Professional Documents

Culture Documents

Innio Ets t2 A4 en 2023 Screen Ijb-123002-En

Uploaded by

Pedro ArmandoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Innio Ets t2 A4 en 2023 Screen Ijb-123002-En

Uploaded by

Pedro ArmandoCopyright:

Available Formats

JENBACHER TYPE 2

Continuous development

for more than 40 years

Introduced in 1976 and continuously improved, the Jenbacher

type 2 engine offers extremely high efficiency in the 250 to

350 kW power range. Its robust design and stationary engine

concept result in excellent component durability and a service

life of 80,000 operating hours before the first major overhaul.

Enhanced components and a proven control and monitoring

concept give this engine outstanding reliability.

Reference installations

J208 Abwasserverband Obere Iller, Germany

Energy source Engine type Electrical output Thermal output Commissioning

Sewage gas 1 x J208 290 kW 371 kW 2016

Every year, the Abwasserverband Obere Iller wastewater treatment plant cleans 13.7 million cubic meters of wastewater from

11 municipalities in the Oberallgäu district. Since 2016, the plant has been able to cover 65% of its power demand and 95% of its

heat demand using a high-efficiency Jenbacher J208 engine.

J208 Biogas plant in Schlitters, Austria

Energy source Engine type Electrical output Thermal output Commissioning

Biogas 1 x J208 350 kW 370 kW 2015

A single J208 engine at the combined heat and power (CHP) station in Schlitters annually transforms about 12,000 tons of lef-

tover food and biowaste into electricity and heat. The residual digested biowaste then is compressed into compost or turned

into liquid manure to fertilize agricultural fields in the region.

J208 ARA Pustertal, Italy

Energy source Engine type Electrical output Thermal output Commissioning

Sewage gas 3 x J208 991 kW 669 kW 2016, 2018, 2019

ARA Pustertal’s plant Tobl treats the wastewater of about 158,000 people in the Pflarenz/Tobl region of St. Lorenzen annually. In

2022, more than 2.15 million cubic meters of sewage gas was produced and used to power three Jenbacher J208 combined

heat and power (CHP) units—meeting 83% of the plant’s annual electricity demand. Exhaust gas heat also is put to use to dry

sewage sludge at the plant.

J208 Endress+Hauser Maulburg II, Germany

Energy source Engine type Electrical output Thermal output Commissioning

Pipeline gas 1 x J208 1,145 kW 1,261 kW 2014

1 x J412 2020

In Maulburg, two Jenbacher gensets with a total of 1,145 kWel supply the Endress+Hauser SE+Co. KG plant. After the first

Jenbacher genset with 845 kWel went into operation in 2014, the Jenbacher J208 genset was installed in 2020.

The Jenbacher CHP solution reliably supplies the company site with electricity and heat.

Technical data

Configuration In line

Dimensions l x w x h (mm)

Bore (mm) 135

Stroke (mm) 145 Generator set 4,900 x 1,700 x 2,000

Displacement / cylinder (lit) 2.08

Cogeneration system 4,900 x 1,700 x 2,000

1,500 (50 Hz)

Speed (rpm)

1,800 (60 Hz)

Container 40-foot 12,200 x 2,500 x 2,600

7.3 (1.500 1 / min)

Mean piston speed (m/s)

8.7 (1.800 1 / min)

Generator set, cogeneration

Scope of supply system, generator set /

cogeneration in container

Weights empty (kg)

Natural gas, flare gas, propane,

Applicable gas types

biogas, landfill gas, sewage gas Generator set 6,000

Engine type J208

No. of cylinders 8

Cogeneration system 6,700

Total displacement (lit) 16.6

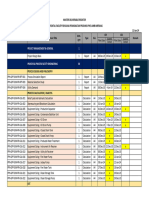

Outputs and efficiencies

Natural gas 1,500 1/min | 50 Hz 1,800 1/min | 60 Hz

NOX < Type Pel (kW)1 Pth (kW)2 ηel (%)1 ηth (%)2 ηtot (%) Pel (kW)1 Pth (kW)2 ηel (%)1 ηth (%)2 ηtot (%)

