermal Shutdown (TSD) U1

SS 5

The thermal shutdown (TSD) circuit of the IC detects

the junction temperature of the IC. When the junction GND

C3

3

temperature exceeds the set value, the TSD turns off the

output by stopping the output transistor. When the

junction temperature drops for about 15 °C from the

thermal shutdown set value, the TSD automatically Figure 10-8. Soft Start Function

restarts the normal operation.

The voltage cannot be externally applied because the

Output Voltage SS pin is pulled up to the internal power supply. Leave

the SS pin open if the soft start function is not used.

Increasing the capacitance of C3 increases the

Protection Set

discharging time at input voltage off. A capacitor of ≤

Restart Set Temperature 10 μF should be used.

Temperature

When the IC operates in discontinuous conduction

mode, the rising time, tS, in actual operation may be

Junction Temperature shorter than the calculated value.

Figure 10-6. Thermal Shutdown Characteristics

SI-8000SD-DSE Rev.2.1 SANKEN ELECTRIC CO., LTD. 11

Aug. 25, 2020 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2011

SI-8000SD

10.6. Output On/Off Function

Output can be turned on/off using the SS pin. To use

on/off function, connect a transistor as shown in Figure

10-9. When the SS pin voltage decreases to be VSSL or

lower, the output is stopped.

U1

SS 5

GND

3

Figure 10-9. On/Off Function

The soft start function can be used in combination with

on/off function by connecting a transistor and a capacitor

as shown in Figure 10-10. In this case, the discharge

current of C3 flows through the transistor for on/off

function. Therefore, protection such as current limiting is

required when the capacitance of C3 is large.

U1

SS 5

GND C3

3

Figure 10-10. Soft Start Function, On/Off Function

The voltage cannot be externally applied because the

SS pin is pulled up to the internal power supply. Leave

the SS pin open if the soft start function is not used.

SI-8000SD-DSE Rev.2.1 SANKEN ELECTRIC CO., LTD. 12

Aug. 25, 2020 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2011

SI-8000SD

11. Design Notes Low Inductance Large Ripple Voltage, Current

11.1. Selecting External Components COUT

11.1.1. Inductor, L1 Figure 11-2. Ripple Voltage and Current (Low

Inductance)

The inductor, L, supplies the current to the load side at

switching transistor turn-off. For the regulator stable

operation, it is required to avoid saturating the inductor Inductance is calculated by the Equation (4).

and excessive self-heating. The following are the key

considerations and the guidelines for selecting an (VIN − VOUT ) × VOUT

inductor. L= (4)

∆IL × VIN × f

a) An inductor should be for switching regulator

Do not use an inductor for noise filter because it has In the Equation, (4), ΔIL shows the ripple current value

a large loss. of the choke coil, and the reference value is set as

follows:

b) Rated current

The inductor rated current must be larger than the ● When the output current in your application is close to

maximum load current according to your application. the maximum rating (3 A): 0.2 to 0.3 times the output

When the load current exceeds the rated current of current

the inductor, the inductance decreases significantly, ● When the output current in your application is

resulting in saturation. Note that in this state, the approximately 1 A or less: 0.3 to 0.4 times the output

high frequency impedance decreases and an current

excessive current flows.

c) Low noise For example, when VIN = 25 V, VOUT = 5 V,

In the open magnetic circuit core such as drum type, ΔIL = 0.5 A, and f = 60 kHz, L is calculated as follows:

the peripheral circuit may be significantly affected

by noise because the magnetic flux passes outside (25 − 5) × 5

L= ≒ 133 μH

the coil. It is recommended to use a closed magnetic 0.5 × 25 × 60 × 103

circuit core coil such as a toroidal type, EI type, or

EE type. Thus, the inductor of about 130 μH should be selected.

d) Inductance value should be appropriate

The larger the inductance of the choke coil, the

larger the external size of the coil. On the other hand, 11.1.2. Input Capacitor, CIN

the ripple current flowing through the coil decreases The input capacitor, CIN, operates as a bypass

and the output ripple voltage also decreases (see capacitor for the input circuit. CIN compensates for the

Figure 11-1). voltage drop in the input side by supplying a steep

The smaller the inductance, the larger the peak current at switching to the regulator. Therefore, CIN

current that flows through the switching transistor or should be placed as close as possible to the IC. When the

diode. Thus, the loss increases and the ripple voltage smoothing capacitor of AC rectifier circuit is in the input

also increases (see Figure 11-2). circuit, the smoothing capacitor can also be used as the

input capacitor.

The following are the key considerations and the

High Inductance Small Ripple Voltage, Current

guidelines for selecting CIN.

a) Within the rated voltage

COUT

b) Within the allowable ripple current

Figure 11-1. Ripple Voltage and Current

(High Inductance)

SI-8000SD-DSE Rev.2.1 SANKEN ELECTRIC CO., LTD. 13

Aug. 25, 2020 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2011

SI-8000SD

for selecting COUT.

IIN U1

VIN IL

1 VIN

L1

Ripple current VOUT

GND Ripple current

CIN 3

ESR RL IOUT

COUT

CIN current waveform

IP

0 COUT current waveform

IV

TON

0 ΔIL

T D = TON / T

The ripple current of the output capacitor is

As the load current increases, the ripple equal to the ripple current of the choke coil and

current of the input capacitor increases. does not change even if the load current

increases or decreases.

