Professional Documents

Culture Documents

Extra Hybrid System

Uploaded by

Sytech PerformOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Extra Hybrid System

Uploaded by

Sytech PerformCopyright:

Available Formats

Find more manuals on: www.pixiomarket.

com

Print-Toyota Service Information 11/3/17, 6(42 pm

Print Exit

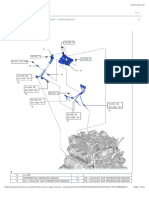

1GD-FTV LUBRICATION ENGINE OIL COOLER COMPONENTS

ILLUSTRATION

om

t.c

ke

ar

m

io

ix

.p

w

*1 OIL COOLER ASSEMBLY *2 WATER OUTLET PIPE GASKET

w

*3 O-RING - -

w

N*m (kgf*cm, ft.*lbf): Specified torque ● Non-reusable part

Engine oil - -

© 2012 TOYOTA MOTOR CORPORATION. All Rights Reserved.

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-j…manual/repair/contents/RM100000000M7T1.html?PUB_TYPE=RM&MODE=1 Page 1 of 1

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(43 pm

Print Exit

1GD-FTV LUBRICATION ENGINE OIL COOLER INSPECTION

PROCEDURE

1.INSPECT OIL COOLER ASSEMBLY 15710

a. Visually check the oil cooler assembly for cracks or damage.

If cracks or damage is found, replace the oil cooler assembly.

om

© 2012 TOYOTA MOTOR CORPORATION. All Rights Reserved.

t.c

ke

ar

m

io

ix

.p

w

w

w

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-j…manual/repair/contents/RM100000000M7T0.html?PUB_TYPE=RM&MODE=1 Page 1 of 1

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(43 pm

Print Exit

1GD-FTV LUBRICATION ENGINE OIL COOLER INSTALLATION

PROCEDURE

1.INSTALL OIL COOLER ASSEMBLY 15710

a. Apply a light coat of engine oil to the 2 new O-rings.

b. Install the 2 O-rings to the cylinder block sub-assembly.

om

c. Install a new water outlet pipe gasket to the cylinder block sub-assembly.

d. Install the oil cooler assembly to the cylinder block sub-assembly with the bolt and 5 nuts.

Torque:

15 N*m (153 kgf*cm, 11 ft.*lbf)

t.c

2.INSTALL TURBOCHARGER SUB-ASSEMBLY 17201

ke

Click hereEngine / Hybrid System>1GD-FTV INTAKE / EXHAUST>EXHAUST MANIFOLD W/

TURBOCHARGER>INSTALLATION

© 2012 TOYOTA MOTOR CORPORATION. All Rights Reserved.

ar

m

io

ix

.p

w

w

w

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…manual/repair/contents/RM100000000M7SZ.html?PUB_TYPE=RM&MODE=1 Page 1 of 1

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(43 pm

Print Exit

1GD-FTV LUBRICATION ENGINE OIL COOLER REMOVAL

PROCEDURE

1.REMOVE TURBOCHARGER SUB-ASSEMBLY 17201

Click hereEngine / Hybrid System>1GD-FTV INTAKE / EXHAUST>EXHAUST MANIFOLD W/

TURBOCHARGER>REMOVAL

om

2.REMOVE OIL COOLER ASSEMBLY 15710

a.

t.c

ke

ar

Bolt

m

Nut

io

ix

Remove the 5 nuts and bolt from the oil cooler assembly.

b. Remove the oil cooler assembly and water outlet pipe gasket from the cylinder block sub-assembly.

.p

c.

w

w

w

Remove the 2 O-rings from the cylinder block sub-assembly.

© 2012 TOYOTA MOTOR CORPORATION. All Rights Reserved.

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-j…manual/repair/contents/RM100000000M7T2.html?PUB_TYPE=RM&MODE=1 Page 1 of 1

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(37 pm

Print Exit

1GD-FTV LUBRICATION LUBRICATION SYSTEM ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

CAUTION:

·

om

t.c

To prevent injury due to contact with an operating fan and generator V-belt or cooling fan, keep your

ke

hands and clothing away from the fan and generator V-belt and cooling fans when working in the engine

compartment with the engine running.

·

ar

m

io

ix

To prevent burns, do not touch the engine, exhaust manifold or other high temperature components

while the engine is hot.

·

.p

w

w

w

To prevent burns, do not remove the engine oil pressure switch assembly while the engine is hot.

PROCEDURE

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…manual/repair/contents/RM100000000M7SL.html?PUB_TYPE=RM&MODE=1 Page 1 of 3

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(37 pm

1.INSPECT OIL QUALITY

a. Check the engine oil for deterioration, water contamination, discoloration or thinning.

If the quality is visibly poor, replace the engine oil and oil filter sub-assembly.

Click hereEngine / Hybrid System>1GD-FTV LUBRICATION>OIL AND OIL FILTER>REPLACEMENT

2.INSPECT ENGINE OIL LEVEL

a. Warm up the engine, and then stop the engine and wait 5 minutes.

b. Check that the engine oil level is between the engine oil level dipstick low level mark and full level mark.

If the engine oil level is low, check for leaks and add engine oil to the full level mark.

om

NOTICE:

Do not fill engine oil above the full level mark.

HINT:

A certain amount of engine oil will be consumed while driving. In the following situations, oil consumption

may increase, and engine oil may need to be refilled in between oil maintenance intervals.

t.c

· When the engine is new, for example directly after purchasing the vehicle or after replacing the

engine.

· If low quality oil or oil of an inappropriate viscosity is used.

· When driving at a high engine speed or with a heavy load, when towing, or when driving while

ke

accelerating or decelerating frequently.

· When idling for a long time, or when driving frequently through heavy traffic.

When judging the amount of oil consumption, keep in mind that the oil may have become diluted, making

it difficult to judge the true level accurately.

ar

3.INSPECT ENGINE OIL PRESSURE

m

CAUTION:

· To prevent injury due to contact with an operating fan and generator V-belt or cooling fan, keep your

io

hands and clothing away from the fan and generator V-belt and cooling fans when working in the engine

compartment with the engine running.

· To prevent burns, do not touch the engine, exhaust manifold or other high temperature components

while the engine is hot.

ix

· To prevent burns, do not remove the engine oil pressure switch assembly while the engine is hot.

.p

a. Remove the engine oil pressure switch assembly.

Click hereEngine / Hybrid System>1GD-FTV LUBRICATION>OIL PRESSURE SWITCH>REMOVAL

b.

w

w

w

*a Oil Pressure Gauge

*b Adapter

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…manual/repair/contents/RM100000000M7SL.html?PUB_TYPE=RM&MODE=1 Page 2 of 3

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(37 pm

Install an oil pressure gauge with the adapter.

NOTICE:

Before and after measurement, clean equipment and hoses.

c. Warm up the engine.

d. Measure the engine oil pressure, and check that it is within the standard range.

Standard Engine Oil Pressure:

Condition Specified Condition

29 kPa (0.3 kgf/cm2, 4.2 psi)

Idle

or higher

245 kPa (2.5 kgf/cm2, 36 psi)

3000 rpm

om

or higher

If the result is not as specified, check the quality of the engine oil and check the oil paths for clogging.

Repair or replace if necessary. If the engine oil pressure is still not as specified, replace the timing chain

case assembly.

t.c

HINT:

Replace the timing chain case assembly as the engine oil pump is built into the timing chain case

assembly.

ke

e. Remove the oil pressure gauge and adapter.

f. Install the engine oil pressure switch assembly.

