Professional Documents

Culture Documents

Us 6210466

Uploaded by

Михаил ПолковниковCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us 6210466

Uploaded by

Михаил ПолковниковCopyright:

Available Formats

USOO6210466B1

(12) United States Patent (10) Patent No.: US 6,210,466 B1

Whysall et al. (45) Date of Patent: Apr. 3, 2001

(54) VERY LARGE-SCALE PRESSURE SWING 4,650,501 3/1987 Hiscock et al. ........................ 95/100

ADSORPTION PROCESSES 4,834,780 5/1989 Benkmann ............................... 95/98

4.913,709 * 4/1990 Kumar ......... ... 9.5/100

(75) Inventors: Michael Whysall, Chicago, IL (US); SE : 13.E.

2 - 2 :

s st al

aWS C a

99.

-- -

'deityan Marie Wagemans, 5,203,888 4/1993 Maurer ................................... 95/101

oersel (BE) 5,258,059 * 11/1993 Yamaguchi et al. ................... 95/100

5,354,346 * 10/1994 Kumar ............. ... 9.5/101

(73) Assignee: UOP LLC, Des Plaines, IL (US) 5,547,492 * 8/1996 Cho et al. . ... 9.5/100

- 0 6,045,603 4/2000 Chen et al. ........................ 95/100 X

(*) Notice: Subject to any disclaimer, the term of this sk -

patent is extended or adjusted under 35 cited by examiner

U.S.C. 154(b) by 0 days. Primary Examiner Robert H. Spitzer

(74) Attorney, Agent, or Firm John G. Tolomei, Richard P.

(21) Appl. No.: 09/371,654 Silverman

(22) Filed: Aug. 10, 1999 (57) ABSTRACT

(51) Int. Cl." ............................................... B01D 53/047 According to the present invention, a proceSS is provided

(52) U.S. Cl. ................................. 95/100; 95/103; 95/105; which Overcomes historical limitations to the capacity of

95/130; 95/136; 95/137; 95/139; 95/140; PSA units for a wide variety of gas Separations. Capacities

95/143 in exceSS of about 110 thousand normal cubic meters per

(58) Field of Search ......................... 95/96-98, 100-105, hour (100 million standard cubic feet per day) can now be

95/130, 136, 137, 139, 140, 143 achieved in a single integrated process train. The corre

sponding Significant equipment reduction results from a

(56) References Cited departure from the accepted principle in the PSA arts that the

length of the purge Step must be equal to or less than the

U.S. PATENT DOCUMENTS length of the adsorption Step. Applicants have discovered

3,176,444 4/1965 Kiyonaga ................................. ss 26 that by increasing the purge time relative to the adsorption

3,430,418 3/1969 Wagner ...... 55/25 step combined with Supplying the purge gas for any adsorp

3,564,816 * 2/1971 Batta ...... ... 9.5/100 tion bed in the train from one or more other adsorption beds

3,636,679 1/1972 Batta ...................................... 95/100 and during the provide-purge Step, the other adsorption beds

3,703,068 11/1972 Wagner ...... ... 55/21 Simultaneously provide the purge gas to essentially all

3,738,087 * 6/1973 McCombs ...... ... 95/98 adsorption beds undergoing the purge Step, that the Single

3,986,849 10/1976 Fuderer et al. ............ 55/25 train can provide for Significant increases in capacity with a

2.92. : Es S. al. ... SR& minimum loSS in recovery or performance. The benefit of

4234.322 * 11/1980 De Meyer et al. .95/98 X this discovery is that very large-scale PSA units can now be

4,402.712 9/1983 Benkmann ............................... 95/98 constructed as a Single train of equipment for a cost signifi

4,468,237 * 8/1984 Fuderer ...... ... 9.5/100 cantly lower than the cost of two or more parallel trains of

4,512,780 4/1985 Fuderer .................................. 95/100 equipment.

4,589,888 5/1986 Hiscock et al. ........................ 95/100

4,650,500 3/1987 Patel ....................................... 95/100 15 Claims, 3 Drawing Sheets

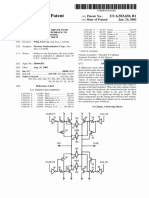

1 ASORPTON EE2E3, E4 PP DuMP PURGE E4 t Ezeir

2 E1RP ASORTION 1234 p. | DUMP Purg E4Es E2

3 E2E1RP ASORPTION 1234 PP UMP Purg E4

4 pullesleslezler ASORPTN 234 PP UMP URGE

s PURGE E4 E3E2E1 RP ASORPTON E1 E2 E34 PP UMP PURGE

6 PURG E4E3 E2ERP ADSORPTION E1234 PP UMP Purs

7 PURG E4E3E2 ERP A SORPTON EE234 PP P PURG

8 PURG 4321|RP AsORPTON EE234 PP UNPPU

9 PURG E4E3EE2ER ASRPON EE2E3E4 PP IDU

o PPUMP PURG E4E3E2ERP ASORPION E1234 PP

1. PP UMP PURGE 432 err ASRPTON 1234

12 3a PP oup PURGE eas 21RP Absorption 12

3 1234 PP oup PURs 4.32 ADSORON

4 AS E23.4 PP DuMP Purg E4 Ese2E1 RP ASORPTION

1s ASORPTIONEEE2E34; PP DuMP URGE E4E3 2RPAbsorption

1s Absorption 234 PP DuMP PURG E4 E3 E2 Ere AoS

U.S. Patent Apr. 3, 2001 Sheet 1 of 3 US 6,210,466 B1

U.S. Patent Apr. 3, 2001 Sheet 2 of 3 US 6,210,466 B1

U.S. Patent Apr. 3, 2001 Sheet 3 of 3 US 6,210,466 B1

US 6,210,466 B1

1 2

VERY LARGE-SCALE PRESSURE SWING range from traces to greater than 95 mole percent. PSA

ADSORPTION PROCESSES Systems are preferred when high concentrations of valuable

feedstock, products, or reusable Solvents are to be recovered.

FIELD OF THE INVENTION A PSA cycle is one in which the desorption takes place at a

The present invention relates to processes for the Separa preSSure much lower than adsorption. In Some applications,

tion of gases using pressure Swing adsorption (PSA). More the desorption takes place under vacuum conditions

particularly, the present invention relates to the use of a vacuum Swing adsorption (VSA). To overcome the inherent

particular combination of PSA Steps in a particular manner low operating loadings on the weak adsorbent, PSA cycles

to significantly expand the capacity of the Separation pro generally have cycle times that are short-on the order of

CCSS. Seconds to minutes-to maintain reasonably sized adsorbent

beds.

