Professional Documents

Culture Documents

Buyer Specification Document - 2023 03 25 16 09 09

Uploaded by

pramodyad5810Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Buyer Specification Document - 2023 03 25 16 09 09

Uploaded by

pramodyad5810Copyright:

Available Formats

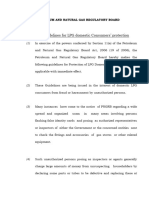

ITEM SPECIFICATION DOCUMENT

Sr Short Text Qty

SULPHUR ANALYZER

SULPHUR ANALYZER ALONG WITH PC, CONSUMABLES AND

AMC FOR CC LABORATORY AS

PER FOLLOWING SPECIFICATIONS:

A) DESCRIPTION:

SUPPLY, INSTALLATION AND COMMISSIONING OF

SULPHUR ANALYZER FOR ANALYSING

SULPHUR CONTENT IN GAS SAMPLES AND LIQUID

PETROLEUM HYDROCARBONS.

ANALYSIS OF FEED FOR SULPHUR CONTENT IS AS

FOLLOWS:

SR.NO. CONSTITUENTS %

1 METHANE/ C1 NOT LESS THAN 80 MOL %

2 ETHANE/ C2 NOT MORE THAN 9.2 MOL %

3 PROPANE / C3 NOT MORE THAN 4.5 MOL %

4 BUTANE / C4 & HEAVIER HYDROCARBONS NOT MORE

THAN 2.5 MOL %

1

5 PENTANE / C5 & HEAVIER HYDROCARBONS NOT MORE 1 NO

THAN 0.35 MOL %

6 NON COMBUSTIBLE GASES OTHER THAN NON

HYDROCARBONS INCLUDING CO2

AND NITROGEN NOT MORE THAN 6.0 MOL %

7 TOTAL SULPHUR INCLUDING H2S 10 PPM MAX

IMPURITIES LIKE OIL, DUST AND WATER VAPOR

MAY EXIST

B) SPECIFICATIONS OF SULPHUR ANALYZER:

1. SUPPLY OF SULPHUR ANALYZER SHALL BE BASED ON

UV-FLUORESCENCE

PRINCIPLE.

2. SYSTEM OPERATION: THE SYSTEM SHOULD HAVE

PLUG-AND-START CONFIGURATION FOR EASIEST

INSTALLATION. IT SHOULD HAVE AUTO-PROTECTION

FUNCTION WITH FULLY-INTEGRATED SAFETY FEATURES

FOR INCREASED OPERATING SAFETY AND MINIMIZED

MAINTENANCE EXPENDITURE. THE APPARATUS SHALL BE

EQUIPPED WITH AN ARRANGEMENT FOR GAS FLOW

CONTROL WITH ELECTRONIC MASS FLOW CONTROLLERS

THAT IS CAPABLE OF USING OXYGEN FOR COMBUSTION

IN ADDITION TO ARGON AS CARRIER GAS MAINTAINING

A CONSTANT SUPPLY OF OXYGEN AND CARRIER GAS AT A

PARTICULAR FLOW RATE. IN ADDITION TO THE FLOW

CONTROLLER, INSTRUMENT SHOULD HAVE ADDITIONAL

ELECTRONIC FLOW SENSOR FOR GAS LEAK AND

OVERPRESSURE DETECTION FOR OPERATING SAFETY.

3. MAIN UNIT: THE INSTRUMENT SHOULD COMPRISE OF

MAIN UNIT CONSISTING OF COMBUSTION FURNACE,

COMBUSTION TUBE, DRYER, FILTER ETC. SAMPLE

INTRODUCTION MODULE FOR LIQUID & GAS SAMPLES

WITH SUITABLE DATA PROCESSING SYSTEM FOR SULPHUR

ESTIMATION.