Figure 11-4. COUT Current Flow

Figure 11-3. CIN Current Flow

● Allowable ripple current

Exceeding the rated voltage or the allowable ripple The ripple effective current of the output capacitor is

current or using without considering the derating may calculated by Equation (6).

cause abnormal oscillation of the switching regulator as

well as shorten the life of the capacitor. Therefore, select

CIN with sufficient margin for the rated voltage and ∆IL

IRMS = (6)

allowable ripple current. The ripple effective current, 2√3

IRMS, flowing through the input capacitor is calculated by

Equation (5). For example, when ΔIL is 0.5 A, IRMS is calculated as

follows:

VOUT

IRMS ≈ 1.2 × × IOUT (5)

VIN 0.5

IRMS = ≈ 0.14 A

2√3

For example, when IOUT = 3 A, VIN = 20 V, and

VOUT = 5 V, IRMS is calculated as follows: Thus, select a capacitor that has an allowable ripple

current of > 0.14 A.

5

IRMS ≈ 1.2 × × 3 = 0.9 A ● Equivalent series resistance (ESR)

20

Select an appropriate value for ESR for stable

Thus, select a capacitor that has an allowable ripple operation. If the ESR is too large, the output ripple

current of > 0.9 A. voltage increases, and abnormal oscillation may be

caused. On the other hand, if the ESR is too small, the

phase margin becomes insufficient. The output ripple

11.1.3. Output Capacitor, COUT voltage is determined by the product of the inductor

ripple current, ΔIL (= COUT charge/discharge current) and

The output capacitor, COUT, operates as an LC low- ESR. For stable operation, the output ripple voltage

pass filter along with the inductor, L1, and operates as a should be 0.5% to 2% of the output voltage. The output

smoothing capacitor for switching output. The output ripple voltage is calculated using equations (7) and (8).

capacitor is charged and discharged with a current equal ESR changes with temperature. Note that the ESR

to the ripple current of the choke coil, ΔI L. Therefore, as decreases at high temperatures.

in the input capacitor, CIN, COUT is selected with

sufficient margin and equivalent series resistance (ESR)

for the rated voltage and allowable ripple current. The

following are the key considerations and the guidelines

SI-8000SD-DSE Rev.2.1 SANKEN ELECTRIC CO., LTD. 14

Aug. 25, 2020 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2011

SI-8000SD

11.1.5. Spike Noise Reduction

(VIN − VOUT ) × VOUT

VRIP ≈ × ESR (7) To reduce spike noise, add a noise reduction circuit

L1 × VIN × f

between the input and output of the IC and both ends of

the freewheeling diode, D1. Note that the efficiency is

decreased.

VRIP ≈ ∆IL × ESR (8) When measuring spike noise with an oscilloscope,

connect the probe to the root of the output capacitor with

If the ESR is too small (about 10 mΩ to 30 mΩ or the shortest probe lead wire. If the probe ground lead

less), the phase delay becomes large and abnormal wire is long, the spike noises may be measured

oscillation may occur. Do not use tantalum capacitors abnormally large because the lead wire acts as an antenna.

and monolithic ceramic capacitors alone for COUT as they

have low ESR. When used at low temperature (0 °C or

less), connecting a tantalum capacitor or a laminated 0 Ω to 20 Ω 100 pF to 3000 pF

ceramic capacitor in parallel with the electrolytic

capacitor is effective in reducing the output ripple U1

voltage. In order to further reduce the output ripple

1 VIN SW 2

voltage, it is effective to add an LC filter to configure a

pi filter (see Figure 11-5). When an LC filter is added, GND 0 Ω to 20 Ω

connect the point A to the VOS pin so that point A in 3 D1

100 pF to 4000 pF

Figure 11-5 is the output voltage detection point. If point

A is not set as the output voltage detection point,

abnormal oscillation may occur.

Figure 11-6. Spike Noise Reduction

A

U1 L1 L2

1 VIN SW 2

GND VOS 4

3 D1

COUT COUT2

Figure 11-5. Pi Filter

(L2: 20 μH, COUT2: 200 μF)

The output capacitor should be placed as close as

possible to the IC. Figure 11-7. Without Noise Reduction Circuit

11.1.4. Freewheeling Diode, D1

The freewheel diode is used to release the energy

stored in the inductor at switching off. Be sure to use a

Schottky diode for the freewheeling diode. If a diode

with a long recovery time and a large forward voltage,

such as a general-purpose rectifier diode, is used, a

reverse voltage is applied to the IC, which may damage

the IC.

The voltage output from the SW pin is close to the

input voltage. Therefore, use a freewheeling diode whose

reverse breakdown voltage is higher than the input

voltage. Do not add ferrite beads to the freewheeling

diode. Figure 11-8. With Noise Reduction Circuit

SI-8000SD-DSE Rev.2.1 SANKEN ELECTRIC CO., LTD. 15

Aug. 25, 2020 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2011

SI-8000SD

11.1.6. Reverse Biasing Protection CIN, COUT

CIN, COUT

For the applications where the output pin voltage is

higher than the input pin voltage (e.g., battery charger),

add a diode for reverse bias protection between the input

and output.