Click hereEngine / Hybrid System>1GD-FTV LUBRICATION>OIL PRESSURE SWITCH>INSTALLATION

ar

© 2012 TOYOTA MOTOR CORPORATION. All Rights Reserved.

m

io

ix

.p

w

w

w

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…manual/repair/contents/RM100000000M7SL.html?PUB_TYPE=RM&MODE=1 Page 3 of 3

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(38 pm

Print Exit

1GD-FTV LUBRICATION OIL AND OIL FILTER COMPONENTS

ILLUSTRATION

om

t.c

ke

ar

m

io

ix

.p

w

w

w

*A for 4WD and Pre-Runner - -

*1 NO. 1 ENGINE UNDER COVER ASSEMBLY *2 NO. 2 ENGINE UNDER COVER ASSEMBLY

*3 OIL FILTER SUB-ASSEMBLY *4 OIL PAN DRAIN PLUG

*5 GASKET *6 OIL FILLER CAP ASSEMBLY

Tightening torque for "Major areas involving

basic vehicle performance such as N*m (kgf*cm, ft.*lbf): Specified torque

moving/turning/stopping" : N*m (kgf*cm,

ft.*lbf)

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…manual/repair/contents/RM100000000M7SN.html?PUB_TYPE=RM&MODE=1 Page 1 of 2

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(38 pm

● Non-reusable part Engine oil

© 2012 TOYOTA MOTOR CORPORATION. All Rights Reserved.

om

t.c

ke

ar

m

io

ix

.p

w

w

w

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7SN.html?PUB_TYPE=RM&MODE=1 Page 2 of 2

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(38 pm

Print Exit

1GD-FTV LUBRICATION OIL AND OIL FILTER COMPONENTS

ILLUSTRATION

om

t.c

ke

ar

m

io

ix

.p

w

w

w

*A for 4WD and Pre-Runner - -

*1 NO. 1 ENGINE UNDER COVER ASSEMBLY *2 NO. 2 ENGINE UNDER COVER ASSEMBLY

*3 OIL FILTER SUB-ASSEMBLY *4 OIL PAN DRAIN PLUG

*5 GASKET *6 OIL FILLER CAP ASSEMBLY

Tightening torque for "Major areas involving

basic vehicle performance such as N*m (kgf*cm, ft.*lbf): Specified torque

moving/turning/stopping" : N*m (kgf*cm,

ft.*lbf)

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…manual/repair/contents/RM100000000M7SN.html?PUB_TYPE=RM&MODE=1 Page 1 of 2

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(38 pm

● Non-reusable part Engine oil

© 2012 TOYOTA MOTOR CORPORATION. All Rights Reserved.

om

t.c

ke

ar

m

io

ix

.p

w

w

w

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7SN.html?PUB_TYPE=RM&MODE=1 Page 2 of 2

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(39 pm

Print Exit

1GD-FTV LUBRICATION OIL AND OIL FILTER REPLACEMENT

CAUTION / NOTICE / HINT

CAUTION:

· Prolonged and repeated contact with engine oil will result in the removal of natural oils from the skin,

leading to dryness, irritation and dermatitis. In addition, used engine oil contains potentially harmful

contaminants which may cause skin cancer.

· Precautions should be taken when replacing engine oil to minimize the risk of your skin making contact

with used engine oil. Protective clothing and gloves that cannot be penetrated by oil should be worn. The

om

skin should be washed with soap and water, or use waterless hand cleaner, to remove any used engine

oil thoroughly. Do not use gasoline, thinners or solvents.

· In order to protect the environment, used oil and used oil filters must be disposed of at designated

disposal sites.

·

t.c

ke

ar

m

io

To prevent burns, do not remove the oil pan drain plug and oil filter sub-assembly while the engine is

ix

hot.

.p

PROCEDURE

w

1.REMOVE NO. 1 ENGINE UNDER COVER ASSEMBLY (for 4WD and Pre-Runner) 51410

w

2.REMOVE NO. 2 ENGINE UNDER COVER ASSEMBLY (for 4WD and Pre-Runner) 51442

w

3.DRAIN ENGINE OIL

CAUTION:

To prevent burns, do not remove the oil pan drain plug while the engine is hot.

a. Remove the oil filler cap assembly.

b. Remove the oil pan drain plug and gasket, and then drain the engine oil into a container.

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7SM.html?PUB_TYPE=RM&MODE=1 Page 1 of 3

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(39 pm

c. Clean and install a new gasket and the oil pan drain plug.

Torque:

40 N*m (408 kgf*cm, 30 ft.*lbf)

4.REMOVE OIL FILTER SUB-ASSEMBLY 15601

CAUTION:

To prevent burns, do not remove the oil filter sub-assembly while the engine is hot.

a.

om

t.c

Using SST, remove the oil filter sub-assembly.

SST

09228-07501

ke

ar

HINT:

· Before removing the oil filter sub-assembly, place cloth where the oil may splash.

· Use a container to catch the draining engine oil.

m

io

5.INSTALL OIL FILTER SUB-ASSEMBLY 15601

ix

a. Check and clean the oil filter sub-assembly installation surface.

b. Apply clean engine oil to the gasket of a new oil filter sub-assembly.

.p

c. Lightly screw the oil filter sub-assembly into place by hand. Tighten it until the gasket contacts the seat.

d.

w

w

w

3/4 Turn

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7SM.html?PUB_TYPE=RM&MODE=1 Page 2 of 3

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(39 pm

Using SST, tighten the oil filter sub-assembly.

SST

09228-07501

i. Depending on the space available, choose from the following.

If enough space is available, use a torque wrench to tighten the oil filter sub-assembly.

Torque:

12 N*m (122 kgf*cm, 9 ft.*lbf)

ii. If enough space is not available to use a torque wrench, tighten the oil filter sub-assembly 3/4 of a turn

by hand or with a common wrench.

om

6.ADD ENGINE OIL

a. Add new engine oil and install the oil filler cap assembly.

t.c

Standard Oil Grade:

Item Oil Grade Oil Viscosity (SAE)

ACEA C2

(Using engine oil other than - 0W-30

w/ DPF

ACEA C2 may damage the - 5W-30

ke

catalytic converter)

- 5W-30

w/o DPF API-CF-4, CF or ACEA B1 - 10W-30

- 15W-40

ar

Standard Capacity:

Item Specified Condition

m

Drain and refill without oil filter sub-assembly

7.0 liters (7.4 US qts, 6.2 Imp. qts)

change

Drain and refill with oil filter sub-assembly

io

7.5 liters (7.9 US qts, 6.6 Imp. qts)

change

Dry fill 8.0 liters (8.5 US qts, 7.0 Imp. qts)

ix

.p

7.INSPECT FOR OIL LEAK

a. Start the engine. Make sure that there are no oil leaks from the areas that were worked on.

w

8.INSPECT ENGINE OIL LEVEL

w

Click hereEngine / Hybrid System>1GD-FTV LUBRICATION>LUBRICATION SYSTEM>ON-VEHICLE INSPECTION

w

9.INSTALL NO. 2 ENGINE UNDER COVER ASSEMBLY (for 4WD and Pre-Runner) 51442

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE ASSEMBLY>INSTALLATION

10.INSTALL NO. 1 ENGINE UNDER COVER ASSEMBLY (for 4WD and Pre-Runner) 51410

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE ASSEMBLY>INSTALLATION

© 2012 TOYOTA MOTOR CORPORATION. All Rights Reserved.

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7SM.html?PUB_TYPE=RM&MODE=1 Page 3 of 3

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(39 pm

Print Exit

1GD-FTV LUBRICATION OIL AND OIL FILTER REPLACEMENT

CAUTION / NOTICE / HINT

CAUTION:

· Prolonged and repeated contact with engine oil will result in the removal of natural oils from the skin,

leading to dryness, irritation and dermatitis. In addition, used engine oil contains potentially harmful

contaminants which may cause skin cancer.

· Precautions should be taken when replacing engine oil to minimize the risk of your skin making contact

with used engine oil. Protective clothing and gloves that cannot be penetrated by oil should be worn. The

om

skin should be washed with soap and water, or use waterless hand cleaner, to remove any used engine

oil thoroughly. Do not use gasoline, thinners or solvents.

· In order to protect the environment, used oil and used oil filters must be disposed of at designated

disposal sites.

·

t.c

ke

ar

m

io

To prevent burns, do not remove the oil pan drain plug and oil filter sub-assembly while the engine is

ix

hot.

.p

PROCEDURE

w

1.REMOVE NO. 1 ENGINE UNDER COVER ASSEMBLY (for 4WD and Pre-Runner) 51410

w

2.REMOVE NO. 2 ENGINE UNDER COVER ASSEMBLY (for 4WD and Pre-Runner) 51442

w

3.DRAIN ENGINE OIL

CAUTION:

To prevent burns, do not remove the oil pan drain plug while the engine is hot.

a. Remove the oil filler cap assembly.

b. Remove the oil pan drain plug and gasket, and then drain the engine oil into a container.

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7SM.html?PUB_TYPE=RM&MODE=1 Page 1 of 3

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(39 pm

c. Clean and install a new gasket and the oil pan drain plug.

