Professional Documents

Culture Documents

Chapter 4

Uploaded by

Sabin MaharjanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 4

Uploaded by

Sabin MaharjanCopyright:

Available Formats

DESIGN GUIDELINES FOR HEADWORKS OF HYDROPOWER PROJECTS

4. FINDINGS OF FIELD STUDY

4.1 GENERAL

In order to incorporate typical Nepali conditions in the guidelines, the Consultant studied

six operational and one under-construction run-of-river hydropower projects in Nepal to

comprehend their planning, design, construction, operation and maintenance. The

findings of the study are summarized in this chapter.

4.2 PROJECT DETAILS

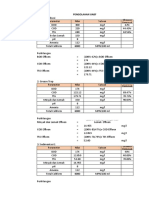

General details of the studied projects are listed in Table 4-1. The data in the table

indicates that the study can be considered representative of run-of-river hydropower

development in Nepal in terms of age, scale, engineering and mode of development and

operation.

Table 4-1: General details of projects

S.N Project Type1 Capacity Year of Owne Engineer

. (MW) commissionin r

g

1. Kali PRoR 144 2002 NEA Morrison Knudsen

Gandaki “A” Inc., USA

HEP

2. Modi Khola SRoR 14.8 2000 NEA Saman Engg.,

HEP Republic of Korea

3. Marsyangdi PRoR 69 1989 NEA Lahmeyer Int.,

HEP Germany

4. Upper Bhote SRoR 36 2001 BKPC Harza Engg.

Koshi HEP Company, USA

5. Sun Koshi PRoR 10.05 1972 NEA People’s Republic

HEP of China

6. Andhi Khola SRoR 5.1 1991 BPC BPC Hydroconsult,

HEP Nepal

7. Middle PRoR 72 Under NEA Fichtner JV,

Marsyangdi construction Germany

1

PRoR – Pondage Run-of-River; SRoR – Simple Run-of-River.

SHAH CONSULT INTERNATIONAL (P.) LTD. 1

DRAFT FINAL REPORT FINDINGS OF FIELD STUDY

HEP

4.3 OBSERVATIONS AND FINDINGS

The study yielded valuable information on the components of the various headworks,

their functions and their principal planning and design parameters. It also provided

insight into the construction practices adopted for these headworks, major problems

encountered and their solutions. Useful knowledge on the problems faced in the

operation of the headworks components and their major maintenance requirements was

also obtained. These issues are discussed in the following sections.

4.3.1 Headworks Components

The basic components of the seven headworks were their diversion structure, intake and

desander. However, the configuration of these components was found to be unique for

each project. These configurations are summarized in Table 4-2. Details of these

configurations are presented at the end of this chapter.

Table 4-2: Principal features of headworks

S.N. Project Diversion structure Intake Desander

1. Kali Gandaki Concrete gravity Gated side intake Twin chamber

“A” HEP dam with gated with undersluice surface basin with

spillway intermittent

flushing

2. Modi Khola Ungated concrete Gated vertical Twin chamber

HEP gravity weir and gravity type intake surface basin, side

flushing sluices with gravel trap spillway,

intermittent

flushing

3. Marsyangdi Gated concrete Ungated intake sill Single chamber

HEP gravity weir with flushing sluice surface basin,

intermittent

flushing

4. Upper Bhote Concrete gravity Gated side intake Single chamber

Koshi HEP dam with gated surface basin, end

spillways and side spillways,

continuous flushing

5. Sun Koshi Concrete barrage Gated side intake Single chamber

HEP with gated with sand-trapping surface basin,

spillways and channel continuous flushing

sluiceways

6. Andhi Khola Ungated concrete Gated side intake Twin chamber

HEP gravity weir with with gravel trap surface basin with

undersluice and excluder serpentine system,

intermittent

flushing

7. Middle Combined gated Submerged tunnel Three desander

Marsyangdi concrete gravity intakes and intake caverns,

HEP dam and rockfill tunnel intermittent vertical

dam flushing system

From Table 4-2, it can be observed that the simple run-of-river plants, viz. Andhi Khola

and Modi Khola have ungated weirs to divert the river water towards their intakes. Gated

SHAH CONSULT INTERNATIONAL (P.) LTD. 2

DRAFT FINAL REPORT FINDINGS OF FIELD STUDY

side undersluices are provided in these headworks to control the water level at the intake

and to flush out the bed load downstream to have unobstructed passage for the intake.

Gated concrete weirs are provided in the four pondage run-of-river projects (Kali

Gandaki “A”, Marsyangdi, Middle Marsyangdi and Sun Koshi HEPs). These weirs work

as spillways during the flood season, store water behind the structures for diurnal

pondage and divert water towards the intake structure.

Different types of desanding, with differing degrees of sophistication, are provided in the

projects. Both intermittent and continuous flushing arrangements are present.

4.3.2 Principal Design Parameters

For Nepali projects, the design flood, the level of seismic resistance and the desander

trapping efficiency are design parameters that primarily govern the hydraulic and

structural adequacy of headworks. These parameters for the seven projects are listed in

Table 4-3.

