Professional Documents

Culture Documents

Ed 720

Uploaded by

Devina FernsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ed 720

Uploaded by

Devina FernsCopyright:

Available Formats

Data Sheet Model ED 720

Model ED 720 | Drying and heating chambers with natural convection

The strengths of a BINDER ED series drying chamber include routine drying and sterilization tasks up to 300 °C. Thanks to the natural convection, all thermal

processes which use this drying chamber are highly ecient. The ED series ensures fast, uniform drying.

BENEFITS

• Best energy eciency on the market

• Excellent temporal and spatial temperature accuracy

• USB connection for recording data

• Temperature range up to +300 °C

Model 720

MAIN FEATURES

• Temperature range: +5 °C above ambient temperature to +300 °C • 2 chrome-plated racks

• Up to 30% lower energy consumption compared to conventional units on • Class 2 integrated independent adjustable temperature safety device

the market (DIN 12880) with visual alarm

• High temperature accuracy thanks to APT.line™ technology • Ergonomic handle design

• Natural convection • USB port for recording data

• Controller with LCD display

• Electromechanical control of the exhaust air flap

ORDERING INFORMATION

Interior volume [L] Voltage Option model Version Art.-No.

743 400 V 3~ ph 50/60 Hz Standard ED720-400V 9010-0341

BINDER Data Sheet | As of: 14.06.2023 Page 1 / 6

Technical specifications are subject to change.

Data Sheet Model ED 720

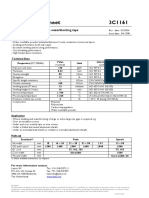

TECHNICAL DATA

Description ED720-400V1

Article Number 9010-0341

Performance Data Temperature

Temperature range +5 °C above ambient temperature to [°C] 300

Temperature variation at 150 °C [± K] 3.2

Temperature fluctuation at 150 °C [± K] 0.8

Heating-up time to 150 °C [min] 85

Recovery time aer 30 seconds door open at 150 °C [min] 25

Tabellen

Air change (approx.) at 100 °C [x/h] 2

Electrical data

Rated Voltage [V] 400

Power frequency [Hz] 50/60

Nominal power [kW] 4.1

Unit fuse [A] 16

Phase (Nominal voltage) 3~

Measures

Interior volume [L] 743

Net weight of the unit (empty) [kg] 161

Permitted load [kg] 315

Load per rack [kg] 45

Wall clearance back [mm] 160

Wall clearance sidewise [mm] 100

Internal Dimensions

Interior width [mm] 960

Interior height [mm] 1280

Interior depth [mm] 605

Doors

Inner doors 2

Unit doors 2

Housing dimensions not incl. ttings and connections

Width net [mm] 1165

Height net [mm] 1590

Depth net [mm] 870

Environment-specic data

Energy consumption at 150 °C [Wh/h] 700

Fixtures

Number of shelves (std./max.) 2/16

1 All technical data is specied for unloaded units with standard equipment at an ambient temperature of +22 °C ±3 °C and a power supply voltage

fluctuation of ±10%. The temperature data is determined in accordance to BINDER factory standard following DIN 12880, observing the recommended

wall clearances of 10 % of the height, width, and depth of the inner chamber. All indications are average values, typical for units produced in series. We

reserve the right to change technical specications at any time.

BINDER Data Sheet | As of: 14.06.2023 Page 2 / 6

Technical specifications are subject to change.

Data Sheet Model ED 720

DIMENSIONS incl. fittings and connections [mm]

OPTIONS

Designation Description * Art.-No.

back

10 mm 01 8012-1282

30 mm 01 8012-0540

50 mm 01 8012-0546

le

10 mm 01 8012-1275

30 mm 01 8012-1018

50 mm 01 8012-1022

100 mm 01 8012-1030

Access port with silicone

right

plug

10 mm 01 8012-1268

30 mm 01 8012-1017

50 mm 01 8012-1021

100 mm 01 8012-1031

top

10 mm 01 8012-1262

30 mm 01 8012-0539

50 mm 01 8012-0545

100 mm 01 8012-1029

Alarm function for

Switchable acoustic alarm, with adjustable limit value on the independent temperature safety device – 8012-1635

overheating

Analog output 4-20 mA for temperature values (output not adjustable) 02 8012-1623