Torque:

40 N*m (408 kgf*cm, 30 ft.*lbf)

4.REMOVE OIL FILTER SUB-ASSEMBLY 15601

CAUTION:

To prevent burns, do not remove the oil filter sub-assembly while the engine is hot.

a.

om

t.c

Using SST, remove the oil filter sub-assembly.

SST

09228-07501

ke

ar

HINT:

· Before removing the oil filter sub-assembly, place cloth where the oil may splash.

· Use a container to catch the draining engine oil.

m

io

5.INSTALL OIL FILTER SUB-ASSEMBLY 15601

ix

a. Check and clean the oil filter sub-assembly installation surface.

b. Apply clean engine oil to the gasket of a new oil filter sub-assembly.

.p

c. Lightly screw the oil filter sub-assembly into place by hand. Tighten it until the gasket contacts the seat.

d.

w

w

w

3/4 Turn

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7SM.html?PUB_TYPE=RM&MODE=1 Page 2 of 3

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(39 pm

Using SST, tighten the oil filter sub-assembly.

SST

09228-07501

i. Depending on the space available, choose from the following.

If enough space is available, use a torque wrench to tighten the oil filter sub-assembly.

Torque:

12 N*m (122 kgf*cm, 9 ft.*lbf)

ii. If enough space is not available to use a torque wrench, tighten the oil filter sub-assembly 3/4 of a turn

by hand or with a common wrench.

om

6.ADD ENGINE OIL

a. Add new engine oil and install the oil filler cap assembly.

t.c

Standard Oil Grade:

Item Oil Grade Oil Viscosity (SAE)

ACEA C2

(Using engine oil other than - 0W-30

w/ DPF

ACEA C2 may damage the - 5W-30

ke

catalytic converter)

- 5W-30

w/o DPF API-CF-4, CF or ACEA B1 - 10W-30

- 15W-40

ar

Standard Capacity:

Item Specified Condition

m

Drain and refill without oil filter sub-assembly

7.0 liters (7.4 US qts, 6.2 Imp. qts)

change

Drain and refill with oil filter sub-assembly

io

7.5 liters (7.9 US qts, 6.6 Imp. qts)

change

Dry fill 8.0 liters (8.5 US qts, 7.0 Imp. qts)

ix

.p

7.INSPECT FOR OIL LEAK

a. Start the engine. Make sure that there are no oil leaks from the areas that were worked on.

w

8.INSPECT ENGINE OIL LEVEL

w

Click hereEngine / Hybrid System>1GD-FTV LUBRICATION>LUBRICATION SYSTEM>ON-VEHICLE INSPECTION

w

9.INSTALL NO. 2 ENGINE UNDER COVER ASSEMBLY (for 4WD and Pre-Runner) 51442

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE ASSEMBLY>INSTALLATION

10.INSTALL NO. 1 ENGINE UNDER COVER ASSEMBLY (for 4WD and Pre-Runner) 51410

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE ASSEMBLY>INSTALLATION

© 2012 TOYOTA MOTOR CORPORATION. All Rights Reserved.

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7SM.html?PUB_TYPE=RM&MODE=1 Page 3 of 3

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(40 pm

Print Exit

1GD-FTV LUBRICATION OIL LEVEL SENSOR COMPONENTS

ILLUSTRATION

om

t.c

ke

ar

m

io

ix

.p

*A for 4WD and Pre-Runner - -

*1 ENGINE OIL LEVEL SENSOR *2 NO. 1 ENGINE UNDER COVER ASSEMBLY

*3 NO. 2 ENGINE UNDER COVER ASSEMBLY - -

w

N*m (kgf*cm, ft.*lbf): Specified torque - -

w

w

© 2012 TOYOTA MOTOR CORPORATION. All Rights Reserved.

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…manual/repair/contents/RM100000000M7SU.html?PUB_TYPE=RM&MODE=1 Page 1 of 1

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(40 pm

Print Exit

1GD-FTV LUBRICATION OIL LEVEL SENSOR COMPONENTS

ILLUSTRATION

om

t.c

ke

ar

m

io

ix

.p

*A for 4WD and Pre-Runner - -

*1 ENGINE OIL LEVEL SENSOR *2 NO. 1 ENGINE UNDER COVER ASSEMBLY

*3 NO. 2 ENGINE UNDER COVER ASSEMBLY - -

w

N*m (kgf*cm, ft.*lbf): Specified torque - -

w

w

© 2012 TOYOTA MOTOR CORPORATION. All Rights Reserved.

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…manual/repair/contents/RM100000000M7SU.html?PUB_TYPE=RM&MODE=1 Page 1 of 1

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

Print Exit

1GD-FTV LUBRICATION OIL LEVEL SENSOR INSPECTION

PROCEDURE

1.INSPECT ENGINE OIL LEVEL SENSOR 89491

a.

om

t.c

ke

ar

Component without harness connected

*a

m

(Engine Oil Level Sensor)

*b On

*c Off

io

Measure the resistance according to the value(s) in the table below.

Standard Resistance:

ix

Tester Switch Specified

Connection Condition Condition

On at below

Below 1 Ω

.p

40°C

Off at below

Below 1 Ω

40°C

1-2

On at 60°C or

w

Below 1 Ω

higher

Off at 60°C or 10 kΩ or

higher higher

w

CAUTION:

w

· Do not put your hands in the water warmed up during the inspection.

· Touching the hot water may result in burns.

NOTICE:

When checking the engine oil level sensor in water, do not allow water to contact the terminals. After

completing the check, dry the engine oil level sensor.

HINT:

· In addition to a level switch, the oil level sensor also has a temperature switch. Therefore, make

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…manual/repair/contents/RM100000000M7SS.html?PUB_TYPE=RM&MODE=1 Page 1 of 2

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

sure to check the oil level sensor at both high and low temperatures.

· If the result is not as specified, replace the engine oil level sensor.

© 2012 TOYOTA MOTOR CORPORATION. All Rights Reserved.

om

t.c

ke

ar

m

io

ix

.p

w

w

w

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…manual/repair/contents/RM100000000M7SS.html?PUB_TYPE=RM&MODE=1 Page 2 of 2

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

Print Exit

1GD-FTV LUBRICATION OIL LEVEL SENSOR INSPECTION

PROCEDURE

1.INSPECT ENGINE OIL LEVEL SENSOR 89491

a.

om

t.c

ke

ar

Component without harness connected

*a

m

(Engine Oil Level Sensor)

*b On

*c Off

io

Measure the resistance according to the value(s) in the table below.

Standard Resistance:

ix

Tester Switch Specified

Connection Condition Condition

On at below

Below 1 Ω

.p

40°C

Off at below

Below 1 Ω

40°C

1-2

On at 60°C or

w

Below 1 Ω

higher

Off at 60°C or 10 kΩ or

higher higher

w

CAUTION:

w

· Do not put your hands in the water warmed up during the inspection.

· Touching the hot water may result in burns.

NOTICE:

When checking the engine oil level sensor in water, do not allow water to contact the terminals. After

completing the check, dry the engine oil level sensor.

HINT:

· In addition to a level switch, the oil level sensor also has a temperature switch. Therefore, make

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…manual/repair/contents/RM100000000M7SS.html?PUB_TYPE=RM&MODE=1 Page 1 of 2

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

sure to check the oil level sensor at both high and low temperatures.

· If the result is not as specified, replace the engine oil level sensor.

© 2012 TOYOTA MOTOR CORPORATION. All Rights Reserved.

om

t.c

ke

ar

m

io

ix

.p

w

w

w

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…manual/repair/contents/RM100000000M7SS.html?PUB_TYPE=RM&MODE=1 Page 2 of 2

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

Print Exit

1GD-FTV LUBRICATION OIL LEVEL SENSOR INSTALLATION

PROCEDURE

1.INSTALL ENGINE OIL LEVEL SENSOR 89491

a. Install the engine oil level sensor to the oil pan sub-assembly with the 4 bolts.

Torque:

12 N*m (122 kgf*cm, 9 ft.*lbf)

om

b. Connect the engine oil level sensor connector.