Improper Pattern Example Proper Pattern Example

Protection Diode

Figure 11-11. Pattern Example

U1

1 VIN SW 2

Figure 11-9. Addition of Reverse Bias Protection

Diode

11.2. PCB Layout

11.2.1. High Current Line

Traces where the switching current flows (bold line in

Figure 11-10) should be as wide and short as possible.

VIN L1 VOUT

U1

1 VIN SW 2

VOS 4

CIN GND COUT

3 D1

GND GND

Figure 11-10. High Current Line

11.2.2. Input/ Output Capacitor

The input capacitor, CIN, and the output capacitor,

COUT, must be placed as close as possible to the IC.

When CIN and COUT are far from the IC, it may cause

poor regulation or abnormal oscillation due to increased

switching ripple.

When a smoothing capacitor for the AC rectifier

circuit is in the input side, the smoothing capacitor can

also be used as the input capacitor. When the input

smoothing capacitor and the IC are distant, connect an

input capacitor separated from the smoothing capacitor.

Since the large current is charged and discharged to the

input/output capacitor at high speed, the lead wire should

be as short as possible. The pattern of the capacitor

should also be the shortest.

SI-8000SD-DSE Rev.2.1 SANKEN ELECTRIC CO., LTD. 16

Aug. 25, 2020 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2011

SI-8000SD

11.3. Operational Waveforms Confirmation When the load current is small, the IC operates in

discontinuous conduction mode. In discontinuous

Whether the switching operation is normal can be conduction mode, the period when the current through

confirmed by the waveform between the SW and GND inductor becomes zero occurs. The damped oscillation

pins of the IC. Figure 11-12 shows examples of occurs in the switching waveform, which is normal

waveforms in normal operation and abnormal oscillation. operation (waveform 2).

When the load current is large, the IC operates in If the IC and CIN, COUT are distant from each other,

continuous conduction mode. In continuous conduction abnormal on/off time of switching is disturbed, and

mode, the period when the current through inductor abnormal oscillation occurs as shown in waveform 3 and

becomes zero does not occur. The switching waveform waveform 4.

has the shape of a normal square wave (waveform 1).

1. Normal operation (continuous conduction mode) 2. Normal operation (discontinuous conduction mode)

異常発振動作(C

3. Abnormal oscillation IN が離れている場合)

(when CIN is distant) 異常発振動作(C

4. Abnormal oscillationOUT が離れている場合)

(when COUT is distant)

Figure 11-12. Waveform Examples

SI-8000SD-DSE Rev.2.1 SANKEN ELECTRIC CO., LTD. 17

Aug. 25, 2020 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2011

SI-8000SD

11.4. Thermal Design Where:

VOUT is the output voltage

Generally, the heat dissipation of an IC depends on the VIN is the input voltage

size and material of the board and the copper area. To IOUT is the output current

improve the thermal performance, the copper area of the η is the efficiency (%) (calculated by Figure 13-1 and

part where the backside of the IC is soldered should be as Figure 13-7)

large as possible. VF is D1 forward voltage

Figure 13-13 shows the thermal derating of the IC.

When using the IC, ensure a sufficient margin. (3) Determine the copper area by confirming the

Follow the procedure below to design heat dissipation. intersection of ambient temperature and power

dissipation by the thermal derating characteristics

(1) Measure the maximum ambient temperature, shown in Figure 13-13.

TA(MAX) of the IC.

(2) PD(MAX) is calculated by changing the input/output For reference, Figure 11-13 shows the relationship

conditions and checking the power dissipation, PD. between the copper area and thermal resistance of a

PD is calculated by Equation (9). single-sided copper foil board, FR-4.

100 VO

PD = VO × IO ( − 1) − VF × IO (1 − ) (9)

η VIN

Junction-to-Ambient Thermal Resistance, θJ-A (°C/W)

Glass-epoxy Board (40 mm × 40 mm)

Copper Area (mm2)

Figure 11-13. Thermal Resistance - Copper Area Reference Characteristics

(Single-sided Copper Foil Board, FR-4)*

*

Limited by the condition of the input voltage and output current because the power dissipation of the IC package is

3 W.

SI-8000SD-DSE Rev.2.1 SANKEN ELECTRIC CO., LTD. 18

Aug. 25, 2020 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2011

SI-8000SD

12. Pattern Layout Example

Connect the ground traces to the GND pin at a single point. Place control components near the IC with a minimal

length of PCB traces.

Figure 12-1. Pattern Layout Example

SI-8000SD-DSE Rev.2.1 SANKEN ELECTRIC CO., LTD. 19

Aug. 25, 2020 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2011

SI-8000SD

13. Typical Characteristics

13.1. SI-8033SD

Unless specifically noted, TA = 25 °C.

