Professional Documents

Culture Documents

Bambu Lab A1 3D

Uploaded by

Angel Jacobo Figueroa Arriola0 ratings0% found this document useful (0 votes)

6 views6 pagesBambu Lab A1 3D

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBambu Lab A1 3D

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views6 pagesBambu Lab A1 3D

Uploaded by

Angel Jacobo Figueroa ArriolaBambu Lab A1 3D

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

PolyLite™ PLA is a high-quality PLA designed for reliability and ease of printing.

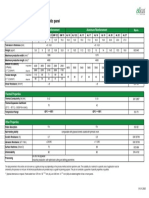

Density ISO1183, GB/T1033 1.17 g/cm3 at 23°C

Melt index 210°C, 2.16kg 7-11 g/10min

Light transmission N/A N/A

Flame retardancy N/A N/A

Effect of weak acids Not resistant

Effect of strong acids Not resistant

Effect of weak alkalis Not resistant

Effect of strong alkalis Not resistant

Effect of organic solvent No data available

Effect of oils and grease No data available

Equilibrium water absorption (%)= 0.51%

Glass transition temperature DSC, 10°C/min 61 °C

Melting temperature DSC, 10°C/min 150 °C

Crystallization temperature DSC, 10°C/min 113.5 °C

Decomposition temperature TGA, 20°C/min N/A

Vicat softening temperature ISO 306, GB/T 1633 62.9 °C

Heat deflection temperature ISO 75 1.8MPa 58.1 °C

Heat deflection temperature ISO 75 0.45MPa 59.8 °C

Thermal conductivity N/A N/A

Heat shrinkage rate N/A N/A

Young’s modulus (X-Y) 2636 ± 330 MPa

ISO 527, GB/T 1040

Young’s modulus (Z) N/A

Tensile strength (X-Y) 46.6 ± 0.9 MPa

ISO 527, GB/T 1040

Tensile strength (Z) 43.5 ± 3.1 MPa

Elongation at break (X-Y) 1.90 ± 0.21 %

ISO 527, GB/T 1040

Elongation at break (Z) N/A

Bending modulus (X-Y) 3283 ± 132 MPa

ISO 178, GB/T 9341

Bending modulus (Z) N/A

Bending strength (X-Y) 85.1 ± 2.9 MPa

ISO 178, GB/T 9341

Bending strength (Z) N/A

Charpy impact strength (X-Y) 2.68 ± 0.16 kJ/m2

ISO 179, GB/T 1043

Charpy impact strength (Z) N/A

* Based on 0.4 mm nozzle and Simplify 3D v.4.0. Printing conditions may vary with different nozzle diameters

Nozzle temperature 190 – 230 (℃)

Build surface material BuildTak® , Glass, Blue Tape

Build surface treatment Glue, Magigoo

Build plate temperature 25 - 60 (˚C)

Cooling fan ON

Printing speed 40-60 (mm/s)

Raft separation distance 0.2 (mm)

Retraction distance 1 (mm)

Retraction speed 20 (mm/s)

Environmental temperature Room temperature

Threshold overhang angle 60 (˚)

Recommended support material PolySupport™ and PolyDissolve™ S1

*All specimens were conditioned at room temperature for 24h prior to testing

Printing temperature 205 °C

Bed temperature 40 °C

Shell 2

Top & bottom layer 4

Infill 100%

Environmental temperature 25 °C

Cooling fan ON

The typical values presented in this data sheet are intended for reference and comparison purposes only. They

should not be used for design specifications or quality control purposes. Actual values may vary significantly with

printing conditions. End- use performance of printed parts depends not only on materials, but also on part design,

environmental conditions, printing conditions, etc. Product specifications are subject to change without notice.

Each user is responsible for determining the safety, lawfulness, technical suitability, and disposal/ recycling

practices of Polymaker materials for the intended application. Polymaker makes no warranty of any kind, unless

announced separately, to the fitness for any use or application. Polymaker shall not be made liable for any damage,

injury or loss induced from the use of Polymaker materials in any application.

