Professional Documents

Culture Documents

TechUpd 2016 - 9 - 9 - Camouflaging Problem Causing Properties of Bunker Fue...

Uploaded by

Badea Ionel Andrei0 ratings0% found this document useful (0 votes)

4 views2 pagesOriginal Title

TechUpd 2016_9_9 - Camouflaging problem causing properties of bunker fue...

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views2 pagesTechUpd 2016 - 9 - 9 - Camouflaging Problem Causing Properties of Bunker Fue...

Uploaded by

Badea Ionel AndreiCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

VISWA LAB Tel: USA (713) 842-1985

12140 Almeda Road, Fax: USA (713) 842-1981

Email: customerhelp@viswalab.com

Houston, Texas 77045, USA Web: http://www.viswalab.com

TECHNICAL UPDATE: 2016/9/9

CAMOUFLAGING PROBLEM CAUSING PROPERTIES OF BUNKER FUEL

Over the last few weeks, very interesting analysis results have been identified in

bunker fuels from South East Asia.

The sediment values (ISO 10307‐1 method) are 0.03% to 0.06%. The stability (ASTM

D4740 method) of these fuels is number 1. However, the Reserve Stability Number

(RSN) (ASTM D7061) is between 14.7 and 16 (one exception at 9.2) and the Xylene

Equivalent Number (XE) (modified BP 230) from 38 to 45 (Normal Average). RSN in

normal fuels is below 5 and XE is below 30.

The ASTM D7061 method says “if the separability number is above 10, the stability

reserve of the oil is very low and asphaltenes will easily flocculate, or have already

started to flocculate”.

According to Diesel United‐Sulzer engine Makers technical document, if the Xylene

Equivalent result is high, there is a real risk of fuel pump problems. As per the Class NK

document “Guidance for Measures to Cope with Degraded Marine Heavy Fuels Version

II”, “When the xylene equivalent becomes greater than 30, problems are likely to

occur.”

When very high values for RSN and XE are observed, the fuel should also normally

show higher sediment values and poor stability values (3, 4,5). In these cases however,

only marginally increased sediment content is noted and the stability is 1.

We feel certain that an additive or a blend component is added to the bunker fuel

which suppresses the organic sediment value and bring it within spec. In this process

the stability test value is also brought to number 1.

It may be argued that when the sediment value is within limits and stability is 1, why

worry about this fuel.

VISWA LAB – HOUSTON – SINGAPORE – UK ‐ UAE 1

As a matter of fact, these fuels have caused problems in the engines. They have also

shown presence of contaminants in the GCMS analysis including high levels of styrene

(300 to 600ppm), indene (500 to 700ppm) phenols (150 to 1050 ppm). In addition a

few other contaminants are noted in the fuel. The type of problems experienced were

piston ring breakage in multiple units and purifier choking.

So how do we protect against such camouflaging? We recommend carrying out a XE

and RSN test when the sediment content is greater than 0.03%/0.04% to make sure

they are not at levels likely to cause problems.

Please do not hesitate to contact us with any questions.

Best regards,

Dr.Vis

VISWA LAB – HOUSTON – SINGAPORE – UK ‐ UAE 2

You might also like

- Calculation of Displacement, LWT and DWTDocument18 pagesCalculation of Displacement, LWT and DWTM.Neuer91% (45)

- Instruction Manual - 205.03.20Document981 pagesInstruction Manual - 205.03.20Silviu NistorNo ratings yet

- Westfalia Separator (Final Drawing)Document142 pagesWestfalia Separator (Final Drawing)LeonidNo ratings yet

- Summary of MAN Service Letter 16/24: Technical Information L InformationDocument10 pagesSummary of MAN Service Letter 16/24: Technical Information L InformationPrinceSadhotraNo ratings yet

- Man 48 60crDocument456 pagesMan 48 60crTran Duy Nam100% (5)

- TechUpd 2011-10-16 - Understanding Piston Ring BreakageDocument2 pagesTechUpd 2011-10-16 - Understanding Piston Ring Breakagevinay3972No ratings yet

- Viswa Lab: 12140 Almeda Road, Houston, Texas 77045, USADocument3 pagesViswa Lab: 12140 Almeda Road, Houston, Texas 77045, USASumit ChandwaniNo ratings yet

- Ariana A. Melendez-Alvarez, Miguel Garcia-Bermudes, Mohammad Tavakkoli, Rocio H. Doherty, Siqi Meng, Dalia S. Abdallah, Francisco M. VargasDocument11 pagesAriana A. Melendez-Alvarez, Miguel Garcia-Bermudes, Mohammad Tavakkoli, Rocio H. Doherty, Siqi Meng, Dalia S. Abdallah, Francisco M. VargasAlexander GerasimovNo ratings yet

