Professional Documents

Culture Documents

GDN 4 13 Abrasive Wheels

GDN 4 13 Abrasive Wheels

Uploaded by

Jaine GalvãoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GDN 4 13 Abrasive Wheels

GDN 4 13 Abrasive Wheels

Uploaded by

Jaine GalvãoCopyright:

Available Formats

Guidance Note 4-13

ABRASIVE WHEELS

Introduction

An abrasive wheel is a cutting tool made of abrasive particles bonded together by various adhesive

substances. They are made in different shapes and sizes and are used for the grinding, cutting, sanding,

deburring and polishing of hard materials.

In use they rotate at very high speeds and create a significant risk of injury should they fail in use or if

the correct control measures are not put into place and enforced. Issues that require consideration by

employers are correct the installation and fitting of abrasive wheels, their maintenance, the way the

equipment is used and the training and competence of employees using them.

Associated Hazards

The use of abrasive wheels gives rise to risks of ill-health as well as risk of injury. There is a risk of

injury caused by an abrasive wheel bursting (breaking up whilst in use), contact with the moving wheel,

including entanglement, and ejected particles that cause eye damage. The health hazards associated with

the use of abrasive wheels include exposure to dust, noise, vibration etc., each of which are covered in

other Guidance Notes.

Please refer to:

Guidance Note 1-7 Occupational Health and Health Surveillance for advice and information on

potential health hazards and the controls required.

Guidance Note 5-21 – Local Exhaust Ventilation systems for information and guidance on

controlling dust emissions.

Guidance Note 5-1 for information and advice on the control of hand arm vibration.

Guidance Note 5-17 for information and advice on controlling noise at work.

Legal Duties

Health and safety legislation requires machinery and equipment to be properly designed, used and

maintained so as not to give rise to health and safety hazards. The supply of machinery legislation

requires essential health and safety information to be provided by the manufacturers and suppliers. It is a

mandatory requirement to train employees and ensure that they are competent to mount or replace

abrasive wheels.

Where you use resin bonded abrasive wheels for precision manufacturing you should also ensure that

you have a competent person to regularly monitor the condition of the abrasive wheels and ensure that

they are maintained in good order.

Recognised Control Measures

Before purchasing any abrasive wheels and associated equipment that you have identified and trained a

competent person to maintain it correctly. Many technical colleges and employers’ associations are able

to offer short formal training courses.

The training should include:

The safe use or mounting of abrasive wheels.

Identification of the hazards and risks associated with the equipment’s use.

The methods of marking abrasive wheels with type, size and maximum speeds.

Abrasive wheel storage, transport and handling.

Inspection and testing.

Methods of dressing abrasive wheels.

Guidance Note 4-13. Abrasive Wheels

Page 1 of 2

Adjusting the work rest.

The use of suitable guards.

The use of personal protective equipment.

Training records can be kept either in personnel files or with safety management papers.

Abrasive wheels should be securely mounted and maintained in accordance with manufacturers’

instructions. All wheels should be examined prior to use. When in storage they should be protected to

prevent damage and should be handled carefully to prevent dropping or bumping; rolling should be

avoided as far as is practicable.

When mounted, wheels should be marked with their maximum safe operational speed, restrictions of use,

the shelf life and a traceable number. The maximum speed can be marked in peripheral speed in metres

per second and rotational speed in revolutions per minute (rpm). Wheels larger than 80mm in diameter

will be marked with their maximum speed: for smaller wheels the maximum speed should be posted on a

notice in a position where it can be easily read. Abrasive wheels should never be operated in excess of

the identified rotational speed.

Abrasive wheel equipment should be fitted with clearly visible and accessible start and stop controls and

appropriate guards to prevent the operator coming into contact with the wheel or injury from flying

fragments in the event of a wheel burst.

Regular inspections and preventative maintenance should be carried out in accordance with

manufacturers’ instructions. These records should be kept with your safety management files.