You might also like

- PolyCast TDS V5.2-20230912Document6 pagesPolyCast TDS V5.2-20230912GoNo ratings yet

- spec sheetDocument6 pagesspec sheettristanNo ratings yet

- PolyLite_ABS_TDS_V5.3-20240324Document6 pagesPolyLite_ABS_TDS_V5.3-20240324Edgar SotoNo ratings yet

- PolyMide CoPA TDS V5.2-20240223Document7 pagesPolyMide CoPA TDS V5.2-20240223Rakan El AtracheNo ratings yet

- PolyTerra-PLA TDS V5.3-20231113Document6 pagesPolyTerra-PLA TDS V5.3-20231113nerze0777No ratings yet

- PolyLite_PETG_TDS_V5.3-20240309Document6 pagesPolyLite_PETG_TDS_V5.3-20240309Freddy ArribasplataNo ratings yet

- PolyCast TDS V3Document2 pagesPolyCast TDS V3jerome.luganNo ratings yet

- PolyMax PLA TDS V4Document2 pagesPolyMax PLA TDS V4fNo ratings yet

- Polymax PC Tds v4Document2 pagesPolymax PC Tds v4Hector GarciaNo ratings yet

- Volumic FT en Pla UltraDocument2 pagesVolumic FT en Pla UltrakaleniaNo ratings yet

- Ultimaker PC Technical Data SheetDocument3 pagesUltimaker PC Technical Data SheetFelipe TeixeiraNo ratings yet

- Ultimaker Nylon: Technical Data SheetDocument3 pagesUltimaker Nylon: Technical Data SheetFelipe TeixeiraNo ratings yet

- Ultimaker PP: Technical Data SheetDocument3 pagesUltimaker PP: Technical Data SheetFelipe TeixeiraNo ratings yet

- Ultimaker CPE+: Technical Data SheetDocument3 pagesUltimaker CPE+: Technical Data SheetFelipe TeixeiraNo ratings yet

- Styrolution Basf Terluran GP-22Document3 pagesStyrolution Basf Terluran GP-22medo.k016No ratings yet

- Raise3d Premium PETG TDS V3Document3 pagesRaise3d Premium PETG TDS V3Faris AlmarshadNo ratings yet

- TDS - Terluran GP-22 PDFDocument3 pagesTDS - Terluran GP-22 PDFebercueNo ratings yet

- ABS N Fisa TehnicaDocument1 pageABS N Fisa TehnicaFloare de PrimavaraNo ratings yet

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNo ratings yet

- PET Technical Handbook 1Document61 pagesPET Technical Handbook 1karismaNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- Technical Characteristics 2020 ENDocument1 pageTechnical Characteristics 2020 ENezzularabNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- Advanced-PP 1102LQ - 0Document1 pageAdvanced-PP 1102LQ - 0Narender RawatNo ratings yet

- TRO CX7323 - E11 - Ad PDFDocument2 pagesTRO CX7323 - E11 - Ad PDFJosip DuvnjakNo ratings yet

- Property Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)MohamadMostafaviNo ratings yet

- Eastar Copolyester GN001 Product Data SheetDocument2 pagesEastar Copolyester GN001 Product Data SheetJosephine NgNo ratings yet

- Duracon M90 44Document2 pagesDuracon M90 44PradeepNo ratings yet

- Advanced PP 1102KDocument1 pageAdvanced PP 1102KLaxman AhirNo ratings yet

- (Jay Shoemaker) Moldflow Design Guide 'A ResourcDocument3 pages(Jay Shoemaker) Moldflow Design Guide 'A ResourcFahri ibişoğluNo ratings yet

- Data Sheet Advanced-PP 1102 K: Properties Unit Test Method ValueDocument1 pageData Sheet Advanced-PP 1102 K: Properties Unit Test Method ValueErnesto Cheguavara100% (1)