4. ANALYSIS RANGE: THE ANALYZER SHOULD BE

CAPABLE OF ACCURATE ANALYSIS FOR TOTAL SULPHUR

OF GAS SAMPLE IN THE RANGE OF 0.05 PPM TO

1.00 PPM WITHOUT ANY ADJUSTMENT OR SELECTION

THROUGH HARDWARE/SOFTWARE.

5. ACCURACY: AS PER METHOD SHOULD BE BETTER THAN

2% COEFFICIENT OF VARIANCE (CV) OR AS PER ASTM

5453

6. COMBUSTION TEMPERATURE OF MINIMUM 1050O C

(STEP OF 1OC) TO ENSURE COMPLETE OXIDATION OF

SAMPLES

7. THE APPARATUS MUST BE EQUIPPED WITH A

MECHANISM FOR THE REMOVAL OF WATER VAPOR.

8. THE SYSTEM SHOULD BE SUPPLIED WITH INJECTOR

SUITABLE FOR INJECTION OF LIQUID SAMPLES UP TO

50 µL AND 100 µL AT CONSTANT RATE

9. INSTRUMENT SHOULD HAVE PROVISION OF INJECTING

GAS SAMPLES WITH INJECTION VOLUME UP TO 10 ML AT

CONSTANT RATE WITHOUT CHANGE OF SYRINGE/LOOP.

10. INSTRUMENT SHOULD USE ARGON AS CARRIER AND

OXYGEN AS COMBUSTION GAS.

11. THE ANALYZER SHOULD BE OF UVFD DETECTOR TO

COVER ALL ANALYSIS REQUIREMENTS.

12. THE SYSTEM SHOULD HAVE INTEGRATED

DIAGNOSTIC FOR FAULTY ANALYSIS AND SYSTEM

CONTAMINATION. ALL RELEVANT PARAMETERS FOR

DEVICE SAFETY AND QUALITY OF ANALYSIS MUST BE

CHECKED AUTOMATICALLY. THE SYSTEM SHOULD BE

CONTROLLED BY MEANS OF A COMPUTER SUPPLIED WITH

SUITABLE LICENSED SOFTWARE WITH ORIGINAL CD. THE

SYSTEM MUST HAVE INTERNAL INTELLIGENCE

FOR AUTO-RECOGNITION AND CONDITIONING OF ALL

MODULES.

13. DESPITE AMC BEING LINED UP, BIDDER SHOULD

PROVIDE COMPLETE LIST OF SPARES /CONSUMABLES

WITH FIXED COST FOR THE DURATION OF TWO YEARS

AFTERWARRANTY/GUARANTEE PERIOD.

14. BIDDER SHALL SUPPLY LATEST VERSION PC (CORE

I7 OR ABOVE, 8GB RAM,

512 GB SSD, AT LEAST 4 USB PORTS, WINDOWS 11

PRO, 21-INCH MONITOR-1 NO),OF BRANDED MAKE LIKE

DELL, HP ETC.MOUSE, KEYBOARD ALONG WITH

INSTRUMENT.

15. PC SOFTWARE SHOULD BE SUCH THAT WE CAN DAILY

SAVE THE ANALYSIS REPORT & AS AND WHEN REQUIRED

WE ARE ABLE TO TAKE PRINTOUT OF REPORT BY

DOWNLOADING REPORT IN PENDRIVE OR ANY DEVICE.

16. THE INSTRUMENT SHALL CARRY A WARRANTY OF AT

LEAST 12 MONTHS AFTER INSTALLATION OR 18 MONTHS

AFTER SUPPLY WHICHEVER IS EARLIER FROM THE

DATE OF COMMISSIONING AGAINST MANUFACTURING

DEFECTS OF ALL STANDARD SUPPLIES.

17. EVALUATION OF ENQUIRY SHALL BE DONE ON

CUMULATIVE PRICE OF BASIC SUPPLY OF INSTRUMENT

WITH PC AND CONSUMABLES AND CYLINDER COST PLUS

AMC CHARGES.

