Professional Documents

Culture Documents

4 CA4250P25K15T1NE5A80 DZ722R 哥伦比亚 维修手册 电气线路图 英文

Uploaded by

Jorge Elieser Sánchez RiosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4 CA4250P25K15T1NE5A80 DZ722R 哥伦比亚 维修手册 电气线路图 英文

Uploaded by

Jorge Elieser Sánchez RiosCopyright:

Available Formats

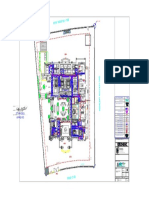

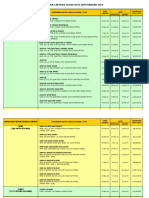

Fuse box assembly Chassis fuse box assembly

Main fuse box

Normal Electricity

(Reserve 10A)

(Reserve 10A)

Key ON Low Speed Wiper Relay Detail drawing

Instrument (Normal Electricity)

Air dryer heating、NOX Sensor

Power supply main switch B+ Rear working lamp The top cover of the terminal post needs to

BCM Power Supply 1

be integrated with the housing

Rear working lamp

(Reserve 25A)

Door Controller(Glass elevating and

lowering atmospheric electricity) Rear working light switch

Door Controller

(Rearview mirror and door lock)

Headlamp Far Light Relay

BCM Power Supply 2 Headlamp left far light Left Auxiliary Far Light

Headlamp right far light Right Auxiliary Far Light Chassis fuse box assembly

Spare

Light switch Company Logo 2 series by Q/CAT-2.1

Main fuse box power supply (normal)

Standby load

Emancipation Mark 4 Series by Q/CAT-2.2 Normal current

Engine Oh6 Ecu

Standby Output Quadrangle relay

Engine ignition coil

Low Speed Wiper Relay

Date label by Q/CAT-3.1 Engine ignition coil power supply

Wiper S-End

control+

Standby input Wiper、Scrubber、Intermittent wiper controller

5 feet

Wiper low speed switch、Intermittent wiper controller control-

KeyACC 75

Engine nozzle relay power supply / Engine ECU( Bosch NG)

Hydraulic Reversal Relay Control+,Inverter (ACC) High Speed Wiper Relay

Trailer, ABS

Wiper low speed Engine nozzle

The cigarette lighter、Receiver/Vehicle Terminal (ACC)、DC-DC Engine nozzle power supply

Wiper High Speed

(Reserve 15A) 5 feet

control+

Air Conditioning Compressor Relay (J4) Wiper High Speed Switch

control-

Rear fog lamp relay

KeyON 15

Rear fog lamp

Hydraulic turnover motor

Door Controller (ON)

Engine brake relay

Rear fog lamp switch Main power

(Reserve 10A) switch B+ Engine Brake

Flasher (ON) Engine brake control+

Fog lamp relay

(Reserve 10A)

Instrument (ON) Engine brake control-

Front fog lamp、Rear fog lamp switch

Back Light, back Buzzer

Front fog lamp switch

ABS Controller (ON)

Accumulator equalizer

Controller (ON)、ECAS(ON) Electrically controlled silicon oil fan relay

Horn relay

(Reserve 10A) Electrically controlled silicon oil fan

Engine ECU (ON)、Brake Signal Separation Relay Control+

Electric horn Electronically controlled silicone oil fan control+

(Reserve 10A) Horn switch

Electronically controlled silicone oil fan control-

Ignition switch power supply

J13 headlamp low-light relay Headlamp left near light

Independent air-conditioning

Headlamp right near light compressor / 1KW inverter

ON power transmission Component number according to Q/CAT-3.1

Light switch Main fuse Box power supply

(main power switch B+)

Air conditioning power supply (ON))、Fan relay control (+)

J14 Small Lamp Relay Cab light

(Reserve 20A) Chassis lamp Manufacturing Plant Code According to Q/CAT-3.1

Air Conditioning Compresso Power Supply (ACC)

Light switch

Air conditioningcompressor relay

Low Voltage Switch for Air Conditioning

Air conditioner

Automatic air conditioning、Low Voltage Switch Control of Air Conditioning+ Integrated Waterproof vent valve at bottom of housing

Air conditioning switch (heater)

Low Voltage Switch Control of Air Conditioning- Warm air control switch control-

Warm air control switch control+

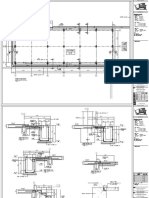

Serial number Position Wire harness end adaptor type Notes

Brake Signal Separation Relay

Checking Brake Signal Connecting to Computer

Brake signal connected to computer

5 feet

Serial number position Type of Wire Harness Side Socket Remarks

Chassis fuse box cover

Brake light switch

Control + (NO gear) The error-proof structure of fuse box

back socket should ensure that the

Engine braking

non-corresponding position numbered

Engine Brake Valve wire harness side socket can not

be inserted.

Engine Brake Control-

Engine Brake Control+

Vehicle Speed Signal Controller Detail drawing

Indoor lamp power supply、Air horn、Sleeping lamp

Nameplate, see 3722151-DZ722S

The door opens the alarm light.Pedal lamp

24V power supply socket

ABS Controller (B+)

220V Inverter Liberation Mark 4 series by Q / CAT-2.2

OBD diagnostic socket

Explain

Press Q / CAT-3.1 for part number

Power Supply of Vehicle Information Service Terminal

Insert Series Specifications,Yes2.8、6.3、9.5

Inter-axle differential lock,Solenoid Valve of Parking Power Takeoff Chassis fuse box cover Fuse sign

Position number of socket in socket

Back Light, back Buzzer

Code number of socket Urea Supply Module Heating Main Relay Power Supply Electrically controlled Electrically controlled silicon oil fan

silicon oil fan relay

Accumulator equalizer

Engine Brake (optional)

ECAS Power Supply Engine brake Hydraulic turnover motor

Stand by

relay (optional) Ignition switch (to cab ignition lock)

Engine nozzle power supply

ECU (Weichai Power 10-litre aircraft)

Interwheel differential lock、Force taker solenoid valve、Shui Hanbao Switch ECU (Weichai 12 L, 13 l)

Engine nozzle

Engine ignition coil power supply Stand by

Trailer, ABS

Stand by

Engine ignition coil

Main power supply of fuse box in cab

Normal power supply for fuse box in cab

Adaption

Company logo 2 series by Q / CAT-2.1

Manufacturer Code, Date Stamp, non-metallic

Material Label Press Q / CAT-3.1

Four of them

The box body is PA6-GF20 and the material specification is JF03-26

The 10A chip type fuse adopts 3722012-50

The 20A chip type fuse adopts 3722014-50

The 30A chip type fuse adopts 3722017-50

Unmarked rounded corner R3 The back terminal is connected by copper plate and the copper plate is wrapped by heat shrinkable tube

Name Fuse box assembly(Style drawing)

Material combustion characteristics according to JF03-64(a) Plug connector by QC / T 417, where the surface of the metal terminal is tinned, by Q / CAYT-4.12

Name Fuse box and accessory equipment assembly of chassis

Technical conditions according to JA3722-A01-1 Drawing Security is Number of Processing Component Document

Picture A total of 1 sheet 1

The waterproof ring is made of transparent silicone with a hardness of Shaw Brothers Studio 405 and a temperature resistance of no less than 40 °C ~ 135 °C Descriptive Security is Number of Processing Component Document

Picture A total of 1 sheet 1

important items method version version drawing important items method version version

Tin plating on the surface of metal terminals in all sockets,Cu/Ep·Sn9,PressQ/CAYT-4.12 Design Wang Muyuan

Product

Nonmetal

Decorative

colour Drawing

Proportion

Technical Specification for fuse box assembly for Chassis Press Ja3722-240-1 Design Tang Chao

Product Nonmetal

Decorative

pattern colour

Drawing

Proportion

reexamination pattern Categories reexamination Categories

Surface Drawing

Before starting the supply,Samples must be re-examined by product design department Proofreading

weight heat treatment

Surface

protection

Drawing

software

Samples shall be re-examined by the product design department before supply begins Proofreading weight heat treatment protection software