- Styro Lution Tds 400900240714Document3 pagesStyro Lution Tds 400900240714vrjrNo ratings yet

- Technical Data Sheet PC: Filament SpecificationsDocument3 pagesTechnical Data Sheet PC: Filament SpecificationsVladimir SarmientoNo ratings yet

- ABS Data Sheet with Heat Resistance and Impact StrengthDocument1 pageABS Data Sheet with Heat Resistance and Impact StrengthDanielNo ratings yet

- OKW ABS,+Guide+ValuesDocument1 pageOKW ABS,+Guide+ValuesDanielNo ratings yet

- Styrolution PS 476L: Technical DatasheetDocument3 pagesStyrolution PS 476L: Technical DatasheetTRUONGNo ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- Zytel® 73G15L NC010-gbDocument12 pagesZytel® 73G15L NC010-gbzoxxxnNo ratings yet

- Raise3D Premium ABS Technical Data Sheet: Physical PropertiesDocument3 pagesRaise3D Premium ABS Technical Data Sheet: Physical PropertiesdeepNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE7501-3AB03-5AA4Document1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE7501-3AB03-5AA4Shekhar PhaseNo ratings yet

- PP TDSDocument2 pagesPP TDSsribachaNo ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- Data Sheet Advanced-PP 1102 K: Properties Unit Test Method ValueDocument1 pageData Sheet Advanced-PP 1102 K: Properties Unit Test Method ValueSekar AyuNo ratings yet

- TDS - Tecomid NB40 GR30 NLDocument1 pageTDS - Tecomid NB40 GR30 NLilkerNo ratings yet

- Luran 368R: Technical DatasheetDocument3 pagesLuran 368R: Technical DatasheetVictor PuertoNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- Filament Specifications Unit ValueDocument4 pagesFilament Specifications Unit ValueRoberto Gonzalo PelazNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- Styrolution TDS400900240711Document3 pagesStyrolution TDS400900240711Indrajit SahaNo ratings yet

- Evonik Corporation Vestamid X7293 Plasticized Nylon 12Document3 pagesEvonik Corporation Vestamid X7293 Plasticized Nylon 12Prabhu MohanNo ratings yet

- Victrex™ Peek 450G™: Product DescriptionDocument2 pagesVictrex™ Peek 450G™: Product DescriptionBerkant CangalNo ratings yet

- Property Test Method Unit Typicalvalue : BL3 License Grade Code HF 4670 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL3 License Grade Code HF 4670 (THT)MohamadMostafaviNo ratings yet

- DMH 401 POM Black: Mechanical, Physical and Thermal PropertiesDocument1 pageDMH 401 POM Black: Mechanical, Physical and Thermal Propertiessetiadi pratondoNo ratings yet

- VictrexTDS150G 151GDocument2 pagesVictrexTDS150G 151GKumaar RanjanNo ratings yet

- DMH 400 Pom: Mechanical, Physical and Thermal PropertiesDocument1 pageDMH 400 Pom: Mechanical, Physical and Thermal PropertiesESTEFANY DE LOS SANTOSNo ratings yet

- DS DMH 400 PomDocument1 pageDS DMH 400 PomESTEFANY DE LOS SANTOSNo ratings yet

- Styrolution PS 158N/L Heat Resistant GPPSDocument3 pagesStyrolution PS 158N/L Heat Resistant GPPSscribdichigoNo ratings yet

- BL6 - HM 7255Document1 pageBL6 - HM 7255ShahryarNo ratings yet

- EAPP Methods Data CollectionDocument7 pagesEAPP Methods Data Collectionjoshua herreraNo ratings yet

- MKTED208071EN CatalogueDocument618 pagesMKTED208071EN Cataloguecarlos augustoNo ratings yet