BACKGROUND OF THE INVENTION One of the problems of building modern gas processing

PSA provides an efficient and economical means for facilities is that the size of the facility or the amount of gas

Separating a multi-component gas Stream containing at least to be treated in any one facility is continuing to increase.

two gases having different adsorption characteristics. The

15 Capacities of modern gas processing complexes are gener

more Strongly adsorbable gas can be an impurity which is ally greater than about 110 thousand normal cubic meters

removed from the leSS Strongly adsorbable gas which is per hour (100 million standard cubic feet per day). Most

PSA vessels are limited to a diameter which can be trans

taken off as product or the more Strongly adsorbable gas can ported to a construction site which generally limits the

be the desired product which is separated from the leSS vessels to a diameter of about 4 meters (about 13 feet) and

Strongly adsorbable gas. For example, it may be desired to the height of the vessel is limited by the crush strength of the

remove carbon monoxide and light hydrocarbons from a adsorbent particle. For capacities greater than about 110

hydrogen-containing feed stream to produce a purified (99 thousand normal cubic meters per hour (100 million stan

percent) hydrogen Stream for a hydrocracking or other dard cubic feet per day), PSA processes are provided in

catalytic process where these impurities could adversely 25 multiple trains of duplicate equipment Such as pumps,

affect the catalyst or the reaction. On the other hand, it may heaters, lines, Valves, Vessels, and compressors.

be desired to recover more Strongly adsorbable gases, Such

as ethylene, from a feedstream to produce an ethylene-rich It is an objective of the present invention to provide a PSA

product. process for very large gas processing units in a single train

In PSA, a multi-component gas is typically fed to at least of equipment.

one of a plurality of adsorption Zones at an elevated pressure It is an objective of the present invention to provide a

effective to adsorb at least one component, while at least one process Sequence which overcomes the physical limitations

other component passes through. At a defined time, the of vessel size and adsorbent Strength to permit the proceSS

feedstream to the adsorber is terminated and the adsorption ing of large amounts of feed without giving up overall

Zone is depressurized by one or more countercurrent depres 35 performance of large-scale gas Separation Systems.

Surization StepS wherein pressure is reduced to a defined SUMMARY OF THE INVENTION

level which permits the Separated, less Strongly adsorbed

component or components remaining in the adsorption Zone According to the present invention, a proceSS is provided

to be drawn off without significant concentration of the more which overcomes historical limitations to the capacity of

Strongly adsorbed components. Then, the adsorption Zone is 40 PSA units for a wide variety of gas Separations. Capacities

depressurized by a countercurrent depressurization Step in exceSS of about 110 thousand normal cubic meters per

wherein the preSSure on the adsorption Zone is further hour (100 million standard cubic feet per day) can now be

reduced by withdrawing desorbed gas countercurrently to achieved in a single integrated process train. This equipment

the direction of the feedstream. Finally, the adsorption Zone reduction is enabled by a departure from the accepted

is purged with the effluent from an adsorption bed under 45 principle in the PSA arts that the length of the purge Step

going a countercurrent depressurization Step and repressur must be equal to or less than the length of the adsorption

ized. The final Stage of repressurization is typically with Step. Applicants have discovered that increasing the purge

product gas and is often referred to as product repressuriza time relative to the adsorption Step can provide for Signifi

tion. In multi-Zone Systems, there are typically additional cant increases in capacity with a minimum loSS in recovery

StepS and those noted above may be done in Stages. U.S. Pat. 50 or performance. The benefit of this discovery is that very

No. 3,176.444 (Kiyonaga), U.S. Pat. No. 3,986,849 (Fuderer large-scale PSA units can now be constructed for a cost

et al.) and U.S. Pat. Nos. 3,430,418 and 3,703,068 (both Significantly lower than the cost of a Second parallel train of

issued to Wagner), among others, describe multi-Zone, adia equipment.

batic PSA Systems employing both countercurrent and coun In one embodiment, the present invention is a process for

tercurrent depressurization and the disclosures of these 55 the Separation of a non-adsorbable gas from a gas mixture

patents are incorporated by reference in their entireties. The comprising the non-adsorbable gas and an adsorbable gas in

above-mentioned patents to Fuderer et al. and Wagner are a single train PSA Zone. The process comprises passing the

herein incorporated by reference. gas mixture to the Single train PSA Zone and withdrawing a

Various classes of adsorbents are known to be suitable for product gas Stream comprising the non-adsorbable gas and

use in PSA systems, the selection of which is dependent 60 a waste gas Stream comprising the adsorbable gas. The

upon the feedstream components and other factors generally Single train PSA Zone has a plurality of adsorption beds

known to those skilled in the art. In general, Suitable wherein each adsorption bed employs an adsorption Step, at

adsorbents include molecular Sieves, Silica gel, activated least three countercurrent equalization Steps including a final

carbon, and activated alumina. For Some Separations, Spe countercurrent equalization Step, a provide-purge Step, a

cialized adsorbents can be advantageous. PSA generally 65 countercurrent blow down Step, a purge Step, at least three

employs weak adsorbents and is used for Separations countercurrent equalization Steps including a final counter

wherein the amount of the component to be separated can current equalization Step and a repressurization Step. Each of

US 6,210,466 B1

3 4

the proceSS Steps occurs in a Sequential manner and are offset Step or undergoing a countercurrent equalization Step. The

in time Such that the adsorption Step occurs over an adsorp first adsorption bed is countercurrently repressurized by

tion Step time, the provide-purge Step occurs over a provide equalizing the pressure in the first adsorption bed with other

purge Step time and a purge Step occurs Over a purge Step adsorption beds wherein each of the other adsorption beds

time. The purge Step time is greater than the adsorption Step have a sequentially higher equalization pressure and this

time, wherein the purge Step comprises a step wherein the countercurrent repressurization Step is repeated at least three

adsorption bed which is undergoing a purge Step is receiving times. The first adsorption bed is a countercurrently repres

a purge gas from one or more other adsorption beds which surized bed with a portion of the adsorption effluent stream

are undergoing the provide-purge Step and wherein these and the above proceSS Steps are repeated to provide a

other adsorption beds are simultaneously providing the 1O continuous process.

purge gas to the adsorption bed undergoing the purge Step.

At any time, the number of adsorption beds undergoing the BRIEF DESCRIPTION OF THE DRAWINGS

adsorption Step is exceeded by the number of adsorption FIG. 1 is a simplified cycle chart illustrating a conven

beds undergoing the purge Step. tional 16-bed PSA separation system of the prior art.

In another embodiment, the present invention is a proceSS 15

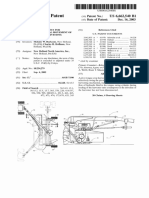

FIG. 2 is a simplified cycle chart illustrating the novel

for the Separation of hydrogen from a gas mixture compris PSA cycle for a 16-bed system of the present invention.

ing hydrogen, carbon dioxide, and nitrogen in a multiple

adsorption bed PSA Zone in a single adsorption train. The FIG. 3 is a simplified cycle chart illustrating a variation of

proceSS comprises passing the gas mixture to the multiple the novel PSA cycle for a 16-bed system of the present

adsorption bed PSA Zone and withdrawing a hydrogen invention.

product and a waste gas Stream. The multiple adsorption bed DETAILED DESCRIPTION OF THE

PSA Zone has a plurality of adsorption beds wherein in each INVENTION

adsorption bed the following Steps are employed: an adsorp

tion Step, at least three countercurrent equalization Steps, a The feed to the process of the current invention can

provide-purge Step, a countercurrent blow down Step, a 25 include hydrogen, carbon monoxide, carbon dioxide,

purge Step, at least three countercurrent equalization Steps, nitrogen, inert gases, and hydrocarbons. The process of the

and a repressurization Step. Each of the Steps occurs in a current invention can be used to Separate hydrogen from