Output Voltage, VOUT (V)

Efficiency, η (%)

Output Current, IOUT (A) Output Current, IOUT (A)

Figure 13-1. Efficiency Figure 13-2. Overcurrent Protection Characteristics

VIN = 15 V, IOUT = 0 A

Output Voltage, VOUT (V)

Output Voltage, VOUT (V)

Input Voltage, VIN (V) Ambient Temperature, TA (°C)

Figure 13-3. Rising Characteristics Figure 13-4. Thermal Shutdown Characteristics

SI-8000SD-DSE Rev.2.1 SANKEN ELECTRIC CO., LTD. 20

Aug. 25, 2020 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2011

SI-8000SD

Efficiency, η (%)

VIN = 15 V, IOUT = 1 A

Output Voltage, VOUT (V)

Output Voltage, VOUT (V)

Frequency (kHz)

Ambient Temperature, TA (°C)

Output Current, IOUT (A)

Figure 13-5. Load Regulation Figure 13-6. Temperature Characteristic

13.2. SI-8050SD

Unless specifically noted, TA = 25 °C.

Output Voltage, VOUT (V)

Efficiency, η (%)

Output Current, IOUT (A)

Output Current, IOUT (A)

Figure 13-7. Efficiency Figure 13-8. Overcurrent Protection Characteristics

SI-8000SD-DSE Rev.2.1 SANKEN ELECTRIC CO., LTD. 21

Aug. 25, 2020 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2011

SI-8000SD

VIN = 20 V, IOUT = 0 A

Output Voltage, VOUT (V)

Output Voltage, VOUT (V)

Input Voltage, VIN (V) Ambient Temperature, TA (°C)

Figure 13-9. Rising Characteristics Figure 13-10. Thermal Shutdown Characteristics

VIN = 20 V, IOUT = 1 A

Efficiency, η (%)

Output Voltage, VOUT (V)

Output Voltage, VOUT (V)

Frequency (kHz)

Output Current, IOUT (A)

Ambient Temperature, TA (°C)

Figure 13-11. Load Regulation Figure 13-12. Temperature Characteristic

SI-8000SD-DSE Rev.2.1 SANKEN ELECTRIC CO., LTD. 22

Aug. 25, 2020 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2011

SI-8000SD

13.3. Thermal Derating Curve

Copper area

40 mm × 40 mm (θJ-A = 33.3 °C/W)

Allowable Power Dissipation, PD (W)

20 mm × 40 mm (θJ-A = 37 °C/W)

20 mm× 20 mm (θJ-A = 44 °C/W)

10 mm × 10 mm (θJ-A = 53 °C/W)

Ambient Temperature, TA (°C)

Figure 13-13. Thermal Derating

SI-8000SD-DSE Rev.2.1 SANKEN ELECTRIC CO., LTD. 23

Aug. 25, 2020 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2011

SI-8000SD

Important Notes

● All data, illustrations, graphs, tables and any other information included in this document (the “Information”) as to Sanken’s

products listed herein (the “Sanken Products”) are current as of the date this document is issued. The Information is subject to any

change without notice due to improvement of the Sanken Products, etc. Please make sure to confirm with a Sanken sales

representative that the contents set forth in this document reflect the latest revisions before use.

● The Sanken Products are intended for use as components of general purpose electronic equipment or apparatus (such as home

appliances, office equipment, telecommunication equipment, measuring equipment, etc.). Prior to use of the Sanken Products,

please put your signature, or affix your name and seal, on the specification documents of the Sanken Products and return them to

Sanken. When considering use of the Sanken Products for any applications that require higher reliability (such as transportation

equipment and its control systems, traffic signal control systems or equipment, disaster/crime alarm systems, various safety

devices, etc.), you must contact a Sanken sales representative to discuss the suitability of such use and put your signature, or affix

your name and seal, on the specification documents of the Sanken Products and return them to Sanken, prior to the use of the

Sanken Products. The Sanken Products are not intended for use in any applications that require extremely high reliability such as:

aerospace equipment; nuclear power control systems; and medical equipment or systems, whose failure or malfunction may result

in death or serious injury to people, i.e., medical devices in Class III or a higher class as defined by relevant laws of Japan

(collectively, the “Specific Applications”). Sanken assumes no liability or responsibility whatsoever for any and all damages and

losses that may be suffered by you, users or any third party, resulting from the use of the Sanken Products in the Specific

Applications or in manner not in compliance with the instructions set forth herein.

● In the event of using the Sanken Products by either (i) combining other products or materials or both therewith or (ii) physically,

chemically or otherwise processing or treating or both the same, you must duly consider all possible risks that may result from all

such uses in advance and proceed therewith at your own responsibility.

● Although Sanken is making efforts to enhance the quality and reliability of its products, it is impossible to completely avoid the

occurrence of any failure or defect or both in semiconductor products at a certain rate. You must take, at your own responsibility,

preventative measures including using a sufficient safety design and confirming safety of any equipment or systems in/for which

the Sanken Products are used, upon due consideration of a failure occurrence rate and derating, etc., in order not to cause any

human injury or death, fire accident or social harm which may result from any failure or malfunction of the Sanken Products.

Please refer to the relevant specification documents and Sanken’s official website in relation to derating.

● No anti-radioactive ray design has been adopted for the Sanken Products.

● The circuit constant, operation examples, circuit examples, pattern layout examples, design examples, recommended examples, all

information and evaluation results based thereon, etc., described in this document are presented for the sole purpose of reference of

use of the Sanken Products.

● Sanken assumes no responsibility whatsoever for any and all damages and losses that may be suffered by you, users or any third

party, or any possible infringement of any and all property rights including intellectual property rights and any other rights of you,

users or any third party, resulting from the Information.