Change Notice Change Notice

Material Science

To examine

Number To examine Number

Number

Material Science

General layout Impact swap sign

Number

date General layout Impact swap sign date

of places

of places

Standardization Standardization

China First Automobile Co., Ltd. Technology Center China First Automobile Co., Ltd. Technology Center

Approval Code

Approval Code

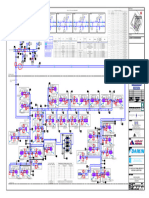

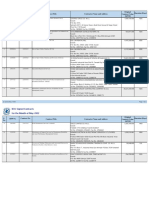

Instrument assembly diagram Elevated Box Wire Harness Assembly

(yellow)

Line number Wire function Conductor cross-sectional area (mm²) colour remarks

Pin number Functional description Signal characteristics

Mechanical pointer meter Emission Fault Alert- Low level Left body wire harness Drive Log

Reserve High level

Indicative velocity (km/h)

Reserve Low level

Left body wire harness Drive Log

Actual velocity (km/h)

At the same time, it supports both hard-wire pulse signal and bus signal: Emission Fault Alert+ High level Left body wire harness Left front porch light

Actual

velocity (km/h) Signal form Signal Source Remarks

Brake level alarm Low level

soldered dot Drive Log

The speed signal of the instrument comes from the PWM pulse signal of the sensor and the speed ratio signal of the whole vehicle from the Gearbox fault alarm High level

Hardwire Pulse signal BCM.When the BCM speed ratio signal is not received,The default speed ratio is 1; the corresponding pulse number per kilometer is 4992.

Far-light indication High level

Left body wire harness Drive Log

Bus From TCO or Autonomous AMT System Automatic identification of information transmitted by various systems Lift buzzer alarm on top Low level Left body wire harness Drive Log

Indicating Speed (r/min) Seatbelt not alarmed Low level

Left body wire harness Door, alarm light.

Speedometer Speed error (r/min) Power Output(vss)

Input signal CAN data Power Output(Barometric pressure sensor) In-room lighting 1 soldered dot

The engine economic speed zone (green zone) is 1000 r/min~1500 r/min, and the dangerous speed zone (red zone) is 2400 r/min~the maximum indicated speed. Power supply (ON gear)

In-room lighting 2 soldered dot

Signals are taken from hard wires。 Power Supply (Battery)

Right turn indication High level

Left front porch light soldered dot

Indicative scale value

NG Gas Scale

NGCylinder pressure(MPa)

Left turn indication High level Elevated Box Light 1 soldered dot

Trailer right turn indication High level

Conversion of input signal voltage to cylinder pressure:(Signal Voltage/5)*100=3.00*Cylinder Pressure(MPa)+5 Elevated Box Light 2 soldered dot

Permissible error Left turn indication of Trailer High level

Indicative scale value(°C)

Cab rollover alarm Low level Elevated Box Light 3 soldered dot

Input signal CAN data ECASCab rollover alarm Low level Drive Log soldered dot

Permissible error(°C) Trailer disconnected alarm Low level

Left body wire harness Drive Log

Coolant When the coolant temperature is above 40 degree C and below 90 degree C,Normal indication according to actual temperature value Railway (Air Pressure Sensor)

thermometer

When the coolant temperature is greater than or equal to 90 degrees C and less than 105 degrees C, the pointer always points to the position of 90 degrees C.

Power supply (instrument lighting) Left body wire harness Interior light on left

ECASLifting shaft indication Low level

When the coolant temperature is greater than 105 C and less than 120 C, it should be indicated according to the actual temperature value. Left body wire harness Interior light on right

The red zone of the coolant thermometer ranges from 105 C to 120 C. When the coolant temperature is greater than 107 C, the alarm sign lights up, and when the coolant temperature is less than 105 C, the alarm sign goes out.

Left body wire harness Door, alarm light.

LCD screen 1 area division (no AMT, alarm information detected) LCD screen 1 area division ( AMT, alarm information detected) Railway (Instrument)

Left body wire harness Door, alarm light.

(blue)

Time information Yellow Alert Indicator Area Red Alert Indicator Area

Left body wire harness Drive Log

Pin number Functional description Signal characteristics

Traffic information Traffic information Left body wire harness Door, alarm light.

Gas volume information Gas volume information Battery Charging Instruction Low level(Generator Excitation Current > 80mA)

Autonomous AMT Information

Coolant level alarm Coolant level is too low and effectively lasts 8 seconds to light up soldered dot Elevated Box Light 1

Brake pressure 1 Brake Pressure Information Parking brake indication Low level

soldered dot Elevated Box Light 2

Interwheel differential lock indication Low level

LCD screen1 Brake pressure 2 Work Indicator Area soldered dot Elevated Box Light 2

Key 1 Key 2

Lighting Fault Alarm Low level

LCD screen2

Engine fault alarm-(yellow) Low level

LCD 1 Display Content Fuel filter blockage alarm Low level

Start-up display company logo and "FAW China" words, display time 2S Engine fault alarm+(yellow) High level

It is divided into red alarm indication area, yellow alarm indication area and white work indication area. Speedometer signal input

Alarm instruction When there are red or yellow alarm instructions, hide time and temperature information, and light the corresponding color alarm symbols here. Reserve Low level

When multiple alarm symbols appear, the 2S cycle is displayed alternately.

Outdoor temperature signal input

When several white work indicators appear, the 2S cycle is displayed alternately. The resistance value < 1K_exceeds 1s.

Gas Leakage Alarm Signal Input Light the corresponding alarm light and buzz

(the buzz can be removed from the menu)

Time format: HH: MM, 24-hour system; instrument internal calculation, display range 00:00-23:59; error < 1.5 seconds/day. CNG cylinder pressure signal input Voltage signal

Observation Direction and Measuring Point of Sheath

time When the instrument is first powered on, the default is 00:00. If the instrument is powered off after the battery is powered on, the digital clock will start the timing work again from 00:00.。 Inter-axle differential lock indication Low level Left body wiring harness

Display time information when there is no red or yellow alarm indication. ABS1Fault Alarm (Main Vehicle) Low level sheath

Outlet end Inlet end

Traffic information includes oil pressure and short-term reminder information. ABS2Trouble Alarm (Trailer) Low level

Company logo 3 series by Q/CAT-2.1 Continuous point press button 1 to realize the following switching display: brake pressure switching display, oil pressure information. (Black) (green)

ASRWork instructions Low level View Direction

Start-up default display instantaneous fuel consumption and lower one-way braking pressure;If the button 1 is pressed in 5s, the brake pressure will automatically switch back to

Traffic information Wireway

show the lower one-way pressure. Working instructions for power harvesters Low level Code number number Number Remarks

Short-term reminder information includes maintenance reminder, speed ratio matching failure, overspeed reminder.The priority decreases in turn, which is higher than the

traffic information, cCand returns automatically after reminding for up to 5 seconds.

Brake system fault alarm Low level Dimensional boundaries

Air filter blockage alarm Low level

Low gear indication Low level

(yellow)

Specific display content of gas pressure value is: gas quantity symbol (same fuel symbol) * X. * MPa Door open alarm Low level Plug-in Characteristic Number(A list of optional relationships)

Gas volume

With 185879-1 (Yellow) Match When the air pressure is less than 6 MPa, the gas sign flickers at a time interval of 1S.At the same time, the text message "insufficient gas" is displayed at the bottom of the LCD screen. Speedometer Signal Output Open collector circuit

information

ECASAltitude indication Low level

The Chinese character information and the content (mileage value) normally displayed in this area are displayed in 2S time interval cycle.Stop flickering and Chinese character

display until air pressure is higher than 6 MPa. Pressure Table 1 Signal Input Wire harness label, label content is "XXXXX" as shown,Clear label content,

Barometer 2 Signal Input

The pasting position is 30-100 mm away from the feeding end of the branch connector.

(blue)

Oil pressure

Display with status bar: display range: (0-1.0) MPa, every 0.1 MPa as a segment; when AMT information is detected, display with numerical value, accuracy is 0.05 MPa;

Led alarm indication LCD Screen 1 alarm instruction Dimension measuring point

Adaptation to 185879-2 (Blue)

When the oil pressure is less than 0.06MPa, the oil pressure alarm sign lights up, and when the oil pressure is more than 0.08MPa, the oil pressure alarm sign goes out.