J208 300 391 39.1 50.9 90.0

500 mg / m3N

J208 330 352 39.4 42.1 81.5 335 393 37.4 43.9 81.3

250 mg / m3N J208 294 363 37.6 46.4 84.1 335 410 36.5 44.6 81.1

Biogas 1,500 1/min | 50 Hz 1,800 1/min | 60 Hz

NOX < Type Pel (kW)1 Pth (kW)2 ηel (%)1 ηth (%)2 ηtot (%) Pel (kW)1 Pth (kW)2 ηel (%)1 ηth (%)2 ηtot (%)

J208 330 394 39.2 46.8 86.1 335 388 36.5 42.2 78.7

500 mg / m3N

J208 249 289 39.7 46.1 85.8

250 mg / m3N J208 330 414 38.2 47.9 86.0

1

Technical data according to ISO 3046

2

Total heat output with a tolerance of +/- 8%, exhaust gas outlet temperature 120°C, for biogas gas outlet temperature 180°C

All data according to full load and subject to technical development and modification.

Further engine versions available on request.

I JB-1 23 002-EN

In general, “Ready for H2” Jenbacher units can be converted to operate on up to

100% hydrogen in the future. Details on the cost and timeline for a future conversion

may vary and need to be clarified individually.

© Copyright 2023 INNIO. Information provided is subject to change without notice.

INNIO, , Jenbacher, are trademarks in the European Union or

Contact us: elsewhere owned by INNIO Jenbacher GmbH & Co OG or one of its affiliates.

jenbacher.com/en/contact All other trademarks and company names are property of their respective owners.

jenbacher.com/en Jenbacher is part of the INNIO Group

You might also like

- Engine Sheet Type 3 e 2015Document2 pagesEngine Sheet Type 3 e 2015Esteban Vasquez GiraldoNo ratings yet

- Manual Waukesha F 18GL PDFDocument2 pagesManual Waukesha F 18GL PDFLuis Eduardo Barón RoblesNo ratings yet

- HL-class Fact SheetDocument2 pagesHL-class Fact SheetadanasporNo ratings yet

- INNIO Jenbacher Type 2 - 2019 - enDocument2 pagesINNIO Jenbacher Type 2 - 2019 - enMartin KratkyNo ratings yet

- Innio Engine Type Sheet t2 en 2021 2Document2 pagesInnio Engine Type Sheet t2 en 2021 2Yasir JamilNo ratings yet

- Innio BR t2 A4 en 2022 ScreenDocument2 pagesInnio BR t2 A4 en 2022 ScreenLorenzo MasottiNo ratings yet

- GE - Engine Type Sheet - Type 2 - EN - 2015 - RZDocument2 pagesGE - Engine Type Sheet - Type 2 - EN - 2015 - RZr.eddie.cookeNo ratings yet

- GE - Engine Type Sheet - Type 3 - EN - 2015 - RZDocument2 pagesGE - Engine Type Sheet - Type 3 - EN - 2015 - RZr.eddie.cookeNo ratings yet

- Gps Waukesha 7042 BrochureDocument2 pagesGps Waukesha 7042 BrochureAlan SantosNo ratings yet

- L8SPDocument1 pageL8SPbfreshdrNo ratings yet

- Iwk 119071 VGF F18GLDocument2 pagesIwk 119071 VGF F18GLAlejandro MuñozNo ratings yet

- L8SPDocument1 pageL8SPDavis AcuñaNo ratings yet

- MTU Marine Spec 8V2000M84 L 1DDocument3 pagesMTU Marine Spec 8V2000M84 L 1Dkhmiri islemNo ratings yet

- VGF L36Gsi: 620 - 800 BHP (460 - 600 KWB)Document2 pagesVGF L36Gsi: 620 - 800 BHP (460 - 600 KWB)Gabrielito PachacamaNo ratings yet