● No information in this document can be transcribed or copied or both without Sanken’s prior written consent.

● Regarding the Information, no license, express, implied or otherwise, is granted hereby under any intellectual property rights and

any other rights of Sanken.

● Unless otherwise agreed in writing between Sanken and you, Sanken makes no warranty of any kind, whether express or implied,

including, without limitation, any warranty (i) as to the quality or performance of the Sanken Products (such as implied warranty

of merchantability, and implied warranty of fitness for a particular purpose or special environment), (ii) that any Sanken Product is

delivered free of claims of third parties by way of infringement or the like, (iii) that may arise from course of performance, course

of dealing or usage of trade, and (iv) as to the Information (including its accuracy, usefulness, and reliability).

● In the event of using the Sanken Products, you must use the same after carefully examining all applicable environmental laws and

regulations that regulate the inclusion or use or both of any particular controlled substances, including, but not limited to, the EU

RoHS Directive, so as to be in strict compliance with such applicable laws and regulations.

● You must not use the Sanken Products or the Information for the purpose of any military applications or use, including but not

limited to the development of weapons of mass destruction. In the event of exporting the Sanken Products or the Information, or

providing them for non-residents, you must comply with all applicable export control laws and regulations in each country

including the U.S. Export Administration Regulations (EAR) and the Foreign Exchange and Foreign Trade Act of Japan, and

follow the procedures required by such applicable laws and regulations.

● Sanken assumes no responsibility for any troubles, which may occur during the transportation of the Sanken Products including

the falling thereof, out of Sanken’s distribution network.

● Although Sanken has prepared this document with its due care to pursue the accuracy thereof, Sanken does not warrant that it is

error free and Sanken assumes no liability whatsoever for any and all damages and losses which may be suffered by you resulting

from any possible errors or omissions in connection with the Information.

● Please refer to our official website in relation to general instructions and directions for using the Sanken Products, and refer to the

relevant specification documents in relation to particular precautions when using the Sanken Products.

● All rights and title in and to any specific trademark or tradename belong to Sanken and such original right holder(s).

DSGN-CEZ-16003

SI-8000SD-DSE Rev.2.1 SANKEN ELECTRIC CO., LTD. 24

Aug. 25, 2020 https://www.sanken-ele.co.jp/en

© SANKEN ELECTRIC CO., LTD. 2011

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Lava DoraDocument13 pagesLava DoraRay Zander FebresNo ratings yet

- STP 13NK50ZDocument16 pagesSTP 13NK50ZisaiasvaNo ratings yet

- CD 00001235Document12 pagesCD 00001235Mob LegNo ratings yet

- 06-22 Sra2203Document4 pages06-22 Sra2203Sandris MainelisNo ratings yet

- v65d v6 0 Instruction ManualDocument57 pagesv65d v6 0 Instruction ManualMr.K ch100% (1)

- LC5901S Data Sheet Rev.1.5: Sanken Electric Co., LTDDocument29 pagesLC5901S Data Sheet Rev.1.5: Sanken Electric Co., LTDRodolfo ArosemenaNo ratings yet

- N-Channel 100 V, 0.0036 Typ., 110 A, Stripfet™ F7 Power Mosfet in A To-220 PackageDocument13 pagesN-Channel 100 V, 0.0036 Typ., 110 A, Stripfet™ F7 Power Mosfet in A To-220 PackageCarautotronica LaboratorioNo ratings yet

- Mosfet B100NFDocument15 pagesMosfet B100NFAfortunaoNo ratings yet

- STR2A100 Series Application Note (Rev.0.3) : Sanken Electric Co., LTDDocument18 pagesSTR2A100 Series Application Note (Rev.0.3) : Sanken Electric Co., LTDАлександр АндриановNo ratings yet

- SMD General Purpose Transistor (PNP)Document3 pagesSMD General Purpose Transistor (PNP)Irfan Indra KurniawanNo ratings yet

- LC5910S Data Sheet: Critical Current Mode Buck LED Driver ICDocument22 pagesLC5910S Data Sheet: Critical Current Mode Buck LED Driver ICnikko hinostrozaNo ratings yet

- Igbt 40N60 - 600V, 40aDocument10 pagesIgbt 40N60 - 600V, 40aLuis HuanqqueNo ratings yet

- IRHM57Z60 InternationalRectifierDocument13 pagesIRHM57Z60 InternationalRectifierGuh CamposNo ratings yet

- STB12NK80Z STP12NK80Z - STW12NK80ZDocument16 pagesSTB12NK80Z STP12NK80Z - STW12NK80ZMAKERNo ratings yet

- UM - SP Series - 75-1000-0390 - A0Document45 pagesUM - SP Series - 75-1000-0390 - A0林介浩No ratings yet

- STP 9 NK 60 ZDocument19 pagesSTP 9 NK 60 Zspider. methanolNo ratings yet

- SRA2201S: PIN Connection DescriptionsDocument4 pagesSRA2201S: PIN Connection DescriptionsYargen GonzalezNo ratings yet

