Professional Documents

Culture Documents

PDFsam - B 390 - 92 (2006)

Uploaded by

mike.jensen05810 ratings0% found this document useful (0 votes)

7 views4 pagesOriginal Title

PDFsam_B 390 - 92 (2006)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views4 pagesPDFsam - B 390 - 92 (2006)

Uploaded by

mike.jensen0581Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

Designation: B 390 – 92 (Reapproved 2006)

Standard Practice for

Evaluating Apparent Grain Size and Distribution of

Cemented Tungsten Carbides1

This standard is issued under the fixed designation B 390; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope as a specification for carbide grades; producers and users may

1.1 This practice for the visual comparison and classifica- use the micrographs and the grain size chart as a guide in

tion of the apparent grain size and distribution of cemented developing their own specifications.

tungsten carbides is limited to cemented tungsten carbides that 5. Specimen Preparation

contain approximately 6, 10, and 18 % cobalt.

1.2 This standard does not purport to address all of the 5.1 Specimens shall be prepared for metallographic exami-

safety concerns, if any, associated with its use. It is the nation in accordance with a procedure suitable for this type of

responsibility of the user of this standard to establish appro- cemented carbides.

priate safety and health practices and determine the applica- NOTE 1—A suitable procedure is described in Test Method B 657 and

bility of regulatory limitations prior to use. Practice B 665.

2. Referenced Documents 6. Procedure

2.1 ASTM Standards: 2 6.1 Examine metallographically the entire surface of an

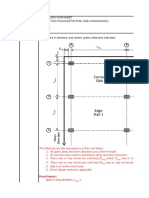

B 657 Guide for Metallographic Identification of Micro- etched specimen at a magnification of 1500 diameters. Select a

structure in Cemented Carbides representative area and make a comparison with the photomi-

B 665 Guide for Metallographic Sample Preparation of crographs in Figs. 1-3.

Cemented Tungsten Carbides 6.2 The nominal analyses of the cemented tungsten carbide

samples that were used to prepare the nine photomicrographs

3. Terminology shown in Figs. 1-3 are as follows:

3.1 Definitions of Terms Specific to This Standard: 6.2.1 Fig. 1—Tungsten carbide plus 6 % cobalt,

3.1.1 apparent grain size—the average diameter of a tung- 6.2.2 Fig. 2—Tungsten carbide plus 10 % cobalt, and

sten carbide particle as measured on an etched metallographi- 6.2.3 Fig. 3—Tungsten carbide plus 18 % cobalt.

cally polished surface of a specimen of sintered cemented 6.3 The grain size for each of these specimens may be

carbide. The apparent grain size is expressed in micrometres designated as follows:

and is generally reported as a range. Type F—Fine grain,

Type M—Medium grain, and

4. Significance and Use Type C—Coarse grain.

4.1 The apparent size and distribution of tungsten carbide

grains in cemented carbides affects the material’s wear resis- 7. Evaluation

tance and fracture. For a given chemical composition, an 7.1 The grain size rating of a cemented tungsten carbide

increase in the average grain size will result in increased specimen is accomplished by selecting the photomicrographs

toughness and decreased wear resistance. This practice illus- in Figs. 1-3 that most nearly match the field observed on the

trates representative micro-structures for a wide range of specimen being evaluated (see Appendix X1).

tungsten carbide-cobalt grades. This is not intended to be used 7.2 A range of numerical values for various concentrations

of tungsten carbide particles, even though arbitrary, is sug-

1

gested in Table 1.

This practice is under the jurisdiction of ASTM Committee B09 on Metal

Powders and Metal Powder Products and is the direct responsibility of Subcom- 8. Report

mittee B09.06 on Cemented Carbides.

Current edition approved April 1, 2006. Published April 2006. Originally 8.1 After visual comparison of a specimen with the photo-

approved in 1962. Last previous edition approved in 2000 as B 390 – 92 (2000). micrographs contained in this practice, the apparent grain size

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

of a particular specimen shall be rated relative to one or more

Standards volume information, refer to the standard’s Document Summary page on of the photomicrographs. Cobalt contents should always be

the ASTM website. specified. For example, a cemented tungsten carbide specimen

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

Copyright by ASTM Int'l (all rights reserved); Thu Apr 16 05:00:31 EDT 2009

Downloaded/printed by

Laurentian University pursuant to License Agreement. No further reproductions authorized.