2.ADD ENGINE OIL

t.c

Click hereEngine / Hybrid System>1GD-FTV LUBRICATION>OIL AND OIL FILTER>REPLACEMENT

3.INSPECT FOR OIL LEAK

ke

Click hereEngine / Hybrid System>1GD-FTV LUBRICATION>OIL AND OIL FILTER>REPLACEMENT

4.INSPECT ENGINE OIL LEVEL

ar

Click hereEngine / Hybrid System>1GD-FTV LUBRICATION>LUBRICATION SYSTEM>ON-VEHICLE INSPECTION

5.INSTALL NO. 2 ENGINE UNDER COVER ASSEMBLY (for 4WD and Pre-Runner) 51442

m

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE ASSEMBLY>INSTALLATION

51410

io

6.INSTALL NO. 1 ENGINE UNDER COVER ASSEMBLY (for 4WD and Pre-Runner)

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE ASSEMBLY>INSTALLATION

ix

© 2012 TOYOTA MOTOR CORPORATION. All Rights Reserved.

.p

w

w

w

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-j…manual/repair/contents/RM100000000M7ST.html?PUB_TYPE=RM&MODE=1 Page 1 of 1

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

Print Exit

1GD-FTV LUBRICATION OIL LEVEL SENSOR INSTALLATION

PROCEDURE

1.INSTALL ENGINE OIL LEVEL SENSOR 89491

a. Install the engine oil level sensor to the oil pan sub-assembly with the 4 bolts.

Torque:

12 N*m (122 kgf*cm, 9 ft.*lbf)

om

b. Connect the engine oil level sensor connector.

2.ADD ENGINE OIL

t.c

Click hereEngine / Hybrid System>1GD-FTV LUBRICATION>OIL AND OIL FILTER>REPLACEMENT

3.INSPECT FOR OIL LEAK

ke

Click hereEngine / Hybrid System>1GD-FTV LUBRICATION>OIL AND OIL FILTER>REPLACEMENT

4.INSPECT ENGINE OIL LEVEL

ar

Click hereEngine / Hybrid System>1GD-FTV LUBRICATION>LUBRICATION SYSTEM>ON-VEHICLE INSPECTION

5.INSTALL NO. 2 ENGINE UNDER COVER ASSEMBLY (for 4WD and Pre-Runner) 51442

m

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE ASSEMBLY>INSTALLATION

51410

io

6.INSTALL NO. 1 ENGINE UNDER COVER ASSEMBLY (for 4WD and Pre-Runner)

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE ASSEMBLY>INSTALLATION

ix

© 2012 TOYOTA MOTOR CORPORATION. All Rights Reserved.

.p

w

w

w

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-j…manual/repair/contents/RM100000000M7ST.html?PUB_TYPE=RM&MODE=1 Page 1 of 1

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(40 pm

Print Exit

1GD-FTV LUBRICATION OIL LEVEL SENSOR REMOVAL

CAUTION / NOTICE / HINT

CAUTION:

To prevent burns, do not remove the engine oil level sensor while the engine is hot.

PROCEDURE

om

1.REMOVE NO. 1 ENGINE UNDER COVER ASSEMBLY (for 4WD and Pre-Runner) 51410

2.REMOVE NO. 2 ENGINE UNDER COVER ASSEMBLY (for 4WD and Pre-Runner) 51442

t.c

3.DRAIN ENGINE OIL

Click hereEngine / Hybrid System>1GD-FTV LUBRICATION>OIL AND OIL FILTER>REPLACEMENT

CAUTION:

4.REMOVE ENGINE OIL LEVEL SENSOR

ke 89491

ar

To prevent burns, do not remove the engine oil level sensor while the engine is hot.

a. Disconnect the engine oil level sensor connector.

m

b.

io

ix

.p

w

Remove the 4 bolts and engine oil level sensor from oil pan sub-assembly.

w

© 2012 TOYOTA MOTOR CORPORATION. All Rights Reserved.

w

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-j…manual/repair/contents/RM100000000M7SV.html?PUB_TYPE=RM&MODE=1 Page 1 of 1

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(39 pm

Print Exit

1GD-FTV LUBRICATION OIL PRESSURE SWITCH COMPONENTS

ILLUSTRATION

om

t.c

ke

ar

m

io

ix

.p

w

w

w

*1 ENGINE OIL PRESSURE SWITCH ASSEMBLY *2 NO. 1 ENGINE UNDER COVER ASSEMBLY

*3 NO. 2 ENGINE UNDER COVER ASSEMBLY - -

TOYOTA Genuine Adhesive 1344, Three Bond

N*m (kgf*cm, ft.*lbf): Specified torque

1344 or equivalent.

Precoated part - -

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…manual/repair/contents/RM100000000M7SQ.html?PUB_TYPE=RM&MODE=1 Page 1 of 2

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(39 pm

© 2012 TOYOTA MOTOR CORPORATION. All Rights Reserved.

om

t.c

ke

ar

m

io

ix

.p

w

w

w

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7SQ.html?PUB_TYPE=RM&MODE=1 Page 2 of 2

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(39 pm

Print Exit

1GD-FTV LUBRICATION OIL PRESSURE SWITCH INSPECTION

PROCEDURE

1.INSPECT ENGINE OIL PRESSURE SWITCH ASSEMBLY 83530

a. Disconnect the engine oil pressure switch connector.

b. Start the engine.

om

c. Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Tester Specified

Condition

Connection Condition

t.c

Engine stopped Below 1 Ω

1 - Body

ground 10 kΩ or

Engine idling

higher

ke

If the result is not as specified, replace the engine oil pressure switch assembly.

d. Connect the engine oil pressure switch connector.

ar

© 2012 TOYOTA MOTOR CORPORATION. All Rights Reserved.

m

io

ix

.p

w

w

w

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-j…manual/repair/contents/RM100000000M7SP.html?PUB_TYPE=RM&MODE=1 Page 1 of 1

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(40 pm

Print Exit

1GD-FTV LUBRICATION OIL PRESSURE SWITCH INSTALLATION

PROCEDURE

1.INSTALL ENGINE OIL PRESSURE SWITCH ASSEMBLY 83530

a.

om

t.c

ke

*a Adhesive

Apply adhesive to 2 or 3 threads of the engine oil pressure switch assembly.

Adhesive:

ar

Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent

NOTICE:

Do not apply adhesive to the oil inlet port of the engine oil pressure switch assembly.

m

b. Using a 24 mm deep socket wrench, install the engine oil pressure switch assembly to the oil filter bracket.

io

Torque:

15 N*m (153 kgf*cm, 11 ft.*lbf)

NOTICE:

ix

Do not start the engine for at least 1 hour after the installation.

.p

c. Connect the engine oil pressure switch connector.

w

2.ADD ENGINE OIL

Click hereEngine / Hybrid System>1GD-FTV LUBRICATION>OIL AND OIL FILTER>REPLACEMENT

w

3.INSPECT FOR OIL LEAK

w

Click hereEngine / Hybrid System>1GD-FTV LUBRICATION>OIL AND OIL FILTER>REPLACEMENT

4.INSTALL NO. 2 ENGINE UNDER COVER ASSEMBLY (for 4WD and Pre-Runner) 51442

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE ASSEMBLY>INSTALLATION

5.INSTALL NO. 1 ENGINE UNDER COVER ASSEMBLY (for 4WD and Pre-Runner) 51410

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE ASSEMBLY>INSTALLATION

© 2012 TOYOTA MOTOR CORPORATION. All Rights Reserved.

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…manual/repair/contents/RM100000000M7SO.html?PUB_TYPE=RM&MODE=1 Page 1 of 1

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(39 pm

Print Exit

1GD-FTV LUBRICATION OIL PRESSURE SWITCH REMOVAL

CAUTION / NOTICE / HINT

CAUTION:

om

t.c

To prevent burns, do not remove the engine oil pressure switch assembly while the engine is hot.

PROCEDURE

ke

ar

1.REMOVE NO. 1 ENGINE UNDER COVER ASSEMBLY (for 4WD and Pre-Runner) 51410

m

2.REMOVE NO. 2 ENGINE UNDER COVER ASSEMBLY (for 4WD and Pre-Runner) 51442

3.DRAIN ENGINE OIL

io

Click hereEngine / Hybrid System>1GD-FTV LUBRICATION>OIL AND OIL FILTER>REPLACEMENT

ix

4.REMOVE ENGINE OIL PRESSURE SWITCH ASSEMBLY 83530

CAUTION:

.p

To prevent burns, do not remove the engine oil pressure switch assembly while the engine is hot.

a. Disconnect the engine oil pressure switch connector.

w

b.

w

w

Using a 24 mm deep socket wrench, remove the engine oil pressure switch assembly from the oil filter

bracket.