Table 4-3: Principal design parameters

S.N Project Diversion structure Desander

.

Design flood Seismic coeff. Trapping efficiency

1. Kali Gandaki “A” 1,000 year 0.3g 100% particles > 0.2 mm,

HEP 95% particles > 0.15 mm

2. Modi Khola HEP 100 year 0.1g 95% particles > 0.2 mm

3. Marsyangdi HEP 1,000 year Not known 100% particles> 0.125

mm, 80% particles > 0.05

mm

4. Upper Bhote 10,000 year 0.2g 99% particles > 0.5 mm,

Koshi HEP 95% particles > 0.3 mm

5. Sun Koshi HEP2 2,150 m3/s 8 grade 100% particles > 0.25 mm

6. Andhi Khola HEP 100 year - 100% particles > 0.3 mm

7. Middle 10,000 year 0.2g 95 % particles > 0.2 mm

Marsyangdi HEP

The design parameters show considerable variation and inconsistency. The design flood,

for example, varies from the 100 year flood to the 10,000 year flood. Although the

selection of flood is very site specific, the choice of very different floods for projects on

the same river and/or with similar consequences of failure is difficult to explain.

The seismic design coefficients also vary considerably. Except in the case of the Kali

Gandaki “A” HEP, the selection of the design seismic coefficients appears to have been

made without sufficient analyses. Considering the fact that Nepal lies in a seismically

active zone, the correctness and variation of the coefficients is a matter of concern.

The trapping efficiency specified for the desander depends primarily on the

characteristics of the sediments in the river. Nevertheless, the frequent wear and tear of

turbines clearly indicates at the insufficiency of these trapping efficiencies at most

projects.

4.3.3 Major Issues in Construction

The main issues related to headworks construction are river diversion during

construction, quality control, instrumentation and monitoring and environmental

2

Equivalent values in terms of return period and percentage of acceleration due to gravity (g) not available.

SHAH CONSULT INTERNATIONAL (P.) LTD. 3

DRAFT FINAL REPORT FINDINGS OF FIELD STUDY

monitoring and control. Of these, the first two issues seem to have been appropriately

taken care of in each project. However, the other two issues, namely instrumentation and

monitoring and environmental monitoring and control, have been introduced to different

extents in most of the recent projects.

4.3.4 Major Issues in Operation and Maintenance

The headworks of six projects studied by the Consultant have been in operation for

varying periods of time. During these periods, some of these headworks have followed

good practices aimed at ensuring proper functioning of the projects. However, these

practices are outweighed by the operational problems and structural damage faced by

these headworks.

The good practices followed at the headworks that were studied are listed in Table 4-4.

The major problems at these headworks are enumerated in Table 4-5.

Table 4-4: Good practices in headworks operation

Project Good practices

Kali Gandaki “A” HEP Regular sediment sampling and testing

Post-construction environmental auditing

Marsyangdi HEP Regular hydrological and sediment data collection

Regular instrumentation monitoring and reporting

Regular monitoring of desander efficiency

Upper Bhote Koshi HEP Regular instrumentation monitoring and reporting

Regular hydrological and sediment data collection

Post-construction environmental auditing

Table 4-5: Major problems in operation

Project Major issues

Kali Gandaki “A” HEP Reservoir sedimentation occurring at rapid pace

Frequent desander flushing during monsoon

Reduction in power production during desander

flushing

Irregular and inadequate instrumentation

monitoring

Desander efficiency not monitored

Spillway ogee surface regularly damaged (Photo

4-1)

Modi Khola HEP Frequent desander flushing during monsoon

Reduction in power production during desander

flushing

Frequent choking of trash racks

Desander efficiency not monitored

Weir surface frequently damaged

Sluice steel lining torn away and reinforcement

exposed (Photo 4-2)

Significant movement of right bank wall

Downstream apron and riprap eroded

Fish ladder ineffective

Marsyangdi HEP Rapid reservoir sedimentation, flushed twice

Frequent desander flushing during monsoon

SHAH CONSULT INTERNATIONAL (P.) LTD. 4

DRAFT FINAL REPORT FINDINGS OF FIELD STUDY

Power outage during desander flushing

Erosion of concrete ogee surface

Steel lining in sluice worn away and concrete

eroded

Upper Bhote Koshi HEP Frequent desander flushing during monsoon

Desander efficiency not monitored

Frequent damage to spillway ogee surface and

stilling basin, with exposure of reinforcement

Sun Koshi HEP Frequent obstruction of guide vanes of flushing

channel

Frequent desander flushing during monsoon

No instrumentation and monitoring

Desander efficiency not monitored

Sluice bays steel lining washed away and concrete

eroded

Damage to gates and trash racks by boulders and

debris (Photo 4-3)

Andhi Khola HEP Very frequent desander flushing during monsoon

Operation of serpentine system difficult in

monsoon, requiring manual cleaning

Reduction in power production during desander

flushing

No instrumentation and monitoring

Desander efficiency not monitored

Photo 4-1: Repaired ogee surface of diversion dam spillway at Kali Gandaki “A” HEP

SHAH CONSULT INTERNATIONAL (P.) LTD. 5

DRAFT FINAL REPORT FINDINGS OF FIELD STUDY

Photo 4-2: Missing steel lining (left) and exposed reinforcement (right) in flushing sluice at

Modi Khola HEP

Photo 4-3: Damage to trash rack from logs at intake of Sun Koshi HEP

4.4 CONCLUSIONS OF THE STUDY

The study of the hydropower projects clearly identified several important issues related

to the planning, design, construction, operation and maintenance that, in the context of

Nepal, need to be considered seriously. These issues are discussed below.