Sequential manner and is offset in time. The adsorption Step adsorbable compounds Such as carbon monoxide, carbon

occurs over an adsorption Step time, the provide-purge Step dioxide, nitrogen, and hydrocarbons or the process can be

occurs over a provide-purge Step time and a purge Step used to Separate methane from leSS adsorbable compounds

occurs over a purge Step time. The purge Step time is greater including carbon dioxide, Sulfur oxides, hydrogen Sulfide,

than the adsorption Step time, wherein the purge Step com heavier hydrocarbons, and mixtures thereof. By the term

prises the adsorption bed undergoing a purge Step receiving “hydrocarbons', it is meant hydrocarbons having from 1 to

a purge gas from one or more other adsorption beds during 8 carbon atoms per molecule including, alkanes, alkenes,

a provide-purge Step and wherein these other adsorption 35 cycloalkenes, and aromatic hydrocarbons Such as benzene.

beds are Simultaneously providing the purge gas to essen By the term “a single train of equipment”, it is meant a

tially all adsorption beds undergoing the purge Step. At any Succession of process equipment including pumps, heaters,

time the number of adsorption beds undergoing the adsorp vessels, valves, lines, and compressors which are assembled

tion Step is exceeded by the number of adsorption beds to perform a specific task Such as gas Separation which does

undergoing the purge Step. 40 not contain a complete duplication of equipment. A Single

In a Still further embodiment, the present invention is a train is contrasted with a multiple train proceSS which

proceSS for the Separation of a non-adsorbable gas from a gas comprises a Series of parallel, identical Successions of Such

mixture comprising the non-adsorbable gas and an adsorb process equipment assembled to perform a single task.

able gas in a multiple adsorption bed PSA Zone. The proceSS Generally, multiple trains of process equipment are

comprises the following Steps. The gas mixture at an adsorp 45 employed when Some physical limit of one or more com

tion preSSure is passed to a first adsorption bed of a plurality ponents of the Succession of a Single train of proceSS

of adsorption beds in the PSA Zone. Each of the adsorption equipment has been exceeded.

beds contains an adsorbent Selective for the adsorption of the In accordance with the present invention, the adsorption

adsorbable gas in an adsorption Step over an adsorption Step pressure is generally from about 350 kPa to about 7 MPa (50

time and an adsorption effluent Stream is recovered there 50 to 1000 psia) and preferably from about 700 kPa to about 3.5

from. The first adsorption Zone is countercurrently depres MPa (100 to 510 psia). The desorption pressure is preferably

Surizing in equalization Steps with other adsorption beds from about 3 to 550 kPa (0.5 to 80 psia) and more preferably

wherein each of the other adsorption beds have a Sequen the desorption pressure ranges from about 3 to about 210

tially lower equalization pressure. The countercurrent kPa (0.5 to 30 psia). Suitable operating temperatures are

depressurization Step is repeated at least three times to reach 55 generally within the range of from about 10 to 65° C. (50°

a last equalization Step. The first adsorption bed is further to 150 F). There can be a variety of countercurrent depres

countercurrently depressurized to provide a desorption efflu Surization Steps to intermediate pressures, countercurrent

ent Stream in a provide-purge Step over a provide-purge time purging Steps, and countercurrent purging Steps, all of which

and Simultaneously the desorption effluent Stream is passed are well known to those skilled in the art and described in the

to at least two other adsorption beds which are undergoing 60 previously cited patents relating to PSA processes. For

the purge Step. The first adsorption bed is countercurrently example, one to five or more of Such countercurrent depres

depressurized to a blow down pressure and a waste Stream Surization StepS can be employed for pressure equalization to

is recovered at a desorption pressure. The first adsorption further improve product recovery Such as disclosed in the

bed is purged with a purge Stream for a purge Step time above-identified U.S. Pat. No. 3,986,849 (Fuderer et al.).

wherein the purge Step time is greater than the adsorption 65 Other details of the PSA process are described in U.S. Pat.

Step time. The purge Stream is passed from one or more No. 3,986,849 (Fuderer et al.), the four adsorption Zone

adsorption beds undergoing a countercurrent provide-purge systems described in U.S. Pat. No. 3,430,418 (Wagner) and

US 6,210,466 B1

S 6

U.S. Pat. No. 3,564,816 (Batta), the three adsorption Zone bed. That is, the number of adsorption beds providing purge

systems described in U.S. Pat. No. 3,636,679 (Batta) and the and the number of adsorption beds receiving purge gas, or

two adsorption Zone systems described in U.S. Pat. No. undergoing the purge Step, are the same. For any adsorbent

3,738,087 (McCombs), the disclosures of which are hereby bed in the cycle, the time for the purge Step, or purge Step

incorporated by reference time, is equal to the time for the provide-purge Step, or

The PSA process of the present invention is of the general provide-purge time. In addition, the time over which the

PSA type. The feedstream is introduced to an adsorbent bed adsorption Step occurs, or the adsorption Step time, is longer

undergoing adsorption at the highest pressure, or the adsorp than either the provide-purge Step or the purge Step.

tion pressure, to an inlet end of an adsorbent bed having the Referring to FIG. 2, a process cycle representative of the

inlet end and a discharge end opposite. present invention is illustrated for 16 adsorbent beds oper

ating in a single train. The cycle depicted in FIG. 2 contains

The adsorbent may comprise powdered Solid, crystalline the same steps as shown in FIG. 1 but differs in that there are

compounds capable of adsorbing and desorbing the adsorb only four adsorption Steps, five purge Steps and purge gas is

able compound. Examples of Such adsorbents include Silica Supplied to more than one adsorption bed at any time in the

gels, activated aluminas, activated carbon, molecular Sieves, 15

cycle. Furthermore, the purge time is significantly longer

and mixtures thereof. Molecular sieves include Zeolite than the adsorption time for any bed in the cycle. Referring

molecular Sieves. The preferred adsorbents are Zeolites. to FIG. 2, following the adsorption step, adsorption bed 1

U.S. Pat. No. 3,986,849 (Fuderer et al.) describes various undergoes four countercurrent depressurization or equaliza

cycles using for example an adsorption time of 240 Seconds tion Steps. During the first equalization Step, adsorption bed

in a 10-adsorbent bed configuration with a total cycle time 1 is countercurrently linked with adsorption bed 6. During

of 13 minutes, 20 seconds. By increasing the number of the next equalization Step, adsorption bed 1 is linked to

adsorption bed 7. During the third equalization Step, adsorp

beds, the total adsorption time can be reduced. For example, tion bed 1 is linked to adsorption bed 8 and during the last

for the same adsorption time of 240 seconds in a 10 or fourth equalization Step, adsorption bed 1 is linked to

12-adsorbent bed configuration, the total cycle time may be adsorption bed 9. Adsorption bed 1 then undergoes a

reduced to 12 minutes. When the same adsorbent volume is 25 provide-purge Step wherein the adsorption bed is

used for the 10- and the 12-adsorbent bed configurations and co-currently depressurized and a purge gas is withdrawn

provided the same relative adsorbent inventory per unit from adsorption bed 1 and passed to adsorption beds 10, 11,