Serial

number

Symbol Display color Significance

Serial

number Symbol Display color Significance Semi-overlapping coating of wear-resistant cloth-based tape for conductors

Serial number function Signal form Remarks

gules Air filter blockage alarm

After wire is semi-laminated with wear-resistant cloth tape, open bellows are tied up.

CAN data, by communication matrix Make full use of the display area, large enough gules STOP Fault Indication

Current gear

gules Parking brake indication gules Door alarm instructions

Target gear CAN data, by communication matrix Blinking display during shift

External semi-overlapping tape with tape size shown here

A/M mode display CAN data, by communication matrix Display "A" or "M" yellow Auxiliary brake indication white Dynamometer indication

AMT Information

E/PMode display CAN data, by communication matrix Display "E" or "P" gules yellow ASRInstructions

Left front porch light

Brake system fault alarm

The manufacturer code, part number

and date label are according to Q/CAT-3.1

C/Mode display CAN data, by communication matrix Display "C" or not gules Coolant level alarm

white

Interwheel differential Vvc

lock indication

Inter-axle differential

Wires are wrapped with open braided polyester sleeves and externally pressed with PVC tape.

L/Mode display CAN data, by communication matrix Display "L" or not blue Far-light indication

Alarm lamp display CAN data, by communication matrix Show red or yellow flash or slow flash in alarm area green Right turn indication

white lock indication

Appendix C of QC/T 29106 is F-PVC/105/R-Tx.

gules Trailer disconnected alarm

The status bar shows the lower one of the two air pressures.The error is 0.05 MPa and the display range is (0-1.2) MPa, each 0.1 MPa is a segment. green Left turn indication yellow Brake lamp fault alarm

pressure Uo= (0.1+0.5714P) xUin (U is the reference voltage, P is the indicator calibration value, Ui is the input voltage) green Trailer right turn indication

gules Brake level alarm

When the air pressure is less than 0.55 MPa, the alarm symbol of the braking system is lit up, and when the air pressure is more than 0.60 MPa,

the alarm symbol of the braking system is extinguished.

green Left turn indication of Trailer

white Low gear indication

Unprotected wires

gules Gas Leak Alarm gules/yellow Gearbox fault alarm

function Signal form functional status describe Oil temperature alarm

gules Oil pressure alarm

gules for gearbox

Semi-overlapping gluing of PVC tape for conductor,Leave bare line for head over 100 mm, 50 mm for head below 100 mm and 30 mm for head below 100 mm.

FCW Fault: Symbols are always bright (LDW takes precedence in the calibration process, and symbols disappear when the calibration is completed and successful)

gules Coolant Temperature Alarm Retarder fault alarm

gules

FCW Close: Symbols are always bright

yellow ABS1 (Main Vehicle) Alarm

CAN data, by gules Retarder temperature alarm

communication matrix。 FCW Alert: Symbol Flash and Sound Reminder (Symbol Flash and Sound Synchronization). Instrument latches the alarm status for 1.4s. yellow ABS2 (trailer) alarm

First-level alarm,The frequency of icon flickering and buzzing is 2.5Hz.Bright 200 ms, 200 ms apart.

yellow Emission Fault Alert

gules

gules

ECAS altitude indication

ECASFault Alert

Wires are tied with open bellows

Secondary alarm,The frequency of icon flickering and buzzing is 5 Hz.Bright 200 ms, 200 ms apart.

yellow Engine fault alarm white ECASLifting shaft indication

FCW Standby: Symbols are always bright

gules Cab rollover alarm white ECASDrive Help Instruction

LDW Fault: Symbol is always bright (in the calibration process, the symbol flickers first, after the calibration is completed and successful, the symbol disappears)

gules Battery Charging Fault Alarm white

ECASFloating Bridge

Lifting Instruction In addition to special requirements for the diameter of bellows and zipper PVC pipes, the filling ratio of conductors to bellows and zipper PVC pipes is required to be more than 50%.

LDW Close: Symbols are always bright

Active security

LDW Standby or Unrecognized Lane Line: Symbol Always Bright

green Cruise instructions gules Seatbelt not alarmed

Except for the special requirements, the conductors protected by bellows or PVC zipper pipes shall be glued as follows inside and outside bellows or PVC zipper pipes ("L" means the length of the bellows):

Buzzer-related functions gules LDWSystem Alert

LDW Alarm: Symbol Alarm and Sound Alarm (Lane Flash and Sound Synchronization)

white LDWsystem standby 1. L 100mm is wrapped in spacer with a distance of 50mm and at least three windings.

Function Explain

CAN data, by

2. L < 100mm is wrapped in interval, the position of wrapping is in the middle of the size, and at least three circles are wound.

communication matrix。

Left and right deviations, corresponding side lane flashing in alarm symbols, gules LDWsystem failure

1. Seatbelt without indicator:Changliang Other constant brightness meters latch this alarm state for 1.4 seconds, during which the lane flicker frequency is 2.5 Hz.

white

Solder joints are the joints of the same functional conductor.

LDWSystem shutdown

A. Entry conditions; 1. Ignition switch ON gear.2) The seat belt is not fastened; Each flash lasts 200 ms, with an interval of 200 ms.

white LDWLane Line Detection

Seatbelt not

B. Conditions for withdrawal:1) OFF/ACC of ignition switch;2) Fasten your seat belt. LDW detects lane lines:Symbols always shine

FCW alarm symbols and LDW alarm symbols are displayed at position 7, and FCW alarm priority is higher than LDW alarm.

white FCWsystem standby Distribution position of each line number connector in the corresponding sheath is viewed from the outlet end.

alarmed 2. Seatbelt without sound alarm:

a、Entry conditions:1)ON gear of ignition switch,2)Unfastened seat belt,3)Vehicle Speed ≥10km/h;

gules FCWSystem Alert

Length measurement refers to the distance from the measuring point to the measuring point, or from the measuring point to the terminal of the conductor.

gules FCWsystem failure

b、Exit Conditions:1)Ignition Switch OFF/ACC,2)Fasten seat belts,3)Buzzer Sound Time≥95S,4)Speed<10km/h function

1. Language Choice

Remarks

You can choose Chinese, English and default Chinese according to your needs. Languages of driving interface white FCWSystem shutdown

The injection dimension is all the length dimensions of straightened wire. When the connector is at one end, the length of the injection dimension at one end is measured from the root of the input end of the connector.

(The return difference of alarm point is not more than 2 km/h, that is, when the speed V is less than 8 km/h, the buzzer must stop.) and menu interface change simultaneously.

Frequency 1 Hz,Sound 500ms,Intermittent 500 ms。

2.Engine fault information Display fault codes and fault text information yellow Alarm for low gas volume Blind plugging is needed for unused holes in waterproof connectors

3.Retarder fault information Recognition of Retarder System,Display fault information; the AMT system is not recognized and the item is not displayed

Lift alarm on top/

When the instrument receives the upper lifting signal, it can buzz to remind.The buzzing frequency is 5 Hz.,That's the sound.100ms,intermission100ms;

When the instrument receives the differential lock signal, it can be reminded by buzzer.The buzzing frequencies are all5Hz,That's the sound.100ms,intermission100ms,

4.Instrument self-test Test instrument signal lamp, finger lamp, buzzer, bus communication status, etc.

At the end of the insulating pipe and the branch of the conductor, tie with tape Left Indoor Lighting Right Indoor Lighting

Differential lock hint

Steering sound/

Press button 2 to close alarm。

When the instrument receives the steering signal or dangerous alarm signal from BCM,The corresponding steering indicator flashes.Drive buzzer at the same time。

5.Maintenance information

6.Brightness regulation

Maintenance mileage inquiry and maintenance reminder mileage setting can be done through menu.

Adjusting Backlight Brightness of Instrument

One-point welding of trunk lines and their branches (except CAN lines)

Danger Alert

Sound Warning When the trailer is connected,The left and right turning lights of the trailer respond at the same time.When the trailer is not connected, the left and right turn lights of the trailer do not respond.

Menu Information

7.Time adjustment Manual adjustment of display time The twisted pair pitch is (27-33) twist/m.