Calibration certificate,

for temperature; for extending the measurement in center of chamber to include another test temperature – 8012-1115

expanded

for temperature, measurement in center of chamber at specied temperature – 8012-1134

Calibration certificate, temperature measurement incl. certicate and 27 measuring points at specied temperature – 8012-1593

temperature temperature measurement incl. certicate, 15- 18 measuring points at specied temperature – 8012-1572

temperature measurement incl. certicate, 9 measuring points at specied temperature – 8012-1551

Class 3.1 independent

temperature safety with visual alarm (DIN 12880) – 8012-0985

device

Clock battery-backed – 8012-1640

Door gasket made of FKM, silicone-free – 8012-1013

Door lock lockable door handle – 8012-1817

Ethernet interface for Multi Management Soware APT-COM™ – 8012-1836

Inner chamber,

max. total load 350 kg – 8012-1827

reinforced

with two 15 W light bulbs

Interior lighting

400 V option model – 8012-1824

* Notes › See last page

BINDER Data Sheet | As of: 14.06.2023 Page 3 / 6

Technical specifications are subject to change.

Data Sheet Model ED 720

Designation Description * Art.-No.

Measurement of air

in accordance with ASTM D5374, denition and protocol according to ambient temperature – 8012-0195

exchange rate

Pt 100 temperature

additional flexible Pt 100, interior, for displaying the temperature on the unit display – 8012-1619

sensor

Viewing window and viewing window (triple insulating glass) in door, 300 x 480 mm, and 30 W interior

interior lighting 400 V option model – 8012-1830

* Notes › See last page

ACCESSORIES

Designation Description * Art.-No.

APT-COM™ 4 BASIC- for simple logging and documentation requirements with up to 5 networked units.

Edition version 4, BASIC edition – 9053-0039

for working under GLP-compliant conditions. Measured values are documented in a tamper-proof way in line with the

APT-COM™ 4 GLP- requirements of FDA Regulation 21 CFR 11.

Edition

version 4, GLP edition – 9053-0042

APT-COM™ 4 convenient unit and user management built on the BASIC edition. Suitable for networking up to 100 units.

PROFESSIONAL-Edition version 4, PROFESSIONAL edition – 9053-0040

pH-neutral detergent concentrated, for gentle remove of residual contaminants; 1 kg – 8012-2250

IQ/OQ documents – supporting documents for validation performed by customers, consisting of: IQ/OQ checklists incl.

calibration guide and comprehensive unit documentation; parameters: temperature, CO2, O2, pressure, depending on

unit

Digital in PDF format – 7057-0001

Hard copy inside folder – 7007-0001

Qualification documents

IQ/OQ/PQ documents – supporting documents for validation performed by customers, according to customer

requirements, PQ section added to qualication folder IQ/OQ; parameters: temperature, CO2, O2 – or pressure,

depending on unit

Digital in PDF format – 7057-0005

Hard copy inside folder – 7007-0005

chrome plated – 8012-2045

Rack

stainless steel – 8012-2174

Rack, heavy load Stainless steel, max. load per rack 70 kg – 8012-2186

Shelf, perforated Stainless steel – 8012-2182

* Notes › See last page

SERVICES

Designation Description * Art.-No.

Maintenance contracts

Installation services

Maintenance services

Calibration services

Validation services

Warranty service

1-year warranty extension The warranty is extended by 1 year from the delivery date, wear parts are excluded – DL50-0010

Maintenance service as contractually agreed, visual inspection of mechanical and electrical components,

BRONZE 3-year maintenance contract 05 DL20-0710

check of control response, 20% discount on spare parts

03, 04,

Calibration of one (1) test temperature specied by the user in center of chamber, including certicate DL30-0101

05

Calibration certicate, temperature

Extension of calibration of one (1) additional test temperature specied by the user in the center of the 03, 04,

DL30-0102

usable space, including certicate 05

Execution of IQ/OQ Execution of IQ/OQ in accordance with qualication folder 05 DL40-0100

Execution of IQ/OQ/PQ Execution of IQ/OQ/PQ in accordance with qualication folder 05 DL44-0500

* Notes › See last page

BINDER Data Sheet | As of: 14.06.2023 Page 4 / 6

Technical specifications are subject to change.