- TJ805PE5L: 50 HZ Diesel Generator SetsDocument4 pagesTJ805PE5L: 50 HZ Diesel Generator SetsAhsan FazalNo ratings yet

- Waukesha Gas Engines VGF F18Gl: 310 - 440 BHP (230 - 330 KWB)Document2 pagesWaukesha Gas Engines VGF F18Gl: 310 - 440 BHP (230 - 330 KWB)Javier F Pacheco PuentesNo ratings yet

- GE - Engine Type Sheet - Type 4 - EN - 2015 - RZDocument2 pagesGE - Engine Type Sheet - Type 4 - EN - 2015 - RZr.eddie.cookeNo ratings yet

- Vgf18Se: Enginator Generating SystemDocument2 pagesVgf18Se: Enginator Generating SystemJuly E. Maldonado M.No ratings yet

- Iwk 119066 VGF L36GL PDFDocument2 pagesIwk 119066 VGF L36GL PDFAlejandro MuñozNo ratings yet

- C18 625 Kva PrimeDocument3 pagesC18 625 Kva PrimeDedi MaryadiNo ratings yet

- Iwk 119061 VGF p48gldDocument2 pagesIwk 119061 VGF p48gldAwaisMughalNo ratings yet

- VHP 5904 LTDDocument2 pagesVHP 5904 LTDBD MNNo ratings yet

- WaukeshaDocument2 pagesWaukeshacarlos angelNo ratings yet

- Image Shown May Not Reflect Actual Configuration: Metric EnglishDocument3 pagesImage Shown May Not Reflect Actual Configuration: Metric EnglishdinukaeeNo ratings yet

- VHP5904LTDocument2 pagesVHP5904LTm.a.hadiNo ratings yet

- GE - Engine Type Sheet - Type 6 - EN - 2015 - RZDocument2 pagesGE - Engine Type Sheet - Type 6 - EN - 2015 - RZr.eddie.cookeNo ratings yet

- Diesel Engine 8V 2000 M61: MarineDocument2 pagesDiesel Engine 8V 2000 M61: MarinenaufragatoNo ratings yet

- Waukesha VHP L5794gsi Product SheetDocument2 pagesWaukesha VHP L5794gsi Product SheetTayyab IftikharNo ratings yet

- Jms Type 3 Fs SP 2016Document2 pagesJms Type 3 Fs SP 2016Jorge SGNo ratings yet

- Cat cG132: Series Gas Generator SetsDocument8 pagesCat cG132: Series Gas Generator SetsCesário GuimarãesNo ratings yet

- Jenbacher Type 6 Fs en Metric 2016Document2 pagesJenbacher Type 6 Fs en Metric 2016laiquz zamanNo ratings yet

- QST30-G4: Fuel OptimizedDocument3 pagesQST30-G4: Fuel OptimizedJavier DominguezNo ratings yet

- Boletin VGF48GSIDocument2 pagesBoletin VGF48GSIJairo Andres Romero QuirogaNo ratings yet

- L7044GSI: VHP Series FourDocument2 pagesL7044GSI: VHP Series FourAditya SafarudinNo ratings yet

- F3514 GsiDocument2 pagesF3514 Gsikman548No ratings yet

- VHP Series Four F3524Gsi: 560 - 840 BHP (418 - 626 KWB)Document2 pagesVHP Series Four F3524Gsi: 560 - 840 BHP (418 - 626 KWB)Sulistiani ArlimNo ratings yet

- Innio BR t6 Update A4 en 2019 Screen Ijb-119006-EnDocument2 pagesInnio BR t6 Update A4 en 2019 Screen Ijb-119006-EnMahdi DehghankarNo ratings yet

- Jenbacher Type 6: Cutting-Edge TechnologyDocument2 pagesJenbacher Type 6: Cutting-Edge TechnologysxturboNo ratings yet

- WUXI PRS QES 60 400-230V 50Hz EN WuxiDocument6 pagesWUXI PRS QES 60 400-230V 50Hz EN WuxiMohammed DjouadjNo ratings yet