Door, alarm light.

Conductor and terminal are crimped

Position light The instrument buzzes when it receives an alarm signal from BCM that the position lamp is not turned off.,The frequency is1Hz,Sound500ms,intermission500ms。 8.Setting Speed Limit Setting Speed Over Value,Instrument buzzing reminder

not turned off alarm

Instrument receives parking brake signal,And when the speed is more than 5 km/h,Light up the parking brake symbols and buzz the reminder at the same time. 9.Basic Instrument Information Display Instrument Basic Information

Parking brake

(The return difference of the alarm point is not more than 2 km/h, that is, when the speed V is less than 3 km/h, the buzzer must stop. ) 10.Buzzing Closure of Gas Leakage Close the current buzz,When the alarm occurs again or the alarm is detected after the power is restarted, the buzzing continues.

Single-layer V-type heat-shrinkable tube for compression joint of single (special) terminal and conductor

Unmarked tolerance see JF03-100

Undeactivated alarm The buzzer has a frequency of 5 Hz, a sound of 100 ms and an interval of 100 ms.

PVC tape is F-PVC/105/R-Tx as specified in Appendix C of QC/T 29106

The background color of instrument panel and instrument dial is dull black,The dials are illuminated by transparent light and the overall illumination of the instrument should be uniform and soft, When the speed reaches or exceeds the set alarm limit, the buzz warns that the speed difference does not exceed 2 km/h.

The panel should be clear and transparent without refraction and scratch. Overspeed reminder

Buzzer 2 s, frequency 1 Hz, ringing 500 ms, intermittent 500 ms.

Display time and temperature in alarm area of LCD screen;Over 10s no operation automatically returns to the default main interface.

UFW bellows are used for bellows according to category A in Appendix D of QC/T 29106.

The indexing lines, characters and signal signs are white.The keys are marked white and the font is Arial bold.The pointer is red, the needle cap is black,

the screen ring is black, and the extinction plastic paint is sprayed. AMT buzzing According to the communication protocol,Buzz one, two, three, continuous. In wear-resistant fabric tape, the specifications of fabric tape are P-PET/105/R-Tp according to appendix C of QC/T 29106.

LCD screen 1 is a monochrome TFT LCD screen.LCD Screen 2 is TBN Segment Code LCD Screen ECAS buzzing alarm According to the communication protocol,Let's say.

Wear resistance: when a = 10mm, the number of cycles > 2000, when a = 5mm, the number of cycles > 1000.

Instrument pointer is driven by stepping motor FCW distinguishes between first and second alarms; LDW includes left-to-right alarm and buzz latch for 1.4s.。

LCD 2 Display Content

Name Elevated Box Wire Harness Assembly

The instrument backlight is white.Brightness can be adjusted manually and automatically

FCW/LDWalert

FCW level 1 alarm, LDW alarm: frequency 2.5 Hz; FCW Level 2 alarm: frequency 5 Hz. They are divided into subtotal mileage (TRIPA) and total mileage (ODO).When displaying the main interface, press button 2 to switch between them. During the test, the tape with length of about 10 cm was adhering to the steel bar with diameter a along the axis. The test method and equipment were 9.3 in GB/T 25085, and the diameter of scraper needle was 0.45 mm.

Mileage information The subtotal mileage can be automatically cleared after reaching 9999.9km.Or when displaying the small mileage in the main interface, it can be cleared manually by pressing 2 keys for a long time.

Nominal voltage:24V

Sound intensity of buzzer above 85dB @10cm

Audio Alert Reminder Priority Definition: The total mileage display range is 999999km and can not be cleared manually.

Double-layer heat-shrinkable pipes are used to protect the solder joints of conductors in wire harness according to category C in Appendix B of QC/T 29106 Security is

Design Tang Chao Number of items Processing method Component version Document version Picture A total of 1 sheet 1

1) ON gear: FCW alarm is higher than LDW alarm, higher than lifting alarm, higher than differential lock alarm, higher than parking brake unarmed alarm, higher than overspeed alarm, higher than ECAS buzzing alarm. The numerical results show that the accuracy is 0.5V.

Plug-in press QC/T 417

important

ECAS fault alarm, ECAS altitude indication and ECAS hoisting axis indication support both CAN bus and hard wire (low level) signals. Voltage information

It is higher than that of seat belt without alarm, higher than that of AMT buzzing alarm, higher than that of turning or dangerous alarm. When the battery voltage is less than 22V or more than 30,The automatic switching interface shows that the battery voltage flag flickers at 1 Hz, and stops flickering when the battery voltage exceeds 22.5V and < 29.5V. Composite Instrument Assembly (Pattern) Product

Nonmetal Decorative pattern Color Drawing Categories Proportion

Main (trailer) vehicle left and right steering indication, far-light operation indication, brake lamp fault signal support CAN bus and shadow line signal at the same time Name Proofreading reexamination

When the coolant temperature alarm lamp, coolant level alarm lamp, oil pressure alarm lamp,

2)OFF file: The position light not turned off alarm is higher than the turning or danger alarm sound warning.

Key function Security is Number Processing Component Document

All conductors are made of thin-walled polyvinyl chloride (PVC) conductors according to GB/T 25085B grade. To examine Weight heat treatment Surface protection Drawing software

cab overturn alarm lamp and brake system fault alarm lamp are on, the STOP lamp should be on at the same time. Design Picture A total of 1 sheet 1

Technical conditions according to QC/T 29106

mportant of items method version version

Product Decorative Drawing

Change Notice

General layout

Electromagnetic Compatibility (EMC) Technical Conditions According to JA3700-93C-1 1、Driving interface, press button 1.Switch traffic information in the following order: brake pressure switch display, instantaneous fuel consumption - > average fuel consumption - > fuel consumption - > oil pressure and voltage information. Proofreading

reexamination

Nonmetal

pattern

colour

Categories

Proportion Number

Key 1

Samples must be re-examined by product design department before starting supply.

Surface Drawing

Other technical conditions according to JA3820-A01-1 2、Driving interface, long press button 1,Enter menu interface;Short press button 1, menu item selection; long press button 1, exit menu. To examine weight heat treatment

protection software Impact swap sign

Number

date

Standardization of places

Material

Change Notice

Prior to commencement of supply,Samples must be re-examined by product design department 1、Driving interface, press button 2.Switch between subtotal mileage and total mileage;Buzzing alarm of differential lock lock is closed by pressing button 2 at the time of buzzing alarm; when displaying the interface of subtotal mileage,

General layout

Number Science

Jointly sign

Material Science

long pressing button 2 will clear the subtotal mileage. sign

Number

Key 2 Standardization Impact swap of places date

2、Menu Interface, Short Press Key 2,Enter the menu item.

Jointly sign Approval Code

FAW Jiefang Qingdao Automobile Co., Ltd.

FAW Jiefang Qingdao Automobile Co., Ltd.

Approval Code

Le body w r ng harness assemb y R gh body w r ng harness assemb y

Le door w r ng harness assemb y R gh door w r ng harness assemb y

R gh chass s harness assemb y ns rumen pane w r ng harness assemb y

Dashboard wire harness

With chassis wire harness

Communication CAN Line(W31, W35, C1, C2) Route Chart: The minimum distance between nodes is 100 Function switch

Docking socket

Composite instrument Fuse box

Composite Dashboard wire harness Chassis wire harness

Hazard alarm switch Indoor lighting control switch Headlight adjustment switch Fog light switch Fog light switch Trumpet switch Inter-axle differential Inter-wheel differential Multistate switch Working light control switch

instrument Engine ECU Hydraulic Flip Control Switch

blue yellow lock switch lock switch

Terminal resistancea

ABS controller

Terminal resistancea

(brown)

(Black)

(Gray)

In-vehicle information

Diagnostic socket Body controller Body controller ABS controller NOX sensor

service terminals

Dashboard wiring and

left body wiring

Put up a danger Attach indoor Paste hydraulic Attach headlight Paste up the Attach the rear Put the horn Attach interaxle Attach interaxle Paste multiple Paste work

alert switch. lighting flip control adjustment fog lamp fog light switch switch on. differential lock differential lock state switches lamp control

Docking socket Matching Labels Symbol Label Switch Symbol Label Switch Symbol Label Switch Symbol Label Symbol Label Switch Symbol Label Symbol Label Switch Symbol Label

Symbol Label Switch Symbol Label

The terminal is:

(orange)

(green)

Left body wire

(Gray)

(blue)

harness

Connection

G socket E Plug Catch H Plug

Left body wire Fuse box 1

harness and

Elevated box Attach overcurrent

wire harness Overflow protection

protection valve

valve reset switch

Docking socket Reset switch

(for CNG cylinders)

symbol label

Paste the retractor Attach to station

In-vehicle information service terminals

Switch retraction

Symbol Label Switch Symbol Label

Elevated box

wire harness

(Yellow) (green) (blue)

Drive Log The socket is mounted on the socket holder

according to the icon position.