4.4.1 Design Parameters

The procedures for selection of design parameters, such as design floods and seismicity,

for the headworks should be well founded. Appropriate methods for selection of the

SHAH CONSULT INTERNATIONAL (P.) LTD. 6

DRAFT FINAL REPORT FINDINGS OF FIELD STUDY

design parameters should be defined in the proposed guidelines to ensure consistency in

approach, adequate safety and economy.

4.4.2 Desanding and Flushing

Despite adoption of different design parameters and techniques, desanding of river water

due to inefficient sediment settling remains a major problem in all projects. An equally

serious problem is the flushing of the settled silt from the desander.

Inadequate desanding has resulted in frequent damage to turbine runners at all projects.

Inefficient flushing mechanisms of the desanders have given rise to the need for frequent

flushing. In most cases, flushing is associated with reduction in power generation. At

present, such outages are inconsequential due to the surplus power available from other

plants during the rainy season; however, they may assume serious proportions in the

future.

In view of the present situation, methods for improving the sediment settling efficiency

of desanders need to be introduced in the proposed guidelines. Efficient flushing

mechanisms that do not require power outages also need to be addressed.

4.4.3 Structural Damage by Sediment-laden Water

Irrespective of their size, Nepali rivers carry large amounts of bed load and suspended

load. The sediments frequently damage the gate sills, spillway ogee surface, glacis and

downstream aprons of diversion structures. Greater damage is witnessed at the

undersluice gate sills, ogee surface and downstream part of energy dissipaters than at

higher levels of the spillways. In some projects, even mild steel plate armoring of the

undersluice surface has been worn out or torn away by the sediment-laden rivers.

This problem is typical to all the projects studied by the Consultant, and the project

owners are spending huge sums on the repair of the damages thus caused. As such,

appropriate methods need to be investigated and incorporated in the guidelines to address

this problem.

4.4.4 Instrumentation and Monitoring

Several of the projects do not have any instrumentation in the headworks. A few of those

that have a comprehensive instrumentation scheme in place do not monitor the

instruments due to lack of trained manpower or malfunctioning of equipment. Regular

and systematic monitoring of instruments, along with recording and interpretation of the

data, is only being performed at Marsyangdi HEP.

The importance of instrumentation and monitoring for the safety of headworks structures

cannot be overemphasized. The insight it can provide into the behaviour of the structures

can be useful for developing specific design procedures suitable for Nepali conditions.

As such, provisions for implementing suitable instrumentation in the projects,

monitoring them and recording and interpreting the data need to be included in the

guidelines.

4.4.5 Data Collection and Documentation

Apart from the Marsyangdi HEP, none of the operational hydropower projects covered in

the study maintains a methodical record of hydrological and sedimentological data. Such

data can be of immense use for analyzing the performance of the concerned headworks

and in its operation. They can also prove valuable input for the design of future projects

in Nepal. As such, mandatory provisions should be made in the guidelines for collection

of hydrological and sedimentological data at the headworks and submission of these

records to DoED.

SHAH CONSULT INTERNATIONAL (P.) LTD. 7

DRAFT FINAL REPORT FINDINGS OF FIELD STUDY

SHAH CONSULT INTERNATIONAL (P.) LTD. 8

DRAFT FINAL REPORT FINDINGS OF FIELD STUDY

Table 4-6: Salient features of Kali Gandaki “A” headworks

Catchment area 7,618 km2

Average annual 288 m3/s

inflow

Minimum inflow 40 m3/s

Annual sediment 37.4 million tons

load

Reservoir levels Operating maximum: El. 524 m

Operating minimum: El. 518 m

Reservoir volume 7,700,000 m3 at El. 524 m

Pondage volume 3,100,000 m3

Diversion dam Concrete gravity dam, 99.263 m long and 43 m high

31.763 m long, concrete monolith non-overflow section

67.5 m long spillway section with three hydraulically operated

radial gates and upstream and downstream stop logs

Roller bucket energy dissipaters with riprap protection

Upstream and downstream bridge decks with gantry cranes

Forebay Concrete guide walls and concrete ogee weir with training wall

Forebay monolith with forebay bottom outlet channel

Fish conveyance facility consisting of hopper, vertical drop shaft

and fishway with outlet

Intake Side intakes with six radial gates, trash racks and stop logs

Eight steel-lined sediment undersluices with trash racks, stop logs

and slide gates

Undersluice tube

Desander Twin chamber surface desander

Intermittent flushing through 12 steel-lined sediment sluices with

radial gates

Collector channel with slide gates

Table 4-7: Salient features of Modi Khola headworks

Catchment area 510 km2

Average annual 45.3 m3/s

inflow

Minimum inflow 8.8 m3/s

Normal water level El. 936.30 m

Diversion weir 5.5 m high, 33 m long concrete gravity structure with uncontrolled

