Professional Documents

Culture Documents

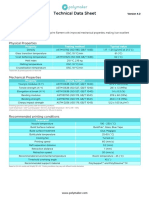

PolyLite PETG TDS V5.3-20240309

Uploaded by

Freddy ArribasplataOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PolyLite PETG TDS V5.3-20240309

Uploaded by

Freddy ArribasplataCopyright:

Available Formats

PolyLite™ PETG is an affordable PETG filament with balanced mechanical properties

and ease of printing.

Property Testing Method Typical Value

Density ISO1183, GB/T1033 1.25 g/cm3 at 23°C

Melt index 240°C, 2.16kg 10.8 g/10min

Light transmission GB/T 2410 90%

Flame retardancy N/A N/A

Property Testing Method

Effect of weak acids Not resistant

Effect of strong acids Not resistant

Effect of weak alkalis Not resistant

Effect of strong alkalis Not resistant

Effect of organic solvent Resistant most

Effect of oils and grease No data available

Equilibrium water absorption (%)= 0.54%

Property Testing Method Typical Value

Glass transition temperature DSC, 10°C/min 81 °C

Melting temperature DSC, 10°C/min N/A

Crystallization temperature DSC, 10°C/min N/A

Decomposition temperature TGA, 20°C/min N/A

Vicat softening temperature ISO 306, GB/T 1633 84 °C

Heat deflection temperature ISO 75 1.8MPa 74.8 °C

Heat deflection temperature ISO 75 0.45MPa 78.4 °C

Thermal conductivity N/A N/A

Low temperature resistance N/A N/A

Heat shrinkage rate N/A N/A

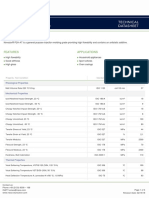

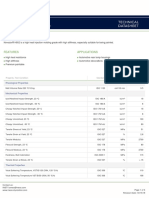

Property Testing Method Typical Value

Young’s modulus (X-Y) 2116.8 ± 68.1 MPa

ISO 527, GB/T 1040

Young’s modulus (Z) 1898.7 ± 98.5 MPa

Tensile strength (X-Y) 50.8 ± 0.9 MPa

ISO 527, GB/T 1040

Tensile strength (Z) 42.8 ± 2.8 MPa

Elongation at break (X-Y) 8.4 ± 1.7 %

ISO 527, GB/T 1040

Elongation at break (Z) 3.3 ± 0.2 %

Bending modulus (X-Y) 1898.5 ± 35.5 MPa

ISO 178, GB/T 9341

Bending modulus (Z) N/A

Bending strength (X-Y) 69.6 ± 0.8 MPa

ISO 178, GB/T 9341

Bending strength (Z) N/A

Charpy impact strength (X-Y) 2.6 ± 0.2 kJ/m2

ISO 179, GB/T 1043

Charpy impact strength (Z) N/A

* Based on 0.4 mm nozzle and Simplify 3D v.4.0. Printing conditions may vary with different nozzle diameters

Parameter

Nozzle temperature 230 – 240 (℃)

Build surface material BuildTak® , Glass

Build surface treatment Glue

Build plate temperature 70 - 80 (˚C)

Cooling fan OFF-20%

Printing speed 30-50 (mm/s)

Raft separation distance 0.14 (mm)

Retraction distance 1 (mm)

Retraction speed 20 (mm/s)

Environmental temperature Room temperature

Threshold overhang angle 60 (˚)

Recommended support material PolyDissolve™ S1

Note:

- It is highly recommended to use the PolyBox™ when printing with PolyLite™

PETG and to store it in the resealable bag.

*All specimens were conditioned at room temperature for 24h prior to testing

Printing temperature 240 °C

Bed temperature 80 °C

Shell 2

Top & bottom layer 4

Infill 100%

Environmental temperature 25 °C

Cooling fan OFF

DISCLAIMER:

The typical values presented in this data sheet are intended for reference and comparison purposes only. They

should not be used for design specifications or quality control purposes. Actual values may vary significantly with

printing conditions. End- use performance of printed parts depends not only on materials, but also on part design,

environmental conditions, printing conditions, etc. Product specifications are subject to change without notice.