Volume of feed is required, this would result in an increased 12, 13, and 14 to provide purge gas for purging essentially

product capacity of about 33 percent. Similarly, for the same all of those beds during a first portion of the provide-purge

adsorption time of 240 seconds in a 14-adsorbent bed Step. In this example, at the same time, adsorption bed 16 is

configuration, the total cycle time would be reduced to 11 also undergoing countercurrent depressurization and provid

minutes, 12 Seconds and an increase in product capacity ing a purge gas to adsorption beds 10, 11, 12, 13, and 14. In

relative to the 10-adsorbent bed configuration of 66 percent. the next portion of the provide-purge Step, purge gas is

The same analysis can be applied to configurations with any provided to adsorption beds 11, 12, 13, 14, and 15 and in the

number of adsorbers, odd or even. In general, holding the 35 final Segment of the provide-purge Step, purge gas is Sup

adsorption time constant reduces the total cycle time and plied to beds 11, 12, 13, 14, and 15. At the same time,

increases the capacity. AS more adsorbent beds are operating adsorption bed 2 is also undergoing countercurrent depres

on the adsorption Step which corresponds to higher feed Surization and providing a purge gas to the same adsorption

rates, the Sub-cycle time, defined as the total cycle time beds 11, 12, 13, 14, and 15. The countercurrent blow down

divided by the number of adsorbent beds, decreases which 40 Step follows the provide-purge Step. In the countercurrent

has the effect of reducing the time available for the other blow down Step, the adsorption bed is depressurized coun

Steps in the cycle. Contrary to previous art, it has been found tercurrently to release a waste gas Stream. The first adsorp

that reducing the time for receiving purge has a more tion bed is then purged countercurrently with purge gas

Significant impact in reducing the recovery of the unad initially from adsorption bed 3, then adsorption beds 3 and

Sorbed product effluent and also increasing the relative 45 4, then adsorption bed 4, then adsorption beds 4 and 5, then

Volume of adsorbent required, compared to reducing the adsorption bed 5, then adsorption beds 5 and 6, then adsorp

time for the adsorption Step. Also, all of the previously tion bed 6, then adsorption beds 6 and 7, then adsorption bed

described cycles have a lower number of adsorbent beds on 7, and finally from adsorption beds 7 and 8. During the

the purge Step than on the adsorption Step. With the excep initial phase of the countercurrent purge of adsorption bed 1,

tion of PSA cycles which employ external tanks, all of the 50 adsorption bed 2 is undergoing countercurrent blow down to

prior art PSA processes require the Same number of adsor waste pressure. Adsorption bed 3 is undergoing a counter

bent beds on the provide-purge Step as on the receiving current provide-purge Step, adsorption bed 4 is undergoing

purge Step, or purge Step. the fourth co-current equalization Step with adsorption bed

The process of the present invention will hereinafter be 12, adsorption bed 5 is undergoing the Second countercur

described with reference to the Figures. 55 rent equalization Step with adsorption bed 11, adsorption

Referring to FIG. 1, a process cycle representation is beds 6, 7, 8, and 9 are on the adsorption step, adsorption bed

presented for a conventional PSA system with 16 adsorbent 10 is undergoing final repressurization, adsorption bed 11 is

beds. The cycle for each adsorbent bed consists of an undergoing Second countercurrent equalization with adsorp

adsorption Step, four countercurrent depressurization Steps, tion bed 5, adsorption bed 12 is undergoing countercurrent

a coutercurrent provide-purge Step, a countercurrent blow 60 equalization with adsorption bed 11, and adsorption beds 13,

down Step, a purge Step, four countercurrent repressurization 14, 15, and 16 are also undergoing countercurrent purge. In

Steps, and a final repressurization Step. Within this conven this manner, purge gas is Supplied from one or more adsorp

tional 16-bed cycle at any time, six adsorbent beds are tion beds to at least two other beds undergoing a purge Step.

operating in an adsorption Step, three adsorbent beds are At the end of the last equalization Step, adsorption bed 1 is

operating in a purge Step and three adsorbent beds are 65 repressurized with the adsorption pressure. Repressurization

operating in a provide-purge Step. The purge gas for any can be accomplished by reintroducing feed or by counter

adsorption bed is directly provided from another adsorption currently introducing a portion of the product Stream.

US 6,210,466 B1

7 8

Referring to FIG. 3, a process cycle of the present 31.3 percent of the total cycle, and the repressurization Steps

invention in an alternative embodiment for a 16-bed cycle is remain at 15.6 percent of the cycle. Although there is leSS

represented. In the 16-bed cycle in FIG. 3, there are four than about a 0.1 percent reduction in the recovery of the

adsorption StepS and six purge Steps. In this configuration, unadsorbed product effluent, there is no increase in the

the countercurrent provide purge is taken for part of the Step requirement for the relative Volume of adsorbent per Volume

Simultaneously with the last countercurrent equalization and of feed and the total cycle time is reduced, translating into

for part of the Step separately. The countercurrent provide

purge is taken from one adsorption bed and is passed to Six an overall increase in the capacity. A further advantage of

adsorption beds Simultaneously. this type of cycle is that there are more adsorbers on the

The following examples are provided for illustrative countercurrent depressurization Step and purge Step, these

purposes and are not intended to limit the Scope of the claims StepS are discharging gas to the low pressure, and the

that follow. composition leaving the adsorber varies with time. Having

more adsorbers on the Step provides for much improved

EXAMPLES mixing of these gases before the mixing (or Surge) drum.

15

Example I This can significantly reduce the Volume required for mixing

and hence the cost of this drum as well as providing for

Table 1 illustrates a conventional PSA cycle according to much better control of the low pressure gas.

U.S. Pat. No. 3,986,849 (Fuderer et al.) for a cycle employ

ing 12 adsorption beds. In the conventional cycle, the TABLE 2

adsorption Step time and the depressurization Step time are

equal and each represents approximately one-third of the Distribution of New PSA Process Steps. 72

total cycle time. Receiving purge gas represents 13 percent Process Step 16-Bed Cycle

of the cycle and repressurization represents approximately

21 percent of the total cycle. Similarly, for a conventional Adsorption 25.0

25 Depressurization 28.1

16-bed cycle of the prior art as shown in FIG. 1, the Receive Purge 31.3

distribution of the steps within the cycle are shown in Table Repressurization 15.6

1 in the 16-bed cycle. Adsorption time now accounts for

approximately 37.5 percent of the cycle, depressurization Total Cycle 1OO.O

amounts to about 31.3 percent of the total cycle, receiving

purge gas amounts to about 15.6 percent of the cycle, and

repressurization amounts to about 15.6 percent of the cycle. Example III

At high feed rates, the volume of the adsorbent bed reaches

the maximum practical size beyond which it is necessary to A pilot plant was used for the evaluation of the effect of

reduce the adsorption time and correspondingly the total

cycle time. This has the desirable effect of reducing the 35 changing the purge time relative to the adsorption time in

specific adsorbent inventory but has the undesirable effect of PSA cycles. The pilot plant consisted of a single adsorbent

reducing the time for receiving purge. Reducing the receiv chamber containing about 340 cc of adsorbent along with

ing purge time significantly reduces the recovery of the the ancillary vessels, valves, and connecting piping required

unadsorbed product effluent and increases the relative Vol 40 to simulate multi-bed PSA cycles. The feed included about

ume of adsorbent required per volume of feed. Thus, the 72.5 mole percent hydrogen, 0.67 mole percent nitrogen,

expected increase in product capacity is not reached and in 2.04 mole percent carbon monoxide, 5.57 mole percent

fact it is doubly penalized. The recovery of the unadsorbed methane, and about 19.2 mole percent carbon dioxide. The

product effluent is reduced and relative volume of adsorbent adsorbent comprised activated carbon and a Zeolite molecu

required per Volume of feed is increased. 45 lar Sieve to produce a product hydrogen which comprised

