Professional Documents

Culture Documents

1010582-PV101-C-v3.1-B

Uploaded by

pabloperezmtz1Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1010582-PV101-C-v3.1-B

Uploaded by

pabloperezmtz1Copyright:

Available Formats

1010582

09-30-10

Section 78

PowerView™ - Model PV101-C

Features

• Tier 4 emissions compliant

• For modern electronic engines and equipment applica-

tions using SAE J1939 Controller Area Network

• Displays over 50 standard SAE J1939 parameters broad-

cast by engine and transmission ECU’s

• Displays active and ECU-stored faults with text

description for diagnosing equipment malfunctions

• Simple connection to optional components

• Software configurable with configuration tool

The PowerView Model PV101, Murphy’s powerful display in the J1939 MurphyLink® family of components, provides a window into

modern electronic engines and transmissions.

The PV101 display is a multifunction tool which enables equipment operators to view many standard engine and transmission parame-

ters as well as active and stored trouble codes. The display can show either a single parameter or a quadrant display showing four

parameters simultaneously. Diagnostic capabilities include codes with text translation for the most common fault conditions. The

enhanced alarm indication has ultra-bright alarm and shutdown LEDs (amber and red).

The PV101 has been enhanced with new features including:

• Tier 4 Emissions Implementation - Three icons indicating Active Regeneration, Inhibit Regeneration, and Diesel Particulate Filter

Restricted. Auto DPF Regen, Request DPF Regen, and Inhibit Regen Menu active only if enabled via the Configuration Tool.

• TSCI (Torque Speed Control) - Allows user to set run speed via CAN if supported by engine manufacturer.

• Additional 4-Up Screen - Allows user to have two 4-Up screens to toggle between. Second user configurable screen is defaulted to

show Tier 4 Parameters; Catalyst Tank Level, DPF Active Regen Status, Exhaust Filter Outlet Temp, and Exhaust Filter Inlet Temp.

• Multiple language options − Russian, Czech, Brazilian Portuguese, Chinese, and Japanese models have been added to the line of

existing languages (English, Spanish, French, German, and Italian).

• Sender Input − select between backlight dimmer function or fuel level. Can be calibrated to use non-Murphy fuel senders.

• Service Reminders – 5 service reminders allow users to set hours for: Change Engine Oil, Change Air Filters, Change Hydraulic Oil,

Service Engine, and Service Machine.

• Select Source Address – select the exact address the PV101 will claim on the Bus.

• Select CANBUS Data Rate – allows user to select CANBUS data rate.

• PV101 Configuration Tool – allows users to create, view, edit and download configurations for the PV101 using their computer.

The PV101 display is compatible with all our current J1939 gages, as well as additional J1939 I/O modules. It is also fully backward com-

patible with it’s predecessor, the PV100.

Other components in the MurphyLink system include micro-processor-based PowerView Analog Gages for displaying critical engine data

broadcast by an electronic engine or transmission’s Engine Control Unit (ECU); engine RPM, oil pressure, coolant temperature, system

voltage, and a combination audible alarm and relay unit for warning and shutdown annunciation. Up to 32 components may be linked to

the PowerView using a simple daisy chain wire connection scheme using RS485. The PowerView and all connected components can be

powered by either 12 or 24-volt systems.

Display Parameters

The following are some of the engine and transmission parameters displayed by the PowerView (when applicable, consult engine or

transmission manufacturer for SAE J1939 supported parameters). The PowerView can display these parameters in all available lan-

guages, as well as in English or Metric units.

.

• Engine RPM • Oil Pressure • Transmission Oil Temperature

• Engine Hours • Fuel Economy • Transmission Gear Position

• Fuel Rate • Throttle Position • Active Service codes

• System Voltage • Engine Manifold Air Temperature • Stored Service Codes (when

• % Engine Load at the Current RPM • Current Fuel Consumption supported)

• Coolant Temperature • Transmission Oil Pressure • View Engine Configuration

• Catalyst Level • NMEA 2000 GPS Parameters Parameters

Specifications

Operating Voltage Case: Polycarbonate/polyester

• 8 VDC minimum to 32 VDC maximum Maximum Panel Thickness: 3/8 inch (9.6 mm)