overflow, crest at El. 936.3 m

Two 3 m wide flushing sluices with 3 m wide, 3.8 m high gates

Fish ladder on left bank

Intake 20.5 m wide, 8.7 m high vertical gravity type

One roller gate, 4.80 m wide and 3.25 m high

Four sets steel trash racks

Box culvert 250 m long conduit between intake and desanding basin

Two 2.25 m wide, 3.2 high chambers

20.8 m long, 1 m high flushing gallery with gate

Desander Two bay Dufour II type, with 100 m long, 10 m wide and 6.5 m

high basins

SHAH CONSULT INTERNATIONAL (P.) LTD. 9

DRAFT FINAL REPORT FINDINGS OF FIELD STUDY

34 m wide, 1 m high side spillway

Intermittent flushing through flushing pipes and gates

Table 4-8: Salient features of Marsyangdi HEP headworks

Catchment area 3,850 km2

Average annual 210 m3/s

inflow

Minimum inflow 33 m3/s

Annual sediment 31.9 million tons

load

Reservoir levels Operating maximum: El. 337.5 m

Operating minimum: El. 333.0 m

Diversion weir 102 m long concrete gravity weir

Five spillway bays with hydraulically operated radial gates

Stilling basin with downstream riprap protection

Upstream bridge deck with gantry crane

Embankment 400 m long rock fill embankment with central clay core

Intake Intake sill at El. 331 m

Gated sediment sluice

Intake canal to pass water to settling basin

Settling basin Single chamber surface desander

Intermittent flushing through gated flushing structure

Compensating pond 120 m long pond passing water to power intake

Table 4-9: Salient features of Upper Bhote Koshi HEP headworks

Catchment area 2,132 km2

Average annual 66.4 m3/s

inflow

Minimum inflow 10.5 m3/s

Annual sediment 10.7 x 106 m3

load

Head pond levels Normal operating level: El. 1434 m

Design flood level: El. 1435 m

Diversion dam Concrete gravity structure, 87 m long and 22 m high

66 m long concrete gravity dam

Two 8 m long spillway bays with hydraulic radial gates and stop

logs

16.5 m long stilling basin

Upstream and downstream aprons and downstream riprap

protection

Upstream bridge decks over spillway bays

Intake Two intake gates for desanding basin, one for bypass conduit

Trash racks and stop logs for each gate

Mechanized trash rack cleaner

Desanding basin Single chamber surface basin

Continuous flushing through three transverse flushing channels and

sluice gates

SHAH CONSULT INTERNATIONAL (P.) LTD. 10

DRAFT FINAL REPORT FINDINGS OF FIELD STUDY

Side and end spillways

Bypass conduit Bypass canal and tunnel with separate intake

Table 4-10: Salient features of Sun Koshi HEP headworks

Catchment area 2,340 km2

Average annual 88 m3/s

inflow

Minimum inflow 13.4 m3/s

Annual sediment 6.72 million tons

load

Water levels Normal water level: El. 808.4 m

Flood water level: El. 811.3 m

Diversion barrage 70.55 m long concrete barrage

Four gated overflow spillways and two gated scouring sluices

Stilling basin with downstream cut-off wall, with steel lining in

sluicing portion

Steel-lined flushing channel with sand guiding sills

Six radial gates and maintenance gates

Two operating decks and a vehicular bridge

Intake Canal intake with four openings

Slide gates and trash racks in each opening

Intake canal Open canal between intake and desanding basin

Lateral sand trapping channel discharging in sand sluicing gallery

Bypass canal Open canal between intake and end of desander

Desanding basin Single chamber surface desander

Flow straightening walls in divergent section

Continuous flushing through sand-trapping channels and sand

flushing galleries

Table 4-11: Salient features of Andhi Khola HEP headworks

Catchment area 444 km2

Average annual 29 m3/s

inflow

Minimum inflow 2.7 m3/s

Water levels Maximum: El. 636 m

Normal: El. 630 m

Diversion weir 65 m long, 6 m high concrete gravity weir

60 m long ungated spillway with flip bucket and plunge pool

2 m wide undersluice

SHAH CONSULT INTERNATIONAL (P.) LTD. 11

DRAFT FINAL REPORT FINDINGS OF FIELD STUDY

Intake Side intake with two gates

2.5 m wide, 2 m high radial gates, trash racks and stop logs

Gravel trap and flushing system

Intake canal 10 m long enclosed, rectangular concrete canal

35.8 m long open, stone masonry canal

Desilting basin Twin chamber surface desander

Intermittent gravity flushing with serpent sediment sluicing system

Table 4-12: Salient features of Middle Marsyangdi HEP headworks

Catchment area 2,729 km2

Average annual 99.5 m3/s

inflow

Reservoir levels Operating maximum: El. 626.0 m

Operating minimum: El. 621.0 m