B 390 – 92 (2006)

FIG. 1 Apparent Grain Size of Tungsten Carbide plus 6 % Cobalt FIG. 2 Apparent Grain Size of Tungsten Carbide plus 10 % Cobalt

(15003) (15003)

containing approximately 6 % cobalt, having a fine grain size

and a grain size distribution similar to the one shown in Fig. 10. Keywords

1(a) would be reported as Type 6-F. The “F” indicates a fine

grain size and the “6” identifies the cobalt content. 10.1 apparent grain size; cemented carbides; cemented

tungsten carbides; grain size distribution; hardmetals; micro-

9. Precision and Bias structure; powder metallurgy

9.1 Visual comparison of cemented carbide microstructures

with the Carbide Grain Size Chart is subjective. No precision

and bias statement can be made for this practice.

2

Copyright by ASTM Int'l (all rights reserved); Thu Apr 16 05:00:31 EDT 2009

Downloaded/printed by

Laurentian University pursuant to License Agreement. No further reproductions authorized.

B 390 – 92 (2006)

FIG. 3 Apparent Grain Size of Tungsten Carbide plus 18 % Cobalt (15003)

TABLE 1 Suggested Range of Values for Concentrations of Particles

Figure Grain High Concentration, Low Concentration, Rating

Number Size µm µm

1(a) fine 0.25 to 1.00 1.25 to 2.00 6-F

1(b) medium 2.00 to 5.00 0.75 to 1.00 6-M

1(c) coarse 4.00 to 6.00 0.50 to 3.00 6-C

2(a) fine 0.25 to 0.75 1.00 to 2.00 10-F

2(b) medium 2.00 to 4.00 0.50 to 1.00 10-M

2(c) coarse 3.00 to 6.00 0.75 to 2.00 10-C

3(a) fine 0.25 to 0.50 1.00 to 2.00 18-F

3(b) medium 1.50 to 4.00 0.50 to 1.00 18-M

3(c) coarse 3.00 to 6.00 0.75 to 2.00 18-C

3

Copyright by ASTM Int'l (all rights reserved); Thu Apr 16 05:00:31 EDT 2009

Downloaded/printed by

Laurentian University pursuant to License Agreement. No further reproductions authorized.

B 390 – 92 (2006)

APPENDIX

(Nonmandatory Information)

X1. CARBIDE GRAIN SIZE CHART

X1.1 Fig. X1.1 illustrates the relationship of grain sizes

from 1 to 10 µm as observed at a magnification of 1500

diameters (1 µm = 0.00003937 in. ).

FIG. X1.1 Relationship of Grain Sizes at Magnification of 1500 Diameters

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

4

Copyright by ASTM Int'l (all rights reserved); Thu Apr 16 05:00:31 EDT 2009

Downloaded/printed by

Laurentian University pursuant to License Agreement. No further reproductions authorized.

You might also like

- Microstructural Geochronology: Planetary Records Down to Atom ScaleFrom EverandMicrostructural Geochronology: Planetary Records Down to Atom ScaleDesmond E. MoserNo ratings yet

- Surface Plasmon Enhanced, Coupled and Controlled FluorescenceFrom EverandSurface Plasmon Enhanced, Coupled and Controlled FluorescenceNo ratings yet

- Evaluating The Microstructure of Graphite in Iron Castings: Standard Test Method ForDocument13 pagesEvaluating The Microstructure of Graphite in Iron Castings: Standard Test Method ForMarlon VillarrealNo ratings yet

- Astm 2016 A247 - 859Document13 pagesAstm 2016 A247 - 859luis_f1l1No ratings yet

- Evaluating The Microstructure of Graphite in Iron Castings: Standard Test Method ForDocument13 pagesEvaluating The Microstructure of Graphite in Iron Castings: Standard Test Method Forraulpalma93No ratings yet

- B 92 - B 92M - 11Document3 pagesB 92 - B 92M - 11phaindikaNo ratings yet

- A 247 - 17 PDFDocument13 pagesA 247 - 17 PDFأسامة وحيد الدين رمضانNo ratings yet

- B 93 - B 93M - 15Document4 pagesB 93 - B 93M - 15phaindikaNo ratings yet

- Unalloyed Magnesium Ingot and Stick For RemeltingDocument3 pagesUnalloyed Magnesium Ingot and Stick For RemeltingRizwanNo ratings yet