- TechUpd 2023 - 10 - 11 Contaminated VLSFO Bunkers From NOLA - An UpdateDocument1 pageTechUpd 2023 - 10 - 11 Contaminated VLSFO Bunkers From NOLA - An UpdateLazar Petre-GabrielNo ratings yet

- TechUpd 2016 - 8 - 8 - A Fresh Look at Sulfur Regulations and Bunker FuelsDocument2 pagesTechUpd 2016 - 8 - 8 - A Fresh Look at Sulfur Regulations and Bunker FuelsBadea Ionel AndreiNo ratings yet

- TechUpd 2016 - 10 - 11 - Continued Supply of Low Flashpoint Distillate Fuels in The New York AreaDocument1 pageTechUpd 2016 - 10 - 11 - Continued Supply of Low Flashpoint Distillate Fuels in The New York AreaBadea Ionel AndreiNo ratings yet

- SealingDocument21 pagesSealingAlexander BowersNo ratings yet

- Marine Fuel Stability and Compatibility TestingDocument4 pagesMarine Fuel Stability and Compatibility TestingRebekah SchmidtNo ratings yet

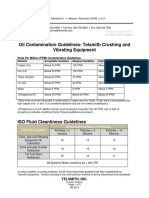

- Oil Contamination GuidelinesDocument2 pagesOil Contamination Guidelinescarlos martinezNo ratings yet

- FACTORS THAT AFFECT CRUDE OIL VISCOSITY AND TECHNIQUES TO REDUCE IT - A REVIEW, Santos, I. C. V. M. 2017, 16 PGDocument16 pagesFACTORS THAT AFFECT CRUDE OIL VISCOSITY AND TECHNIQUES TO REDUCE IT - A REVIEW, Santos, I. C. V. M. 2017, 16 PGjoselosse desantosNo ratings yet

- Nas and IsoDocument3 pagesNas and IsoAshwini Baurasia0% (1)

- Fuel Oil Analysis: Know The Condition of The Fuel Oils You Use!Document6 pagesFuel Oil Analysis: Know The Condition of The Fuel Oils You Use!lolo100% (1)

- Fuel Oil AnalysisDocument6 pagesFuel Oil AnalysisPawan BeniwalNo ratings yet

- Spe 138275 MS PDFDocument9 pagesSpe 138275 MS PDFSergio SaenzNo ratings yet

- What Is GASOLINE?Document2 pagesWhat Is GASOLINE?Anonymous QqyLDoW1No ratings yet

- Epa Requirements For Emergency EnginesDocument10 pagesEpa Requirements For Emergency EnginesMocharu ArtNo ratings yet

- 10 1 1 533 3935 PDFDocument19 pages10 1 1 533 3935 PDFZohaib MaqboolNo ratings yet

- High Pressure Gas Reservoir Waxing ProblemDocument41 pagesHigh Pressure Gas Reservoir Waxing ProblemAoun FatehNo ratings yet

- OTC-27226-MS Prediction of Asphaltene Onset Pressure From Dead Oil StabilityDocument10 pagesOTC-27226-MS Prediction of Asphaltene Onset Pressure From Dead Oil StabilityAnonymous 8te2h1No ratings yet

- TechUpd 2016 - 10 - 12 - IMO Confirms 0.5 Percent Global Sulfur Cap From 2020Document1 pageTechUpd 2016 - 10 - 12 - IMO Confirms 0.5 Percent Global Sulfur Cap From 2020Badea Ionel AndreiNo ratings yet

- TLT Techbeat 9 06Document9 pagesTLT Techbeat 9 06alexsv_17No ratings yet

- TechUpd 2016 - 10 - 10 - Increased Number of Low Flashpoint Fuels in The New...Document1 pageTechUpd 2016 - 10 - 10 - Increased Number of Low Flashpoint Fuels in The New...Badea Ionel AndreiNo ratings yet

- Spe 171295 MsDocument9 pagesSpe 171295 MsAlfonso RamosNo ratings yet

- Nap Acid Paper FinalDocument18 pagesNap Acid Paper Finalpapaya123No ratings yet

- A4502a09 1b49Document44 pagesA4502a09 1b49Darmawan PutrantoNo ratings yet

- Seright2016 TGL 7Document32 pagesSeright2016 TGL 7VeronicaNo ratings yet

- CDUDocument4 pagesCDUmohamedyoussef1No ratings yet

- J Petrol 2019 03 074Document9 pagesJ Petrol 2019 03 074wilfred gomezNo ratings yet

- Comparison of Hydraulic Fluid Cleanliness StandardsDocument4 pagesComparison of Hydraulic Fluid Cleanliness StandardsmahaveenNo ratings yet

- 2007 NPRA Q&A and Technology Forum: Answer Book: Austin, TexasDocument131 pages2007 NPRA Q&A and Technology Forum: Answer Book: Austin, TexasОскар ЛинаресNo ratings yet