- PDF Sanken 882276Document13 pagesPDF Sanken 882276Moises CelosoNo ratings yet

- STB60NF10 STB60NF10-1 - STP60NF10: N-Channel 100V - 0.019 - 80A - TO-220 - D Pak - I PAK Stripfet™ Ii Power MosfetDocument15 pagesSTB60NF10 STB60NF10-1 - STP60NF10: N-Channel 100V - 0.019 - 80A - TO-220 - D Pak - I PAK Stripfet™ Ii Power MosfetAnonymous C6Vaod9No ratings yet

- Mosfet - STF11NM80Document14 pagesMosfet - STF11NM80brunex000No ratings yet

- Stp130N6F7: N-Channel 60 V, 4.2 Mω Typ., 80 A Stripfet™ F7 Power Mosfet In A To-220 PackageDocument12 pagesStp130N6F7: N-Channel 60 V, 4.2 Mω Typ., 80 A Stripfet™ F7 Power Mosfet In A To-220 PackageOsmir MonteiroNo ratings yet

- Mje13005G Switchmodet Series NPN Silicon Power TransistorsDocument7 pagesMje13005G Switchmodet Series NPN Silicon Power TransistorswalterNo ratings yet

- Stp10Nk70Zfp Stp10Nk70Z: N-Channel 700V - 0.75 - 8.6A - To220-To220Fp Zener-Protected Supermesh™ MosfetDocument13 pagesStp10Nk70Zfp Stp10Nk70Z: N-Channel 700V - 0.75 - 8.6A - To220-To220Fp Zener-Protected Supermesh™ MosfetRoiser DelgadoNo ratings yet

- 2N3055A (NPN), MJ15015 (NPN), MJ15016 (PNP) Complementary Silicon High Power TransistorsDocument6 pages2N3055A (NPN), MJ15015 (NPN), MJ15016 (PNP) Complementary Silicon High Power Transistorsklaus allowsNo ratings yet

- STP80NF12Document12 pagesSTP80NF12vanuzalopeslopes1No ratings yet

- Mosfet: FCU360N65S3R0 - Power, N-Channel, SUPERFET III, Easy DriveDocument10 pagesMosfet: FCU360N65S3R0 - Power, N-Channel, SUPERFET III, Easy DriveJuan HerreraNo ratings yet

- 2SB698/2SD734: 1W AF Output, Electronic Governor, DC-DC Converter ApplicationsDocument4 pages2SB698/2SD734: 1W AF Output, Electronic Governor, DC-DC Converter ApplicationsMauricio MaldonadoNo ratings yet

- Str-A606xh Ds enDocument28 pagesStr-A606xh Ds enGiovanni Carrillo VillegasNo ratings yet

- Datasheet Del 2n3669-3670-1518495Document4 pagesDatasheet Del 2n3669-3670-1518495Alejandro CaparachinNo ratings yet

- Optoacoplador 817aDocument9 pagesOptoacoplador 817aDario AcostaNo ratings yet

- STP 80 NF 10Document14 pagesSTP 80 NF 10Mateus BelettiNo ratings yet

- STD1LNK60Z-1 Stq1Nk60Zr-Ap - Stn1Nk60ZDocument16 pagesSTD1LNK60Z-1 Stq1Nk60Zr-Ap - Stn1Nk60ZThanh ChelseabunNo ratings yet

- Mje13009 Switchmodet Series NPN Silicon Power Transistors: - C - CT - C Is 120 Ns (Typ)Document10 pagesMje13009 Switchmodet Series NPN Silicon Power Transistors: - C - CT - C Is 120 Ns (Typ)isaacalencarNo ratings yet

- Udf025n150m UtcDocument3 pagesUdf025n150m Utcvui01No ratings yet

- Skiip 2013Gb173-4Dl I. Power Section Absolute Maximum Ratings Skiip 3 SK Integrated Intelligent Power 2-Pack Skiip 2013Gb173-4DlDocument2 pagesSkiip 2013Gb173-4Dl I. Power Section Absolute Maximum Ratings Skiip 3 SK Integrated Intelligent Power 2-Pack Skiip 2013Gb173-4Dljoe smythNo ratings yet

- 2 SIC9231SE EN Rev1.0Document6 pages2 SIC9231SE EN Rev1.0Vishal dtuNo ratings yet

- PNP Silicon Surface Mount Transistor With Monolithic Bias Resistor NetworkDocument10 pagesPNP Silicon Surface Mount Transistor With Monolithic Bias Resistor Networkyesid velasco ninaNo ratings yet

- Data SheetDocument17 pagesData SheetVagner SilvaNo ratings yet

- 300/600ma, Ultra-Fast Transient Response LDO Regulator: General Description FeaturesDocument15 pages300/600ma, Ultra-Fast Transient Response LDO Regulator: General Description FeaturesDouglas RodriguesNo ratings yet

- LC5910S Data Sheet: Critical Current Mode Buck LED Driver ICDocument22 pagesLC5910S Data Sheet: Critical Current Mode Buck LED Driver ICalvaro marcos manuel lopezNo ratings yet

- stp110n8f6 230421 205435Document14 pagesstp110n8f6 230421 205435Andres PaezNo ratings yet

- PIN Connection Descriptions: - Switching Application - Interface Circuit and Driver Circuit ApplicationDocument4 pagesPIN Connection Descriptions: - Switching Application - Interface Circuit and Driver Circuit ApplicationShames ElhoryaNo ratings yet