- Magnesium Alloys in Ingot Form For Sand Castings, Permanent Mold Castings, and Die CastingsDocument4 pagesMagnesium Alloys in Ingot Form For Sand Castings, Permanent Mold Castings, and Die CastingsnightweisoNo ratings yet

- Evaluating The Microstructure of Graphite in Iron Castings: Standard Test Method ForDocument13 pagesEvaluating The Microstructure of Graphite in Iron Castings: Standard Test Method ForHERNAN DARIO INCHIMA CALDERONNo ratings yet

- Evaluating The Microstructure of Graphite in Iron Castings: Standard Test Method ForDocument2 pagesEvaluating The Microstructure of Graphite in Iron Castings: Standard Test Method ForJohn HollandNo ratings yet

- Evaluating The Microstructure of Graphite in Iron Castings: Standard Test Method ForDocument13 pagesEvaluating The Microstructure of Graphite in Iron Castings: Standard Test Method ForidanfriNo ratings yet

- Detecting Mu-Phase in Wrought Nickel-Rich, Chromium, Molybdenum-Bearing AlloysDocument10 pagesDetecting Mu-Phase in Wrought Nickel-Rich, Chromium, Molybdenum-Bearing AlloysOmar SasaNo ratings yet

- Magnesium Alloys in Ingot Form For Sand Castings, Permanent Mold Castings, and Die CastingsDocument4 pagesMagnesium Alloys in Ingot Form For Sand Castings, Permanent Mold Castings, and Die CastingsDhavalNo ratings yet

- Evaluating The Microstructure of Graphite in Iron Castings: Standard Test Method ForDocument2 pagesEvaluating The Microstructure of Graphite in Iron Castings: Standard Test Method Forsharon blushteinNo ratings yet

- F 15 - 98 - Rje1ltk4 PDFDocument7 pagesF 15 - 98 - Rje1ltk4 PDFYayan RnsNo ratings yet

- B92B92MDocument2 pagesB92B92MDhavalNo ratings yet

- Magnesium-Alloy Investment Castings: Standard Specification ForDocument4 pagesMagnesium-Alloy Investment Castings: Standard Specification ForJefferson Castro AriasNo ratings yet

- B23 PDFDocument3 pagesB23 PDFHector SilvaNo ratings yet

- A247-10 - Classificação Ferro FundidoDocument2 pagesA247-10 - Classificação Ferro Fundidofbotini32No ratings yet

- Astm A247 06Document1 pageAstm A247 06juancarlosdominguezlopez49No ratings yet

- QN QP NQDocument2 pagesQN QP NQOsama TaghlebiNo ratings yet

- ASTM A247-10.20903 Grafito PDFDocument3 pagesASTM A247-10.20903 Grafito PDFOscar Fabian Mayorga RodriguezNo ratings yet

- De-Agglomeration of Refractory Metal Powders and Their Compounds Prior To Particle Size AnalysisDocument3 pagesDe-Agglomeration of Refractory Metal Powders and Their Compounds Prior To Particle Size AnalysisDanZel DanNo ratings yet

- PDFsam - B 440 - 12Document3 pagesPDFsam - B 440 - 12mike.jensen0581No ratings yet

- Copper Alloy Sand Castings For Valve ApplicationDocument6 pagesCopper Alloy Sand Castings For Valve ApplicationROHITNo ratings yet

- Prime Western Grade-Recycled (PWG-R) Zinc: Standard Specification ForDocument3 pagesPrime Western Grade-Recycled (PWG-R) Zinc: Standard Specification ForSofia YuliNo ratings yet

- B403-12 Standard Specification For Magnesium-Alloy Investment CastingsDocument4 pagesB403-12 Standard Specification For Magnesium-Alloy Investment CastingsmithileshNo ratings yet

- Magnesium Alloy Anodes For Cathodic ProtectionDocument2 pagesMagnesium Alloy Anodes For Cathodic Protectiongautam100% (1)

- B925-03 - Standard Practices For Production and Preparation of PM Test Specimens PDFDocument15 pagesB925-03 - Standard Practices For Production and Preparation of PM Test Specimens PDFakjeevananthamNo ratings yet

- E310Document4 pagesE310MoralesNo ratings yet

- A 874 - A 874M - 98 - Qtg3nc9bodc0tqDocument3 pagesA 874 - A 874M - 98 - Qtg3nc9bodc0tqQaisir MehmoodNo ratings yet