Employees who use abrasive wheels must be trained to recognise the hazards and how to minimise risk

when using them. Be sure to record the training given and the date. Use regular toolbox talks to reinforce

the training message.

Appropriate protective equipment, as identified in your risk assessments, should be worn when using

abrasive wheels to protect against such risks as eye injury from debris and metallic particles, inhalation

of dust, physical injury from flying wheel fragments, noise, vibration, head, foot or hand injury.

To prevent entanglement, loose clothing and any other items such as rags should be secured, when using

abrasive wheels. Arrangements should be made for the protection of persons within the working area and

demarcation lines and warning signs should be positioned to warn of the hazards present.

Abrasive wheels used in circumstances where they generate significant amounts of harmful or respirable

dust will need to be fitted with suitable dust control measures. See Guidance Note 1-7 – Occupational

Health and Health Surveillance for advice and information on potential health hazards and the controls

required. Guidance Note 5-21 – Local Exhaust Ventilation systems provides information and guidance

on controlling dust emissions.

Further advice and guidance on the storage and use of abrasive wheels or any of the issues contained in

this guidance note is available from our 24 Hour Advice Service.

In Great Britain call 0844 892 2785;

In Northern Ireland call 0844 892 2786 option 2; or

In the Republic of Ireland call 01 855 5050 option 2.

Guidance Notes are regularly revised and updated to reflect current best practice, standards or legislation. The latest version

of every Guidance Note is always available in your online system.

Guidance Note 4-13. Abrasive Wheels

Page 2 of 2

You might also like

- Safety Guide: Tire, Wheel & Rim AssemblyDocument16 pagesSafety Guide: Tire, Wheel & Rim AssemblyRick100% (1)

- Troy Bilt Riding Tractor InstructionsDocument68 pagesTroy Bilt Riding Tractor InstructionsjimNo ratings yet

- Intensive Thai - Solution BookDocument18 pagesIntensive Thai - Solution Bookkawaii shoujo100% (1)

- Charles Finney - Sermons From The Penny Pulpit - Part 2Document183 pagesCharles Finney - Sermons From The Penny Pulpit - Part 2knowhim26002No ratings yet

- Durma Press Brake Safety32310Document5 pagesDurma Press Brake Safety32310Ivan BaraćNo ratings yet

- Perator S Anual: Hydrostatic Garden Tractor, 900 SeriesDocument36 pagesPerator S Anual: Hydrostatic Garden Tractor, 900 SeriesThomas SwinneyNo ratings yet

- Nbme 1 Block 1-4Document75 pagesNbme 1 Block 1-4Eimad Atif100% (1)

- Abrasive WheelDocument2 pagesAbrasive WheelErica LindseyNo ratings yet

- SOP For Use of Grinder Machines in WorkshopDocument8 pagesSOP For Use of Grinder Machines in WorkshopFaisal RajaNo ratings yet

- Reach Stacker SOM Manual-20180315 - CompressedDocument550 pagesReach Stacker SOM Manual-20180315 - CompressedМитя Гайдаш100% (6)

- Chip Inductors (Chip Coils) : Cat - No.O05E-21Document136 pagesChip Inductors (Chip Coils) : Cat - No.O05E-21testaremariusNo ratings yet

- Pre-Lab Questions: © Escience Labs, 2016Document6 pagesPre-Lab Questions: © Escience Labs, 2016PsudopodNo ratings yet

- Troybilt Lawnmower ManualDocument56 pagesTroybilt Lawnmower ManualVerne BettsNo ratings yet

- Safe Use of Power Tools Rev0Document92 pagesSafe Use of Power Tools Rev0mohapatrarajNo ratings yet

- FA2-FA2 5 Service Manual Parts ListDocument61 pagesFA2-FA2 5 Service Manual Parts ListERNESTO NEGRETENo ratings yet

- Sistema Lubricacion Cummins Diesel C8.3Document6 pagesSistema Lubricacion Cummins Diesel C8.3Pitricio Campos Del Río100% (2)