The exit direction is as shown in the figure.

Door controller DJ431-8E torque 11 ± 1N · M

Dashboard wire harness

With chassis wire harness

Alignment

Receptor switch Parking Receptor Switch

Dashboard wire harness Chassis wire harness Receptor.

OBD diagnostic socket

Engine ECU

Function switch

Terminal resistancea

At the factory, C1, C2, and C3 are plugged into each other.

24VPower outlet

A cigarette lighter

In-vehicle information

service terminals

Inner core:

Automatic air conditioning

white (green)

ECAScontroller Car Network Box

Body controller×1

Cover Observation Direction

and Measurement Point

Cover.

Outlet Line End (Yellow)

View Direction Body controller×2

wire

Size Limits (brown) (Black) (Gray)

Independent

warm wind

Plug-in feature number(corresponding to the selection relationship list)

Independent warm wind

Length of wire beam(corresponding to selection list) Body controller×3-A

The wire beam label, the label content is shown in "XXXXX", the label content is clear,

Paste position(30-100) mm away from the end of the branch socket feed Throttle pedal

This branch line needs to be buried in 100mm of the trunk line indicated by the arrow, and then use PVC tape semi-overlapping adhesive

Size measurement point

Body controller×3-B

Semi-laminated tape with wear-resistant cloth for wires

Ignition switch Right body wire harness

After the wire is covered with a semi-overlapping type of wear-resistant cloth base tape, tie the open corrugated pipe;

The size here is in the pictorial wrap pattern with a half stack of adhesive tape.

Headlight and Variable Switches Cruise switch

90Curved. Scraters and auxiliary brake switches OBDDiagnostic socket

Multi-function steering wheel switch

Wrap the mark with green PVC tape Combination switch

Traverse Direction Mark in Plug

(Black) (Gray)

(blue) (orange) (Gray) (green)

The wire is wrapped with an open braided polyester sleeve, and the outside is wrapped with PVC tape, PVC tape pressing

Left body wire harness

The specification in Appendix C of QC/T 29106 is F-PVC / 105 / R-Tx Chassis wire harness

Line Traverse cross- Line Traverse cross- Line Traverse cross- Line Traverse cross- Line Traverse cross- Line Traverse cross- Line Traverse cross- Line Traverse cross-

Unprotected wires Wire function colour remarks Wire function colour remarks Wire function colour remarks Wire function colour remarks Wire function colour remarks Wire function colour remarks Wire function colour remarks Wire function colour remarks code number number remarks

number sectional area( mm²) number sectional area( mm²) number sectional area( mm²) number sectional area( mm²) number sectional area( mm²) number sectional area( mm²) number sectional area( mm²) number sectional area( mm²)

Chassis wire harness Fuse box

Traverse with PVC tape semi-overlapping plastic, more than 100mm head left bare line 50mm, 100mm below the head 30mm Ignition switch Fuse box

Ignition switch Fuse box

Wire bound with PVC sleeve Chassis wire harness Fuse box

Ignition switch Fuse box1

Bind and close the bellows after the wire is coated with wear resistant cloth base tape. Start switch Fuse box

Start switch Chassis wire harness Supply along with the wire harness.

Bind wires with open bellows Chassis wire harness Composite instrument

Combination switch Fuse box

Bind wire with closed bellows Ignition switch Body controller×3

Fuse box Chassis wire harness

Coarse tape tape for wire, press QC/T 29106 Function switch Ignition switch

Fuse box Chassis wire harness

After the wire is semi-stacked with wear-resistant cloth base tape, bind the open corrugated pipe, and use Ignition switch Left body wire harness

PVC tape semi-overlapping tape outside the corrugated pipe.

Combination switch Fuse box

After the wire is semi-stacked with wear-resistant cloth base tape, bind the open corrugated pipe,

and use the wear-resistant cloth base tape semi-overlapping tape outside the corrugated pipe. Ignition switch Body controller×3 Select Relation List

Fuse box Chassis wire harness Plug feature number

Fuse box Chassis wire harness

In addition to the special requirements for corrugated tubes and zippered PVC tubes, the required lead to the corrugated pipe, zippered PVC tube fill rate of more than 50 <UNK> Composite instrument Ignition switch

Wire number

Except for special provisions, wires protected by a bellows or PVC zipper tubes are Left body wire harness Ignition switch

covered both inside and outside the bellows or PVC zipper tubes as follows(`` L "indicates the length of the bellows):

Combination switch Fuse box

1, L & GT; 100Mm with interval plastic, plastic spacing 50mm, at least winding 3 laps;

Ignition switch Body controller×3

2, L ≤ 100mm with interval adhesive, adhesive position in the middle of the size, winding at least 3 laps

Fuse box Chassis wire harness

Welding point refers to the connection point of the same function wire

Composite instrument Ignition switch

The position of each line number socket in the corresponding sheath is viewed from the qualifying end

In-vehicle information service terminals Ignition switch figure number Selection Description

Length measurement refers to the distance from the point of measurement to the point of measurement, or the distance from the point of measurement to the end of the wire Not loaded with a retractor.

Left body wire harness Ignition switch

The size of the injection is the length of the wire after straightening. When one end is a plug, its length is measured from the end of the plug. Load

Function switch Ignition switch Note: "×" indicates no choice

Holes not used for waterproof plugs need to be blocked with blind plugs

Automatic air conditioning Ignition switch Ground Wire

At the end and branch of the insulated tube, bind with tape

Function switch Ignition switch

Main line and its branch lines are welded at one point(except CAN lines)

Function switch Ignition switch

The twisted pair is(27~33)+wis+/m

Function switch Ignition switch

The wire and terminal are connected by compression

Function switch Ignition switch

Single V-shaped heat condenser for single(special) terminals and wire compression

Function switch Ignition switch

PVC tape is F-PVC / 105 / R-Tx according to the specification in QC/T 29106 Appendix C

Function switch Ignition switch

The bellows are UFW type bellows, according to Category A in Appendix D of QC/T 29106

Function switch Ignition switch

PVC casing in line with JF03-117

Function switch Ignition switch

In the abrasion-resistant tape, the tape size is P-PET/105 / R-TP according to the specification in Appendix C of QC/T 29106,

Multi-function steering wheel Ignition switch

Wear resistance: When a = 10mm, the number of cycles & GT; 2000 times, when a = 5 mm, the number of cycles & GT; 1,000 times.,

At the time of testing, take a length of about 10cm tape and stick it along the shaft to a steel rod with a diameter. Chassis wire harness Ignition switch

The test method and equipment press 9.3 in GB/T 25085, in which the diameter of the scratch needle is 0.45 mm.

Function switch Ignition switch Fuse box 1 Chassis harness

Technical conditions of cable for ABS solenoid valve and sensor in GB / T 25087 name

Function switch Ignition switch Fuse box 1 Chassis harness

Core in Cable GB/T 25085, Class B

Function switch Ignition switch Fuse box 1 Chassis harness

ABS solenoid valve socket size according to code 1 requirements in | SO 15170.1, test and request according to | SO 15170.2

Fuse box

Security Number

Chassis wire harness matters.