- Aluminum Bronze Rod, Bar, and Shapes: Standard Specification ForDocument7 pagesAluminum Bronze Rod, Bar, and Shapes: Standard Specification FormahfuzNo ratings yet

- B23 - 00 ISO StandDocument4 pagesB23 - 00 ISO StandRizwanNo ratings yet

- PDFsam - B 364 - 96 (2009)Document3 pagesPDFsam - B 364 - 96 (2009)mike.jensen0581No ratings yet

- ASTM B466 (2009) - Standard Specification For Seamless Copper-Nickel Pipe and TubeDocument6 pagesASTM B466 (2009) - Standard Specification For Seamless Copper-Nickel Pipe and Tubeanoop100% (1)

- D 4373 - 02 - Standard Test Method For Rapid Determination of Carbonate Content of SoilsDocument5 pagesD 4373 - 02 - Standard Test Method For Rapid Determination of Carbonate Content of Soilsina_criNo ratings yet

- Continuous Galvanizing Grade (CGG) Zinc Alloys For Hot-Dip Galvanizing of Sheet SteelDocument3 pagesContinuous Galvanizing Grade (CGG) Zinc Alloys For Hot-Dip Galvanizing of Sheet SteelDanZel DanNo ratings yet

- B843-93-ASTM - Standard For Magnesium Alloy Anodes For Cathodic ProtectionDocument2 pagesB843-93-ASTM - Standard For Magnesium Alloy Anodes For Cathodic Protectionderek vaughnNo ratings yet

- Specification For Copper-Silicon Alloy Plate, Sheet, Strip, and Rolled Bar For General Purposes and Pressure VesselsDocument4 pagesSpecification For Copper-Silicon Alloy Plate, Sheet, Strip, and Rolled Bar For General Purposes and Pressure VesselsBILLY CODYNo ratings yet

- ASTM International - 2017 - ASTM B91 Standard Specification For Magnesium-Alloy ForgingsDocument5 pagesASTM International - 2017 - ASTM B91 Standard Specification For Magnesium-Alloy Forgingswanghongxuan66No ratings yet

- B29 - 03 ISO StandDocument3 pagesB29 - 03 ISO StandRizwanNo ratings yet

- B 90 - B 90M - 13Document8 pagesB 90 - B 90M - 13phaindikaNo ratings yet

- ASTM B574 - 2006e1Document4 pagesASTM B574 - 2006e1Cesar ParadaNo ratings yet

- Brass Plate, Sheet, Strip, and Rolled Bar: Standard Specification ForDocument8 pagesBrass Plate, Sheet, Strip, and Rolled Bar: Standard Specification ForTony VazquezNo ratings yet

- B 91 - 12Document5 pagesB 91 - 12phaindikaNo ratings yet

- Brass Plate, Sheet, Strip, and Rolled Bar: Standard Specification ForDocument9 pagesBrass Plate, Sheet, Strip, and Rolled Bar: Standard Specification Foralucard375No ratings yet

- 42 % Nickel-6 % Chromium-Iron Sealing Alloy: Standard Specification ForDocument4 pages42 % Nickel-6 % Chromium-Iron Sealing Alloy: Standard Specification ForROHITNo ratings yet

- Astm B206Document4 pagesAstm B206BhanuNo ratings yet

- Low-Carbon Nickel-Chromium-Molybdenum, Low-Carbon Nickel-Molybdenum-Chromium-Tantalum, Low-Carbon Nickel-Chromium-Molybdenum-Copper, and Low-Carbon Nickel-Chromium-Molybdenum-Tungsten Alloy RodDocument4 pagesLow-Carbon Nickel-Chromium-Molybdenum, Low-Carbon Nickel-Molybdenum-Chromium-Tantalum, Low-Carbon Nickel-Chromium-Molybdenum-Copper, and Low-Carbon Nickel-Chromium-Molybdenum-Tungsten Alloy RodiyamNo ratings yet

- B23-00 (2014) Standard Specification For White Metal Bearing Alloys (Known Commercially As  Œbabbitt Metalâ )Document4 pagesB23-00 (2014) Standard Specification For White Metal Bearing Alloys (Known Commercially As  Œbabbitt Metalâ )Fanir ZNo ratings yet

- Astm B387Document4 pagesAstm B387raulNo ratings yet

- A 483 - 64 R00 - QTQ4MWDocument2 pagesA 483 - 64 R00 - QTQ4MWluis fernando beltran balderasNo ratings yet