Each user is responsible for determining the safety, lawfulness, technical suitability, and disposal/ recycling

practices of Polymaker materials for the intended application. Polymaker makes no warranty of any kind, unless

announced separately, to the fitness for any use or application. Polymaker shall not be made liable for any damage,

injury or loss induced from the use of Polymaker materials in any application.

You might also like

- HSBC in A Nut ShellDocument190 pagesHSBC in A Nut Shelllanpham19842003No ratings yet

- Expectation Vs Reality: Job Order and Contract of ServiceDocument10 pagesExpectation Vs Reality: Job Order and Contract of ServiceMikee Louise MirasolNo ratings yet

- Spec SheetDocument6 pagesSpec SheettristanNo ratings yet

- Bambu Lab A1 3DDocument6 pagesBambu Lab A1 3DAngel Jacobo Figueroa ArriolaNo ratings yet

- PolyLite ABS TDS V5.3-20240324Document6 pagesPolyLite ABS TDS V5.3-20240324Edgar SotoNo ratings yet

- PolyCast TDS V5.2-20230912Document6 pagesPolyCast TDS V5.2-20230912GoNo ratings yet

- PolyTerra-PLA TDS V5.3-20231113Document6 pagesPolyTerra-PLA TDS V5.3-20231113nerze0777No ratings yet

- PolyMide CoPA TDS V5.2-20240223Document7 pagesPolyMide CoPA TDS V5.2-20240223Rakan El AtracheNo ratings yet

- PolyCast TDS V3Document2 pagesPolyCast TDS V3jerome.luganNo ratings yet

- Polymax PC Tds v4Document2 pagesPolymax PC Tds v4Hector GarciaNo ratings yet

- Raise3d Premium PETG TDS V3Document3 pagesRaise3d Premium PETG TDS V3Faris AlmarshadNo ratings yet

- PolyMax PLA TDS V4Document2 pagesPolyMax PLA TDS V4fNo ratings yet

- Volumic FT en Pla UltraDocument2 pagesVolumic FT en Pla UltrakaleniaNo ratings yet

- Ultimaker PC: Technical Data SheetDocument3 pagesUltimaker PC: Technical Data SheetFelipe TeixeiraNo ratings yet

- Styrolution Basf Terluran GP-22Document3 pagesStyrolution Basf Terluran GP-22medo.k016No ratings yet

- Ultimaker PP: Technical Data SheetDocument3 pagesUltimaker PP: Technical Data SheetFelipe TeixeiraNo ratings yet

- Raise3D Premium ABS Technical Data Sheet: Physical PropertiesDocument3 pagesRaise3D Premium ABS Technical Data Sheet: Physical PropertiesdeepNo ratings yet

- Testing ReportDocument1 pageTesting ReportfaizNo ratings yet

- Ultimaker Nylon: Technical Data SheetDocument3 pagesUltimaker Nylon: Technical Data SheetFelipe TeixeiraNo ratings yet

- OKW ABS,+Guide+ValuesDocument1 pageOKW ABS,+Guide+ValuesDanielNo ratings yet

- OKW ABS,+Guide+ValuesDocument1 pageOKW ABS,+Guide+ValuesDanielNo ratings yet

- Elix ABS M220: Technical InformationDocument3 pagesElix ABS M220: Technical InformationDiegoTierradentroNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- TDS - Terluran GP-22 PDFDocument3 pagesTDS - Terluran GP-22 PDFebercueNo ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- Filament Specifications Unit ValueDocument4 pagesFilament Specifications Unit ValueRoberto Gonzalo PelazNo ratings yet

- Eastman Copolyester Eastar GN 001Document2 pagesEastman Copolyester Eastar GN 001Josephine NgNo ratings yet

- Ultimaker CPE+: Technical Data SheetDocument3 pagesUltimaker CPE+: Technical Data SheetFelipe TeixeiraNo ratings yet

- Elix ABS E401: Technical InformationDocument3 pagesElix ABS E401: Technical InformationDiegoTierradentroNo ratings yet

- ABS N Fisa TehnicaDocument1 pageABS N Fisa TehnicaFloare de PrimavaraNo ratings yet

- Technical Data Sheet PC: Filament SpecificationsDocument3 pagesTechnical Data Sheet PC: Filament SpecificationsVladimir SarmientoNo ratings yet