Double layer heat condensation pipe protection at wire soldering point in wire beam, according to Category C in Appendix B of QC/T 29106

Right body wire harness Ignition switch Connect the engine harness Instrument panel harness Establishment

Product

reinspection

Plug press QC/T 417 Weight

Function switch Fuse box Connect the engine harness Instrument panel harness

All conductors are PVC thin-walled conductors, press GB/T 25085 B

Function switch Ignition switch

Technical conditions QC/T 29106

Function switch Ignition switch standardization

material

Samples must be re-examined by the Product Design Department before starting supply

Function switch Ignition switch

Wiring harness gp-air conditioner Backbridge Wire Assembly

Line number Conductor cross-sectional area(mm²) colour remarks

Wire beam label, label content as shown in "XXXXX", label content is clear,

Evaporator temperature sensor Internal and external loop steering Water valve motor

Paste position from branch socket end(30-100) mm

Control panel

Cover:

Size measurement point

Terminal:

Unprotected wires

Wire with PVC tape bound to surface, PVC tape in accordance with JF03-76

(more than 100mm head left bare line 50mm, 100mm below left head 30mm)

Wire bound with bellows, bellows with UFW type bellows, press JF03-159(Class B)

Wrap waterproof bellows with PVC tape and follow JF03-76 with PVC tape

Front defrost motor

Side defrost motor

Wire bound with closed bellows, with UFW type bellows, press JF03-159(Class B) Connect chassis wire harness

Wire bound with a zipper PVC sleeve, in accordance with JF03-117

Connect the car body with a wire beam. After the wire is semi-stacked with wear-resistant cloth base tape, bind the zipper PVC sleeve, PVC

Casing in JF03-117

After the wire is covered with a semi-overlapping type of wear-resistant cloth base tape, bind the corrugated pipe, and use the

wear-resistant cloth outside the corrugated pipe.

Semi-laminated adhesive base tape with UFW type bellows, press JF03-159(class B)

All connectors connected to the bellows must have rear protection that matches the bellows

Ventilator and speed control resistor

In addition to the special requirements for the diameter of the corrugated pipe, the filling rate of the required wire relative to the corrugated tube is 70 % to 80 % Differential lock between

bridge wheels

Differential lock between

rear-axle wheels

In addition to special regulations, the wire wrapped with a corrugated pipe adopts the following coating method outside

the corrugated pipe(L indicates the length of the corrugated tube):

Cover Observation Direction and Measurement Point

1、L 〉100mm with an interval coating, a spacing of 50mm, and a minimum of 3 circles of winding;

Outlet

Cover.

Line End 2, L ≤ 100mm with an interval coating, the adhesive position in the middle of the size, winding at least 3 laps;

View Direction wire

Size Limits Welding point refers to the connection point of the same function wire

Inter-bridge differential Backbridge inter-wheel

Speed regulating module The position of each line number socket in the corresponding sheath is viewed from the qualifying end lock indicator switch differential lock indicator switch

Dimension measuring point

Semi-overlapping coating of wear-resistant cloth-based tape for conductors

Length measurement refers to the distance from the point of measurement to the point of measurement, or the distance from

Semi-overlapping tape gluing for wire,Flannel tape according to Q/CAM-371 the point of measurement to the end of the wire

Unprotected wires

Conductor for surface binding of PVC tape,PVC tape according to JF03-76

The size of the injection is the length of the wire after straightening. When one end is a plug, its length is measured from the end of the plug.

(Leave bare line on head over 100 mm, 50 mm on head below 100 mm, 30 mm on head below 100 mm)

Holes not used for waterproof plugs need to be blocked with blind plugs

Except for special requirements for bellows diameter,The filling rate of conductor relative bellows is 70%-80%.

Except for special provisions,Wires wrapped with bellows,The bellows are wrapped in the following way ("L" means the length of the bellows): At the end and branch of the insulated tube, bind with tape

Main lines and their branch lines are welded at one point(except CAN lines)

1、L〉100mmUse spacer coating,The distance between coatings is 50mm, with at least 3 windings.

2、L≤100mmUse spacer coating,The encapsulation position is in the middle of the dimension, winding at least 3 circles.

Solder joints are the joints of the same functional conductor.

Distribution of line number connectors in corresponding sheaths,Look from the end of the line

Double twisted distance(27-33) twist / M

Line number Wire function Conductor cross-sectional area(mm²) colour remarks Line number Wire function Conductor cross-sectional area(mm²)

Backbridge Wire Assembly

colour remarks

Length measurement refers to the measurement point to the measurement point.,Or the distance from the measuring point to the conductor terminal

Body wire harness Speed regulating module Control panel1 Front defrost motor The wire and terminal are connected by compression name

The dimension of the injection is the length dimension of the wire after straightening out.,One end is the connector.,Its length is measured from the root of the socket inlet end. soldered dot blower Control panel1 Body wire harness call

Blind plugging is needed for unused holes in waterproof connectors Body wire harness Speed regulating module Control panel1 Side defrost motor Single V-shaped heat condenser for single(special) terminals and wire compression

At the end of the insulating pipe and the branch of the conductor, tie with tape Speed regulating module blower Control panel1 Side defrost motor Security Number Processing Widget Document

One-point welding of trunk lines and their branches (except CAN lines) Control panel1 Water valve motor Double layer heat condensation tube protection at wire welding point in wire beam Drawing

matters. of items methods version Version

Diagram A total of 1 card

Twisted pair pitch (27-33) twist/m Control panel1 Inner and outer circular steering Control panel1 Water valve motor Product Flower Drawing

Design Tangchao nonmetal Shade. Comparison

Conductor and terminal are crimped Control panel1 Inner and outer circular steering Control panel1 Body wire harness

name

Plug press QC/T417, where the surface of the metal terminal is tin-plated, Cu/Ep · Sn9, Q/CAYT -4 .12 reinspection pattern

heat Surface

categories

Drawing

Single-layer V-type heat-shrinkable tube for compression joint of single (special) terminal and conductor Control panel1 Front defrost motor Control panel1 Speed regulating module call Air conditioning wire harness assembly Proofreading Weight

treatment protection software

Double-layer heat-shrinkable pipe protection for wire solder joint in wire harness Control panel1 Front defrost motor Control panel1 Water valve motor All conductors are PVC thin-walled conductors, according to QC/T 730, B To examine

Change of

Control panel1 Front defrost motor Control panel1 Body wire harness Drawing

Security is Number Processing Component

B.4

Document Picture A total of 1 sheet 1 Notice Number

Technical conditions QC/T 29106

important of items method version version

Plug in QC/T 417,Among them, the surface of the metal terminal is tin plated, copper/Ep.Sn9, according to Q/CAYT-4.12. Product ree Decorative Drawing

Control panel1 Body wire harness Control panel1 Body wire harness

Design Mengfanhua Nonmetal Color Proportion

Number

Thin-walled polyvinyl chloride conductors are used for all conductors,According to QC/T 730, B Proofreading Huruixia

xamination

Weight

pattern

heat Surface

Categories

Drawing General layout material Impact swaps tag date

Control panel1 Evaporator temperature sensor Control panel1 Body wire harness treatment protection software of posts

Samples must be re-examined by the Product Design Department before starting supply

Change Notice

Technical conditions according to QC/T 29106 To examine Yu Meng CA4250P25K2T1E4A_Z00021_04

Control panel1 Evaporator temperature sensor material

Number

Standardization

Production Yanxiaodong Number

General layout material Impact swap sign date 20141225

Samples must be re-examined by product design department before starting supply. of places

Control panel1 Water valve motor FAW Jiefang Qingdao Automobile Co., Ltd.

preparation Standardization Yangzhaoyang

China First Automobile Co., Ltd. Technology Center

Approval Subcode

soldered dot Front defrost motor Approval JiaoXueMing Code

Trailer Socket Wire Harness Assembly for ABS

Line number Conductor cross-sectional area(mm²) colour remarks

Cover Observation Direction and

Measurement Point

Cover.

Outlet Line End

View Direction wire

Size Limits

Dimension measuring point

Trailer power outlet for ABS

Distribution of line number connectors in corresponding sheaths,Look from the end of the line

(Shenzhen Jijia Baowei Co. , Ltd. )

Length measurement refers to the measurement point to the measurement point.,

Or the distance from the measuring point to the conductor terminal Chassis harness

The dimension of the injection is the length dimension of the wire after straightening out.,

One end is the connector.,Its length is measured from the root of the socket inlet end.