- Phosphor Bronze Wire: Standard Specification ForDocument3 pagesPhosphor Bronze Wire: Standard Specification Forbenedick barquinNo ratings yet

- PDFsam - B 391 - 09e1Document3 pagesPDFsam - B 391 - 09e1mike.jensen0581No ratings yet

- Aluminum Bronze Sheet, Strip, and Rolled Bar: Standard Specification ForDocument4 pagesAluminum Bronze Sheet, Strip, and Rolled Bar: Standard Specification Forbenedick barquinNo ratings yet

- Magnesium-Alloy Sheet and Plate: Standard Specification ForDocument8 pagesMagnesium-Alloy Sheet and Plate: Standard Specification ForRizwanNo ratings yet

- B 29 - 14Document4 pagesB 29 - 14ruben carcamoNo ratings yet

- Naval Brass Rod, Bar, and Shapes: Standard Specification ForDocument7 pagesNaval Brass Rod, Bar, and Shapes: Standard Specification ForHoang Duy PhuongNo ratings yet

- PDFsam - B 418 - 16aDocument3 pagesPDFsam - B 418 - 16amike.jensen0581No ratings yet

- PDFsam - B 424 - 11 (2016)Document4 pagesPDFsam - B 424 - 11 (2016)mike.jensen0581No ratings yet

- PDFsam - B 447 - 12aDocument10 pagesPDFsam - B 447 - 12amike.jensen0581No ratings yet

- PDFsam - B 423 - 11 (2016)Document4 pagesPDFsam - B 423 - 11 (2016)mike.jensen0581No ratings yet

- PDFsam - B 422 - B 422M - 15Document5 pagesPDFsam - B 422 - B 422M - 15mike.jensen0581No ratings yet

- PDFsam - B 417 - 13Document3 pagesPDFsam - B 417 - 13mike.jensen0581No ratings yet

- PDFsam - B 416 - 98 (2013)Document4 pagesPDFsam - B 416 - 98 (2013)mike.jensen0581No ratings yet

- PDFsam - B 386 - 03 (2011)Document5 pagesPDFsam - B 386 - 03 (2011)mike.jensen0581No ratings yet

- PDFsam - B 401 - 12 (2016)Document5 pagesPDFsam - B 401 - 12 (2016)mike.jensen0581No ratings yet

- PDFsam - B 389 - 81 (2016)Document4 pagesPDFsam - B 389 - 81 (2016)mike.jensen0581No ratings yet

- PDFsam - B 379 - 11Document5 pagesPDFsam - B 379 - 11mike.jensen0581No ratings yet

- PDFsam - B 393 - 09e1Document6 pagesPDFsam - B 393 - 09e1mike.jensen0581No ratings yet

- PDFsam - B 400 - B 400M - 14Document6 pagesPDFsam - B 400 - B 400M - 14mike.jensen0581No ratings yet

- PDFsam - B 380 - 97 (2013)Document3 pagesPDFsam - B 380 - 97 (2013)mike.jensen0581No ratings yet

- PDFsam - B 367 - 13Document6 pagesPDFsam - B 367 - 13mike.jensen0581No ratings yet

- PDFsam - B 366 - B 366M - 16Document9 pagesPDFsam - B 366 - B 366M - 16mike.jensen0581No ratings yet

- PDFsam - B 371 - B 371M - 15Document4 pagesPDFsam - B 371 - B 371M - 15mike.jensen0581No ratings yet

- PDFsam - B 374 - 06 (2011)Document10 pagesPDFsam - B 374 - 06 (2011)mike.jensen0581No ratings yet

- PDFsam - B 360 - 15Document5 pagesPDFsam - B 360 - 15mike.jensen0581No ratings yet

- PDFsam - B 361 - 16Document5 pagesPDFsam - B 361 - 16mike.jensen0581No ratings yet

- PDFsam - B 49 - 16Document8 pagesPDFsam - B 49 - 16mike.jensen0581No ratings yet

- PDFsam - B 363 - 14Document4 pagesPDFsam - B 363 - 14mike.jensen0581No ratings yet

- First Floor PlanDocument1 pageFirst Floor PlanHEET MEWADANo ratings yet

- Module 1.6 Settling and SedimentationDocument37 pagesModule 1.6 Settling and SedimentationLong ENo ratings yet

- Weldwell Spectrum July Dec 2019Document20 pagesWeldwell Spectrum July Dec 2019Mahesh DeshmukhNo ratings yet