18. BIDDER SHALL SUPPLY ONE NO OF SMALL/ MINI

TABLE TOP UPS IN ORDER TO AVOID EEFCT OF POWER

FLUCTUATION/INTERUPPTION ON INSTURMENT SULPUR

ANALYZER AND FOR SMOOTH RUNNING OF INSTRUMENTS.

19. BIDDER SHALL BRING ONE NUMBER OF ARGON

CYLINDER AND ONE NUMBER OF OXYGEN CYLINDER WITH

VALID CERTIFICATE AT THE TIME OF COMMISSIOING OF

INSTRUMENT. AFTER SUCCESSFUL COMMISSIONING OF

INSTRUMENT, CYLINDERS SHALL BE RETURNED BACK TO

BIDDER.

20. BIDDER SHALL SUPPLY 2 STAGE REGULATOR WITH

SS DIAPHRAGM, TUBING

(APPROX. 10 M) AND SWAGELOK FITTINGS ALONG WITH

SUPPLY OF INSTRUMENT.

C) AMC SERVICE CONTRACT:

a) BIDDER SHALL OFFER ANNUAL MAINTENANCE/

SERVICE SUPPORT CONTRACT AFTER COMPLETION OF

WARRANTY PERIOD FOR NEXT 4 YEARS AS PER SCOPE

BELOW:

b) COMPLETE SULPHUR ANALYZER, AND OTHER SUPPLIED

CONSUMABLES/SPARES,

UPS AND PC RELATED ISSUES SHALL BE COVERED UNDER

THIS CONTRACT.

c) BIDDER SHALL PROVIDE WARANTY OF PC FOR 2

YEARS AFTER COMPLETION OF WARRANTY PERIOD

d) BIDDER SHALL DEPUTE EXPERIENCED ENGINEER(S)

FOR EXECUTION OF THE JOB.

e) ENGINEER SHALL VISIT THE SITE ON REQUEST FROM

RCF FOR BREAKDOWN MAINTENANCE /PREVENTIVE

MAINTENANCE /CALIBRATION SERVICES OR PC RELATED

AS AND WHEN REQUIRED.

f) PAYMENT SHALL BE MADE FOR THE ACTUAL DAYS

VISITED AFTER COMPLETION

OF EACH VISIT.

g) CHARGES ARE TO BE QUOTED FOR 4 MAN DAYS/YEAR.

CHARGES QUOTED SHALL BE INCLUSIVE OF ALL,

INCLUDING TRAVELING, LODGING, BOARDING AND LOCAL

TRAVEL.BIDDER SHALL ALSO FURNISH VISIT

CHARGES/DAY BASIS FOR ANY ADDITIONAL VISIT.

D) LIST OF SPARES TO BE SUPPLIED ALONG WITH

INSTRUMENT:

a) 1. SEPTUM- 50 PIECES

b) STD. GAS CANISTER CRM WITH PRESSURE GAUGE,

CONTROL VALVE AND SAMPLE POINT WITH SEPTUM- 1)

BLANK STANDARD (1 NO), 2) 1 PPM (1 NO) OR

NEARSEST AND 3) 1.5/2.0 PPM (1 NO)

c) DRYER COMPLETE SET- 1 NO.

d) COMPLETE COMBUSTION TUBE- 1NO.

e) 50 µL AND 100 µL SYRINGE FOR LIQUID SAMPLE

INJECTOR- 02 NO. EACH

f) 10 ML SYRINGE FOR GAS INJECTION - 4 NO

g) REMOVABLE NEEDLES FOR 50 µL AND 100 µL

SYRINGE- 02 NO. EACH.

h) REMOVABLE NEEDLES FOR 10 ML SYRINGE – 5 NO.