Blind plugging is needed for unused holes in waterproof connectors

No special instructions for plug-in Hebi Tianhai Electric Appliance Co. , Ltd. , Zhengzhou Lianming Electric

Appliance Co. , Ltd. and Ningbo Zhengyao Automobile Electric Appliance Co. , Ltd.

Single-layer V-type heat-shrinkable tube for compression joint of single (special) terminal and conductor

Thin-walled polyvinyl chloride conductors are used for all conductors,According to QC/T 730, C

Plug in QC/T 417,Among them, the surface of the metal terminal is tin plated, copper/Ep.Sn9, according to Q/CAYT-4.12.

At the end of the insulating pipe and the branch of the conductor,

tie with tape

name Trailer Socket Wire Harness Assembly for ABS

Note the connector right clearly manufacturers note that the need call

to comply with the implementation, such as: 1928404195 Bosch

Conductor and terminal are crimped Drawing

Security Number Processing Widget Document

Diagram A total of 1 card

matters. of items methods version Version

Technical conditions according to QC/T 29106 Design XuiFeng Product

reinspection

nonmetal

Flower

pattern

Shade.

Drawing

categories

Comparison

heat Surface Drawing

Samples must be re-examined by product design department Proofreading ZhangJinBo Weight

treatment protection software

before starting supply. To examine LiGuoHui

Change of

Notice Number

Number

Production General layout ZhangYanHui material Impact swaps tag

of posts

date

preparation Standardization YangChaoYang

China First Automobile Co., Ltd. Technology Center

Approval JiaoXueMing Subcode

You might also like

- EX1200-Electrical Circuit Diagram (Cummins Engine Specification)Document1 pageEX1200-Electrical Circuit Diagram (Cummins Engine Specification)Norman CoetzeeNo ratings yet

- Manual Mincarg S590Document214 pagesManual Mincarg S590Yeison Jair Guaca Trujillo100% (2)

- 3406 - 3406 C - 3456 Gen Set Emcp IiDocument4 pages3406 - 3406 C - 3456 Gen Set Emcp IiFernando Tovar100% (2)

- 007 - Cat-6060 - Travel SystemDocument47 pages007 - Cat-6060 - Travel SystemJorby CuadrosNo ratings yet

- 3406, 3406C & 3456 Generator Set Electrical System With EMCP IIDocument4 pages3406, 3406C & 3456 Generator Set Electrical System With EMCP IIKhalifaNo ratings yet

- Independent Suspension System Full ReportDocument21 pagesIndependent Suspension System Full Reportmonikaneha12380% (5)

- FH400 73158464 Pca-6.140Document431 pagesFH400 73158464 Pca-6.140IgorGorduz100% (1)

- Parts Catalogue - Yamaha SCORPIODocument60 pagesParts Catalogue - Yamaha SCORPIOAdrianus Aja100% (4)

- Cat Dcs Sis ControllerDocument2 pagesCat Dcs Sis ControllerЮрий Шариков100% (5)

- CAUTION: Parts Numbers On The Drawing Are Provided Only For Reference Purpose. To Order Parts On The Drawing, Be Sure To Consult The Parts CatalogDocument30 pagesCAUTION: Parts Numbers On The Drawing Are Provided Only For Reference Purpose. To Order Parts On The Drawing, Be Sure To Consult The Parts CatalogMarius BLAGANo ratings yet

- Service Manual: Chassis & Mast E3000, E3500, EC4000Document9 pagesService Manual: Chassis & Mast E3000, E3500, EC4000Kevin Daughton0% (2)

- Manual FZ 25Document328 pagesManual FZ 25skick198414No ratings yet

- 15174198-Linhai Lh400cuv-2 Bighorn Cuv Workshop Service Repair ManualDocument208 pages15174198-Linhai Lh400cuv-2 Bighorn Cuv Workshop Service Repair ManualRandy SharpNo ratings yet

- Manual de Entrenamiento Cessna 208 (212-217)Document6 pagesManual de Entrenamiento Cessna 208 (212-217)leonardoNo ratings yet

- Product CatalogDocument124 pagesProduct CatalogBien NguyenNo ratings yet

- Mech Engine PowerShift Transm PDFDocument2 pagesMech Engine PowerShift Transm PDFFútbol y másNo ratings yet

- 2010 Haro BMXDocument48 pages2010 Haro BMXJT OrtegaNo ratings yet

- 250 KVA Genset Wiring PDFDocument1 page250 KVA Genset Wiring PDFSZANo ratings yet

- EGM - Technical Information - 2003 - UK PDFDocument83 pagesEGM - Technical Information - 2003 - UK PDFJuan100% (2)

- Manual de Entrenamiento Cessna 208 (226-283)Document58 pagesManual de Entrenamiento Cessna 208 (226-283)leonardoNo ratings yet

- (Â ) (Paper Model) (Aircraft) (Modelart - Scale 1.32) - GER - Dornier DO17.P - v.GERDocument37 pages(Â ) (Paper Model) (Aircraft) (Modelart - Scale 1.32) - GER - Dornier DO17.P - v.GERpaulagrant91% (11)

- Bomba Grindex Master NDocument20 pagesBomba Grindex Master Ncarlos sanabria ninamango100% (3)

- Iris MeadowsDocument3 pagesIris MeadowsGenna ContinoNo ratings yet

- 245 Ecs 9001 - 0Document1 page245 Ecs 9001 - 0sareluis2727No ratings yet

- Floor Plan - Em-Schematic RiserDocument1 pageFloor Plan - Em-Schematic Riserisyed1948No ratings yet

- Ad-90.0-E-02108-Pdf Small Power Layout Ls&admin BLDNGDocument1 pageAd-90.0-E-02108-Pdf Small Power Layout Ls&admin BLDNGmcaslamNo ratings yet

- H-Buster Hbd-9210av DVD Player SCHDocument1 pageH-Buster Hbd-9210av DVD Player SCHtarifasstarwayNo ratings yet

- Container Vessel GADocument1 pageContainer Vessel GAAswin SathianNo ratings yet

- Group 3 Electrical Circuit (1/3)Document3 pagesGroup 3 Electrical Circuit (1/3)Vu HoiNo ratings yet

- Gutter Detail XX: West Elevation 1:100 South Elevation 1:100Document1 pageGutter Detail XX: West Elevation 1:100 South Elevation 1:100tngaraNo ratings yet

- Ground Floor HVAC LayoutDocument1 pageGround Floor HVAC LayoutMohammed AzharNo ratings yet

- Engine Harness P/N 0587299-00 Diagram Revision - A - : Component ListDocument1 pageEngine Harness P/N 0587299-00 Diagram Revision - A - : Component ListPabloAntonioCerdaSotoNo ratings yet

- Side View: Fire and Safety PlanDocument1 pageSide View: Fire and Safety PlanEnggar DywariNo ratings yet

- 6295 2 10 6cyl 11x17foldout PDFDocument2 pages6295 2 10 6cyl 11x17foldout PDFTrent ScheuerNo ratings yet

- 1801-FR02-42-R-XD-00009 - C1 - General Arrangement - S42PD530A Scale Inhibitor - SubseaDocument1 page1801-FR02-42-R-XD-00009 - C1 - General Arrangement - S42PD530A Scale Inhibitor - SubseaNam DHNo ratings yet

- Drawing 2Document1 pageDrawing 2Fuji HidayatNo ratings yet

- Karjan East RWSS - R1-ModelDocument1 pageKarjan East RWSS - R1-Modeldeekarjan11No ratings yet

- NE40E-X8A Quick Installation GuideDocument1 pageNE40E-X8A Quick Installation Guiderodrigo viverosNo ratings yet

- Panasonic Chassis Alpha 2Document4 pagesPanasonic Chassis Alpha 2parvualexandruNo ratings yet

- Keyplan: PT Katalis Sinergi IndonesiaDocument1 pageKeyplan: PT Katalis Sinergi IndonesiaFebry YantaNo ratings yet

- Overlay Control PlansDocument1 pageOverlay Control PlansSTS-SPARK GAMINGNo ratings yet

- Planta 04 Sin ColorDocument1 pagePlanta 04 Sin ColorDIEGO FERNANDO GARCIA CARMONANo ratings yet