Data Sheet Model ED 720

Designation Description * Art.-No.

Maintenance service as contractually agreed, visual inspection of mechanical and electrical components,

check of control response, 20% discount on spare parts, testing of all key functions, replacement of

GOLD 3-year maintenance contract 05 DL20-0910

wear parts, calibration of one test temperature specied by the user in the center of the usable space,

including certicate

One-o maintenance service in accordance with maintenance schedule. Visual inspection of mechanical

Maintenance and electrical components, testing of all key functions. Calibration of a test temperature specied by the 05 DL20-0200

user in center of usable space without certicate

03, 04,

Measurement of air exchange rate including certicate (in accordance with ASTM D5374) DL33-0000

05

Maintenance service as contractually agreed, visual inspection of mechanical and electrical components,

SILVER 3-year maintenance contract check of control response, 20% discount on spare parts, testing of all key functions, calibration of one 05 DL20-0810

test temperature specied by the user in the center of the usable space, without certicate

Temperature measurement, 18 Temperature measurement with 18 measuring points with a set value specied by the user, including 03, 04,

DL30-0118

measuring points certicate 05

Temperature measurement, 27 Temperature measurement with 27 measuring points with a set value specied by the user, including 03, 04,

DL30-0127

measuring points certicate 05

Temperature measurement, 9 Temperature measurement with 9 measuring points with a set value specied by the user, including 03, 04,

DL30-0109

measuring points certicate 05

Connect the unit to the customer-side connections (electricity, water, wastewater, gas), basic functions

Unit commissioning check, brief operating instructions. (excl.: unpacking, setup, controller instructions, programming, 05 DL10-0100

installation work)

Instruction regarding operating principle and basic functions of the unit, operation of the control

Unit instructions 05 DL10-0500

electronics including programming

* Notes › See last page

BINDER Data Sheet | As of: 14.06.2023 Page 5 / 6

Technical specifications are subject to change.

Data Sheet Model ED 720

NOTES

01 Condensation may occur in the area around the access port. Access ports may be placed in custom locations for an additional charge.

02 UL mark is not granted when this option is used.

03 Sensor calibration is performed in an accredited calibration laboratory.

04 Calibration is performed according to the BINDER factory standard.

05 Quoted prices do not include travel costs. Please refer to the chapter on BINDER Service for travel costs for your region. Quoted prices for services performed in Switzerland do not

include a country-specic added fee (available on request).

BINDER GmbH BINDER Asia Pacific (Hong Kong) Ltd.

Tuttlingen, Germany Kowloon, Hong Kong, P.R. China

TEL +49 7462 2005 0 TEL +852 39070500

FAX +49 7462 2005 100 FAX +852 39070507

info@binder-world.com asia@binder-world.com

www.binder-world.com www.binder-world.com

BINDER Environmental Testing BINDER Inc.

Equipment (Shanghai) Co., Ltd. Bohemia, NY, USA

Shanghai, P.R. China TEL +1 631 224 4340

TEL +86 21 685 808 25 FAX +1 631 224 4354

FAX +86 21 685 808 29 usa@binder-world.com

china@binder-world.com www.binder-world.us

www.binder-world.com

BINDER Data Sheet | As of: 14.06.2023 Page 6 / 6

Technical specifications are subject to change.

You might also like

- Quartile1 PDFDocument2 pagesQuartile1 PDFHanifah Edres DalumaNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Smart Grid TechnologyDocument43 pagesSmart Grid Technologyarnav LakshkarNo ratings yet

- Dharmakirti39s Commentary On ChakrasamvaraDocument15 pagesDharmakirti39s Commentary On ChakrasamvaraThiago AlbuquerqueNo ratings yet

- Data Sheet Model BF 400 enDocument5 pagesData Sheet Model BF 400 enDiego RomeroNo ratings yet

- Data Sheet Model ED 056 enDocument6 pagesData Sheet Model ED 056 enwaelNo ratings yet

- Data Sheet Model ED 115 enDocument6 pagesData Sheet Model ED 115 enAhmad HamdounNo ratings yet

- Data Sheet Model FD 115 enDocument6 pagesData Sheet Model FD 115 enYousuf ZNo ratings yet