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…manual/repair/contents/RM100000000M7SR.html?PUB_TYPE=RM&MODE=1 Page 1 of 2

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(39 pm

© 2012 TOYOTA MOTOR CORPORATION. All Rights Reserved.

om

t.c

ke

ar

m

io

ix

.p

w

w

w

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7SR.html?PUB_TYPE=RM&MODE=1 Page 2 of 2

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

Print Exit

1GD-FTV LUBRICATION OIL PUMP COMPONENTS

ILLUSTRATION

om

t.c

ke

ar

m

io

ix

.p

w

w

w

*A w/ DPF - -

*1 DIFFERENTIAL PRESSURE SENSOR *2 NO. 1 EXHAUST GAS TEMPERATURE SENSOR

*3 NO. 2 EXHAUST GAS TEMPERATURE SENSOR *4 NO. 3 EXHAUST GAS TEMPERATURE SENSOR

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7SX.html?PUB_TYPE=RM&MODE=1 Page 1 of 24

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

*5 NO. 1 VACUUM PIPE *6 NO. 2 VACUUM PIPE

*7 PIPE CLAMP *8 CLAMP

N*m (kgf*cm, ft.*lbf): Specified torque * For use with union nut wrench

ILLUSTRATION

om

t.c

ke

ar

m

io

ix

.p

w

w

w

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7SX.html?PUB_TYPE=RM&MODE=1 Page 2 of 24

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

om

t.c

ke

ar

m

io

ix

.p

w

w

w

*A for Cold Area Specification Vehicles - -

*1 DIESEL THROTTLE BODY ASSEMBLY *2 DIESEL TURBO PRESSURE SENSOR

*3 ENGINE COVER BRACKET *4 GAS FILTER

*5 HOSE BRACKET *6 INTERCOOLER AIR TUBE

*7 NO. 2 ENGINE COVER BRACKET *8 NO. 2 HOSE TO HOSE TUBE

*9 NO. 2 WATER BY-PASS PIPE *10 NO. 11 WATER BY-PASS HOSE

*11 NO. 14 WATER BY-PASS HOSE *12 GASKET

N*m (kgf*cm, ft.*lbf): Specified torque ● Non-reusable part

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7SX.html?PUB_TYPE=RM&MODE=1 Page 3 of 24

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

ILLUSTRATION

om

t.c

ke

ar

m

io

ix

.p

w

w

w

*A for Cold Area Specification Vehicles - -

*1 CONNECTING WIRE *2 EGR VALVE BRACKET

NO. 1 EGR COOLER AND NO. 2 EGR VALVE

*3 ENGINE OIL LEVEL DIPSTICK GUIDE *4 ASSEMBLY WITH ELECTRIC EGR CONTROL

VALVE ASSEMBLY

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7SX.html?PUB_TYPE=RM&MODE=1 Page 4 of 24

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

*5 NO. 1 EGR PIPE SUB-ASSEMBLY *6 NO. 2 EGR PIPE

*7 NO. 3 WATER BY-PASS PIPE SUB-ASSEMBLY *8 NO. 4 WATER BY-PASS PIPE SUB-ASSEMBLY

*9 VACUUM CONTROL VALVE SET *10 ENGINE OIL LEVEL DIPSTICK

*11 GASKET *12 O-RING

*13 STUD BOLT - -

N*m (kgf*cm, ft.*lbf): Specified torque ● Non-reusable part

Engine oil - -

om

ILLUSTRATION

t.c

ke

ar

m

io

ix

.p

w

w

w

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7SX.html?PUB_TYPE=RM&MODE=1 Page 5 of 24

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

om

t.c

ke

ar

m

io

ix

.p

w

w

w

*A w/ DPF - -

*1 FUEL INJECTION PUMP COVER SUB-ASSEMBLY *2 FUEL PUMP MOTOR WIRE

*3 MANIFOLD STAY *4 NO. 1 FUEL HOSE

*5 NO. 2 FUEL HOSE *6 NO. 2 FUEL PIPE

*7 NO. 3 FUEL PIPE *8 NO. 4 FUEL PIPE SUB-ASSEMBLY

*9 WIRING HARNESS CLAMP BRACKET *10 FUEL PIPE CLAMP

*11 SUPPLY PUMP HOLLOW SCREW *12 UNION BOLT

*13 GASKET - -

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7SX.html?PUB_TYPE=RM&MODE=1 Page 6 of 24

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

N*m (kgf*cm, ft.*lbf): Specified torque ● Non-reusable part

ILLUSTRATION

om

t.c

ke

ar

m

io

ix

.p

w

w

w

*A w/ DPF - -

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7SX.html?PUB_TYPE=RM&MODE=1 Page 7 of 24

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

*1 FUEL INLET PIPE SUB-ASSEMBLY *2 INTAKE MANIFOLD

*3 NO. 2 NOZZLE LEAKAGE PIPE ASSEMBLY *4 WIRING HARNESS CLAMP BRACKET

*5 INJECTION PIPE CLAMP *6 NO. 2 INJECTION PIPE CLAMP

*7 GASKET - -

Tightening torque for "Major areas involving

basic vehicle performance such as

N*m (kgf*cm, ft.*lbf): Specified torque

moving/turning/stopping" : N*m (kgf*cm,

ft.*lbf)

* For use with SST or union nut wrench ● Non-reusable part

ILLUSTRATION

om

t.c

ke

ar

m

io

ix

.p

w

w

w

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7SX.html?PUB_TYPE=RM&MODE=1 Page 8 of 24

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

om

t.c

ke

ar

m

io

ix

.p

w

w

w

*A w/ DPF *B w/ Air Conditioning System

*C w/o Air Conditioning System - -

*1 NO. 1 COMPRESSOR MOUNTING BRACKET *2 NO. 1 FUEL PIPE

*3 IDLER PULLEY SUB-ASSEMBLY *4 NO. 1 INJECTION PIPE SUB-ASSEMBLY

*5 NO. 2 INJECTION PIPE SUB-ASSEMBLY *6 NOZZLE LEAKAGE PIPE ASSEMBLY

*7 WIRING HARNESS CLAMP BRACKET *8 UNION BOLT

*9 GASKET - -

Tightening torque for "Major areas involving

basic vehicle performance such as N*m (kgf*cm, ft.*lbf): Specified torque

moving/turning/stopping" : N*m (kgf*cm,

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7SX.html?PUB_TYPE=RM&MODE=1 Page 9 of 24

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

ft.*lbf)

* For use with SST ● Non-reusable part

ILLUSTRATION

om

t.c

ke

ar

m

io

ix

.p

w

w

w

*A w/ DPF - -

EXHAUST MANIFOLD CONVERTER SUB-

*1 AIR FUEL RATIO SENSOR *2

ASSEMBLY

https://toyotamanuals.com.au/docs/hilux-service-repair-manual…anual/repair/contents/RM100000000M7SX.html?PUB_TYPE=RM&MODE=1 Page 10 of 24

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

*3 EXHAUST PIPE SUPPORT STAY *4 NO. 1 EXHAUST MANIFOLD HEAT INSULATOR

*5 NO. 1 INJECTOR HOLDER *6 NO. 1 TURBO INSULATOR

*7 NO. 1 WATER HOSE CLAMP BRACKET *8 NO. 2 EXHAUST PIPE SUPPORT STAY

*9 NO. 4 WATER BY-PASS HOSE *10 NO. 5 WATER BY-PASS HOSE

*11 EXHAUST PIPE CLAMP *12 GASKET

N*m (kgf*cm, ft.*lbf): Specified torque * For use with SST

● Non-reusable part - -

ILLUSTRATION

om

t.c

ke

ar

m

io

ix

.p

w

w

w

https://toyotamanuals.com.au/docs/hilux-service-repair-manual…anual/repair/contents/RM100000000M7SX.html?PUB_TYPE=RM&MODE=1 Page 11 of 24

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

om

t.c

ke

ar

m

io

ix

.p

w

w

w

*A w/o DPF - -

EXHAUST MANIFOLD CONVERTER SUB-

*1 *2 EXHAUST PIPE SUPPORT STAY

ASSEMBLY

*3 NO. 1 EXHAUST MANIFOLD HEAT INSULATOR *4 NO. 1 TURBO INSULATOR

*5 NO. 2 EXHAUST PIPE SUPPORT STAY *6 EXHAUST PIPE CLAMP

*7 GASKET - -

N*m (kgf*cm, ft.*lbf): Specified torque ● Non-reusable part

https://toyotamanuals.com.au/docs/hilux-service-repair-manual…anual/repair/contents/RM100000000M7SX.html?PUB_TYPE=RM&MODE=1 Page 12 of 24