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- Lesson 5 - Single Sideband System: ECE121 - Principles of CommunicationsDocument67 pagesLesson 5 - Single Sideband System: ECE121 - Principles of CommunicationsJhezreel JohnNo ratings yet

- ID DCU IndustrialDocument4 pagesID DCU IndustrialRoozbeh BahmanyarNo ratings yet

- Sany Src45 ManualDocument590 pagesSany Src45 ManualAlex Ignatov100% (6)

- 350 Series Broom Operators Manual PDFDocument63 pages350 Series Broom Operators Manual PDFALVARO100% (1)

- Safety in The Use of Grinding Wheels (Quick View)Document6 pagesSafety in The Use of Grinding Wheels (Quick View)aloordominicNo ratings yet

- Aircraft Ground Handling. PDFDocument72 pagesAircraft Ground Handling. PDFSOHAM PANDYANo ratings yet

- PIONEER Wet End Automation Training Material enDocument617 pagesPIONEER Wet End Automation Training Material enRishikishore ReddyNo ratings yet

- HSE Amusement ParkDocument73 pagesHSE Amusement Parkjefry2002No ratings yet

- Manual de Operador Barredora Broce 350Document63 pagesManual de Operador Barredora Broce 350Sergio TrejoNo ratings yet

- PQ190 A Operational ManualDocument285 pagesPQ190 A Operational Manualdharan100% (3)

- Samuel Beckett - Dante... Bruno. Vico... JoyceDocument8 pagesSamuel Beckett - Dante... Bruno. Vico... JoyceLore Buchner100% (1)

- Abrasive Wheels ProcedureDocument5 pagesAbrasive Wheels Procedureashikshah100% (1)

- Winching Operations in Forestry: Technical GuideDocument30 pagesWinching Operations in Forestry: Technical GuideAshrafELWardagyNo ratings yet

- Perator S Anual: Self Propelled Mower - Models TB 220, TB 230, TB 240, & TB 280 EsDocument52 pagesPerator S Anual: Self Propelled Mower - Models TB 220, TB 230, TB 240, & TB 280 EsSteve BullNo ratings yet

- User Manual For Push Mower Model 02BDocument40 pagesUser Manual For Push Mower Model 02BshayetftNo ratings yet

- GDN 4 41 All Terrain Vehicles AtvsDocument5 pagesGDN 4 41 All Terrain Vehicles AtvsJaine GalvãoNo ratings yet

- Mower - ManualDocument44 pagesMower - ManualAmanda ThompsonNo ratings yet

- Qcs 2010 Section 11 Part 1.4 Regulatory Document - SAFE USE OF PLANT PDFDocument130 pagesQcs 2010 Section 11 Part 1.4 Regulatory Document - SAFE USE OF PLANT PDFbryanpastor106No ratings yet

- Gangway Operator Course Chapter 2 - HSEDocument8 pagesGangway Operator Course Chapter 2 - HSEsvetlanaNo ratings yet

- SM 1 UnlockedDocument105 pagesSM 1 UnlockedVasilescu SorinNo ratings yet

- FPM - Operation Manual - Disc Mowers DK 627 712-713-726Document62 pagesFPM - Operation Manual - Disc Mowers DK 627 712-713-726vlada.klenje68No ratings yet

- Hoh Chainsaw PolicyDocument11 pagesHoh Chainsaw Policyapi-299221104No ratings yet

- 2006 Sys Statrack-1000 OmDocument15 pages2006 Sys Statrack-1000 Omli geneNo ratings yet

- Anbr Cama: PresentsDocument35 pagesAnbr Cama: PresentsYvonne RiveraNo ratings yet

- 06L61 01a - DL1050M2Document309 pages06L61 01a - DL1050M2gulatarikNo ratings yet

- John Deere Et 3301 J Manual de UsuarioDocument52 pagesJohn Deere Et 3301 J Manual de UsuarioManuel Fernandez MoraNo ratings yet

- Chapter 14 - Shop SafetyDocument11 pagesChapter 14 - Shop Safetymega87_2000No ratings yet