Reversed Polarity: Withstands reversed battery terminal polarity indef- Auxiliary RS485 Communications Port

initely within operating temperatures. • User configurable as Modbus MASTER or Modbus RTU SLAVE

Environmental • MASTER ACTIVE (default) drives optional PVA or PVM gages

Operating Temperature: -40o to +85oC (-40o to +185oF) • SLAVE ACTIVE offers user adjustable communication parameters

Display Viewing Temperature: -29o to +85oC (-20o to +185oF) Resistive Input: (user selectable as one of the following)

• Backlighting Poteniometer: 1 K Ohm, 1/4 W

Storage Temperature: -40o to +85oC (-40o to +185oF) • Murphy Fuel Sender: 33 Ohm full, 240 Ohm empty set standard from

Environmental Sealing: IP68, +/-5 PSI (+/- 34kPa) factory for use with Murphy fuel sender. Programmable for use with

non-Murphy fuel senders.

Power Supply Operating Current

• (@ 14VDC) 52 mA min.: 300 mA max Shipping Weights (all models): 1 Lb. (450 g.)

• (@ 32VDC) 1A max (with LCD heater) Clamp: PBT

CAN Bus: SAE J1939 compliant Connectors: 6-pin Deutsche DT Series

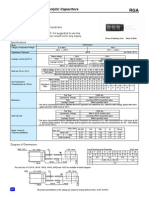

Product Dimensions

How to Order

Part Number Model Number Description Languages Available

78700439 PV101-C-MSTD Murphy STD English, Spanish, French, Italian, German

78700497 PV101-C-M01 Murphy STD Russian English, Russian, French, German, Spanish

78700498 PV101-C-M02 Murphy STD Chinese English, Chinese

78700499 PV101-C-M03 Murphy STD Japanese English, Japanese

78700500 PV101-C-M04 Murphy STD Brazilian Portuguese English, Brazilian Portuguese, French, German, Spanish

78700501 PV101-C-M05 Murphy STD Czech English, Czech, French, German, Spanish

78700435 PV101-C Configuration Tool User Configuration Tool

Kit

You might also like

- MurphyDocument18 pagesMurphyRoger Pozo AriasNo ratings yet

- DKG 545 EnglishDocument49 pagesDKG 545 EnglishrogerioNo ratings yet

- Catálogo de Productos MurphyDocument28 pagesCatálogo de Productos MurphyRené GPNo ratings yet

- DKG 509 - UserDocument56 pagesDKG 509 - Userhackerland_1No ratings yet

- Manual PowerFlex 70 (Tabela de Resistor)Document54 pagesManual PowerFlex 70 (Tabela de Resistor)William RodrigoNo ratings yet

- Dkg-509 Automatic Mains Failure Unit With J1939 Port: FeaturesDocument59 pagesDkg-509 Automatic Mains Failure Unit With J1939 Port: FeaturesAziz ArrahalNo ratings yet

- Generator 307 USERDocument54 pagesGenerator 307 USERLiviu PopaNo ratings yet

- Dkg-507 Automatic Mains Failure Unit: Canbus and Mpu VersionsDocument54 pagesDkg-507 Automatic Mains Failure Unit: Canbus and Mpu VersionsFuqqi BhaiNo ratings yet

- Dkg-309 Automatic Mains Failure Unit: Canbus and Mpu VersionsDocument61 pagesDkg-309 Automatic Mains Failure Unit: Canbus and Mpu VersionsKhaleel KhanNo ratings yet

- DataKom 309J - USERDocument61 pagesDataKom 309J - USERKhaleel KhanNo ratings yet

- Product Profile: Provide Optimized SimplicityDocument4 pagesProduct Profile: Provide Optimized SimplicitySudipta Kumar GarnayakNo ratings yet

- E500 Series: E F C PDocument44 pagesE500 Series: E F C Pnghienhugo100% (1)

- 22_enovation_pv101_salesbulletinDocument2 pages22_enovation_pv101_salesbulletinmr mohamedNo ratings yet

- Kg545 II UserDocument86 pagesKg545 II Usersaneesh81100% (1)