- Evonik Corporation Vestamid X7293 Plasticized Nylon 12Document3 pagesEvonik Corporation Vestamid X7293 Plasticized Nylon 12Prabhu MohanNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNo ratings yet

- Styrolution PS 476L: Technical DatasheetDocument3 pagesStyrolution PS 476L: Technical DatasheetTRUONGNo ratings yet

- Evonik Corporation Vestamid® L1833 30% Glass Filled Nylon 12Document3 pagesEvonik Corporation Vestamid® L1833 30% Glass Filled Nylon 12ken bernard BurburanNo ratings yet

- PET Technical Handbook 1Document61 pagesPET Technical Handbook 1karismaNo ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- Achieve™ Advanced PP7123KNE1: Polypropylene Impact CopolymerDocument2 pagesAchieve™ Advanced PP7123KNE1: Polypropylene Impact CopolymermosesNo ratings yet

- CYCOLAC™ Resin - DL100 - Asia - Technical - Data - SheetDocument2 pagesCYCOLAC™ Resin - DL100 - Asia - Technical - Data - SheetKishore Gowda A SNo ratings yet

- Styro Lution Tds 400900240714Document3 pagesStyro Lution Tds 400900240714vrjrNo ratings yet

- Elix ABS P2M-AT: Technical InformationDocument3 pagesElix ABS P2M-AT: Technical InformationDiegoTierradentroNo ratings yet

- NORYL™ Resin - SE1GFN2 - Asia - Technical - Data - Sheet PDFDocument3 pagesNORYL™ Resin - SE1GFN2 - Asia - Technical - Data - Sheet PDFbhushansalunkeNo ratings yet

- Domamid 6g30st1Document1 pageDomamid 6g30st1shahin_723No ratings yet

- Styron ATECH 1175 DatasheetDocument3 pagesStyron ATECH 1175 DatasheetbobNo ratings yet

- XENOY™ Resin - 5220U - Europe - Technical - Data - SheetDocument2 pagesXENOY™ Resin - 5220U - Europe - Technical - Data - SheetEduardo TreviñoNo ratings yet

- Technical Characteristics 2020 ENDocument1 pageTechnical Characteristics 2020 ENezzularabNo ratings yet

- Pulse A 35-105 BlackDocument3 pagesPulse A 35-105 BlackTaoufik KheddarNo ratings yet

- Luran 368R: Technical DatasheetDocument3 pagesLuran 368R: Technical DatasheetVictor PuertoNo ratings yet

- Data Sheet Advanced-PP 1102 K: Properties Unit Test Method ValueDocument1 pageData Sheet Advanced-PP 1102 K: Properties Unit Test Method ValueErnesto Cheguavara100% (1)

- Elix Ultra hh4115Document3 pagesElix Ultra hh4115DiegoTierradentroNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ISO)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ISO)DiegoTierradentroNo ratings yet

- Terluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Mahdi VolgarNo ratings yet

- TDS Mafill CRHT6344Document1 pageTDS Mafill CRHT6344marcohang00No ratings yet

- Datasheet CX02-81Document2 pagesDatasheet CX02-81jprodriguezNo ratings yet

- Property Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)MohamadMostafaviNo ratings yet

- Exxonmobil™ Pp7905E1: Polypropylene Impact CopolymerDocument2 pagesExxonmobil™ Pp7905E1: Polypropylene Impact CopolymermosesNo ratings yet

- Elix Pc-Abs 5130Document4 pagesElix Pc-Abs 5130DiegoTierradentroNo ratings yet

- Technyl Star S 218 V30 BK 31NDocument3 pagesTechnyl Star S 218 V30 BK 31Nratz23695No ratings yet

- TDS - Pla Pro HT - Rev 2.0Document2 pagesTDS - Pla Pro HT - Rev 2.0okta wijayaNo ratings yet

- Manufacturing Surface Technology: Surface Integrity and Functional PerformanceFrom EverandManufacturing Surface Technology: Surface Integrity and Functional PerformanceRating: 5 out of 5 stars5/5 (1)

- High-Performance Gradient Elution: The Practical Application of the Linear-Solvent-Strength ModelFrom EverandHigh-Performance Gradient Elution: The Practical Application of the Linear-Solvent-Strength ModelNo ratings yet