- Perator S Anual: Push Mower - Models Tb110 & Tb130Document40 pagesPerator S Anual: Push Mower - Models Tb110 & Tb130FXNScottNo ratings yet

- Perator S Anual: Model Series 760-770 Lawn TractorDocument68 pagesPerator S Anual: Model Series 760-770 Lawn TractorMichael RapinoNo ratings yet

- Remington TrimmerDocument16 pagesRemington TrimmerBenjamin DoverNo ratings yet

- Mounting and Dismounting Construction EquipmentDocument2 pagesMounting and Dismounting Construction EquipmentKarhysNo ratings yet

- Machine SafeguardingDocument51 pagesMachine SafeguardingComputer Maintainance Hardware and softwareNo ratings yet

- Troybilt TB200Document48 pagesTroybilt TB200Homer SilvaNo ratings yet

- Operating Instructions FZA Pump PDFDocument14 pagesOperating Instructions FZA Pump PDFPipe RoblesNo ratings yet

- Cortadora de PastoDocument44 pagesCortadora de PastoFabys JNo ratings yet

- C.cesped 070Document20 pagesC.cesped 070Marco DE LA CruzNo ratings yet

- Perator S Anual: Model Series 760-770 Lawn TractorDocument68 pagesPerator S Anual: Model Series 760-770 Lawn TractorMichael RapinoNo ratings yet

- SPA8 Instruction ManualDocument25 pagesSPA8 Instruction ManualCHRISNo ratings yet

- Rotary Tiller (Smooth Top) Manual - (272L) 07617Document28 pagesRotary Tiller (Smooth Top) Manual - (272L) 07617Alexutza StanNo ratings yet

- Generation III Sonic Feeder Control System Manual 20576Document32 pagesGeneration III Sonic Feeder Control System Manual 20576julianmataNo ratings yet

- Machine Safeguarding: Using The Quarter-Inch Rule: Safety and Health Resource ManualDocument4 pagesMachine Safeguarding: Using The Quarter-Inch Rule: Safety and Health Resource ManualAhmed ReguiegNo ratings yet

- Unit 4Document80 pagesUnit 4Madhuri MogalNo ratings yet

- Land Rover Vehicle Communications Software Manual: February 2011Document52 pagesLand Rover Vehicle Communications Software Manual: February 2011David González EnriquezNo ratings yet

- Ford - New Holland Tractors 8670, 8670A, 8770, 8770A, 8870, 8870A, 8970, 8970A Service Manual - CompressedDocument2,105 pagesFord - New Holland Tractors 8670, 8670A, 8770, 8770A, 8870, 8870A, 8970, 8970A Service Manual - CompressednoshansNo ratings yet

- MGC Site Safety OrientationDocument14 pagesMGC Site Safety OrientationJitendra SharmaNo ratings yet

- 060 1815 2 PDFDocument107 pages060 1815 2 PDFpatNo ratings yet

- Mower - Operator - S ManualDocument40 pagesMower - Operator - S ManualAmanda ThompsonNo ratings yet

- Volvo Vehicle Communication Software ManualDocument41 pagesVolvo Vehicle Communication Software ManualthisiserichillNo ratings yet

- New Holland G170 G190 G210 G240 Repair ManualDocument2,105 pagesNew Holland G170 G190 G210 G240 Repair ManualDing DangNo ratings yet

- 554511.a.0 2Document32 pages554511.a.0 2vinnyNo ratings yet

- SRB 870Document70 pagesSRB 870Trung Kính NguyễnNo ratings yet

- GDN 1-1 The Management of Health and Safety at WorkDocument4 pagesGDN 1-1 The Management of Health and Safety at WorkJaine GalvãoNo ratings yet

- Accident Incident Investigation FormDocument5 pagesAccident Incident Investigation FormJaine GalvãoNo ratings yet

- Battery Operated Fire Detection Equipment Inspection RecordDocument2 pagesBattery Operated Fire Detection Equipment Inspection RecordJaine GalvãoNo ratings yet