- MJW3281A Audio Amplif 100WDocument9 pagesMJW3281A Audio Amplif 100WRaduNo ratings yet

- DatasheetDocument5 pagesDatasheetEdgarNo ratings yet

- 20N60M2EP Mark STP20N60M2-EP 600V 13A FETDocument14 pages20N60M2EP Mark STP20N60M2-EP 600V 13A FETRuslanNo ratings yet

- 1A Low-Dropout Voltage Regulator With Low Saturation: BA BC0 SeriesDocument20 pages1A Low-Dropout Voltage Regulator With Low Saturation: BA BC0 SeriesservoilNo ratings yet

- STP3NK80Z - STF3NK80Z STD3NK80Z - STD3NK80Z-1Document18 pagesSTP3NK80Z - STF3NK80Z STD3NK80Z - STD3NK80Z-1Luciano BarbonNo ratings yet

- SI-8120JD: Step-Down To 12.0 V, 1.5 A, DC/DC ConverterDocument10 pagesSI-8120JD: Step-Down To 12.0 V, 1.5 A, DC/DC ConverterStuxnetNo ratings yet

- STP10NK80Z, STP10NK80ZFP, STW10NK80ZDocument17 pagesSTP10NK80Z, STP10NK80ZFP, STW10NK80ZAgustin Caceres GimenezNo ratings yet

- STW 34 NM 60 NDocument12 pagesSTW 34 NM 60 NSujit KumarNo ratings yet

- Stp10Nk80Zfp Stp10Nk80Z - Stw10Nk80Z: N-Channel 800V - 0.78 - 9A - To-220/Fp-To-247 Zener-Protected Supermesh MosfetDocument15 pagesStp10Nk80Zfp Stp10Nk80Z - Stw10Nk80Z: N-Channel 800V - 0.78 - 9A - To-220/Fp-To-247 Zener-Protected Supermesh MosfetBlakeNo ratings yet

- Stp9Nk65Z Stp9Nk65Zfp: N-Channel 650 V, 1 Ω, 6.4 A, To-220, To-220Fp Zener-Protected Supermesh™ Power MosfetDocument16 pagesStp9Nk65Z Stp9Nk65Zfp: N-Channel 650 V, 1 Ω, 6.4 A, To-220, To-220Fp Zener-Protected Supermesh™ Power MosfetAndyMahataraNo ratings yet

- Small Signal Schottky Diodes: DescriptionDocument12 pagesSmall Signal Schottky Diodes: Descriptionjohn9999_502754No ratings yet

- stth60rq06 M2yDocument12 pagesstth60rq06 M2yRahul SinghNo ratings yet

- Dta123Yua Fra: OutlineDocument8 pagesDta123Yua Fra: Outlineedicruz10hotmailcomNo ratings yet

- Diodo Scorthy EncapsulamentoDocument12 pagesDiodo Scorthy EncapsulamentoRoberto TandaucaneNo ratings yet

- DTC123J UtcDocument4 pagesDTC123J UtcAnderson GomesNo ratings yet

- Off-Line Quasi-Resonant Switching Regulators: STR-X6729Document9 pagesOff-Line Quasi-Resonant Switching Regulators: STR-X6729perro sNo ratings yet

- 0 o 392713 Coo 0 PWJ 4 Ejh 3 Ad 28 FJ 7 yDocument6 pages0 o 392713 Coo 0 PWJ 4 Ejh 3 Ad 28 FJ 7 yAnto PurwantoNo ratings yet

- TL WR703N SchematicDocument1 pageTL WR703N SchematicAnto PurwantoNo ratings yet

- Product Information: Infovision Optoelectronics (Kunshan) Co., LTDDocument34 pagesProduct Information: Infovision Optoelectronics (Kunshan) Co., LTDAnto PurwantoNo ratings yet

- LG+ EAY62810301+LGP32-13PL1 Crystal SysbDocument37 pagesLG+ EAY62810301+LGP32-13PL1 Crystal Sysbdreamyson1983No ratings yet

- Let's Go: Zte Mf90 Getting Started With Your DeviceDocument2 pagesLet's Go: Zte Mf90 Getting Started With Your DeviceAnto PurwantoNo ratings yet

- Philips 223V5LSB00 Chassis Meridian 5Document143 pagesPhilips 223V5LSB00 Chassis Meridian 5Ricardo EmilioNo ratings yet

- Product Specification: ( Final SpecificationsDocument32 pagesProduct Specification: ( Final Specificationsqab90021No ratings yet

- Ua 23 H 4003 ArDocument44 pagesUa 23 H 4003 ArJustin NgNo ratings yet

- Datasheet PDFDocument26 pagesDatasheet PDFHoàng Việt HùngNo ratings yet

- BD 9883Document6 pagesBD 9883luisfeipezzNo ratings yet

- Specification FOR Approval: 17.1" Wxga TFT LCD TitleDocument27 pagesSpecification FOR Approval: 17.1" Wxga TFT LCD TitleAnto PurwantoNo ratings yet

- Panasonic Tc-L42et60 Chassis La41Document70 pagesPanasonic Tc-L42et60 Chassis La41Anto PurwantoNo ratings yet