E) SCOPE OF INSTALLATION SERVICES:

BIDDER SHALL PROVIDE SERVICES FOR INSTALLATION

AND COMMISSIONING OF SULPHUR ANALYZER AS PER

SCOPE BELOW:

a. BIDDER SHALL DEMONSTRATE THE CALIBRATION AND

OTHER FEATURES OF THE

SULPHUR ANALYZER BEFORE HANDOVER.

b. BIDDER SHALL EXECUTE THE COMPLETE JOB OF

INSTALLATION & COMMISSIONING WITHIN 03 DAYS.

c. ALL ITEMS, HARDWARE OR SOFTWARE, IRRESPECTIVE

OF WHETHER MENTIONED

IN THIS SCOPE OR NOT, BUT REQUIRED FOR

SUCCESSFUL AND EFFECTIVE

COMMISSIONING, SHALL BE IN THE BIDDER'S SCOPE.

d. ALL TOOLS AND TACKLES, LAPTOP, ETC. THAT MAY

BE REQUIRED FOR

TROUBLESHOOTING/ CHECKING/ TESTING DURING THE

COMMISSIONING JOB SHALL BE

BROUGHT TO SITE BY THE BIDDER.

e. IN DEPTH TRAINING WITH CALIBRATION PROCEDURE

ETC. TO BE GIVEN TO THE PLANT PERSONNEL AT THE

SITE.

f. HANDOVER OF SOFT AND HARD COPIES OF OPERATION

AND MAINTENANCE MANUALS.

g. LUMP SUM SERVICE CHARGES ARE TO BE QUOTED.

CHARGES QUOTED SHALL BE INCLUSIVE OF ALL,

INCLUDING TRAVELING, LODGING, BOARDING AND LOCAL

TRAVEL CONVEYANCE.

F) RCF SCOPE:

1. ROOM FOR SULPHUR ANALYZER INSTALLATION.

2. SAMPLE GAS WILL BE MADE AVAILABLE AT ANALYZER

ROOM

3. AIR AT 5 KG/CM2

4. POWER 230V+/- 10 %, 50 HZ, SINGLE POINT

You might also like

- Liquid Sample Introduction in ICP Spectrometry: A Practical GuideFrom EverandLiquid Sample Introduction in ICP Spectrometry: A Practical GuideRating: 4 out of 5 stars4/5 (6)

- Tender22 8Document38 pagesTender22 8er_bhavin3119100% (1)

- Fike Co2 With SHP ProDocument10 pagesFike Co2 With SHP ProTri Cahyono YuniantoNo ratings yet

- 2020 طلبية GT3Document7 pages2020 طلبية GT3omar alnasserNo ratings yet

- Use of The (Nline Gas Chromatograph For Gas Sales From An Offshor PlatformDocument22 pagesUse of The (Nline Gas Chromatograph For Gas Sales From An Offshor PlatformAlcimar MonteiroNo ratings yet

- 7.5.2 13 LGA Sprinkler StandardsDocument16 pages7.5.2 13 LGA Sprinkler StandardsWinarkoNo ratings yet

- Procedure Guides For The Measurement of Quantity & Quality of Gas at Gas Plants, RefineriesDocument45 pagesProcedure Guides For The Measurement of Quantity & Quality of Gas at Gas Plants, Refineriesokey obi100% (2)

- Diesel Smoke Opacity Meter SpecificationDocument12 pagesDiesel Smoke Opacity Meter SpecificationupenderNo ratings yet

- Ine - Chiller Carrier - 30rb090Document13 pagesIne - Chiller Carrier - 30rb090yves2329No ratings yet

- 0708 R RE 001 Design BasisDocument11 pages0708 R RE 001 Design BasisHimawan Sigit NugrohoNo ratings yet

- WMD - Sepcifications For The CHNS Analyzer PDFDocument6 pagesWMD - Sepcifications For The CHNS Analyzer PDFAngel Miguel Mejia RodasNo ratings yet

- Gas Turbine EngDocument11 pagesGas Turbine EngRodriguez ArthursNo ratings yet

- Technical Specification - PumpDocument7 pagesTechnical Specification - PumpBalasundaramSrinivasaRajkumarNo ratings yet