- Man Hinh Dieu Khien EMCP4.3Document4 pagesMan Hinh Dieu Khien EMCP4.3Nhanh Ngô VănNo ratings yet

- C17 C28D5 X2.5Document4 pagesC17 C28D5 X2.5Pritesh Kumar100% (1)

- ComAp Marine Brochure 2011-11 CPCEMARIDocument52 pagesComAp Marine Brochure 2011-11 CPCEMARIsdiaman100% (1)

- 800 KW Containerised Diesel GenDocument15 pages800 KW Containerised Diesel Genhermit44535No ratings yet

- Emcp 4: EMCP 4.2 Generator Set ControllerDocument3 pagesEmcp 4: EMCP 4.2 Generator Set ControllerdinukaeeNo ratings yet

- 26 29 23 Drives MM430Document5 pages26 29 23 Drives MM430Jose HernandezNo ratings yet

- Flex Pak 3000Document24 pagesFlex Pak 3000Maitry ShahNo ratings yet

- DKG 517 J Manual de UsuarioDocument38 pagesDKG 517 J Manual de Usuarioenriquecourtadep100% (1)

- RFQ No. ASPA17.030 Supply & Delivery of VFDs For The Tafuna WWTP-Attachment B - VFD SpecificationDocument6 pagesRFQ No. ASPA17.030 Supply & Delivery of VFDs For The Tafuna WWTP-Attachment B - VFD SpecificationPRABHU SHANKAR MNo ratings yet

- DataKom 537 - USERDocument39 pagesDataKom 537 - USERKhaleel KhanNo ratings yet

- AC Invertor1000dsDocument20 pagesAC Invertor1000dsRonak PatelNo ratings yet

- db_reg_p_gbDocument4 pagesdb_reg_p_gbkader arbiaNo ratings yet

- 240V Class: To 175 HP 480V Class: 1 To 1000 HP 600V Class: 2 To 250 HPDocument52 pages240V Class: To 175 HP 480V Class: 1 To 1000 HP 600V Class: 2 To 250 HPSyed Shahbaz AliNo ratings yet

- Yaskawa P7 Drives PDFDocument2 pagesYaskawa P7 Drives PDFMukti AwanNo ratings yet

- AC Inverter Drive: A1000 SeriesDocument8 pagesAC Inverter Drive: A1000 Seriesabhi_0302No ratings yet

- Datakom DKG109 Control Auto Start Panel Engine GensetDocument46 pagesDatakom DKG109 Control Auto Start Panel Engine GensetWira Karya DieselNo ratings yet

- Microprocessor Engine/Generator Controller: Model MEC 20Document4 pagesMicroprocessor Engine/Generator Controller: Model MEC 20Gerardo OrtizNo ratings yet

- DataKom 507 - J - USERDocument42 pagesDataKom 507 - J - USERKhaleel KhanNo ratings yet

- DKG 309Document48 pagesDKG 309Dikr ElhakimNo ratings yet

- CM20181017 22854 24044Document4 pagesCM20181017 22854 24044elgourch saidNo ratings yet

- Jaquet FT 1400 eDocument4 pagesJaquet FT 1400 eAnonymous AeIfk4RKnNo ratings yet

- Datakom-Dkg 517Document39 pagesDatakom-Dkg 517Hernan100% (2)

- Firetrol SBP1100JDocument13 pagesFiretrol SBP1100JJlavieraNo ratings yet

- MD380 AC Drive User Manual-20121225Document292 pagesMD380 AC Drive User Manual-20121225Ks Bharathiyar100% (2)

- STG820 - Steam Turbine Governor: ALSPA P320 System - Technical Data Sheet P-TP09-A49052Document3 pagesSTG820 - Steam Turbine Governor: ALSPA P320 System - Technical Data Sheet P-TP09-A49052hudson100% (2)

- Fuji Frenic-Vg7sDocument50 pagesFuji Frenic-Vg7sMathawee ChotchaiNo ratings yet

- CCCCCCCCCCCCCCCCCCCCCC C CC C C CDocument5 pagesCCCCCCCCCCCCCCCCCCCCCC C CC C C CPrashil BambaleNo ratings yet