TABLE 1. less than about 1 ppm carbon monoxide and about 1 ppm

methane. The chamber was operated in a cyclic adsorption

Distribution of PSA Process Steps, 72 and desorption Sequence over a range of operating pressures

Process Step 12-Bed Cycle 16-Bed Cycle

from about 2200 kPa (320 psia) to about 160 kPa (23 psia).

50 The purge pressure was about 160 kPa (23 psia), the last

Adsorption 33.O 37.5 equalization pressure was about 614 kPa (89 psia), and the

Depressurization 33.O 31.3 provide-purge pressure was about 255 kPa (37 psia). The

Receive Purge 13.0 15.6

Repressurization 21.0 15.6 bed was repressurized with product gas at a product preSSure

55

of about 2140 kPa (310 psia). The feed temperature was

Total Cycle 1OO.O 1OO.O maintained at the ambient temperature which averaged

about 21° C. (70 F). The temperature of the adsorbent

chamber was essentially the same as the feed temperature or

Example II within about 6 C. of the feed temperature with surprisingly

Table 2 illustrates a PSA cycle of the present invention for 60 little variation during the adsorption time in the cycle. The

a 16-bed cycle as shown in FIG. 2. According to the present PSA cycle time employed for the field tests comprised an

invention, the time on the receiving purge Step is increased adsorption time which ranged from about 90 seconds to

and the provide-purge Step is de-coupled from the receive about 180 seconds. The equalization time and the blow

purge Step. The adsorption Step now amounts to approxi down step times were about 30 seconds and the provide

mately 25 percent of the total cycle, the depressurization 65 purge Step time was about 60 Seconds. The performance in

StepS amount to approximately 28.1 percent of the total terms of hydrogen recovery and capacity in terms of feed per

cycle, the receive purge Steps account for approximately cycle was measured as shown in Table 3.

US 6,210,466 B1

9 10

rality of adsorption beds employing in each adsorption bed

TABLE 3 an adsorption Step, at least three cocurrent equalization Steps

including a final cocurrent equalization Step, a provide

PSA Performance

purge Step, a countercurrent blow down Step, a purge Step,

Adsorption Time, seconds 18O 18O 90 at least three countercurrent equalization Steps including a

final countercurrent equalization Step and a repressurization

Purge Time, seconds

H. Recovery, 76

90

87.4

45

85.9

90

87.2

Step, each of Said Steps occurring in a Sequential manner and

Capacity 1OO 91 1OO offset in time wherein the adsorption Step occurs over an

adsorption Step time, the provide-purge Step occurs over a

provide-purge Step time and a purge Step occurs Over a purge

These results clearly Show that reducing the adsorption Step time, the purge Step time being greater than the adsorp

step time by a ratio of about 2 (from 180 seconds to 90 tion Step time and wherein Said purge Step comprises the

Seconds) results in a change in the hydrogen recovery of adsorption bed undergoing a purge Step receiving a purge

about 0.2 percent while a change in the purge Step time by gas from one or more other adsorption beds undergoing the

a similar ratio (from 90 to 45 seconds) results in a change in 15 provide-purge Step wherein Said other adsorption beds are

hydrogen recovery of about 1.5 percent. Thus, the effect of Simultaneously providing the purge gas to the adsorption

reducing the purge Step time is 8 to 10 times more significant bed undergoing the purge Step and wherein at any time the

than reducing the adsorption Step time. In a PSA process, the number of adsorption beds undergoing the adsorption Step is

total cycle time has a direct relationship to the cost of the exceeded by the number of adsorption beds undergoing the

equipment. The Shorter the total cycle time, the lower the purge Step.

cost. AS Supported by the above results, the total cycle time 2. The process of claim 1 wherein a ratio of the purge Step

can be shortened with minimal effect on the overall recovery time to the adsorption Step time comprises greater than about

by increasing the purge Step time relative to the adsorption 1.0 and less than about 2.0.

Step time. 3. The process of claim 1 wherein the gas mixture is

25 passed to the Single train pressure Swing adsorption Zone at

Example IV a feed rate greater than about 110 thousand normal cubic

The pilot plant and procedure described in Example III meters per hour (100 million standard cubic feet per day).

was used to evaluate the effect on product recovery and 4. The process of claim 1 wherein the Single train pressure

cycle time for reducing the adsorption Step time relative to Swing adsorption Zone comprises from about 10 to about 20

the provide-purge Step time. Table 4 Summarizes the results adsorption beds.

for a hydrogen feed containing about 99 mole percent 5. The process of claim 1 wherein the Single train pressure

hydrogen and 1 mole percent carbon monoxide. The adsor Swing adsorption Zone comprises a Single train of at least

bent employed for the separation was a molecular sieve of about 10 adsorption beds.

the 5A type and the adsorption took place at about 21 C. 6. The process of claim 1 wherein the Single train pressure

(70 F). The PSA process comprised three equalization 35 Swing adsorption Zone comprises a single train of about 16

StepS. adsorption beds, wherein the proceSS comprises at least four

adsorption Steps, at least five purge Steps, and the purge Step

TABLE 4 time exceeds the adsorption Step time by a ratio of about

1.25 times the adsorption Step time.

PSA Performance 40 7. The process of claim 1 wherein the purge Step time

Adsorption Time, seconds 18O 60 exceeds the adsorption Step time by a ratio of between about

1.25 and about 1.50 times the adsorption step time.

Purge Time, seconds

H. Recovery, 76

90

89.4

90

89.2

8. The process of claim 1 wherein a portion of the purge

Capacity 1OO 96

gas is provided by an adsorption bed undergoing the final

45 cocurrent equalization Step.

9. The process of claim 1 wherein the provide-purge Step

The first column in Table 4 shows the hydrogen recovery occurs over the provide-purge Step time and the provide

for a 180-second adsorption step time in a conventional PSA purge time is less than the purge time, Said provide-purge

cycle with a 12-minute total cycle time wherein the ratio of step time comprising between about 0.15 and about 0.4

the purge Step time to the adsorption Step time was about 0.5. 50 times the purge Step time.