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

ILLUSTRATION

om

t.c

ke

ar

m

io

ix

.p

w

w

w

*A except Cold Area Specification Vehicles *B for Cold Area Specification Vehicles

*C w/ Viscous Heater - -

*1 NO. 1 VISCOUS HEATER BRACKET SUB- *2 NO. 3 WATER BY-PASS PIPE

ASSEMBLY

*3 PCV HOSE *4 PCV PIPE

https://toyotamanuals.com.au/docs/hilux-service-repair-manual…anual/repair/contents/RM100000000M7SX.html?PUB_TYPE=RM&MODE=1 Page 13 of 24

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

N*m (kgf*cm, ft.*lbf): Specified torque - -

ILLUSTRATION

om

t.c

ke

ar

m

io

ix

.p

w

w

w

*1 NO. 1 TURBO WATER HOSE *2 NO. 2 TURBO WATER HOSE

https://toyotamanuals.com.au/docs/hilux-service-repair-manual…anual/repair/contents/RM100000000M7SX.html?PUB_TYPE=RM&MODE=1 Page 14 of 24

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

*3 TURBO OIL INLET PIPE SUB-ASSEMBLY *4 TURBO OIL OUTLET PIPE

*5 TURBOCHARGER STAY *6 TURBOCHARGER SUB-ASSEMBLY

*7 UNION BOLT *8 GASKET

Tightening torque for "Major areas involving

basic vehicle performance such as N*m (kgf*cm, ft.*lbf): Specified torque

moving/turning/stopping" : N*m (kgf*cm,

ft.*lbf)

● Non-reusable part - -

ILLUSTRATION

om

t.c

ke

ar

m

io

ix

.p

w

w

w

*A w/ DPF *B for Cold Area Specification Vehicles

*1 NO. 1 WATER BY-PASS PIPE *2 NO. 2 WATER BY-PASS PIPE SUB-ASSEMBLY

*3 THERMOSTAT *4 WATER INLET

https://toyotamanuals.com.au/docs/hilux-service-repair-manual…anual/repair/contents/RM100000000M7SX.html?PUB_TYPE=RM&MODE=1 Page 15 of 24

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

*5 WATER OUTLET SUB-ASSEMBLY *6 GASKET

N*m (kgf*cm, ft.*lbf): Specified torque ● Non-reusable part

ILLUSTRATION

om

t.c

ke

ar

m

io

ix

.p

w

w

w

*A w/o Viscous Heater *B w/ Viscous Heater

*1 CRANKSHAFT PULLEY *2 CRANKSHAFT PULLY COVER

*3 NO. 1 IDLER PULLEY SUB-ASSEMBLY *4 VISCOUS HEATER CRANKSHAFT PULLEY

*5 V-RIBBED BELT TENSIONER ASSEMBLY *6 CRANKSHAFT PULLEY SET BOLT

https://toyotamanuals.com.au/docs/hilux-service-repair-manual…anual/repair/contents/RM100000000M7SX.html?PUB_TYPE=RM&MODE=1 Page 16 of 24

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

N*m (kgf*cm, ft.*lbf): Specified torque ● Non-reusable part

ILLUSTRATION

om

t.c

ke

ar

m

io

ix

.p

w

w

w

*A w/ DPF *B w/o DPF

https://toyotamanuals.com.au/docs/hilux-service-repair-manual…anual/repair/contents/RM100000000M7SX.html?PUB_TYPE=RM&MODE=1 Page 17 of 24

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

*1 GENERATOR BRACKET SUB-ASSEMBLY *2 INJECTION PUMP INSULATOR

*3 NO. 1 ENGINE HANGER *4 SUPPLY PUMP ASSEMBLY

*5 TIMING CHAIN COVER PLATE *6 SUPPLY PUMP SHAFT NUT

*7 NO. 1 FUEL PUMP BRACKET *8 GASKET

*9 O-RING - -

Tightening torque for "Major areas involving

basic vehicle performance such as

N*m (kgf*cm, ft.*lbf): Specified torque

moving/turning/stopping" : N*m (kgf*cm,

ft.*lbf)

● Non-reusable part - -

ILLUSTRATION

om

t.c

ke

ar

m

io

ix

.p

w

w

w

*1 CAMSHAFT POSITION SENSOR *2 CYLINDER HEAD COVER SUB-ASSEMBLY

https://toyotamanuals.com.au/docs/hilux-service-repair-manual…anual/repair/contents/RM100000000M7SX.html?PUB_TYPE=RM&MODE=1 Page 18 of 24

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

*3 INJECTOR ASSEMBLY *4 NOZZLE HOLDER GASKET

*5 CYLINDER HEAD COVER GASKET *6 NO. 2 CYLINDER HEAD COVER GASKET

*7 CAMSHAFT BEARING CAP OIL HOLE GASKET *8 NOZZLE HOLDER CLAMP

*9 INJECTION NOZZLE SEAT *10 NOZZLE HOLDER CLAMP SEAT

*11 WASHER *12 O-RING

Tightening torque for "Major areas involving

basic vehicle performance such as

N*m (kgf*cm, ft.*lbf): Specified torque

moving/turning/stopping" : N*m (kgf*cm,

ft.*lbf)

● Non-reusable part Engine oil

om

ILLUSTRATION

t.c

ke

ar

m

io

ix

.p

w

w

w

https://toyotamanuals.com.au/docs/hilux-service-repair-manual…anual/repair/contents/RM100000000M7SX.html?PUB_TYPE=RM&MODE=1 Page 19 of 24

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

om

t.c

ke

ar

m

io

ix

.p

w

w

w

*1 ENGINE OIL LEVEL SENSOR *2 OIL PAN COVER SILENCER

*3 OIL PAN SUB-ASSEMBLY *4 OIL PAN DRAIN PLUG

*5 GASKET - -

N*m (kgf*cm, ft.*lbf): Specified torque ● Non-reusable part

https://toyotamanuals.com.au/docs/hilux-service-repair-manual…anual/repair/contents/RM100000000M7SX.html?PUB_TYPE=RM&MODE=1 Page 20 of 24

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

ILLUSTRATION

om

t.c

ke

ar

m

io

ix

.p

w

w

w

*1 CAMSHAFT TIMING SPROCKET (for Exhaust *2 CAMSHAFT TIMING SPROCKET (for Intake

Side) Side)

*3 FRONT CRANKSHAFT OIL SEAL *4 NO. 2 CHAIN SUB-ASSEMBLY

*5 NO. 2 CHAIN TENSIONER ASSEMBLY *6 NO. 2 CHAIN TENSIONER SLIPPER

*7 NO. 2 CHAIN VIBRATION DAMPER *8 TIMING CHAIN COVER SUB-ASSEMBLY

*9 TIMING CHAIN GUIDE *10 TIMING CHAIN CASE GASKET

*11 CAMSHAFT TIMING SPROCKET BOLT - -

https://toyotamanuals.com.au/docs/hilux-service-repair-manual…anual/repair/contents/RM100000000M7SX.html?PUB_TYPE=RM&MODE=1 Page 21 of 24

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

N*m (kgf*cm, ft.*lbf): Specified torque ● Non-reusable part

MP grease Engine oil

ILLUSTRATION

om

t.c

ke

ar

m

io

ix

.p

w

w

w

https://toyotamanuals.com.au/docs/hilux-service-repair-manual…anual/repair/contents/RM100000000M7SX.html?PUB_TYPE=RM&MODE=1 Page 22 of 24

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

om

t.c

ke

ar

m

io

ix

.p

w

w

w

*1 CRANKSHAFT TIMING SPROCKET *2 INJECTION PUMP DRIVE GEAR

*3 NO. 1 CHAIN SUB-ASSEMBLY *4 ENGINE WATER PUMP ASSEMBLY

*5 NO. 1 CHAIN TENSIONER ASSEMBLY *6 NO. 1 CHAIN TENSIONER SLIPPER

*7 NO. 1 CHAIN VIBRATION DAMPER *8 OIL PUMP DRIVE GEAR

*9 TIMING CHAIN CASE ASSEMBLY *10 NO. 1 CHAIN TENSIONER ASSEMBLY BODY

*11 SPRING *12 PLUNGER

*13 GASKET *14 O-RING

N*m (kgf*cm, ft.*lbf): Specified torque ● Non-reusable part

https://toyotamanuals.com.au/docs/hilux-service-repair-manual…anual/repair/contents/RM100000000M7SX.html?PUB_TYPE=RM&MODE=1 Page 23 of 24

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(41 pm

Engine oil - -

© 2012 TOYOTA MOTOR CORPORATION. All Rights Reserved.

om

t.c

ke

ar

m

io

ix

.p

w

w

w

https://toyotamanuals.com.au/docs/hilux-service-repair-manual…anual/repair/contents/RM100000000M7SX.html?PUB_TYPE=RM&MODE=1 Page 24 of 24

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(42 pm

Print Exit

1GD-FTV LUBRICATION OIL PUMP INSTALLATION

CAUTION / NOTICE / HINT

NOTICE:

· When replacing the parts in the following chart (A), replace the No. 1 injection pipe sub-assembly, No. 2

injection pipe sub-assembly and/or fuel inlet pipe sub-assembly with new ones.