- We A14 Optimization of Alkaline-Surfactant-Polymer (ASP) Flooding Minimizing Risk of Scale DepositionDocument20 pagesWe A14 Optimization of Alkaline-Surfactant-Polymer (ASP) Flooding Minimizing Risk of Scale Depositionselynda nemtaNo ratings yet

- SARA Method D4124Document9 pagesSARA Method D4124mahamuninaresh1No ratings yet

- R111 With Updated CoverDocument21 pagesR111 With Updated CoverAhmed ElShoraNo ratings yet

- SPE 167294 Novel Asphaltene Inhibitor For Direct Application To ReservoirDocument7 pagesSPE 167294 Novel Asphaltene Inhibitor For Direct Application To ReservoirGabriel EduardoNo ratings yet

- 4.david .PanicDocument6 pages4.david .PanicRoss WaringNo ratings yet

- FanPro Special Tests Brochure IIDocument8 pagesFanPro Special Tests Brochure IIsubrahmanyam.knvNo ratings yet

- Article: Vlsfos - The Concerning Fuel Management Issues So Far.... by Stanley GeorgeDocument8 pagesArticle: Vlsfos - The Concerning Fuel Management Issues So Far.... by Stanley GeorgeРуслан КостюкNo ratings yet

- AsphaltenesDocument22 pagesAsphaltenesElroi Felix100% (1)

- 1-3 Thursday - WEDA Midwest Dredge Meeting 4-2012Document19 pages1-3 Thursday - WEDA Midwest Dredge Meeting 4-2012Bharan KailashNo ratings yet

- S BraneDocument16 pagesS Branemsr22No ratings yet

- Gisele Mendes, Helga G. Aleme, Paulo J.S. Barbeira: Sciverse SciencedirectDocument6 pagesGisele Mendes, Helga G. Aleme, Paulo J.S. Barbeira: Sciverse SciencedirectIan RidzuanNo ratings yet

- Spe 165358 MSDocument20 pagesSpe 165358 MSMurat SyzdykovNo ratings yet

- Sae Technical Paper Series: Ken MitchellDocument12 pagesSae Technical Paper Series: Ken MitchellMilad YadollahiNo ratings yet

- Emergency Generator Tier Types PDFDocument2 pagesEmergency Generator Tier Types PDFmarkigldmm918No ratings yet

- Ethanol Future PDFDocument10 pagesEthanol Future PDFrp00212No ratings yet

- Derakane Momentum 470-300Document5 pagesDerakane Momentum 470-300maniastur365100% (1)

- Biodiesel 2015Document2 pagesBiodiesel 2015ClydeA.SardoncilloNo ratings yet

- SPE-181275-MS Successful Development and Implementation of 9 5/8 Subsurface Safety Valve For High Pressure, High Rate Gas WellsDocument11 pagesSPE-181275-MS Successful Development and Implementation of 9 5/8 Subsurface Safety Valve For High Pressure, High Rate Gas WellsLuis David Concha CastilloNo ratings yet

- Fuel Quality ClaimsDocument16 pagesFuel Quality Claimspavlo_790317697No ratings yet

- Case Study Corrosion Monitoring of Oilfield Production TubingDocument9 pagesCase Study Corrosion Monitoring of Oilfield Production TubingYousuf MemonNo ratings yet

- Understanding NAS Values in Engine OilsDocument2 pagesUnderstanding NAS Values in Engine Oilsmohan_krishna372No ratings yet

- Determination of Wear Metals in Used Motor Oil by Flame AtomicDocument4 pagesDetermination of Wear Metals in Used Motor Oil by Flame AtomicanNo ratings yet

- Advanced Strategies For Selecting Oil Analysis Alarms and LimitsDocument6 pagesAdvanced Strategies For Selecting Oil Analysis Alarms and Limitsho-fa100% (1)

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument17 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsperryNo ratings yet

- Stay Clean Paste FluxMSDSDocument8 pagesStay Clean Paste FluxMSDSJeifer ArgumedoNo ratings yet

- Fuel Quality Test SMCS 1280 081Document2 pagesFuel Quality Test SMCS 1280 081Upali JayawardanaNo ratings yet

- SPE-199236-PA Acidfrac Vs MatrixDocument23 pagesSPE-199236-PA Acidfrac Vs MatrixKevin WiriandoNo ratings yet

- Understanding NAS Values in Engine OilsDocument4 pagesUnderstanding NAS Values in Engine OilschrisNo ratings yet

- 11-6005 CS Process FinalDocument2 pages11-6005 CS Process FinalChung ChuanNo ratings yet

- TechUpd 2016 - 10 - 10 - Increased Number of Low Flashpoint Fuels in The New...Document1 pageTechUpd 2016 - 10 - 10 - Increased Number of Low Flashpoint Fuels in The New...Badea Ionel AndreiNo ratings yet