- KJ 117 o en Sac 00 Zme 0303Document1 pageKJ 117 o en Sac 00 Zme 0303Abdullah ObeidatNo ratings yet

- SSWP - Notch Area Working Sequence For Perimeter FormDocument2 pagesSSWP - Notch Area Working Sequence For Perimeter Formpolaris projectNo ratings yet

- Circuit Diagrams: MAIN PWB CIRCUIT DIAGRAM (AV-29B316/B) (1/4) (2/4) SHEET1Document4 pagesCircuit Diagrams: MAIN PWB CIRCUIT DIAGRAM (AV-29B316/B) (1/4) (2/4) SHEET1Fede DiNo ratings yet

- Group 2 Electrical CircuitDocument2 pagesGroup 2 Electrical CircuitLuciano SantosNo ratings yet

- Sd-Msp-El-Pd-204 Mall Lantai m2 Instalasi Penerangan r.3 Maw Coment-Layout1Document1 pageSd-Msp-El-Pd-204 Mall Lantai m2 Instalasi Penerangan r.3 Maw Coment-Layout1slamet santosoNo ratings yet

- Nolimit Wahda Floor LayoutDocument1 pageNolimit Wahda Floor Layoutvasanth kumarNo ratings yet

- FSP SabrinaDocument1 pageFSP SabrinaSabrina salsabilahNo ratings yet

- Working Drawings: Key PlanDocument1 pageWorking Drawings: Key PlanSharanyaNo ratings yet

- mcc2 PDFDocument1 pagemcc2 PDFSravyaSree100% (2)

- 3406C Eng SchematicDocument4 pages3406C Eng SchematicTakeshi RomeroNo ratings yet

- TTPD850 EN 01 - CircuitDocument37 pagesTTPD850 EN 01 - CircuitPatrice GuilhaumonNo ratings yet

- Esquema Electrico H160Document1 pageEsquema Electrico H160Renato SanchezNo ratings yet

- E19016-MDE-90-90-E-GG-002-1C (Exterior Site Power Cable Routing Plan) - E19016-MDE-90-90-E-GG-002Document1 pageE19016-MDE-90-90-E-GG-002-1C (Exterior Site Power Cable Routing Plan) - E19016-MDE-90-90-E-GG-002SADDAMNo ratings yet

- 1879b8cd58a3aae31a0ab3679f11f05eDocument1 page1879b8cd58a3aae31a0ab3679f11f05eDEVCHADDHANo ratings yet

- Power Layout Circuit-R1 (SF)Document1 pagePower Layout Circuit-R1 (SF)Electrical PCBL TeamNo ratings yet

- Power Layout Circuit-R1 (3F)Document1 pagePower Layout Circuit-R1 (3F)Electrical PCBL TeamNo ratings yet

- 7088 SchematicsDocument4 pages7088 SchematicsFernando RiquelmeNo ratings yet

- Project 2 Arch Dwg-Layout1 - Plan - MonochromeDocument1 pageProject 2 Arch Dwg-Layout1 - Plan - MonochromeAbdul khaliquNo ratings yet

- 3 Phase VE Bus BMS System 5 Pin With 3xquattro and 4x200ah 24V Li Rev C1Document1 page3 Phase VE Bus BMS System 5 Pin With 3xquattro and 4x200ah 24V Li Rev C1Alba Car MarNo ratings yet

- Diagrama DataCenter - Yungay 8.11.2022Document1 pageDiagrama DataCenter - Yungay 8.11.2022Carmen RodriguezNo ratings yet

- G3306 Generator Set Electrical System: Control Panel (Emcpii+)Document2 pagesG3306 Generator Set Electrical System: Control Panel (Emcpii+)Mr.Thawatchai hansuwanNo ratings yet

- Tower-2 (3BHK) ELECTRICAL LAYOUT C2 PDFDocument1 pageTower-2 (3BHK) ELECTRICAL LAYOUT C2 PDFakhilNo ratings yet

- SLAB T 200mm EL+450: Main Office Denah Saluran Shop DrawingDocument2 pagesSLAB T 200mm EL+450: Main Office Denah Saluran Shop Drawingsinartech sosmedNo ratings yet

- Elevation - A Elevation - B Section - 1: A B C D E F H I G D1Document1 pageElevation - A Elevation - B Section - 1: A B C D E F H I G D1buildings departmentNo ratings yet

- Gas Option 2 210504Document1 pageGas Option 2 210504Md ShahinNo ratings yet

- A/C Main House Tabulation: Site PlanDocument12 pagesA/C Main House Tabulation: Site PlanPedro Morales YallesNo ratings yet

- Ant e 0107 G Ed 3003 Planta General Rev 2 v01Document2 pagesAnt e 0107 G Ed 3003 Planta General Rev 2 v01claudio3aNo ratings yet

- 1801-FR02-42-R-XD-00008 - C1 - General Arrangement - S42PD528 - S42PD537 Scale Inhibitor Topside - PolyelectrolyteDocument1 page1801-FR02-42-R-XD-00008 - C1 - General Arrangement - S42PD528 - S42PD537 Scale Inhibitor Topside - PolyelectrolyteNam DHNo ratings yet

- EASA MS880 - and - Rallye - 100 - SeriesDocument44 pagesEASA MS880 - and - Rallye - 100 - SeriesPhilNo ratings yet

- The First Electric Vehicle Was A Three-Wheeler, Invented by Scooter's India PVT LTD in 1996, and It Was Named VIKRAM SAFADocument2 pagesThe First Electric Vehicle Was A Three-Wheeler, Invented by Scooter's India PVT LTD in 1996, and It Was Named VIKRAM SAFANayan B BijuNo ratings yet

- Product Recommendation Mercedes-Benz (EU) Public-Service-Buses Conecto (O 345) Euro 3 OM457hLA (2002-2007)Document3 pagesProduct Recommendation Mercedes-Benz (EU) Public-Service-Buses Conecto (O 345) Euro 3 OM457hLA (2002-2007)EmilNo ratings yet

- CRJ ChecklistDocument2 pagesCRJ ChecklistMarie100% (1)

- S40 Quick Guide MY08 en Tp9255webDocument8 pagesS40 Quick Guide MY08 en Tp9255webpietiscNo ratings yet

- @enmagazine Car Driver 2020 06 PDFDocument84 pages@enmagazine Car Driver 2020 06 PDFmano1574100% (1)

- Mechanical Disc Brakes: Dealer's ManualDocument19 pagesMechanical Disc Brakes: Dealer's ManualDwika YanuariNo ratings yet

- CURRENTFACRULESDocument23 pagesCURRENTFACRULESchand198No ratings yet

- Techn. Data Heavy RangeDocument16 pagesTechn. Data Heavy Rangeratninp9368No ratings yet

- Group Tour Jogja 2D1N 2019 PDFDocument13 pagesGroup Tour Jogja 2D1N 2019 PDFMuhammad Fauzan AzizNo ratings yet

- Atlantic 125-250 2006-2008Document86 pagesAtlantic 125-250 2006-2008Nelson RodrigoNo ratings yet

- Manual de ArmadoDocument2 pagesManual de ArmadoCristian BascuñanNo ratings yet

- Telescopic Crawler Crane: Model TK750Document6 pagesTelescopic Crawler Crane: Model TK750Mohan CharanchathNo ratings yet

- INNOVA J With SpecsDocument2 pagesINNOVA J With SpecsLoren Delos SantosNo ratings yet

- Sum 28022019Document31 pagesSum 28022019JooSie241No ratings yet

- Contract Title Contract No. Contractor Name and Address Original Contract Value (KWD) RFP No. Duration (Days) S. NoDocument2 pagesContract Title Contract No. Contractor Name and Address Original Contract Value (KWD) RFP No. Duration (Days) S. NoKoteswar MandavaNo ratings yet

- Project Report - 30% Work CompletedDocument16 pagesProject Report - 30% Work CompletedSuyog JadhavNo ratings yet

- 2017 - Baja SAE India Rulebook - Rev00Document73 pages2017 - Baja SAE India Rulebook - Rev00Tanmay WalkeNo ratings yet