- Data Sheet Model ED 023 enDocument6 pagesData Sheet Model ED 023 enAhmad HamdounNo ratings yet

- Binder BD 115 Gravity Convection Incubator Lab OvenBrochureDocument5 pagesBinder BD 115 Gravity Convection Incubator Lab OvenBrochureFredy AlvaroNo ratings yet

- 201 400Document206 pages201 400Thuy NguyenNo ratings yet

- Data Sheet Model ED 115 enDocument6 pagesData Sheet Model ED 115 enEmmanuelNo ratings yet

- Binder - ED - 56 (9010-0333)Document5 pagesBinder - ED - 56 (9010-0333)ekoNo ratings yet

- Data Sheet Model FD 115 enDocument6 pagesData Sheet Model FD 115 enBudiNo ratings yet

- Incubadora Binder KB115Document5 pagesIncubadora Binder KB115Kelly VillamilNo ratings yet

- BD 53Document5 pagesBD 53Ahmed AlkabodyNo ratings yet

- RV6009Document3 pagesRV6009shiauyunn.yeohNo ratings yet

- Data Sheet Model BD 56 enDocument4 pagesData Sheet Model BD 56 enRenaldo MoontriNo ratings yet

- Data Sheet Model VD 115Document5 pagesData Sheet Model VD 115Bősze GáborNo ratings yet

- Fan Module 5503020Document4 pagesFan Module 5503020Zak zsNo ratings yet

- HT-G2088 Flap BarrierDocument1 pageHT-G2088 Flap BarrierWin TeknologiNo ratings yet

- IMPAC Infrared: ThermometersDocument2 pagesIMPAC Infrared: ThermometersAlfonso BlancoNo ratings yet

- Amatris G3 C04 WR 2000-840 ETDD 01 TOC 7633151 10229225 enDocument2 pagesAmatris G3 C04 WR 2000-840 ETDD 01 TOC 7633151 10229225 enNIKINo ratings yet

- Rectilinear Displacement Transducer: Technical Data Mechanical DimensionsDocument2 pagesRectilinear Displacement Transducer: Technical Data Mechanical DimensionsJansirani SelvamNo ratings yet

- Hit-5000 Series: FeaturesDocument1 pageHit-5000 Series: FeaturesWin TeknologiNo ratings yet

- DSPCDocument2 pagesDSPCHector van AardtNo ratings yet

- Transductor GefranDocument2 pagesTransductor GefranMarco Martinez SantiagoNo ratings yet

- Muchmoon 3000-830 Op-Ll 22W Etdd L2,0 05 9002155634 enDocument1 pageMuchmoon 3000-830 Op-Ll 22W Etdd L2,0 05 9002155634 enDani Good VibeNo ratings yet

- RO1364Document2 pagesRO1364shiauyunn.yeohNo ratings yet

- Indracontrol S20 Analog Input Module 8 Inputs: FeaturesDocument20 pagesIndracontrol S20 Analog Input Module 8 Inputs: FeaturesDaniel LimaNo ratings yet

- 7.P-0111ABC-350x 300CNFC5132-132kW - Motor DataDocument3 pages7.P-0111ABC-350x 300CNFC5132-132kW - Motor DatanachiappanNo ratings yet

- AccurL ESAY BEND NC Press Brake MB7-220Tx4000 E21Document5 pagesAccurL ESAY BEND NC Press Brake MB7-220Tx4000 E21EnriqueMiguelPriceNo ratings yet

- Contura - Wall TypeDocument4 pagesContura - Wall TypeMohamed ImranNo ratings yet

- Product Datasheet Product Datasheet PL PFM 1200x300 30 W 940 UGR19Document7 pagesProduct Datasheet Product Datasheet PL PFM 1200x300 30 W 940 UGR19Catalin DulceataNo ratings yet

- Baumer ITD21H00 EN 20200210 DSDocument5 pagesBaumer ITD21H00 EN 20200210 DSAdolfo SantoyaNo ratings yet

- Tesfa0 2024 01 25 00 05Document6 pagesTesfa0 2024 01 25 00 05Ivan NikodijevicNo ratings yet

- DS MLC500T14300-90600 Eng 68096009Document9 pagesDS MLC500T14300-90600 Eng 68096009yosu.lezanaNo ratings yet