In the Second column, the results of a cycle of the present 10. The process of claim 1 wherein the non-adsorbable

invention are shown wherein the ratio of the purge Step time component comprises hydrogen and the adsorbable compo

to the adsorption Step time is increased to about 1.5 and the nent is Selected from the group consisting of hydrocarbons,

total cycle time is reduced to 10 minutes. The results of carbon dioxide, carbon monoxide, nitrogen, and mixtures

Example IV show that for a 20 percent decrease in the cycle 55 thereof.

time by decreasing the adsorption Step time relative to the 11. The process of claim 1 wherein the non-adsorbable

purge Step time, the hydrogen recovery is only reduced component comprises methane and the adsorbable compo

Slightly. nent is Selected from the group consisting of carbon dioxide,

We claim: hydrocarbons with more than one carbon atom, Sulfur

1. A process for the Separation of a non-adsorbable gas 60 oxides, hydrogen Sulfide, and mixtures thereof.

from a gas mixture comprising the non-adsorbable gas and 12. A process for the Separation of hydrogen from a gas

an adsorbable gas in a Single train preSSure Swing adsorption mixture comprising hydrogen, carbon dioxide, and nitrogen

Zone, the process comprising passing the gas mixture to the in a multiple adsorption bed pressure Swing adsorption Zone

Single train pressure Swing adsorption Zone and withdrawing in a single adsorption train, the proceSS comprising passing

a product gas Stream comprising the non-adsorbable gas and 65 the gas mixture to the multiple adsorption bed preSSure

a waste gas Stream comprising the adsorbable gas, Said Swing adsorption Zone and withdrawing a hydrogen product

Single train pressure Swing adsorption Zone having a plu and a waste gas Stream, Said multiple adsorption bed pres

US 6,210,466 B1

11 12

Sure Swing adsorption Zone having a plurality of adsorption c) further cocurrently depressurizing the first adsorption

beds employing in each adsorption bed an adsorption Step, bed to provide a desorption effluent Stream in a

at least three cocurrent equalization Steps, a provide-purge provide-purge Step over a provide-purge time and

Step, a countercurrent blow down Step, a purge Step, at least Simultaneously passing the desorption effluent Stream

three countercurrent equalization Steps, and a repressuriza to at least two other adsorption beds undergoing the

tion Step, each of Said Steps occurring in a Sequential manner purge Step,

and offset in time wherein the adsorption Step occurs over an d) countercurrently depressurizing the first adsorption bed

adsorption Step time, the provide-purge Step occurs over a to a blow down pressure and recovering a waste Stream

provide-purge Step time and the purge Step occurs over a at a desorption pressure;

purge Step time, the purge Step time being greater than the 1O e) purging the first adsorption bed with a purge Stream for

adsorption Step time and wherein Said purge Step comprises a purge Step time wherein the purge Step time is greater

the adsorption bed receiving a purge gas from one or more than the adsorption Step time, Said purge Stream being

other adsorption beds during a provide-purge Step wherein passed from one or more adsorption beds undergoing a

Said other adsorption beds Simultaneously provide the purge cocurrent provide-purge Step or undergoing a cocurrent

gas to essentially all adsorption beds undergoing the purge 15 equalization Step;

Step and wherein at any time the number of adsorption beds f) countercurrently repressurizing the first adsorption bed

undergoing the adsorption Step is exceeded by the number of by equalizing the pressure in the first adsorption bed

adsorption beds undergoing the purge Step. with other adsorption beds, each of the other adsorption

13. A process for the Separation of a non-adsorbable gas beds having a sequentially higher equalization preSSure

from a gas mixture comprising the non-adsorbable gas and and repeating this countercurrent repressurization Step

an adsorbable gas in a multiple adsorption bed pressure at least three times,

Swing adsorption Zone, the proceSS comprising: g) countercurrently repressurizing the first adsorption bed

a) passing the gas mixture at an adsorption pressure to a with a portion of the adsorption effluent Stream; and,

first adsorption bed of a plurality of adsorption beds in h) repeating steps (a) through (g) to provide a continuous

Said pressure Swing adsorption Zone, each of Said 25

proceSS.

adsorption beds containing an adsorbent Selective for 14. The process of claim 13 wherein the gas mixture is

the adsorption of the adsorbable gas in an adsorption passed to the multiple adsorption bed pressure Swing adsorp

Step for an adsorption Step time and recovering an tion Zone at a capacity of greater than about 110 thousand

adsorption effluent Stream; normal cubic meters per hour (100 million standard cubic

b) cocurrently depressurizing the first adsorption Zone in feet per day).

equalization Steps with other adsorption beds, each of 15. The process of claim 13 wherein the multiple adsorp

the other adsorption beds having Sequentially lower tion bed pressure Swing adsorption Zone comprises at least

equalization pressure and repeating this cocurrent ten adsorption beds.

depressurization Step at least three times to a last

equalization Step;

You might also like

- Method For Quenching A Gas Stream in The Production of Vinyl Chlorde MonomerDocument9 pagesMethod For Quenching A Gas Stream in The Production of Vinyl Chlorde Monomeru2051721No ratings yet

- Patent of Quench TankDocument9 pagesPatent of Quench TankAbdulrahman ezzaldeenNo ratings yet

- US6709486Document11 pagesUS6709486Михаил ПолковниковNo ratings yet

- Eye Notch Range: Ls Measured Engine - Yes. ADocument11 pagesEye Notch Range: Ls Measured Engine - Yes. ABala RajuNo ratings yet

- Acid Based Micro-EmulsionsDocument8 pagesAcid Based Micro-Emulsionsazzrizalz1470No ratings yet

- United States Patent (19) 11 Patent Number: 5,997,619Document13 pagesUnited States Patent (19) 11 Patent Number: 5,997,619nooraaNo ratings yet

- Patent eDocument12 pagesPatent eivan de jesusNo ratings yet

- Us 5902917Document8 pagesUs 5902917RafliNo ratings yet

- Spotting FluidsDocument16 pagesSpotting FluidsEduardo PeraltaNo ratings yet

- United States Patent (10) Patent No.: US 7,188.478 B2: Bourgeois (45) Date of Patent: Mar. 13, 2007Document10 pagesUnited States Patent (10) Patent No.: US 7,188.478 B2: Bourgeois (45) Date of Patent: Mar. 13, 2007Mateus GaygerNo ratings yet

- Us5753799 PDFDocument17 pagesUs5753799 PDFDeepak DeepuNo ratings yet

- Air To Fuel Ratio Control For Gas Engine and Method of OperationDocument6 pagesAir To Fuel Ratio Control For Gas Engine and Method of OperationRezaNadianNo ratings yet

- United States Patent (191: Epperson, JRDocument6 pagesUnited States Patent (191: Epperson, JRAparnaNo ratings yet

- United States Patent (19) 11 Patent Number: 6,124,044: Swidler (45) Date of Patent: Sep. 26, 2000Document7 pagesUnited States Patent (19) 11 Patent Number: 6,124,044: Swidler (45) Date of Patent: Sep. 26, 2000Alexander Franco CastrillonNo ratings yet

- Patent PSA HYDROGEN US6849106Document8 pagesPatent PSA HYDROGEN US6849106nysa arientikaNo ratings yet

- Us6111198 - Duplex Feedthrough and Method ThereforDocument9 pagesUs6111198 - Duplex Feedthrough and Method ThereforNosfe Matingli DiazNo ratings yet

- Device For Monitoring A Magnetic Field Emanating From An OrganismDocument14 pagesDevice For Monitoring A Magnetic Field Emanating From An OrganismDAVIDNo ratings yet