- Government of West Bengal Finance (Audit) Department: NABANNA', HOWRAH-711102 No. Dated, The 13 May, 2020Document2 pagesGovernment of West Bengal Finance (Audit) Department: NABANNA', HOWRAH-711102 No. Dated, The 13 May, 2020Satyaki Prasad MaitiNo ratings yet

- Unit-5 Shell ProgrammingDocument11 pagesUnit-5 Shell ProgrammingLinda BrownNo ratings yet

- L1 L2 Highway and Railroad EngineeringDocument7 pagesL1 L2 Highway and Railroad Engineeringeutikol69No ratings yet

- Lockbox Br100 v1.22Document36 pagesLockbox Br100 v1.22Manoj BhogaleNo ratings yet

- TSB 120Document7 pagesTSB 120patelpiyushbNo ratings yet

- 18 - PPAG-100-HD-C-001 - s018 (VBA03C013) - 0 PDFDocument1 page18 - PPAG-100-HD-C-001 - s018 (VBA03C013) - 0 PDFSantiago GarciaNo ratings yet

- Applied-Entrepreneurship PPTDocument65 pagesApplied-Entrepreneurship PPTJanice EscañoNo ratings yet

- Unit 2Document97 pagesUnit 2MOHAN RuttalaNo ratings yet

- M J 1 MergedDocument269 pagesM J 1 MergedsanyaNo ratings yet

- Data Sheet WD Blue PC Hard DrivesDocument2 pagesData Sheet WD Blue PC Hard DrivesRodrigo TorresNo ratings yet

- Difference Between Mountain Bike and BMXDocument3 pagesDifference Between Mountain Bike and BMXShakirNo ratings yet

- Jerome4 Sample Chap08Document58 pagesJerome4 Sample Chap08Basil Babym100% (7)

- Guide For Overseas Applicants IRELAND PDFDocument29 pagesGuide For Overseas Applicants IRELAND PDFJasonLeeNo ratings yet

- 1 PBDocument14 pages1 PBSaepul HayatNo ratings yet

- Sky ChemicalsDocument1 pageSky ChemicalsfishNo ratings yet

- IdM11gR2 Sizing WP LatestDocument31 pagesIdM11gR2 Sizing WP Latesttranhieu5959No ratings yet

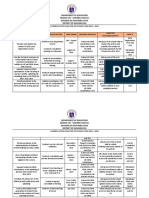

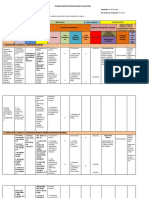

- Action Plan Lis 2021-2022Document3 pagesAction Plan Lis 2021-2022Vervie BingalogNo ratings yet

- Fidp ResearchDocument3 pagesFidp ResearchIn SanityNo ratings yet

- Recall, Initiative and ReferendumDocument37 pagesRecall, Initiative and ReferendumPhaura Reinz100% (1)

- Cabling and Connection System PDFDocument16 pagesCabling and Connection System PDFLyndryl ProvidoNo ratings yet

- 48 Volt Battery ChargerDocument5 pages48 Volt Battery ChargerpradeeepgargNo ratings yet

- Wiley Chapter 11 Depreciation Impairments and DepletionDocument43 pagesWiley Chapter 11 Depreciation Impairments and Depletion靳雪娇No ratings yet

- Engineering Management (Final Exam)Document2 pagesEngineering Management (Final Exam)Efryl Ann de GuzmanNo ratings yet

- Avalon LF GB CTP MachineDocument2 pagesAvalon LF GB CTP Machinekojo0% (1)

- Delta AFC1212D-SP19Document9 pagesDelta AFC1212D-SP19Brent SmithNo ratings yet

- Instructions For Microsoft Teams Live Events: Plan and Schedule A Live Event in TeamsDocument9 pagesInstructions For Microsoft Teams Live Events: Plan and Schedule A Live Event in TeamsAnders LaursenNo ratings yet

- JAZEL Resume-2-1-2-1-3-1Document2 pagesJAZEL Resume-2-1-2-1-3-1GirlieJoyGayoNo ratings yet

- Module 5 Data Collection Presentation and AnalysisDocument63 pagesModule 5 Data Collection Presentation and AnalysisAngel Vera CastardoNo ratings yet