- SBTL7000+Series Leaflet 20210323+ (UPDATED)Document2 pagesSBTL7000+Series Leaflet 20210323+ (UPDATED)Prajwal shettyNo ratings yet

- Datasheet DFV60A-22PC65536 1051309 enDocument9 pagesDatasheet DFV60A-22PC65536 1051309 enAdria PlayNo ratings yet

- Offer For ACCURL Smart Swing Beam Shear MS7-12x3200-Crys PDFDocument7 pagesOffer For ACCURL Smart Swing Beam Shear MS7-12x3200-Crys PDFJ Jack GutierrezNo ratings yet

- Rectilinear Displacement Transducer: Technical Data Mechanical DimensionsDocument2 pagesRectilinear Displacement Transducer: Technical Data Mechanical DimensionsJan MaksNo ratings yet

- Altendorf WA8 Manual v1.0 2006 ManualDocument49 pagesAltendorf WA8 Manual v1.0 2006 ManualClaudio Rafael Deola Sada100% (1)

- Rodless Rectilinear Displacement Transducer: Technical Data Mechanical DimensionsDocument2 pagesRodless Rectilinear Displacement Transducer: Technical Data Mechanical DimensionsAli AlhaidarNo ratings yet

- Ebara CDX 2 Poles 50 en LDocument20 pagesEbara CDX 2 Poles 50 en LAdi AlsonNo ratings yet

- MRC - Ovens - DFOI Series - Data SheetDocument2 pagesMRC - Ovens - DFOI Series - Data Sheetgeetha raniNo ratings yet

- SlicelO (E) 01Document2 pagesSlicelO (E) 01pc100xohmNo ratings yet

- Pos.7 - Temperature Sensor - TT5050 ENGDocument3 pagesPos.7 - Temperature Sensor - TT5050 ENGДмитрий МазуренкоNo ratings yet

- Water Swallable TapeDocument1 pageWater Swallable TapeSanthosh V RaajendiranNo ratings yet

- WEG 132kW SpecificationDocument8 pagesWEG 132kW Specificationbonginkosi mathunjwaNo ratings yet

- Tm2Ari8Lrj: Product DatasheetDocument7 pagesTm2Ari8Lrj: Product DatasheetAgil PranataNo ratings yet

- Encoder Siemens 6fx2001-5wd13-0aa1Document3 pagesEncoder Siemens 6fx2001-5wd13-0aa1oswaldoNo ratings yet

- Temperature Measurement TS500Document4 pagesTemperature Measurement TS500ari_prasNo ratings yet

- 94 10 KbgiDocument2 pages94 10 KbgiTokallah MohamedNo ratings yet

- PLC-OSC-5DC/ 24DC/ 2/ACT: Order No.: 2980144Document6 pagesPLC-OSC-5DC/ 24DC/ 2/ACT: Order No.: 2980144dNo ratings yet

- Fume HoodDocument3 pagesFume HoodMuhammad Abdur RashidNo ratings yet

- Crouzet 24 V MotorDocument4 pagesCrouzet 24 V Motorth.wilbersNo ratings yet

- Revisar CMV 273mmDocument1 pageRevisar CMV 273mmGuadalupe Beltrán PacíficoNo ratings yet

- Ex Single Data Sheet Linear Luminaire With Led GRP 6002 4128 0110 172 1110 11 8500 272391 en GB RstahlDocument5 pagesEx Single Data Sheet Linear Luminaire With Led GRP 6002 4128 0110 172 1110 11 8500 272391 en GB Rstahlsuresheee2001No ratings yet

- LED Flood Lights SDS - 265004 - en-GBDocument3 pagesLED Flood Lights SDS - 265004 - en-GBAnonymous SOQFPWBNo ratings yet

- Partial Door For VX - SV 9682.160: Date: Dec 24, 2020Document3 pagesPartial Door For VX - SV 9682.160: Date: Dec 24, 2020Myaidi MyaidisNo ratings yet

- Dc-Motors-Dc-Direct-Drive-Brushed-Motors-42-Mm-10-And-17-Watts-10-W-Part Number-82810017Document4 pagesDc-Motors-Dc-Direct-Drive-Brushed-Motors-42-Mm-10-And-17-Watts-10-W-Part Number-82810017Sandeep SNo ratings yet