- Sierra Marine Parts CatalogDocument1,180 pagesSierra Marine Parts CatalogVinicius Assis de OliveiraNo ratings yet

- Product Catalog XDocument16 pagesProduct Catalog XBadea Ionel AndreiNo ratings yet

- TASCO Communication New Procedure For Tanker ReacceptanceDocument1 pageTASCO Communication New Procedure For Tanker ReacceptanceBadea Ionel AndreiNo ratings yet

- Abrevieri CharterDocument16 pagesAbrevieri CharterBadea Ionel AndreiNo ratings yet

- LPG Cargo Measurement and Calculation ProcedureDocument4 pagesLPG Cargo Measurement and Calculation ProcedureBadea Ionel AndreiNo ratings yet

- Remote Oil Spill SensingDocument7 pagesRemote Oil Spill SensingPavel TatarintsevNo ratings yet

- 9x2MW HFO Diesel Power Plant Project Design SpecificationsDocument18 pages9x2MW HFO Diesel Power Plant Project Design SpecificationsRohit Sorte100% (4)

- Heavy Fueledpeakingpowergen Morocco PowerGenAfrica2012Document18 pagesHeavy Fueledpeakingpowergen Morocco PowerGenAfrica2012HazimNo ratings yet

- HANDBOOK of LNG Baltic Sea Ports PDFDocument60 pagesHANDBOOK of LNG Baltic Sea Ports PDFHRC100% (1)

- Water Cooling System Quiz: During Underway and When Ship Is Far Away From The SeabedDocument11 pagesWater Cooling System Quiz: During Underway and When Ship Is Far Away From The SeabedJohn Noel BasNo ratings yet

- Marine Operations Notes Part 2Document32 pagesMarine Operations Notes Part 2Ekiyo PiusNo ratings yet

- Mepc 281Document12 pagesMepc 281Özkan YILDIRIMNo ratings yet

- How The Polar Code Protects The Environment (English Infographic)Document1 pageHow The Polar Code Protects The Environment (English Infographic)Jeetu Prakash Sangwani100% (1)

- Product: WM Burners With Oil PreheatingDocument48 pagesProduct: WM Burners With Oil PreheatingjambukuningNo ratings yet

- Boiler Questions and AnswersDocument10 pagesBoiler Questions and AnswersAustin UdofiaNo ratings yet

- Excellent - Change Over Procedure in SECADocument14 pagesExcellent - Change Over Procedure in SECAFilip NikolevskiNo ratings yet

- Lubricant Equivalent Chart - Quantum Marine Solutions Pte LTDDocument10 pagesLubricant Equivalent Chart - Quantum Marine Solutions Pte LTDMenara Hijau MandiriNo ratings yet

- Asm PolarDocument5 pagesAsm Polarsureen123No ratings yet

- KRAL Pump Stations. Series DKC/DMC. The New GenerationDocument16 pagesKRAL Pump Stations. Series DKC/DMC. The New GenerationИгорь КлимовNo ratings yet

- Miles Mathis Guest Writer - Fridges (And Other Musings)Document10 pagesMiles Mathis Guest Writer - Fridges (And Other Musings)Evgyrt NesralNo ratings yet

- OILDocument4 pagesOILJoão LucasNo ratings yet

- Service Bulletin - (OI00-0000-13) - Low Sulphur Fuel OilDocument4 pagesService Bulletin - (OI00-0000-13) - Low Sulphur Fuel Oilps_visjehotmailcomNo ratings yet

- Mas Marine Academy: A Global MET Member InstitutionDocument3 pagesMas Marine Academy: A Global MET Member InstitutionImran AhmedNo ratings yet

- MAN Diesel: Treatment of Lubricating OilDocument2 pagesMAN Diesel: Treatment of Lubricating OilSona NarulaNo ratings yet

- HFO Feeder 3.0 - Operation Manual - ENDocument40 pagesHFO Feeder 3.0 - Operation Manual - ENzia45No ratings yet

- Hyundai Man BW Cat FineDocument7 pagesHyundai Man BW Cat FineParthiban NagarajanNo ratings yet

- Unep Project Proposal Saudi Arabia-2015Document42 pagesUnep Project Proposal Saudi Arabia-2015MATHEW JOSEPHNo ratings yet

- LEBW0014-01 Proyecto EjenploDocument106 pagesLEBW0014-01 Proyecto EjenploJose FavaNo ratings yet

- To Access The Fuel Oil Management Plan Sample TemplateDocument35 pagesTo Access The Fuel Oil Management Plan Sample TemplateΦοίβος ΖούκηςNo ratings yet

- Bunkering Operation Training - Cercs-2Document25 pagesBunkering Operation Training - Cercs-2Julia AbalosNo ratings yet