Pondage volume 1,650,000 m3

Diversion dam Combined concrete gravity dam and rockfill dam

55 m long, 56 m high concrete gravity dam with three gated

spillways, crest at El. 629 m

40 m long rockfill dam with impervious core, crest at El. 630 m

Upstream and downstream bridge decks with gantry cranes

Intake structures 35 m long intake structure with three submerged tunnel intakes

having ogee overflow weirs, stop logs and trash racks

70-75 m long, 4 m wide “D” tunnels connecting intake structure

with desander caverns, with roller gates at entrance

Desander Three underground desander caverns, each 130 m long, 15 m wide

and 25-27 m high

Two desander basins per cavern, each 100.75 m long, 7.5 m wide

and 25.1 m high

Intermittent flushing using BIERI system

30 m long, 15 m wide and 21 m high gate chamber structure with

outlet bulkheads to convey water to headrace tunnel

119 m long flushing tunnel for discharging sediments into river

Table 4-13: Salient features of Sun Koshi HEP headworks

Catchment area 2,340 km2

Average annual 88 m3/s

inflow

Minimum inflow 13.4 m3/s

Annual sediment 6.72 million tons

SHAH CONSULT INTERNATIONAL (P.) LTD. 12

DRAFT FINAL REPORT FINDINGS OF FIELD STUDY

load

Water levels Normal water level: El. 808.4 m

Flood water level: El. 811.3 m

Diversion barrage 70.55 m long concrete barrage

Four gated overflow spillways and two gated scouring sluices

Stilling basin with downstream cut-off wall, with steel lining in

sluicing portion

Steel-lined flushing channel with sand guiding sills

Six radial gates and maintenance gates

Two operating decks and a vehicular bridge

Intake Canal intake with four openings

Slide gates and trash racks in each opening

Intake canal Open canal between intake and desanding basin

Lateral sand trapping channel discharging in sand sluicing gallery

Bypass canal Open canal between intake and end of desander

Desanding basin Single chamber surface desander

Flow straightening walls in divergent section

Continuous flushing through sand-trapping channels and sand

flushing galleries

SHAH CONSULT INTERNATIONAL (P.) LTD. 13

You might also like

- An Introduction to Ultrathin Organic Films: From Langmuir--Blodgett to Self--AssemblyFrom EverandAn Introduction to Ultrathin Organic Films: From Langmuir--Blodgett to Self--AssemblyNo ratings yet

- C 2 Shipaeva M S Geochemical Analysis of Formation Water As A ToolDocument12 pagesC 2 Shipaeva M S Geochemical Analysis of Formation Water As A ToolМария ШипаеваNo ratings yet

- Capacitor Discharges - Magnetohydrodynamics - X-Rays - UltrasonicsFrom EverandCapacitor Discharges - Magnetohydrodynamics - X-Rays - UltrasonicsRating: 5 out of 5 stars5/5 (1)

- Relief-Well Planning and Drilling For A North Sea Underground BlowoutDocument8 pagesRelief-Well Planning and Drilling For A North Sea Underground BlowoutAli mohammadNo ratings yet

- GPS Khan Wali Kaley (Bara) For C&W Dept. MS Haji Turab Date 22-06-23Document7 pagesGPS Khan Wali Kaley (Bara) For C&W Dept. MS Haji Turab Date 22-06-23Muhammad AsimNo ratings yet

- Water 2022 (Compressed)Document25 pagesWater 2022 (Compressed)AnithaNo ratings yet

- 04042019PW2G2LUWDPRDocument185 pages04042019PW2G2LUWDPRpraveenNo ratings yet

- GGPS Babo Khan Killi (Bara) For C&W MS Haji Turab Khan Date 22-05-23Document7 pagesGGPS Babo Khan Killi (Bara) For C&W MS Haji Turab Khan Date 22-05-23Muhammad AsimNo ratings yet

- Irrigation Engineering Ce-432 LDocument18 pagesIrrigation Engineering Ce-432 LAhmed FiazNo ratings yet

- SPE - 187159 Challenging Reservoir Modeling Case Study For Naturally Fractured High-Pressure-High-Temperature Gas Sand ReservoirDocument23 pagesSPE - 187159 Challenging Reservoir Modeling Case Study For Naturally Fractured High-Pressure-High-Temperature Gas Sand ReservoirBangsawan AriefNo ratings yet

- The Basics Regarding Site Selection Criteria For Reservoir AsDocument3 pagesThe Basics Regarding Site Selection Criteria For Reservoir AsameykatdareNo ratings yet

- SPE 100888 The First Horizontal Underbalanced Well Drilled in Libya: A Case StudyDocument6 pagesSPE 100888 The First Horizontal Underbalanced Well Drilled in Libya: A Case StudyhkaqlqNo ratings yet

- Chapter 2 Introduction2Document78 pagesChapter 2 Introduction2Omer IkhlasNo ratings yet

- 2010 HP&D Asia - Feasibility Study For Baleh Hydroelectric Project - BARKER Et Al PDFDocument10 pages2010 HP&D Asia - Feasibility Study For Baleh Hydroelectric Project - BARKER Et Al PDFHuy Lê QuangNo ratings yet