Replaced Parts (A) Pipes Requiring New Replacement

· Injector assembly (including shuffling the

om

injector assemblies between the

· No. 1 injection pipe sub-assembly

cylinders)

· No. 2 injection pipe sub-assembly

· Common rail assembly

· Cylinder head sub-assembly

· Supply pump assembly

t.c

· Common rail assembly

· Cylinder block sub-assembly

· Cylinder head sub-assembly Fuel inlet pipe sub-assembly

· Cylinder head gasket

· Timing chain case assembly

·

ke

After removing the No. 1 injection pipe sub-assembly, No. 2 injection pipe sub-assembly and/or fuel inlet

pipe sub-assembly, clean them with a brush and compressed air.

The injector assembly is a precision instrument. Do not use the injector assembly if it is struck or

ar

dropped.

· Make sure foreign matter does not enter the fuel path.

· The supply pump assembly is a precision instrument. Do not use the supply pump assembly if it is struck

or dropped.

m

· Hold the supply pump assembly itself during removal and installation. Do not hold the pre-stroke control

valve or fuel pipe, etc.

io

PROCEDURE

ix

1.INSTALL TIMING CHAIN CASE ASSEMBLY AND ENGINE WATER PUMP ASSEMBLY 11310

.p

a. Apply a light coat of engine oil to the 4 new O-rings.

b. Install the 4 O-rings to the cylinder block sub-assembly and cylinder head sub-assembly.

w

c. Clean and degrease the contact surfaces of the timing chain case assembly, cylinder head sub-assembly

and cylinder block sub-assembly.

w

d. Apply a coating of seal packing to the timing chain case assembly at the points shown in the illustration.

w

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7TG.html?PUB_TYPE=RM&MODE=1 Page 1 of 17

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(42 pm

om

t.c

ke

ar

m

io

ix

.p

w

*a 46 mm (1.81 in.) *b 50 mm (1.97 in.)

*c 2.0 to 3.0 mm (0.0787 to 0.118 in.) *d 2.5 to 3.5 mm (0.0984 to 0.138 in.)

*e 3.0 to 4.0 mm (0.118 to 0.158 in.) *f 1.5 to 2.5 mm (0.0591 to 0.0984 in.)

w

*g 13 to 15 mm (0.512 to 0.591 in.) *h 9.0 to 11 mm (0.354 to 0.433 in.)

*i 31 to 33 mm (1.22 to 1.30 in.) - -

w

Seal packing:

for line area D:

Toyota Genuine Seal Packing 1282B, Three Bond 1282B or equivalent.

for line area A-A, B-B, C-C and E:

Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent.

Seal Packing Application Specification:

Seal Packing Seal Packing

Line Type and Area Application Area

Diameter Application Length

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7TG.html?PUB_TYPE=RM&MODE=1 Page 2 of 17

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(42 pm

Dashed Line 1.5 to 2.5 mm (0.0591 2.0 to 3.0 mm (0.0787 -

to 0.0984 in.) to 0.118 in.)

2.5 to 3.5 mm (0.0984 2.0 to 3.0 mm (0.0787

A-A 46 mm (1.81 in.)

to 0.138 in.) to 0.118 in.)

2.5 to 3.5 mm (0.0984 2.0 to 3.0 mm (0.0787

B-B 50 mm (1.97 in.)

to 0.138 in.) to 0.118 in.)

1.5 to 2.5 mm (0.0591 3.0 to 4.0 mm (0.118 to

D -

to 0.0984 in.) 0.158 in.)

NOTICE:

· Using non-residue solvent, clean and remove any oil from the installation surface.

· Install the part within 3 minutes and tighten the bolts within 10 minutes after applying seal

om

packing.

· Do not add engine oil for at least 2 hours after installation.

· Do not start the engine within 2 hours after installation.

e. Temporarily install the timing chain case assembly with the 15 bolts.

t.c

ke

ar

m

io

*a Type of bolt *b Tightening

ix

Bolt Length:

Thread

Item Length

Diameter

.p

30 mm (1.18 8.0 mm (0.315

Bolt A

in.) in.)

45 mm (1.77 8.0 mm (0.315

w

Bolt B

in.) in.)

65 mm (2.56 8.0 mm (0.315

Bolt C

in.) in.)

w

30 mm (1.18 10 mm (0.394

Bolt D

in.) in.)

w

f. Temporarily install a new gasket and the engine water pump assembly with the 8 bolts.

g. Tighten the 23 bolts in the order shown in the illustration.

Torque:

for bolt A, B and C : 25 N*m (255 kgf*cm, 18 ft.*lbf)

for bolt D : 43 N*m (438 kgf*cm, 32 ft.*lbf)

NOTICE:

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7TG.html?PUB_TYPE=RM&MODE=1 Page 3 of 17

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(42 pm

Check the torque of bolt 1 after tightening bolt 23.

2.INSTALL INJECTION PUMP INSULATOR 22815A

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE UNIT>REASSEMBLY

3.INSTALL SUPPLY PUMP ASSEMBLY 22100

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE UNIT>REASSEMBLY

4.INSTALL NO. 1 CHAIN TENSIONER SLIPPER 13559

om

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE UNIT>REASSEMBLY

5.TEMPORARILY INSTALL NO. 1 CHAIN VIBRATION DAMPER 13561

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE UNIT>REASSEMBLY

t.c

6.INSTALL CRANKSHAFT TIMING SPROCKET, INJECTION PUMP DRIVE GEAR WITH 13506

NO. 1 CHAIN SUB-ASSEMBLY

ke

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE UNIT>REASSEMBLY

7.TIGHTEN NO. 1 CHAIN VIBRATION DAMPER 13561

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE UNIT>REASSEMBLY

ar

8.INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY 13540

m

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE UNIT>REASSEMBLY

9.INSTALL SUPPLY PUMP SHAFT NUT

io

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE UNIT>REASSEMBLY

10.INSTALL CAMSHAFT TIMING SPROCKET 13523

ix

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE UNIT>REASSEMBLY

.p

11.INSTALL NO. 2 CHAIN VIBRATION DAMPER 13562

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE UNIT>REASSEMBLY

w

12.INSTALL NO. 2 CHAIN SUB-ASSEMBLY 13507

w

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE UNIT>REASSEMBLY

13.INSTALL NO. 2 CHAIN TENSIONER SLIPPER 13559

w

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE UNIT>REASSEMBLY

14.INSTALL NO. 2 CHAIN TENSIONER ASSEMBLY 13550

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE UNIT>REASSEMBLY

15.INSTALL TIMING CHAIN GUIDE 13566B

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>CAMSHAFT>INSTALLATION

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7TG.html?PUB_TYPE=RM&MODE=1 Page 4 of 17

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(42 pm

16.CHECK NO. 1 CYLINDER TO TDC/COMPRESSION

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE UNIT>REASSEMBLY

17.INSTALL OIL PUMP DRIVE GEAR 13519

a. Install the oil pump drive gear to the crankshaft.