- L&T's New 1000 Series AC DrivesDocument20 pagesL&T's New 1000 Series AC Drivesjunfa0% (1)

- 02058-iGuard-BDocument2 pages02058-iGuard-Bpabloperezmtz1No ratings yet

- Advanced Motion Controls Dzxcante-008l080Document7 pagesAdvanced Motion Controls Dzxcante-008l080ElectromateNo ratings yet

- 109 User Manual PDFDocument46 pages109 User Manual PDFHa Xuan NguyenNo ratings yet

- MD380 USER MANUAL (English Version)Document296 pagesMD380 USER MANUAL (English Version)Ingeniería AplicacionesNo ratings yet

- Product Profile: Powerflex® 400 Ac DriveDocument2 pagesProduct Profile: Powerflex® 400 Ac DrivebpakkuNo ratings yet

- DGC-2020 BrochureDocument12 pagesDGC-2020 BrochureRoque PadillaNo ratings yet

- 200 KVA Perkins Diesel Generator SetDocument5 pages200 KVA Perkins Diesel Generator SetPopa AurelNo ratings yet

- Compacte Handleiding V7Document60 pagesCompacte Handleiding V7gui9871No ratings yet

- Dkg-517-J Manual and Remote Start Unit With J1939 Interface: DescriptionDocument2 pagesDkg-517-J Manual and Remote Start Unit With J1939 Interface: DescriptionJorge Omar ToroNo ratings yet

- EMCP 3 Controller: Electric PowerDocument29 pagesEMCP 3 Controller: Electric Powerabailey12100% (2)

- Spec Sheet - 3508 910 kVA PrimeDocument4 pagesSpec Sheet - 3508 910 kVA PrimeTarekAsfourNo ratings yet

- EMCP 3 1 Generator Controller SetDocument4 pagesEMCP 3 1 Generator Controller SetAziz ArrahalNo ratings yet

- Quickly position loads with DX servo actuatorsDocument26 pagesQuickly position loads with DX servo actuatorsCreuza BarbosaNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- 94134-M25-50 valves-BDocument4 pages94134-M25-50 valves-Bpabloperezmtz1No ratings yet

- 99026-SV valve-BDocument4 pages99026-SV valve-Bpabloperezmtz1No ratings yet

- 94129-Pneumatic valves-BDocument2 pages94129-Pneumatic valves-Bpabloperezmtz1No ratings yet

- 0710175-XM500-BDocument2 pages0710175-XM500-Bpabloperezmtz1No ratings yet

- 95145-PD8100-BDocument2 pages95145-PD8100-Bpabloperezmtz1No ratings yet

- 95-8699-2.1_(X5200G)Document2 pages95-8699-2.1_(X5200G)pabloperezmtz1No ratings yet

- 03020-Wiring harness-PVA-BDocument2 pages03020-Wiring harness-PVA-Bpabloperezmtz1No ratings yet

- 95-8686-(Q9033-Collar)Document4 pages95-8686-(Q9033-Collar)pabloperezmtz1No ratings yet

- 00-02-0642Document1 page00-02-0642pabloperezmtz1No ratings yet

- Instructions: UVIR Flame Detector Series Model X5200, X5200G, and X5200MDocument35 pagesInstructions: UVIR Flame Detector Series Model X5200, X5200G, and X5200MLuis Alberto Serrano MesaNo ratings yet

- 95-8790- (X-Series-Flame-Detectors-with-Pulse-Output)Document16 pages95-8790- (X-Series-Flame-Detectors-with-Pulse-Output)pabloperezmtz1No ratings yet

- 9100T Sensor High TemperatureDocument2 pages9100T Sensor High Temperaturepabloperezmtz1No ratings yet

- 9000A Sensor General PurposeDocument2 pages9000A Sensor General Purposepabloperezmtz1No ratings yet

- What is an electrolyser and how does it generate hydrogenDocument1 pageWhat is an electrolyser and how does it generate hydrogenbhaidadaNo ratings yet

- Platform Demand ManagementDocument21 pagesPlatform Demand ManagementNoshaba MalikNo ratings yet

- Information Sheet 2Document7 pagesInformation Sheet 2Candice SumayangNo ratings yet