- Paper HOLA14-144Document12 pagesPaper HOLA14-144Elizabeth Vicente MedranoNo ratings yet

- Tips para Manejo YacimientoDocument7 pagesTips para Manejo YacimientoHebert FerneynesNo ratings yet

- Discharge Water Handling and Treatment: Problems and Solutions at A Large Pittsburgh Seam Coal Mine J. D. ByarsDocument8 pagesDischarge Water Handling and Treatment: Problems and Solutions at A Large Pittsburgh Seam Coal Mine J. D. ByarsEngr. Nadeem AhmadNo ratings yet

- Rajak 2018 IOP Conf. Ser. Mater. Sci. Eng. 377 012152Document9 pagesRajak 2018 IOP Conf. Ser. Mater. Sci. Eng. 377 012152Tamani MoyoNo ratings yet

- Hydraulic Fracturing of Tight Gas Reservoir of Pab Sandstone at POGC Rehman-1 PakistanDocument16 pagesHydraulic Fracturing of Tight Gas Reservoir of Pab Sandstone at POGC Rehman-1 PakistankhairullahksNo ratings yet

- JournalofGeophysicalScienceandEngg PaperDocument16 pagesJournalofGeophysicalScienceandEngg PaperMaria Fernanda Landa ElizaldeNo ratings yet

- Barrier DesignDocument57 pagesBarrier DesignNoah DengNo ratings yet

- MS of Diversion Canal Proposal For Re DredgingDocument8 pagesMS of Diversion Canal Proposal For Re DredgingAbdullah Al MarufNo ratings yet

- Internship Report Khan Khwar BeshamDocument21 pagesInternship Report Khan Khwar BeshamGeologist Fazal ElahiNo ratings yet

- Spillways 6Document4 pagesSpillways 6lrbs3083No ratings yet

- The Peoples Democratic Republic of AlgeriaDocument8 pagesThe Peoples Democratic Republic of AlgeriaAhmed ChahineNo ratings yet

- IGJpapergroutingpublishedDocument17 pagesIGJpapergroutingpublishedeminentparkmNo ratings yet

- Overview of The Strucrural Framework and Hydrocarbon Plays in The Penyu BasinDocument23 pagesOverview of The Strucrural Framework and Hydrocarbon Plays in The Penyu Basinmuhd nurismail abdul rahmanNo ratings yet

- PetroBowl - QuizletDocument8 pagesPetroBowl - QuizletAndreas DimasNo ratings yet

- Ground Water EngineeringDocument3 pagesGround Water EngineeringAnil MarsaniNo ratings yet

- 726-Article Text-2010-1-10-20200306Document11 pages726-Article Text-2010-1-10-20200306Hatef SardariNo ratings yet

- Pinnapuram Vol 1 - Main ReportDocument252 pagesPinnapuram Vol 1 - Main ReportMOHD SALMANNo ratings yet

- AHydrogeochemical Properties and The Exhaustion Groundwater Reserve From Dammam Aquifer at Al-Najaf Governorate, Middle IraqDocument18 pagesAHydrogeochemical Properties and The Exhaustion Groundwater Reserve From Dammam Aquifer at Al-Najaf Governorate, Middle IraqAymen AlsudanyNo ratings yet

- Importante Rao - 2021 - IOP - Conf. - Ser. - Earth - Environ. - Sci. - 783 - 012049Document9 pagesImportante Rao - 2021 - IOP - Conf. - Ser. - Earth - Environ. - Sci. - 783 - 012049filipeciganoNo ratings yet

- Compressive Pile Load Test On CFA Piles & On A Driven Timber PileDocument4 pagesCompressive Pile Load Test On CFA Piles & On A Driven Timber PilepatybagNo ratings yet

- Dry Holes Analysis Leads To Exploration - AssessmenDocument4 pagesDry Holes Analysis Leads To Exploration - AssessmenMujtabaNo ratings yet

- Seepage Through Till Foundations of Dams of The Eastmain-Opican-La Grande DiversioDocument18 pagesSeepage Through Till Foundations of Dams of The Eastmain-Opican-La Grande DiversioRaul Robles BustiosNo ratings yet

- In Situ Leaching of UraniumDocument7 pagesIn Situ Leaching of UraniumRodrigo GarcíaNo ratings yet

- Geotechnical Foundation Engineering: Public For Public UseDocument6 pagesGeotechnical Foundation Engineering: Public For Public UseMike SyNo ratings yet

- Earth Sciences Research JournalDocument6 pagesEarth Sciences Research JournalPaulo RoseroNo ratings yet

- Topic6 MiningMethods PartII SurfaceMining PlanningandDesignofOpenPitMiningDocument95 pagesTopic6 MiningMethods PartII SurfaceMining PlanningandDesignofOpenPitMiningVasanthakumar ThanigaimalaiNo ratings yet

- Numerical Analysis of Steady-State Groundwater in Ow Into Tabriz Line 2 Metro Tunnel, Northwestern Iran, With Special Consideration of Model DimensionsDocument12 pagesNumerical Analysis of Steady-State Groundwater in Ow Into Tabriz Line 2 Metro Tunnel, Northwestern Iran, With Special Consideration of Model DimensionsTareq Al ShyoukhyNo ratings yet