- Test CO2 SystemsDocument5 pagesTest CO2 SystemsAntonio FilipeNo ratings yet

- Fuel System Presentation - Rev ADocument19 pagesFuel System Presentation - Rev AaltipatlarNo ratings yet

- 3 Instrumentation PDFDocument11 pages3 Instrumentation PDFRakeshNo ratings yet

- Gases Nox SopmDocument17 pagesGases Nox SopmDienNo ratings yet

- Gas Chromatographs PDFDocument10 pagesGas Chromatographs PDFwq22030202No ratings yet

- Diesel PP SpecsDocument19 pagesDiesel PP SpecsMico AndresNo ratings yet

- Annexure NewDocument6 pagesAnnexure Newknp_rmgNo ratings yet

- DGSEngineering Circular 1 of 2022Document12 pagesDGSEngineering Circular 1 of 2022Audumbar BhoiNo ratings yet

- Gujarat State Electricity Corporation LimitedDocument5 pagesGujarat State Electricity Corporation LimitedSylab InstrumentsNo ratings yet

- I CR 100Document20 pagesI CR 100zulfuyildirim9485No ratings yet

- Standard Operating Procedure: Validation of Heating Ventilation and Air Conditioning (Hvac) SystemDocument20 pagesStandard Operating Procedure: Validation of Heating Ventilation and Air Conditioning (Hvac) SystemMaryanthony Namyalo100% (3)

- Revised Guidelines For The Approval of Equivalent Fixed Gas Fire-Extinguishing Systems, As Referred To in Solas 74, For Machinery Spaces and Cargo Pump-RoomsDocument18 pagesRevised Guidelines For The Approval of Equivalent Fixed Gas Fire-Extinguishing Systems, As Referred To in Solas 74, For Machinery Spaces and Cargo Pump-RoomsDanial Haidhar YusoffNo ratings yet

- Bhel LP-HP Bypass OrderDocument32 pagesBhel LP-HP Bypass OrderGiriDharanNo ratings yet

- RB1-5 (3) CO Sensor CatalogueDocument10 pagesRB1-5 (3) CO Sensor CataloguedimchienNo ratings yet

- Ip060-45!62!01 Control Valve (Glove) (Buyer's Scope)Document5 pagesIp060-45!62!01 Control Valve (Glove) (Buyer's Scope)Rahul DevaNo ratings yet

- Ni 2916Document13 pagesNi 2916nandafontenelleNo ratings yet

- Fike Fm-200 With SHP ProDocument8 pagesFike Fm-200 With SHP ProGovinda GopinathNo ratings yet

- 4 Pollution Control MeasuresDocument4 pages4 Pollution Control MeasuresChava TejaNo ratings yet

- Specifications For Transformer Online Dissolved Gas Analyser (DGA)Document3 pagesSpecifications For Transformer Online Dissolved Gas Analyser (DGA)crazy devilNo ratings yet

- Ultrasonic Flow Meter Compliance With Api 14.10 Measurement of Flow To FlaresDocument10 pagesUltrasonic Flow Meter Compliance With Api 14.10 Measurement of Flow To FlaresVictor Enrique Rosales ParadaNo ratings yet

- Ni 2914Document9 pagesNi 2914nandafontenelleNo ratings yet

- Fire Protection Test ProcedureDocument7 pagesFire Protection Test Procedurekunalji_jainNo ratings yet

- Kewaunee LV Fume Hood SpecsDocument14 pagesKewaunee LV Fume Hood SpecsprabhudNo ratings yet

- MR Num5-EnDocument13 pagesMR Num5-EnaminardakaniNo ratings yet

- CEMS SpecificationDocument10 pagesCEMS SpecificationPriyabrat KumarNo ratings yet