- MSG Hydraulic Gear Pump (Anjas)Document9 pagesMSG Hydraulic Gear Pump (Anjas)Anjas Maulana IswantoNo ratings yet

- IOT Based Accident Prevention and Detection System Using GSM-GPS, Eye Blink, and Alcohol SensorDocument8 pagesIOT Based Accident Prevention and Detection System Using GSM-GPS, Eye Blink, and Alcohol SensorIJRASETPublicationsNo ratings yet

- ICT AssignmentDocument8 pagesICT Assignmentlij yoNo ratings yet

- DPWH DupaDocument274 pagesDPWH DupaCelsoRapi80% (5)

- Data Driven Energy The Advanced Energy Management Solution Ge DigitalDocument12 pagesData Driven Energy The Advanced Energy Management Solution Ge DigitalRegis MurenziNo ratings yet

- 6 - Instructional Materials Development For ESPDocument12 pages6 - Instructional Materials Development For ESPMerren Monta100% (1)

- Allison Transmission ECUDocument1 pageAllison Transmission ECULouis Hardy50% (2)

- Global USS - Inside Sales Account ManagerDocument2 pagesGlobal USS - Inside Sales Account Managerneeraj viharNo ratings yet

- Investor Customer'S Option To Receive Payments Through: No/Ledger Folio NoDocument3 pagesInvestor Customer'S Option To Receive Payments Through: No/Ledger Folio NoAnkur Bharat VermaNo ratings yet

- IQ Range: Installation and Maintenance InstructionsDocument3 pagesIQ Range: Installation and Maintenance InstructionszeeshanNo ratings yet

- Elec Cold Test - Smdb-Roof AtkinsDocument2 pagesElec Cold Test - Smdb-Roof AtkinsNabilBouabanaNo ratings yet

- NPTEL Online Certification Courses Programming in Java Assignment 5 MCQ QuestionsDocument5 pagesNPTEL Online Certification Courses Programming in Java Assignment 5 MCQ QuestionsAbhinav ReddyNo ratings yet

- Design and Optimization of Modular Production System Distribution and Pick & Place StationDocument9 pagesDesign and Optimization of Modular Production System Distribution and Pick & Place StationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Scribd For IphoneDocument3 pagesScribd For IphoneScribd50% (2)

- HTZ 121 DVDDocument96 pagesHTZ 121 DVDtoyioriginalNo ratings yet

- AbstractDocument22 pagesAbstractSangeeta JamadarNo ratings yet

- Don't Gamble with Your Crops! Accurately Measure Soil Moisture with the Handi-TRASEDocument2 pagesDon't Gamble with Your Crops! Accurately Measure Soil Moisture with the Handi-TRASERiego GeomembranaNo ratings yet

- AWS Deployment GuideDocument40 pagesAWS Deployment GuideJOJINo ratings yet

- Convolution 18.031, Haynes Miller and Jeremy OrloffDocument10 pagesConvolution 18.031, Haynes Miller and Jeremy OrloffPrineezyNo ratings yet

- English 5 Video Script - FinalDocument12 pagesEnglish 5 Video Script - FinalEspie CosteloNo ratings yet

- General Specification # GS 327 Model # 6836 - XPM2 Reflow Soldering / Curing SystemsDocument7 pagesGeneral Specification # GS 327 Model # 6836 - XPM2 Reflow Soldering / Curing SystemsManojNo ratings yet

- Kta50 Injector TimingDocument17 pagesKta50 Injector TimingSebastian Nicușor PărăoanuNo ratings yet

- JK Water Leaks AllDocument144 pagesJK Water Leaks Allkacos2000100% (5)

- ASTM C131/C131M 14: Standard Test Method For Resistance To Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in The Los Angeles MachineDocument5 pagesASTM C131/C131M 14: Standard Test Method For Resistance To Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in The Los Angeles MachineShaheer Ahmad100% (1)

- Lelon RGADocument5 pagesLelon RGAAnonymous xvd6YfftNo ratings yet

- Analytic and Harmonic FunctionsDocument54 pagesAnalytic and Harmonic FunctionsATCNo ratings yet

- Report Writing - PankajDocument13 pagesReport Writing - PankajPankaj GoyalNo ratings yet