- Iii Iii Iiii: United States Patent (19) 11) Patent Number: 5,531,823Document10 pagesIii Iii Iiii: United States Patent (19) 11) Patent Number: 5,531,823Shruti raghuvanshiNo ratings yet

- Us 6304954Document28 pagesUs 6304954Ahmed EidNo ratings yet

- US6007606Document22 pagesUS6007606Михаил ПолковниковNo ratings yet

- Jose, CA (US) 95.125 Joseph Zappel, E. "E. E. 35,: (12) United States Patent (10) Patent No.: US 6,332,229 B1Document41 pagesJose, CA (US) 95.125 Joseph Zappel, E. "E. E. 35,: (12) United States Patent (10) Patent No.: US 6,332,229 B1Alex KattamisNo ratings yet

- United States Patent: GuirgisDocument11 pagesUnited States Patent: Guirgisamd mhmNo ratings yet

- United States Patent: Rosenberg Et Al. (45) Date of Patent: Jul. 9, 2002Document27 pagesUnited States Patent: Rosenberg Et Al. (45) Date of Patent: Jul. 9, 2002Syed IzzatNo ratings yet

- US6789288 PatenteDocument19 pagesUS6789288 PatenteJorge ZamudioNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7,349,557 B2Document18 pagesUnited States Patent: (12) (10) Patent No.: US 7,349,557 B2Alex MungaiNo ratings yet

- United States Patent (10) Patent No.: US 7,536,948 B1: Cockrum (45) Date of Patent: May 26, 2009Document28 pagesUnited States Patent (10) Patent No.: US 7,536,948 B1: Cockrum (45) Date of Patent: May 26, 2009Solomon HassanNo ratings yet

- United States Patent (10) Patent N0.2 US 6,583,656 B1Document10 pagesUnited States Patent (10) Patent N0.2 US 6,583,656 B1SaurabhABCNo ratings yet

- United States Patent (10) Patent No.: US 6,662,540 B1: Harkcom Et Al. (45) Date of Patent: Dec. 16, 2003Document9 pagesUnited States Patent (10) Patent No.: US 6,662,540 B1: Harkcom Et Al. (45) Date of Patent: Dec. 16, 2003devanasokaNo ratings yet

- Iii Iihiiii: United States Patent (19) 11 Patent Number: 5,565,128Document14 pagesIii Iihiiii: United States Patent (19) 11 Patent Number: 5,565,128Walid Ebid ElgammalNo ratings yet

- US6953534Document13 pagesUS6953534MaboodNo ratings yet

- US6293141Document24 pagesUS6293141Miroljub MaksimovicNo ratings yet

- Ulllted States Patent (19) (11) Patent Number: 6,065,404: Ripingill, Jr. Et Al. (45) Date 0f Patent: May 23, 2000Document13 pagesUlllted States Patent (19) (11) Patent Number: 6,065,404: Ripingill, Jr. Et Al. (45) Date 0f Patent: May 23, 2000willNo ratings yet

- (12 Ulllted States Patent (10) Patent N0.: US 6,236,330 B1Document8 pages(12 Ulllted States Patent (10) Patent N0.: US 6,236,330 B1sonyaNo ratings yet

- Flat Glass Annealing LehrsDocument7 pagesFlat Glass Annealing LehrsHồng ĐàoNo ratings yet

- United States Patent (10) Patent No.: US 6,341,271 B1: Heather Ann Relyea, Niskayuna Wo 135, 40 or GO6F/17/60Document15 pagesUnited States Patent (10) Patent No.: US 6,341,271 B1: Heather Ann Relyea, Niskayuna Wo 135, 40 or GO6F/17/60Syed IzzatNo ratings yet

- Air Cleaner For Internal Combustion EngineDocument6 pagesAir Cleaner For Internal Combustion EngineSirDeparnieux100% (1)

- U S Patent Documents Giivvvifirt?iiisid 111111111 Fitidmillmll?ffg 355E331 VIIIDocument8 pagesU S Patent Documents Giivvvifirt?iiisid 111111111 Fitidmillmll?ffg 355E331 VIIIFranco LazzaroniNo ratings yet

- United States Patent (19) 11 Patent Number: 5,928,426: Aitchison (45) Date of Patent: Jul. 27, 1999Document17 pagesUnited States Patent (19) 11 Patent Number: 5,928,426: Aitchison (45) Date of Patent: Jul. 27, 1999hosseinNo ratings yet

- GW1949 PatentDocument17 pagesGW1949 PatentChris TianNo ratings yet

- US6235961Document11 pagesUS6235961Sidharth SinghNo ratings yet

- Laminated ManufactureDocument9 pagesLaminated Manufactureconfused597No ratings yet

- United States Patent (19) : Naseem (45) Date of Patent: Jan. 9, 1990Document8 pagesUnited States Patent (19) : Naseem (45) Date of Patent: Jan. 9, 1990Hisham ButtNo ratings yet

- US5121329Document15 pagesUS5121329AndersonNo ratings yet

- United States Patent (10) Patent No.: US 6,772,583 B2Document8 pagesUnited States Patent (10) Patent No.: US 6,772,583 B2RohitNo ratings yet

- US6169135Document13 pagesUS6169135NidaNo ratings yet

- United States Patent: Gaydos Et AlDocument8 pagesUnited States Patent: Gaydos Et AlHugo Mauricio Echeverry HerreraNo ratings yet

- Us6415847 PDFDocument10 pagesUs6415847 PDFMuhammad UmerNo ratings yet

- Liqued Phase EthylbenzeneDocument9 pagesLiqued Phase Ethylbenzenesahar vahdatifarNo ratings yet

- United States Patent: (10) Patent No.: US 6,293,891 B1Document8 pagesUnited States Patent: (10) Patent No.: US 6,293,891 B1Dejan ZdravkovskiNo ratings yet

- US6185288Document36 pagesUS6185288arungarg_itNo ratings yet

- United States Patent (10) Patent No.: US 6,770,854 B1Document30 pagesUnited States Patent (10) Patent No.: US 6,770,854 B1Ianculescu RaduNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument22 pagesUnited States Patent: (10) Patent No.: (45) Date of Patent63No ratings yet

- Us 5228327Document32 pagesUs 5228327Aziz FassisNo ratings yet

- Slurry Reaction AgitatorsDocument10 pagesSlurry Reaction AgitatorsManoj BNo ratings yet

- US5549333Document13 pagesUS5549333ZwanNo ratings yet

- H2 Recovery by PSADocument14 pagesH2 Recovery by PSAGiang ĐàoNo ratings yet

- United States Patent (10) Patent No.: US 6,888,037 B2: Dandekar Et Al. (45) Date of Patent: May 3, 2005Document4 pagesUnited States Patent (10) Patent No.: US 6,888,037 B2: Dandekar Et Al. (45) Date of Patent: May 3, 2005claver donald AkréNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7,322,545 B2Document13 pagesUnited States Patent: (12) (10) Patent No.: US 7,322,545 B2rakkaNo ratings yet

- Patente 2Document17 pagesPatente 2Manuela Rodriguez AvilaNo ratings yet

- 14 Joachim Von Scheele LindeDocument27 pages14 Joachim Von Scheele LindeМихаил ПолковниковNo ratings yet