- Automated Hand Arm Vibration CalculatorDocument2 pagesAutomated Hand Arm Vibration CalculatorJaine GalvãoNo ratings yet

- Planta 1Document1 pagePlanta 1Jaine GalvãoNo ratings yet

- GDN 4 41 All Terrain Vehicles AtvsDocument5 pagesGDN 4 41 All Terrain Vehicles AtvsJaine GalvãoNo ratings yet

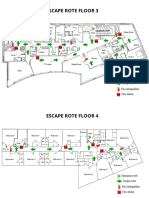

- Escape Rote FloorsDocument3 pagesEscape Rote FloorsJaine GalvãoNo ratings yet

- Abrasive Wheel ChecksDocument2 pagesAbrasive Wheel ChecksJaine GalvãoNo ratings yet

- Biology Samp WDocument41 pagesBiology Samp WMark DeaconNo ratings yet

- NeerajKrSingh IphoneDocument6 pagesNeerajKrSingh IphonejeevansapNo ratings yet

- POH 125-02-114 Cessna R&S Feb 2017Document188 pagesPOH 125-02-114 Cessna R&S Feb 2017Abdulfetah NesredinNo ratings yet

- AIS Manipulation - Windward-October 2014Document9 pagesAIS Manipulation - Windward-October 2014grzug111No ratings yet

- Erikson Daily Report 14 JanuaryDocument12 pagesErikson Daily Report 14 Januaryrizal355No ratings yet

- Additives For Adhesives and Sealants Catalogue EuropeDocument24 pagesAdditives For Adhesives and Sealants Catalogue EuropeAlexi WiedemannNo ratings yet

- LagundiDocument4 pagesLagundiAileen A. MonaresNo ratings yet

- BSE Traded Stocks 03.09.2021fullDocument308 pagesBSE Traded Stocks 03.09.2021fullM StagsNo ratings yet

- Plant Embryonic Development - WikipediaDocument10 pagesPlant Embryonic Development - WikipediaNeetu rani RaniNo ratings yet

- Presented By-Mahak Ralli Final YearDocument44 pagesPresented By-Mahak Ralli Final Yearfelaxis fNo ratings yet

- Test-Certificate: To Whom It May ConcernDocument2 pagesTest-Certificate: To Whom It May ConcernsahanNo ratings yet

- Electric Motor Basics: Why Are Rotors Skewed?: by Cyndi Nyberg EASA Technical Support SpecialistDocument2 pagesElectric Motor Basics: Why Are Rotors Skewed?: by Cyndi Nyberg EASA Technical Support SpecialistsebastianNo ratings yet

- Unit 4 The Forrestry Territory WebDocument29 pagesUnit 4 The Forrestry Territory Webapi-241427002No ratings yet

- Assignment 1 (LAB)Document7 pagesAssignment 1 (LAB)Zain NajamNo ratings yet

- Herbal Plants Tamil Names and UsesDocument2 pagesHerbal Plants Tamil Names and UsesBalaji Venktesh100% (1)

- SEPPO - KFT - Capabilities - WP-FL-WLP - 2017 - 1Document65 pagesSEPPO - KFT - Capabilities - WP-FL-WLP - 2017 - 1Julio AraujoNo ratings yet

- ForaminiferaDocument20 pagesForaminiferaMuhammad HidayatNo ratings yet

- Circular FunctionsDocument15 pagesCircular Functionsleah rualesNo ratings yet

- ebffiledoc_259Download textbook Antibody Engineering Methods And Protocols Damien Nevoltris ebook all chapter pdfDocument53 pagesebffiledoc_259Download textbook Antibody Engineering Methods And Protocols Damien Nevoltris ebook all chapter pdfmariano.nichols460100% (15)

- SLED Vs CRRT PDFDocument9 pagesSLED Vs CRRT PDFquilino2012No ratings yet

- DP126LA: Doosan Infracore Generator EngineDocument4 pagesDP126LA: Doosan Infracore Generator EnginehirararaNo ratings yet