- BinderDocument72 pagesBinderDevina FernsNo ratings yet

- Uf 750Document4 pagesUf 750Devina FernsNo ratings yet

- Price Comparison For Saliva Test KitDocument2 pagesPrice Comparison For Saliva Test KitDevina FernsNo ratings yet

- Special Access List of Covid-19 Test Kit (For Professional Use Only)Document2 pagesSpecial Access List of Covid-19 Test Kit (For Professional Use Only)Devina FernsNo ratings yet

- Training Course CertificatesDocument1 pageTraining Course CertificatesDevina FernsNo ratings yet

- WorkDocument2 pagesWorkDevina FernsNo ratings yet

- Training Course CertificatesDocument1 pageTraining Course CertificatesDevina FernsNo ratings yet

- YoungMan EN131 GUIDEDocument16 pagesYoungMan EN131 GUIDErcpawar100% (1)

- Metal Workers BizHouse - UkDocument3 pagesMetal Workers BizHouse - UkAlex BekeNo ratings yet

- 01-20 Optical Multiplexer and Demultiplexer BoardDocument57 pages01-20 Optical Multiplexer and Demultiplexer BoardDaler ShorahmonovNo ratings yet

- Reading Part 2Document14 pagesReading Part 2drama channelNo ratings yet

- Physics Unit 11 NotesDocument26 pagesPhysics Unit 11 Notesp.salise352No ratings yet

- Project ReportDocument14 pagesProject ReportNoah100% (7)

- Entero SequencesDocument12 pagesEntero SequencesKelvin SueyzyNo ratings yet

- Valdez, Shenny RoseDocument3 pagesValdez, Shenny Roseyeng botzNo ratings yet

- Patel 2013Document116 pagesPatel 2013hnphuocNo ratings yet

- Coding Decoding Sheet - 01 1678021709186Document9 pagesCoding Decoding Sheet - 01 1678021709186Sumit VermaNo ratings yet

- ContempoDocument4 pagesContempoPrincess Jonette YumulNo ratings yet

- Hashimoto's Thyroiditis: Veena RedkarDocument10 pagesHashimoto's Thyroiditis: Veena RedkarSan RedkarNo ratings yet

- F24 60manual (New)Document14 pagesF24 60manual (New)Robert CumpaNo ratings yet

- Asme b16-25Document22 pagesAsme b16-25JamesNo ratings yet

- LinkageDocument9 pagesLinkageHarshu JunghareNo ratings yet

- BIF-V Medium With Preload: DN Value 130000Document2 pagesBIF-V Medium With Preload: DN Value 130000Robi FirdausNo ratings yet

- TheBasicsofBrainWaves - RS PDFDocument4 pagesTheBasicsofBrainWaves - RS PDFOnutu Adriana-LilianaNo ratings yet

- Theoretical CyclesDocument49 pagesTheoretical CyclesMariaEzzaSyUyNo ratings yet

- The History of AstrologyDocument36 pagesThe History of AstrologyDharani Dharendra DasNo ratings yet

- Automatic Train OperationDocument6 pagesAutomatic Train OperationAnupam KhandelwalNo ratings yet

- Science Magazine February 2020Document133 pagesScience Magazine February 2020Elena González GonzálezNo ratings yet

- Scholomance 1 GravitonDocument18 pagesScholomance 1 GravitonFabiano SaccolNo ratings yet

- Notes Transfer of Thermal EnergyDocument12 pagesNotes Transfer of Thermal Energymahrosh mamoon100% (2)

- Cold Regions Science and TechnologyDocument8 pagesCold Regions Science and TechnologyAbraham SilesNo ratings yet

- Synthesis Essay Coming To Grips With GenesisDocument11 pagesSynthesis Essay Coming To Grips With Genesisapi-259381516No ratings yet

- Etoricoxib - Martindale 39thDocument2 pagesEtoricoxib - Martindale 39thCachimbo PrintNo ratings yet

- Frye LGD As A Function of The Default Rate 091013 PDFDocument13 pagesFrye LGD As A Function of The Default Rate 091013 PDFSushant SinghNo ratings yet