- HP by Pass System-ModifiedDocument21 pagesHP by Pass System-Modifiedsrigirisetty208100% (1)

- TLS-350R UST Monitoring and Leak Detection System 577013-368 Rev. BDocument32 pagesTLS-350R UST Monitoring and Leak Detection System 577013-368 Rev. BShalvaTavdgiridzeNo ratings yet

- HC Compliance Status Dec 20Document93 pagesHC Compliance Status Dec 20Hrushikesh ReddyNo ratings yet

- METHOD 14 - 2017 - Determination of Fluoride Emissions From Potroom Roof Monitors For Primary Aluminum PlantsDocument15 pagesMETHOD 14 - 2017 - Determination of Fluoride Emissions From Potroom Roof Monitors For Primary Aluminum PlantsdevspacebrNo ratings yet

- Annexure - IDocument4 pagesAnnexure - IZakNo ratings yet

- Interconnection Design Gas PipelinesDocument96 pagesInterconnection Design Gas PipelinesBeatriz Adams Garcia100% (2)

- Specification For Supply & Installation of Window Type Air Conditioning Units & AccessoriesDocument9 pagesSpecification For Supply & Installation of Window Type Air Conditioning Units & AccessoriesChamin SubhawickramaNo ratings yet

- Liquid Measurement Station DesignDocument10 pagesLiquid Measurement Station Designsigit.kurniadiNo ratings yet

- Blood Gas Analyser With Electrolyte SpecificationsDocument3 pagesBlood Gas Analyser With Electrolyte Specificationsrk927No ratings yet

- PR#12354332 - Decontamination Jobs - Sow 2016 OLE III TADocument11 pagesPR#12354332 - Decontamination Jobs - Sow 2016 OLE III TAGanga DaranNo ratings yet

- Testing and Commissioning (ACMV)Document5 pagesTesting and Commissioning (ACMV)Alex Choong100% (1)

- 53-TMSS-03 (Rev 00)Document8 pages53-TMSS-03 (Rev 00)GardellNo ratings yet

- Flow Sensor: AHS 1853 Automotive Sensor & Actuator HairulazmiDocument27 pagesFlow Sensor: AHS 1853 Automotive Sensor & Actuator Hairulazmiamirul lex100% (1)

- P 1-22 FF Suppression PipingDocument22 pagesP 1-22 FF Suppression PipingMahmoud GwailyNo ratings yet

- SH1 RFP - P4 OTR - Ch8 Balance of Plant - p17-20Document4 pagesSH1 RFP - P4 OTR - Ch8 Balance of Plant - p17-20SonNguyenNo ratings yet

- P6076b PrattWhitney FT8MobilePac PowerPlant Estimated Performance and Emi2Document10 pagesP6076b PrattWhitney FT8MobilePac PowerPlant Estimated Performance and Emi2lifemillion2847100% (1)

- CDA Clean Dry AirDocument15 pagesCDA Clean Dry AirJonNo ratings yet

- Stack Monitoring KitDocument53 pagesStack Monitoring KitknbiolabsNo ratings yet

- Barmer To Salaya Pipeline Project: Material RequisitionDocument12 pagesBarmer To Salaya Pipeline Project: Material Requisitionsajeesh5113699No ratings yet

- WBMSC Notice 1762Document7 pagesWBMSC Notice 1762kuntal dasNo ratings yet

- 23-04 - Fire Fighting SystemsDocument21 pages23-04 - Fire Fighting SystemsCip Zerkop100% (1)

- IGS-M-IN-104 (1) July 2014: Multipath Ultrasonic Transit-Time Gas Flow MeterDocument15 pagesIGS-M-IN-104 (1) July 2014: Multipath Ultrasonic Transit-Time Gas Flow Metermamady88No ratings yet

- Skylab BrochureDocument2 pagesSkylab Brochurepramodyad5810No ratings yet

- CFR 2021 Title21 Vol1 Sec11 2Document1 pageCFR 2021 Title21 Vol1 Sec11 2pramodyad5810No ratings yet