- Panel LG Display Lp156wh4-Tln1 2Document32 pagesPanel LG Display Lp156wh4-Tln1 2Anto PurwantoNo ratings yet

- Panasonic Tc-L42et60 Chassis La41Document70 pagesPanasonic Tc-L42et60 Chassis La41Anto PurwantoNo ratings yet

- Color Monitor: Service ManualDocument26 pagesColor Monitor: Service ManualAnto PurwantoNo ratings yet

- Datasheet PDFDocument26 pagesDatasheet PDFHoàng Việt HùngNo ratings yet

- Panel LG Display Lp156wh4-Tln1 2Document32 pagesPanel LG Display Lp156wh4-Tln1 2Anto PurwantoNo ratings yet

- Color Monitor: Service ManualDocument26 pagesColor Monitor: Service ManualAnto PurwantoNo ratings yet

- Thesis Yizhe 11 May 2019 PDFDocument108 pagesThesis Yizhe 11 May 2019 PDFAhmed EmadNo ratings yet

- (D) Unit-I: Mapping of CO's With PO's/PSO's: Department of Electronics and Communication EngineeringDocument1 page(D) Unit-I: Mapping of CO's With PO's/PSO's: Department of Electronics and Communication EngineeringAnonymous eWMnRr70qNo ratings yet

- UC3845Document13 pagesUC3845roozbehxoxNo ratings yet

- Oscillators Lecture April 142021Document89 pagesOscillators Lecture April 142021Eos BanaNo ratings yet

- Ccs333 Augmented Reality/Virtual Reality Practical Exercises: 30 PeriodsDocument10 pagesCcs333 Augmented Reality/Virtual Reality Practical Exercises: 30 PeriodsBalaNo ratings yet

- Moog® Minimoog Manual - Universal Audio Support HomeDocument32 pagesMoog® Minimoog Manual - Universal Audio Support HomeMichel BeauregardNo ratings yet

- Microwave Journal-December 2022Document116 pagesMicrowave Journal-December 2022nube giveawayNo ratings yet

- BH1417 Stereo FM TransmitterDocument10 pagesBH1417 Stereo FM TransmitterDalibor GašićNo ratings yet

- Data Sheet: Greenchip Smps Control IcDocument21 pagesData Sheet: Greenchip Smps Control IcAndrea Baez BarraganNo ratings yet

- GeotechDocument6 pagesGeotechAndresVillaNo ratings yet

- Full Book Electronics PDFDocument329 pagesFull Book Electronics PDFVasanth Raghavan0% (1)

- Tda7000 For Narrowband FM ReceptionDocument13 pagesTda7000 For Narrowband FM ReceptionPeter KrabawaziNo ratings yet

- Jntuk R07 ECE SyllabusDocument83 pagesJntuk R07 ECE Syllabussravankumar493100% (1)

- MIT Radiaton Lab Series V23 Microwave ReceiversDocument636 pagesMIT Radiaton Lab Series V23 Microwave ReceiverskgrhoadsNo ratings yet

- Session PlanDocument3 pagesSession PlanAmudha VNo ratings yet

- Aic QB - 1Document45 pagesAic QB - 1SriramNo ratings yet

- DiDocument5 pagesDiByron DamaniaNo ratings yet

- Electronic Principles 9Th Edition Albert P Malvino Full ChapterDocument51 pagesElectronic Principles 9Th Edition Albert P Malvino Full Chaptermary.roy331100% (5)

- Alignment Using A Wobbulator PDFDocument10 pagesAlignment Using A Wobbulator PDFsEbyRESNo ratings yet

- Chapter-6: Radio Transmitters and ReceiversDocument51 pagesChapter-6: Radio Transmitters and ReceiverstsegayNo ratings yet

- Chapter 2 Radio-Frequency CircuitsDocument6 pagesChapter 2 Radio-Frequency Circuitsmarkanthonycorpin100% (1)

- RL78 L1B UsermanualDocument1,062 pagesRL78 L1B UsermanualHANUMANTHA RAO GORAKANo ratings yet

- 660-ShipHorn Kahlenberg KB-20 InstOper Manual 4-12-2017Document19 pages660-ShipHorn Kahlenberg KB-20 InstOper Manual 4-12-2017agusNo ratings yet

- Varactor Modulator Pre EmphasisDocument22 pagesVaractor Modulator Pre EmphasisAsfand yar khanNo ratings yet

- Introduction To Electronics and Communication (BESCK104C/BESCK204C) - Question Bank - VTUDocument14 pagesIntroduction To Electronics and Communication (BESCK104C/BESCK204C) - Question Bank - VTUShrishail Bhat100% (1)

- Project 2Document12 pagesProject 2SAYYAMNo ratings yet

- Research Paper of OscillatorsDocument10 pagesResearch Paper of OscillatorsRam MNo ratings yet

- Patente Del Señor Edwin H. Colpitts 1918 US1624537Document5 pagesPatente Del Señor Edwin H. Colpitts 1918 US1624537Adrian GarciaNo ratings yet

- Power Plant CatalogueDocument3 pagesPower Plant CatalogueMeasurement Technologies Corp.No ratings yet

- 1040 L Scheme EceDocument201 pages1040 L Scheme EceEng Abdulkadir MahamedNo ratings yet