- M701F Series MistsubishiDocument13 pagesM701F Series MistsubishiVuthpalachaitanya KrishnaNo ratings yet

- Waukesha Gas Engines VGF Series Vgf36Gsid: Enginator Generating SystemDocument2 pagesWaukesha Gas Engines VGF Series Vgf36Gsid: Enginator Generating SystemJuly E. Maldonado M.No ratings yet

- Waukesha VHP L5794gsi Product SheetDocument2 pagesWaukesha VHP L5794gsi Product SheetUmair A. KhanNo ratings yet

- 331107C DS C1000S HPNGDocument2 pages331107C DS C1000S HPNGJimmy F HernandezNo ratings yet

- 3516 1280kWDocument3 pages3516 1280kWKaala DNo ratings yet

- TSS DM1909 04 GS Epg 9463839Document3 pagesTSS DM1909 04 GS Epg 9463839mnezamiNo ratings yet

- Siemens Industrial Gas TurbineDocument8 pagesSiemens Industrial Gas TurbineRiza Agung NugrahaNo ratings yet

- TJ66BD5L (400 VAC) TJ66BD5L (400 VAC) : 50 HZ 50 HZ Diesel Generator Sets Diesel Generator SetsDocument4 pagesTJ66BD5L (400 VAC) TJ66BD5L (400 VAC) : 50 HZ 50 HZ Diesel Generator Sets Diesel Generator SetsEurl SODI MEP PLUS ELECTRICALNo ratings yet

- Package Performance: Standby: 60 HZDocument30 pagesPackage Performance: Standby: 60 HZGerman E.No ratings yet

- Image Shown May Not Reflect Actual Configuration: Metric EnglishDocument3 pagesImage Shown May Not Reflect Actual Configuration: Metric EnglishAkilaJosephNo ratings yet

- LDocument2 pagesLmohamed hamedNo ratings yet

- Innio BR t3 Update A4 en 2021 Update NovDocument2 pagesInnio BR t3 Update A4 en 2021 Update NovRogelio PerozoNo ratings yet

- Marine Spec 12V2000M61 1A PDFDocument2 pagesMarine Spec 12V2000M61 1A PDFnaufragatoNo ratings yet

- Weifang Haitai Power Machinery Co.,Ltd: To Be The Best Partner For PowerDocument4 pagesWeifang Haitai Power Machinery Co.,Ltd: To Be The Best Partner For PowerShaina OrnopiaNo ratings yet

- TSS DM8233 01 GS Epg 7335016Document3 pagesTSS DM8233 01 GS Epg 7335016MikaelNo ratings yet

- Apg 680Document7 pagesApg 680Magaly PeraltaNo ratings yet

- (Catalog SOFC) PID000155 - FCE - DFC300 - r1 - HiresDocument2 pages(Catalog SOFC) PID000155 - FCE - DFC300 - r1 - HiresppourmoghaddamNo ratings yet

- TP700TDocument4 pagesTP700Topik maulanaNo ratings yet

- Technical - Info MTU 20V4000L62Document7 pagesTechnical - Info MTU 20V4000L62Marvin Tejerina Garfias100% (1)

- Tj509dw5a enDocument4 pagesTj509dw5a enMohamed SalahNo ratings yet

- Published Journal by J MetDocument14 pagesPublished Journal by J Mettranquanglinhtql0710No ratings yet

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 326431-0151-99Document63 pagesParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 326431-0151-99zoopladoNo ratings yet

- Fuel System A5 B8Document69 pagesFuel System A5 B8ArturoRatierNo ratings yet

- Thảm Họa Lọc Dầu ở Texas 2005Document29 pagesThảm Họa Lọc Dầu ở Texas 2005thanh.nguyenmuc061001No ratings yet

- 2.1 Condensing Unit DSA1321R3-OA Tech SpecsDocument1 page2.1 Condensing Unit DSA1321R3-OA Tech SpecsMicrotech HVACNo ratings yet