- General Chapter 643Document2 pagesGeneral Chapter 643pramodyad5810No ratings yet

- Final Attendee List Company.Document81 pagesFinal Attendee List Company.pramodyad5810No ratings yet

- LPG GuidelineDocument4 pagesLPG Guidelinepramodyad5810No ratings yet

- Journalism of Courage: SINCE 1932Document13 pagesJournalism of Courage: SINCE 1932pramodyad5810No ratings yet

- 04 User Manual 3000 Systems V2.0 PDFDocument169 pages04 User Manual 3000 Systems V2.0 PDFpramodyad5810No ratings yet

- CH 4 05 TS-UV Service Manual 1 (1) .3Document43 pagesCH 4 05 TS-UV Service Manual 1 (1) .3pramodyad5810No ratings yet

- White : Smartcare Crack SealDocument2 pagesWhite : Smartcare Crack Sealpramodyad5810No ratings yet

- Deposit Confirmation/Renewal AdviceDocument1 pageDeposit Confirmation/Renewal Advicepramodyad5810No ratings yet

- Guidelinesforinternationalarrivals PDFDocument2 pagesGuidelinesforinternationalarrivals PDFpramodyad5810No ratings yet

- Enquiry Cum Scope of Supply & Technical Specifications of Tender ITEM NO:-10 QUANTITY: - 1 EA (Each) Item DescriptionDocument5 pagesEnquiry Cum Scope of Supply & Technical Specifications of Tender ITEM NO:-10 QUANTITY: - 1 EA (Each) Item Descriptionpramodyad5810No ratings yet

- StudentWisePaper T.Y.B.Com. 05092018111346AMDocument73 pagesStudentWisePaper T.Y.B.Com. 05092018111346AMpramodyad5810No ratings yet

- India's Fresh Cases Soar by 544, 65% of Them Linked To TablighiDocument14 pagesIndia's Fresh Cases Soar by 544, 65% of Them Linked To Tablighipramodyad5810No ratings yet

- Value RelationshipDocument3 pagesValue Relationshippramodyad5810No ratings yet

- Office of The Collector and District Magistrate: Datta Prasad Datta Ali Tilak Chowk Kalyan West Pincode 421301Document1 pageOffice of The Collector and District Magistrate: Datta Prasad Datta Ali Tilak Chowk Kalyan West Pincode 421301pramodyad5810No ratings yet

- Special Instructions To The Bidder For Participating in E-TenderDocument17 pagesSpecial Instructions To The Bidder For Participating in E-Tenderpramodyad5810No ratings yet

- Bharat Petroleum Corporation Limited: General Purchase ConditionsDocument25 pagesBharat Petroleum Corporation Limited: General Purchase Conditionspramodyad5810No ratings yet

- Guidelinesforinternationalarrivals PDFDocument2 pagesGuidelinesforinternationalarrivals PDFpramodyad5810No ratings yet

- How To Submit Bid As " " Bidder: PreferentialDocument6 pagesHow To Submit Bid As " " Bidder: Preferentialpramodyad5810No ratings yet

- ANATEL A643a TOC Analyzer Operator Manual PDFDocument222 pagesANATEL A643a TOC Analyzer Operator Manual PDFpramodyad5810No ratings yet

- Instructions To Bidder (S) (Itb)Document101 pagesInstructions To Bidder (S) (Itb)pramodyad5810No ratings yet

- Index This File Contains Following Six DocumentsDocument52 pagesIndex This File Contains Following Six Documentspramodyad5810No ratings yet

- Sub-Zero Refrigerator Use & CareDocument44 pagesSub-Zero Refrigerator Use & CarephilaskNo ratings yet

- CNC Milling: Technical DescriptionDocument15 pagesCNC Milling: Technical Descriptiongia1985No ratings yet