- RT Series Manual v005Document44 pagesRT Series Manual v005Muhammed Abo-FandoodNo ratings yet

- ROUTE MAPDocument5 pagesROUTE MAPNishant PathakNo ratings yet

- Book v. Movie Rubric Eng 11 - Rev. 12 - 19Document2 pagesBook v. Movie Rubric Eng 11 - Rev. 12 - 19Lucia Perez ValenciaNo ratings yet

- Cat Reforming Part 2 3 PDF FreeDocument68 pagesCat Reforming Part 2 3 PDF FreeLê Trường AnNo ratings yet

- Crystal Report Viewer 1Document2 pagesCrystal Report Viewer 1David Lemayian SalatonNo ratings yet

- May DAY EVE LessonsDocument4 pagesMay DAY EVE LessonsFerdinand Pinon100% (1)

- FINALby REDAZADocument3 pagesFINALby REDAZANoreen RedazaNo ratings yet

- Manufacturing Process AssignmentDocument5 pagesManufacturing Process AssignmentPalani SuntharajanNo ratings yet

- Sustainable Livelihood Security Index Measures Development Planning in GujaratDocument11 pagesSustainable Livelihood Security Index Measures Development Planning in GujaratTundeNo ratings yet

- AtmakarakaDocument3 pagesAtmakarakaswamyvk100% (1)

- 2020 DecDocument61 pages2020 DecLokeshNo ratings yet

- BAH Series 6000 Manguard - 113534-91Document40 pagesBAH Series 6000 Manguard - 113534-91AhmedNo ratings yet

- 1000-211-V8-0000-01003 Concrete Works (Trial Mix)Document38 pages1000-211-V8-0000-01003 Concrete Works (Trial Mix)hodigojiggfjlgkdgiohghfdiohghjfNo ratings yet

- Sensair Manual 1.0 en PDFDocument104 pagesSensair Manual 1.0 en PDFPaul KinsellaNo ratings yet

- Assignment 1: InstructionsDocument6 pagesAssignment 1: InstructionsAsim MughalNo ratings yet

- Tata Teleservices LTDDocument19 pagesTata Teleservices LTDrajvarshaNo ratings yet

- Egs630-6 Komatsu GensetDocument2 pagesEgs630-6 Komatsu GensetimamfadiliNo ratings yet

- IM Vlad_Akselrod Tactics RatingDocument7 pagesIM Vlad_Akselrod Tactics RatingpontathesmithjapanNo ratings yet

- Learning Based Exposition-The Simple Present TenseDocument12 pagesLearning Based Exposition-The Simple Present Tenseyuri Berrocal YanceNo ratings yet

- Phase Locked LoopDocument17 pagesPhase Locked LoopPaulo Toro OlivosNo ratings yet

- Cablemaster RLC - ManualDocument8 pagesCablemaster RLC - ManualGlendinning Products, LLC.No ratings yet

- Principles of PaleontologyDocument10 pagesPrinciples of Paleontologyvitrinite50% (2)

- Political Discourse A Critical Discourse Discourse A Critical Discourse AnalysisDocument13 pagesPolitical Discourse A Critical Discourse Discourse A Critical Discourse AnalysisJennina MazoNo ratings yet

- ACCC/TW BRUSSELS DATA SHEETDocument1 pageACCC/TW BRUSSELS DATA SHEETkmiqdNo ratings yet

- CIRPs Ending in Resolution - 30sept 2022Document10 pagesCIRPs Ending in Resolution - 30sept 2022dip downNo ratings yet

- Annual Report Final 2017-18 enDocument232 pagesAnnual Report Final 2017-18 enNidhi DesaiNo ratings yet

- Electrical Circuits 2 AssignmentDocument5 pagesElectrical Circuits 2 Assignmentangelo dedicatoriaNo ratings yet

- Basic Measurement PiezoeletricDocument6 pagesBasic Measurement PiezoeletricALEX_INSPETORNo ratings yet