- Imploader - Business OverviewDocument7 pagesImploader - Business OverviewElwa SzaboNo ratings yet

- Turbine Auxilaries: Ranjeet Kumar Agrawal Assistant Manager NTPC KorbaDocument72 pagesTurbine Auxilaries: Ranjeet Kumar Agrawal Assistant Manager NTPC KorbaSourav Saha100% (1)

- SPX Power Team Electric Pump Pump Parts SheetDocument18 pagesSPX Power Team Electric Pump Pump Parts SheetGeorge Ciro MarconiNo ratings yet

- Moulded Case Circuit Breakers: User Centric InnovationDocument14 pagesMoulded Case Circuit Breakers: User Centric InnovationCREATIVE ELECTRICALSNo ratings yet

- RAC MCQ Set 1Document58 pagesRAC MCQ Set 1aditya NirmalNo ratings yet

- IH process-SOPDocument2 pagesIH process-SOPSelvakumar MNo ratings yet

- Questions - HEATTRANSFER - PROCESSING (2022)Document196 pagesQuestions - HEATTRANSFER - PROCESSING (2022)Jake BalilaNo ratings yet

- EcoTherm BrochureDocument20 pagesEcoTherm BrochureRoberto TyNo ratings yet

- Fe C.PDocument29 pagesFe C.PTomiwa FaithNo ratings yet

- The Death of Karen Silkwood: Joyce HannamDocument4 pagesThe Death of Karen Silkwood: Joyce HannamSample Tom100% (1)

- Four-Wire Feeder Schedule Feeder Wire Ground Conduit 208V Max. 480V Max. Name Size Wire Size Size Length LengthDocument4 pagesFour-Wire Feeder Schedule Feeder Wire Ground Conduit 208V Max. 480V Max. Name Size Wire Size Size Length Lengthabhiknit100% (1)

- Pollution Under Control Certificate: Form 59Document1 pagePollution Under Control Certificate: Form 59vijay.princeverma786No ratings yet

- EC3-X33 Superheat ControllerDocument1 pageEC3-X33 Superheat Controllerron68xNo ratings yet

- Balancing Infrastructure Development and Community LivelihoodsDocument52 pagesBalancing Infrastructure Development and Community LivelihoodsBigBlue SpotNo ratings yet

- 9 U9 OXRVW7 PHxyahef X5 QT I8 ZDBM 6Document17 pages9 U9 OXRVW7 PHxyahef X5 QT I8 ZDBM 6Karan ChadhaNo ratings yet

- FPT Hoa Lac - EngReport V1Document30 pagesFPT Hoa Lac - EngReport V1Nguyên Trịnh CaoNo ratings yet

- Owners Manual MFL69168201Document20 pagesOwners Manual MFL69168201Clarissee VidalNo ratings yet

- 10W To 1200W COMPACT HV Power Source: Spellman High Voltage Electronics CorporationDocument5 pages10W To 1200W COMPACT HV Power Source: Spellman High Voltage Electronics CorporationGopichand GaddamNo ratings yet

- Shindo B SeriesDocument42 pagesShindo B SeriesnazirulNo ratings yet

- BOQ Kopel Dumai SipilDocument5 pagesBOQ Kopel Dumai SipilFahrizal Tri PrasetyoNo ratings yet

- Discussion TextDocument3 pagesDiscussion TextRefo NandaNo ratings yet

- Best Practice For Consigning Lithium Cells / Batteries in Hong KongDocument8 pagesBest Practice For Consigning Lithium Cells / Batteries in Hong KongPhilip LoNo ratings yet

- b2 First Word Formation 2Document3 pagesb2 First Word Formation 2Sentido Común Alternativo SCANo ratings yet

- Instructions - Sun 12 16k sg01lp1 Eu - 240203 - enDocument48 pagesInstructions - Sun 12 16k sg01lp1 Eu - 240203 - enf789sgacanonNo ratings yet

- Target Submission PPN 12 Jan 2024Document5 pagesTarget Submission PPN 12 Jan 2024faridferdiansyahNo ratings yet