- UOP Hydrogen Solutions DatasheetDocument2 pagesUOP Hydrogen Solutions DatasheetМихаил ПолковниковNo ratings yet

- Velocity in Pipeline For Natural GasDocument8 pagesVelocity in Pipeline For Natural GasМихаил ПолковниковNo ratings yet

- Demonstration of Carbon Capture and Sequestration of Steam Methane Reforming Process Gas Used For Large-Scale Hydrogen ProductionDocument57 pagesDemonstration of Carbon Capture and Sequestration of Steam Methane Reforming Process Gas Used For Large-Scale Hydrogen ProductionМихаил ПолковниковNo ratings yet

- PSA H2 - AdsorbentsDocument4 pagesPSA H2 - AdsorbentsМихаил ПолковниковNo ratings yet

- v4.231105 Hydrogen PSA Valve RequirementsDocument4 pagesv4.231105 Hydrogen PSA Valve RequirementsМихаил ПолковниковNo ratings yet

- Thesis Doctor of Philosophy GUO YalouDocument163 pagesThesis Doctor of Philosophy GUO YalouМихаил ПолковниковNo ratings yet

- Hydro ABC Enanced CvatDocument11 pagesHydro ABC Enanced CvatМихаил ПолковниковNo ratings yet

- d3 2 2 Dynamis h2 Quality Recommendations1Document23 pagesd3 2 2 Dynamis h2 Quality Recommendations1Михаил ПолковниковNo ratings yet

- Kosaplus 1 1. Pneumatic Actuator - ADocument7 pagesKosaplus 1 1. Pneumatic Actuator - AМихаил ПолковниковNo ratings yet

- Npra Paper FinalDocument10 pagesNpra Paper FinalМихаил ПолковниковNo ratings yet

- Fault Detection in Pressure Swing Adsorption Systems-Farshad AmiriDocument76 pagesFault Detection in Pressure Swing Adsorption Systems-Farshad AmiriМихаил ПолковниковNo ratings yet

- Comparative Analysis of Pressure Swing Adsorption and Supersonic Separators For High-Purity Hydrogen ApplicationsDocument6 pagesComparative Analysis of Pressure Swing Adsorption and Supersonic Separators For High-Purity Hydrogen ApplicationsМихаил ПолковниковNo ratings yet

- US6007606Document22 pagesUS6007606Михаил ПолковниковNo ratings yet

- VV 2-0 PDFDocument7 pagesVV 2-0 PDFA MahmoodNo ratings yet

- Texebo S1024+S1153Document6 pagesTexebo S1024+S1153Saidur Rahman SajibNo ratings yet

- Guidelines For Chemical Waste DisposalDocument8 pagesGuidelines For Chemical Waste DisposalJamina CaliganNo ratings yet

- Industrial Scale Production of Palm Super Olein Using Modified and Innovative Dry Fractionation TechniqueDocument12 pagesIndustrial Scale Production of Palm Super Olein Using Modified and Innovative Dry Fractionation TechniqueeyobNo ratings yet

- Chapter09 Lesson 7 Chemical BondingDocument73 pagesChapter09 Lesson 7 Chemical BondingJohn Matthew GicomNo ratings yet

- Acids and Bases and Reactivity Series WorksheetDocument19 pagesAcids and Bases and Reactivity Series WorksheetSherey FathimathNo ratings yet

- Practical Boiler Water TreatmentDocument285 pagesPractical Boiler Water TreatmentLuciano Cardoso Vasconcelos100% (14)

- Pipeline DesignDocument42 pagesPipeline DesignMahmoud El Shorafa100% (2)

- Iso17632 ADocument3 pagesIso17632 Apomabe13No ratings yet

- Hot-Dip Zinc Coating On Structural Steel Bars For Concrete Reinforcement - SpecificationDocument7 pagesHot-Dip Zinc Coating On Structural Steel Bars For Concrete Reinforcement - SpecificationRajashekar.PNo ratings yet

- 1020am - 3.sunil Jayant Kulkarni - FINDocument4 pages1020am - 3.sunil Jayant Kulkarni - FINRuben Aldi WicaksonoNo ratings yet

- Introduction To The ASTM Designation SystemDocument6 pagesIntroduction To The ASTM Designation Systemmajor_duanNo ratings yet

- MSDS - TX Lime - Hydrated LimeDocument4 pagesMSDS - TX Lime - Hydrated LimeiastraNo ratings yet

- QUIZ-5-SANKALP022-6-09-2021-Question PaperDocument11 pagesQUIZ-5-SANKALP022-6-09-2021-Question Paperaryan bhartiNo ratings yet

- Evaluation The Effects of Styrene Butadiene Rubber Addition As A New Soil Stabilizer On Geotechnical PropertiesDocument14 pagesEvaluation The Effects of Styrene Butadiene Rubber Addition As A New Soil Stabilizer On Geotechnical PropertiesIonut PatrasNo ratings yet

- Tumid Venus Clam (Gafrarium Tumidum) As An Additive For Starch-Based Bioplastic: Extraction and Characterization of ChitosanDocument9 pagesTumid Venus Clam (Gafrarium Tumidum) As An Additive For Starch-Based Bioplastic: Extraction and Characterization of ChitosanVaughn DumpitNo ratings yet

- Westbury High School: Science Department Lesson PlanDocument3 pagesWestbury High School: Science Department Lesson PlanHazel Jane Malicdem100% (1)

- The P-Block ElementsDocument32 pagesThe P-Block Elementstannie2512No ratings yet

- BiomoleculesDocument27 pagesBiomoleculesEreeNo ratings yet

- Acids and Bases QuestionsDocument14 pagesAcids and Bases Questionsmariam saikNo ratings yet

- Amspec Techtalk - Pona PianoDocument4 pagesAmspec Techtalk - Pona PianoAshutosh MishraNo ratings yet

- Pre Project Report For Waste Tire To EnergyDocument21 pagesPre Project Report For Waste Tire To EnergynathnkNo ratings yet

- 9 Stain Removal ChartDocument28 pages9 Stain Removal ChartKabil DivayNo ratings yet

- Molylube Extreme Pressure High Viscosity GreaseDocument2 pagesMolylube Extreme Pressure High Viscosity GreaseGilmer Williams Cáceres BenaventeNo ratings yet

- Aromatic Amines As Nucleophiles in The Bargellini Reaction PDFDocument4 pagesAromatic Amines As Nucleophiles in The Bargellini Reaction PDFdavidNo ratings yet

- 59-2016 Dolinska PDFDocument5 pages59-2016 Dolinska PDFYordanos SolomonNo ratings yet

- Geniosil Stpe 10Document2 pagesGeniosil Stpe 10GİZEM D.No ratings yet

- Ship Construction - NotesDocument117 pagesShip Construction - NotesKrishna ChandraNo ratings yet

- GELOY™ Resins Product GuideDocument2 pagesGELOY™ Resins Product Guidejonathan6657No ratings yet

- Vinylester Resin Ce7.Safety Data Sheet - enDocument11 pagesVinylester Resin Ce7.Safety Data Sheet - enAndrei GheorghicaNo ratings yet