- FOUNDATION RCD of Footings 1 Square FTGDocument5 pagesFOUNDATION RCD of Footings 1 Square FTGChris Michelle JapinNo ratings yet

- Thermal Design Analysis of A Liquid Hydrogen VesselDocument9 pagesThermal Design Analysis of A Liquid Hydrogen Vessel이경률No ratings yet

- (English) Translating Chemistry Word Problems (DownSub - Com)Document4 pages(English) Translating Chemistry Word Problems (DownSub - Com)ikhsania utamiNo ratings yet

- Atomic Absorption & EmissionDocument80 pagesAtomic Absorption & EmissionAkshay Patil100% (1)

- Sodium SilicateDocument7 pagesSodium Silicateshivam_ent07No ratings yet

- Flat SlabDocument69 pagesFlat Slabmukhlesh100% (1)

- Mechanical Properties: Issues To Address..Document40 pagesMechanical Properties: Issues To Address..Mat MatttNo ratings yet

- HCLDocument13 pagesHCLHussein AlkafajiNo ratings yet

- BSR 2014 PDFDocument134 pagesBSR 2014 PDFRavindu RansaraNo ratings yet

- Soil Micronutrients FinalDocument56 pagesSoil Micronutrients Finalsundar100% (2)

- Method Statement For Stone Finish GRC Fabrication and ErectionDocument5 pagesMethod Statement For Stone Finish GRC Fabrication and ErectionAnjo MolinaNo ratings yet

- Pyrojet-Burner (34201)Document12 pagesPyrojet-Burner (34201)Long LêNo ratings yet

- Torsion: Torsional ReinforcingDocument9 pagesTorsion: Torsional ReinforcingRuel ElidoNo ratings yet

- T.Y.Yeh Professor Department of Civil and Environmental EngineeringDocument14 pagesT.Y.Yeh Professor Department of Civil and Environmental EngineeringAlberto Acabal IINo ratings yet

- 4860 Molenaar IIIDocument165 pages4860 Molenaar IIIJhinson BriceñoNo ratings yet

- Proprietary Drawing: CAA VPN 01/12/21 First Issue 0Document2 pagesProprietary Drawing: CAA VPN 01/12/21 First Issue 0Francelina VegaNo ratings yet

- Value EngineeringDocument20 pagesValue EngineeringSakshi SinghNo ratings yet

- Trends in Period 3Document47 pagesTrends in Period 3abby jacksonNo ratings yet

- PDS Petrygo Heavy AntifreezeDocument2 pagesPDS Petrygo Heavy AntifreezemostafaNo ratings yet

- Plaxis L11 - Slope Stability Including Unsaturated BehaviourDocument24 pagesPlaxis L11 - Slope Stability Including Unsaturated BehaviourBayo Regar Mangharopsamoniscinta100% (2)

- Case Study On Operational Inspection of A Fluidised Bed Combustion BoilerDocument31 pagesCase Study On Operational Inspection of A Fluidised Bed Combustion Boilerparthi20065768No ratings yet

- Enzymatic Assay of XYLANASE (EC 3.2.1.8) PrincipleDocument4 pagesEnzymatic Assay of XYLANASE (EC 3.2.1.8) Principlesyaza amiliaNo ratings yet

- Wearing Coat ThicknessDocument1 pageWearing Coat ThicknessanjanaNo ratings yet

- Materials Comparison DIN / EN / ASTM: Pipes / Tubes Flanges Buttwelding FittingsDocument1 pageMaterials Comparison DIN / EN / ASTM: Pipes / Tubes Flanges Buttwelding Fittingsnaseema1No ratings yet

- Carbopol® Ultrez 21 Polymer: The Lubrizol Corporation 29400 Lakeland Boulevard Wickliffe, Ohio 44092 Tel: (440) 943-4200Document7 pagesCarbopol® Ultrez 21 Polymer: The Lubrizol Corporation 29400 Lakeland Boulevard Wickliffe, Ohio 44092 Tel: (440) 943-4200Ana Paula JimenezNo ratings yet

- PREP FOR Fire Water Line PDFDocument154 pagesPREP FOR Fire Water Line PDFDusngi MoNo ratings yet

- Paper - Chevron Natural Gas Carbon Capture Technology Testing ProjectDocument10 pagesPaper - Chevron Natural Gas Carbon Capture Technology Testing ProjectendosporaNo ratings yet