- KEN BETWA Design AspectsDocument81 pagesKEN BETWA Design AspectsN.J. Patel100% (1)

- Analysis of Field Performance of Embankments On Soft Clay Deposit With and Without PVD-improvementDocument23 pagesAnalysis of Field Performance of Embankments On Soft Clay Deposit With and Without PVD-improvementlingamkumarNo ratings yet

- 04.real-Time Geomechanics Modeling For A Challenging Deepwater Exploration Southern Basin Exploration (Sbe) WellDocument12 pages04.real-Time Geomechanics Modeling For A Challenging Deepwater Exploration Southern Basin Exploration (Sbe) WellHerry SuhartomoNo ratings yet

- An Effective Well Development Method For Deep Screen Completed WellsDocument6 pagesAn Effective Well Development Method For Deep Screen Completed WellsMonica UrbietaNo ratings yet

- Study of A Scientific Article: Academic Year 2019-20Document20 pagesStudy of A Scientific Article: Academic Year 2019-20Ahmed. Touati GCNo ratings yet

- 6 SiximepublicationDocument11 pages6 SiximepublicationPedro SiriasNo ratings yet

- Lei 2005Document9 pagesLei 2005Amr HegazyNo ratings yet

- David Muir Wood Slides PDFDocument118 pagesDavid Muir Wood Slides PDFserçinNo ratings yet

- M.reynolds PrintDocument48 pagesM.reynolds PrintDanilson Paulo MelicioNo ratings yet

- Spe 30532 JPT PDFDocument6 pagesSpe 30532 JPT PDFRafael FloresNo ratings yet

- Manual Guidelines Mine Haul Road Design Haul Trucks Roads Planning Alignment Sections Surface Construction EconomicsDocument95 pagesManual Guidelines Mine Haul Road Design Haul Trucks Roads Planning Alignment Sections Surface Construction EconomicsKRUSHNA CHANDRA GUJIRINo ratings yet

- Field Report 070BCE004 PDFDocument11 pagesField Report 070BCE004 PDFbinud das0% (1)

- Water & Gas Coning in Horizontal & Vertical WellDocument21 pagesWater & Gas Coning in Horizontal & Vertical WellNoraeen EleanorNo ratings yet

- Total and Differential Settlement of A Heap Leach Pad Founded On An Existing Mine Waste DumpDocument13 pagesTotal and Differential Settlement of A Heap Leach Pad Founded On An Existing Mine Waste DumpmarcosNo ratings yet

- 4-3-1 DesignDocument28 pages4-3-1 DesignArmend AvdiuNo ratings yet

- Paper 2 Engineering GeologyDocument93 pagesPaper 2 Engineering Geologya4abhirawatNo ratings yet

- Earthfill Dams: Most Common Type of Dam. Designed As A Non-Overflow Section With Separate SpillwayDocument37 pagesEarthfill Dams: Most Common Type of Dam. Designed As A Non-Overflow Section With Separate SpillwayNayr OnxseNo ratings yet

- CofferdampptDocument26 pagesCofferdampptunnijrtcetNo ratings yet

- Sampling & Data AssayDocument22 pagesSampling & Data AssayFerdinand SiahaanNo ratings yet

- Chapter 5Document8 pagesChapter 5Sabin MaharjanNo ratings yet

- Salient Features LMHEP - RevisedDocument4 pagesSalient Features LMHEP - RevisedSabin MaharjanNo ratings yet

- Design of BridgeDocument24 pagesDesign of BridgeSabin MaharjanNo ratings yet

- Regional Modeling For Estimation of Runoff From Ungauged Catchments: Case Study of The Saptakoshi Basin, NepalDocument8 pagesRegional Modeling For Estimation of Runoff From Ungauged Catchments: Case Study of The Saptakoshi Basin, NepalSabin MaharjanNo ratings yet

- 31 Steel Design Guide Castellated and CeDocument117 pages31 Steel Design Guide Castellated and CeSabin MaharjanNo ratings yet

- Design of A Pedestrian-Steel Bridge Crossing Auchi-Benin ExpresswayDocument9 pagesDesign of A Pedestrian-Steel Bridge Crossing Auchi-Benin ExpresswaySabin MaharjanNo ratings yet

- Application For Protective Irrigation ProjectDocument5 pagesApplication For Protective Irrigation Projectsoumya ranjan majhiNo ratings yet

- Water Demand Analysis of Municipal Water Supply Using EPANet Software PDFDocument12 pagesWater Demand Analysis of Municipal Water Supply Using EPANet Software PDFJanssen Gerardo Valbuena100% (1)

- Design of Sewer Network For Vijayapur City Using SEWER Version 3.0 SoftwareDocument6 pagesDesign of Sewer Network For Vijayapur City Using SEWER Version 3.0 SoftwareMurugesh KattiNo ratings yet

- Ational Law University Odisha, Cuttack: SubjectDocument95 pagesAtional Law University Odisha, Cuttack: SubjectAAYUSH AKARNo ratings yet