- Column K PDFDocument27 pagesColumn K PDFAngelika Caguioa BiayNo ratings yet

- Error Control CodingDocument252 pagesError Control Codingbesniku_k100% (8)

- Coba CobaDocument5 pagesCoba CobaMuhammad Khoirul AnwarNo ratings yet

- QPT Assembly InstuctionsDocument2 pagesQPT Assembly InstuctionsSimon CooperNo ratings yet

- Introduction To Phased Array AntennasDocument7 pagesIntroduction To Phased Array AntennasNaniNo ratings yet

- Piaggio Fly150 Service Manual 150ccmDocument239 pagesPiaggio Fly150 Service Manual 150ccmgtperformasNo ratings yet

- How To CrackDocument369 pagesHow To CrackNaveen ManiNo ratings yet

- Half Rate in BSCDocument80 pagesHalf Rate in BSCarthenianNo ratings yet

- Top 11 Books On Cybersecurity That You Can Read On Your Kindle PDFDocument9 pagesTop 11 Books On Cybersecurity That You Can Read On Your Kindle PDFram prakashNo ratings yet

- 10 Easy Tips To Keep Your Bathroom Smelling Fresh NaturallyDocument10 pages10 Easy Tips To Keep Your Bathroom Smelling Fresh NaturallyHaria BitalangisNo ratings yet

- Tajima Librarian by PulseDocument12 pagesTajima Librarian by PulseArnold PereaNo ratings yet

- Cryptography and Network SecurityDocument24 pagesCryptography and Network SecuritykavithamargretNo ratings yet

- Exp 01Document8 pagesExp 01MohamedElSayedNo ratings yet

- GE Range JGB735SP1SS Parts ListDocument2 pagesGE Range JGB735SP1SS Parts ListMuller SolimanNo ratings yet

- A Brief Lesson Plan in TLE FO NC2Document2 pagesA Brief Lesson Plan in TLE FO NC2Anthony MonticilloNo ratings yet

- Visualize and Graph ESP-32 Sensor DataDocument23 pagesVisualize and Graph ESP-32 Sensor DataObi InwelegbuNo ratings yet

- R12 Uploading A Journal Using Web ADI - Step by Step - Oracle Techno & FunctionalDocument18 pagesR12 Uploading A Journal Using Web ADI - Step by Step - Oracle Techno & FunctionalMadhavi SinghNo ratings yet

- A Novel Approach To Shale Gas Evaluation Using A Cased Hole Pulsed Neutron ToolDocument15 pagesA Novel Approach To Shale Gas Evaluation Using A Cased Hole Pulsed Neutron ToolTwirXNo ratings yet

- Ksih-6y6tlv R0 en 2 PDFDocument9 pagesKsih-6y6tlv R0 en 2 PDFdexiNo ratings yet

- CMM Probing, Good Practice GuideDocument104 pagesCMM Probing, Good Practice GuideTomas Trojci Trojcak100% (1)

- Show Report-Edutech2019-Education Expo 2019 PDFDocument16 pagesShow Report-Edutech2019-Education Expo 2019 PDFDichivithena DivacanyaNo ratings yet

- ManualDocument40 pagesManualDiego MonroyNo ratings yet

- WA CA7 BestPractices ENUDocument113 pagesWA CA7 BestPractices ENULove FeastNo ratings yet

- Beck, Ulrich & Lau, Christoph - Second Modernity As A Research Agenda (2005)Document33 pagesBeck, Ulrich & Lau, Christoph - Second Modernity As A Research Agenda (2005)Germán GiupponiNo ratings yet

- Setting Up The System in BODSDocument21 pagesSetting Up The System in BODSPayal MohantyNo ratings yet

- CV Exim RudiDocument1 pageCV Exim RudiPrimantara SentosaNo ratings yet

- Communication and Global VillageDocument8 pagesCommunication and Global VillageMuhammad Mohkam Ud DinNo ratings yet