- 9 Geography NcertSolutions Chapter 3Document5 pages9 Geography NcertSolutions Chapter 3Nehal AshrafNo ratings yet

- Chapter 1 - Quantity of WaterDocument13 pagesChapter 1 - Quantity of WaterAzhar farooqueNo ratings yet

- Bab I PendahuluanDocument16 pagesBab I PendahuluanRahman Wahyu NurmajidNo ratings yet

- Catalogue: Technical ServicesDocument12 pagesCatalogue: Technical ServicesmsagaliwaNo ratings yet

- WRE FinalDocument15 pagesWRE FinalNIKHIL PARDESHINo ratings yet

- Gondar University Institute of Technology: Architectural Science II (Water and Sewage Lecture Note) Chapter-1Document68 pagesGondar University Institute of Technology: Architectural Science II (Water and Sewage Lecture Note) Chapter-1julieNo ratings yet

- Nara CanalDocument3 pagesNara CanalAli AmeerNo ratings yet

- Excel PerhitunganDocument15 pagesExcel PerhitunganFirman MuhNo ratings yet

- New Generation University: Department of AgricultureDocument2 pagesNew Generation University: Department of AgriculturenimcanNo ratings yet

- Water in The World Local and Global ChallengesDocument24 pagesWater in The World Local and Global ChallengeshasibmceNo ratings yet

- Flood Routing 18 7 07Document27 pagesFlood Routing 18 7 07Sohail SakhaniNo ratings yet

- Moscow PresentationDocument17 pagesMoscow PresentationArendraNo ratings yet

- Grade 4 Cause Effect ADocument3 pagesGrade 4 Cause Effect AAisha BessaNo ratings yet

- Amendment No6 To 30 MLD SWRO LSTK TenderDocument2 pagesAmendment No6 To 30 MLD SWRO LSTK TenderRaj SelvamNo ratings yet

- Infographic On WASH Facts PDFDocument6 pagesInfographic On WASH Facts PDFAbdul SalamNo ratings yet

- 5 - Stormwater PDFDocument127 pages5 - Stormwater PDFAlex WNo ratings yet

- Sample Board Exam Questions 5Document2 pagesSample Board Exam Questions 5qiritical99No ratings yet

- Water Sector in IndiaDocument8 pagesWater Sector in IndiaBoyina PrabhakarNo ratings yet

- WREDocument25 pagesWREcj salesNo ratings yet

- Washington State Department of Health: DOH Form 331-527-F Revised 4/4/2019Document8 pagesWashington State Department of Health: DOH Form 331-527-F Revised 4/4/2019rabii elarfaouiNo ratings yet

- 03 Water Resources of PakistanDocument13 pages03 Water Resources of PakistanShahid AliNo ratings yet

- Impacts of Waste Water Irrigation On Water Quality andDocument4 pagesImpacts of Waste Water Irrigation On Water Quality andhycarpenterNo ratings yet

- Introductory Concepts of Water Management and Irrigation Water ManagementDocument22 pagesIntroductory Concepts of Water Management and Irrigation Water ManagementPrimoJr Carillo100% (2)

- Compiled AR of WP&P, CWC, 2014-15Document51 pagesCompiled AR of WP&P, CWC, 2014-15rajat sharmaNo ratings yet

- Class 4 Aquifer TypeDocument2 pagesClass 4 Aquifer TypeMayuri MukherjeeNo ratings yet

- Worksheet-Sources of Water - Water Cycle - Where Is The Water StoredDocument2 pagesWorksheet-Sources of Water - Water Cycle - Where Is The Water StoredEeshaalNo ratings yet

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontRating: 4.5 out of 5 stars4.5/5 (18)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- Slow Violence and the Environmentalism of the PoorFrom EverandSlow Violence and the Environmentalism of the PoorRating: 4 out of 5 stars4/5 (5)

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (52)

- Busted!: Drug War Survival Skills and True Dope DFrom EverandBusted!: Drug War Survival Skills and True Dope DRating: 3.5 out of 5 stars3.5/5 (7)

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionFrom Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionNo ratings yet

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaFrom EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaRating: 4 out of 5 stars4/5 (1)

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksFrom EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksNo ratings yet

- Environmental Education in Practice: Concepts and ApplicationsFrom EverandEnvironmental Education in Practice: Concepts and ApplicationsNo ratings yet

- Dawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawFrom EverandDawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawRating: 4 out of 5 stars4/5 (334)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontRating: 4.5 out of 5 stars4.5/5 (9)

- Down to the Wire: Confronting Climate CollapseFrom EverandDown to the Wire: Confronting Climate CollapseRating: 4.5 out of 5 stars4.5/5 (8)

- Principles of direct and superior responsibility in international humanitarian lawFrom EverandPrinciples of direct and superior responsibility in international humanitarian lawNo ratings yet

- Climate Action Challenge: A Proven Plan for Launching Your Eco-Initiative in 90 DaysFrom EverandClimate Action Challenge: A Proven Plan for Launching Your Eco-Initiative in 90 DaysNo ratings yet

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933From EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933No ratings yet