18.INSTALL TIMING CHAIN COVER PLATE 11324

Click hereEngine / Hybrid System>1GD-FTV FUEL>FUEL SUPPLY PUMP>INSTALLATION

om

19.INSTALL TIMING CHAIN COVER SUB-ASSEMBLY 11302

a. Apply a light coat of engine oil to a new timing chain case gasket.

b. Install the timing chain case gasket to the timing chain case assembly.

t.c

c. Clean and degrease the contact surfaces of the timing chain cover sub-assembly and timing chain case

assembly.

ke

d. Apply a coating of seal packing to the timing chain cover sub-assembly at the points shown in the

illustration. ar

m

io

ix

.p

w

w

w

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7TG.html?PUB_TYPE=RM&MODE=1 Page 5 of 17

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(42 pm

om

t.c

ke

ar

m

io

ix

.p

w

*a 2.0 to 3.0 mm (0.0787 to 0.118 in.) *b 2.5 to 3.5 mm (0.0984 to 0.138 in.)

w

Seal packing:

Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent.

w

Standard seal packing diameter:

2.5 to 3.5 mm (0.0984 to 0.138 in.)

NOTICE:

· Using non-residue solvent, clean and remove any oil from the installation surface.

· Install the part within 3 minutes and tighten the bolts within 10 minutes after applying seal

packing.

· Do not add engine oil for at least 2 hours after installation.

· Do not start the engine within 2 hours after installation.

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7TG.html?PUB_TYPE=RM&MODE=1 Page 6 of 17

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(42 pm

e. Temporarily install the timing chain cover sub-assembly with the 20 bolts.

om

*a Type of bolt *b Tightening

t.c

Bolt Length:

Thread

Item Length

ke

Diameter

40 mm (1.57 8.0 mm (0.315

Bolt A

in.) in.)

25 mm (0.984 8.0 mm (0.315

Bolt B

ar

in.) in.)

m

f. Tighten the 20 bolts in the order shown in the illustration.

Torque:

21 N*m (214 kgf*cm, 15 ft.*lbf)

io

NOTICE:

Check the torque of bolt 1 after tightening bolt 20.

ix

20.INSTALL FRONT CRANKSHAFT OIL SEAL 11303A

.p

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>FRONT CRANKSHAFT OIL

SEAL>INSTALLATION

w

21.INSTALL OIL PAN SUB-ASSEMBLY 12101

w

a. Clean and degrease the contact surfaces of the oil pan sub-assembly and cylinder block sub-assembly.

w

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7TG.html?PUB_TYPE=RM&MODE=1 Page 7 of 17

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(42 pm

b.

om

Seal Packing

t.c

Apply seal packing in a continuous line as shown in the illustration.

Seal packing:

Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

ke

Standard seal diameter:

3.5 to 4.5 mm (0.138 to 0.177 in.)

NOTICE:

· Remove any oil from the contact surface.

ar

· Install the oil pan sub-assembly within 3 minutes and tighten the bolts and nuts within 10 minutes

after applying seal packing.

· Do not add engine oil within 2 hours after installation.

· Do not start the engine for at least 2 hours after installation.

m

c.

io

ix

.p

w

w

Bolt

w

Nut

Install the oil pan sub-assembly to the cylinder block sub-assembly with the 23 bolts and 2 nuts.

Torque:

10 N*m (102 kgf*cm, 7 ft.*lbf)

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7TG.html?PUB_TYPE=RM&MODE=1 Page 8 of 17

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(42 pm

NOTICE:

Check the torque of all nuts and bolts labeled A again.

22.INSTALL ENGINE OIL LEVEL SENSOR 89491

Click hereEngine / Hybrid System>1GD-FTV LUBRICATION>OIL LEVEL SENSOR>INSTALLATION

23.INSTALL OIL PAN COVER SILENCER 12144

a. Install the oil pan cover silencer to the oil pan sub-assembly with the 5 bolts.

Torque:

om

10 N*m (102 kgf*cm, 7 ft.*lbf)

24.INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY 11201

t.c

a. Apply a light coat of engine oil to the O-ring of the camshaft position sensor.

b. Install a new cylinder head cover gasket, No. 2 cylinder head cover gasket and 2 camshaft bearing cap oil

hole gaskets to the cylinder head cover sub-assembly.

ke

c. Clean and degrease the contact surfaces of the cylinder head cover sub-assembly and cylinder head sub-

assembly.

ar

d. Apply seal packing as shown in the illustration.

m

io

ix

.p

w

w

w

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7TG.html?PUB_TYPE=RM&MODE=1 Page 9 of 17

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(42 pm

*1 Timing Chain Cover Sub-assembly *2 Timing Chain Case Assembly

*3 Cylinder Head Sub-assembly *4 No. 3 Camshaft Bearing Cap

Seal Diameter: 3.0 to 6.0 mm (0.118 to 0.236

*a *b Application Width: 7.0 mm (0.276 in.)

in.)

*c Application Width: 9.0 mm (0.354 in.) *d Application Width: 11.0 mm (0.433 in.)

Seal packing:

Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

Standard seal diameter:

3.0 to 6.0 mm (0.118 to 0.236 in.)

NOTICE:

om

· Remove any oil from the contact surface.

· Install the cylinder head cover sub-assembly within 3 minutes and tighten the bolts within 10

minutes after applying seal packing.

· Do not add engine oil for at least 2 hours after installation.

· Do not start the engine within 2 hours after installation.

t.c

e.

ke

ar

m

io

Bolt

ix

Nut

.p

Nozzle Holder Clamp Seat

w

w

Tighten the 14 bolts, 4 nozzle holder clamp seats, 2 nuts and camshaft position sensor in the order shown

in the illustration.

w

Torque:

10 N*m (102 kgf*cm, 7 ft.*lbf)

NOTICE:

· When reusing the camshaft position sensor, check the O-rings.

· Make sure that the O-ring is not cracked or jammed when installing it on the cylinder head cover

sub-assembly.

· Replace with a new part if it is dropped or if it receives a strong impact.

· Check the torque of bolts 1 to 4 again.

https://toyotamanuals.com.au/docs/hilux-service-repair-manual…anual/repair/contents/RM100000000M7TG.html?PUB_TYPE=RM&MODE=1 Page 10 of 17

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(42 pm

25.INSTALL NOZZLE HOLDER GASKET 23682

Click hereEngine / Hybrid System>1GD-FTV FUEL>FUEL INJECTOR>INSTALLATION

26.TEMPORARILY INSTALL INJECTOR ASSEMBLY 23670

Click hereEngine / Hybrid System>1GD-FTV FUEL>FUEL INJECTOR>INSTALLATION

27.INSTALL GENERATOR BRACKET SUB-ASSEMBLY 12501

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE UNIT>REASSEMBLY

om

28.INSTALL NO. 1 ENGINE HANGER 12281A

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE UNIT>REASSEMBLY

29.INSTALL NO. 1 WATER HOSE CLAMP BRACKET (w/ DPF) 16575C

t.c

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE UNIT>INSTALLATION

30.INSTALL CRANKSHAFT PULLEY 13471

ke

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>FRONT CRANKSHAFT OIL

SEAL>INSTALLATION

31.INSTALL CRANKSHAFT PULLEY COVER 13496

ar

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>FRONT CRANKSHAFT OIL

SEAL>INSTALLATION

m

32.INSTALL VISCOUS HEATER CRANKSHAFT PULLEY (w/ Viscous Heater) 88451B

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>FRONT CRANKSHAFT OIL

SEAL>INSTALLATION

io

33.INSTALL V-RIBBED BELT TENSIONER ASSEMBLY 16620

ix

a. Install the V-ribbed belt tensioner assembly to the timing chain cover sub-assembly with 3 bolts.

Torque:

21 N*m (214 kgf*cm, 15 ft.*lbf)

.p

w

34.INSTALL NO. 1 IDLER PULLEY SUB-ASSEMBLY 16603

a. Install the No. 1 idler pulley sub-assembly to the generator bracket sub-assembly with the bolt.

w

Torque:

43 N*m (438 kgf*cm, 32 ft.*lbf)

w

35.INSTALL THERMOSTAT 16331A

Click hereEngine / Hybrid System>1GD-FTV COOLING>THERMOSTAT>INSTALLATION

36.INSTALL WATER INLET 16321

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE UNIT>INSTALLATION

https://toyotamanuals.com.au/docs/hilux-service-repair-manual-…anual/repair/contents/RM100000000M7TG.html?PUB_TYPE=RM&MODE=1 Page 11 of 17

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(42 pm

37.INSTALL WATER OUTLET SUB-ASSEMBLY 16304

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE UNIT>INSTALLATION

38.INSTALL NO. 2 WATER BY-PASS PIPE SUB-ASSEMBLY 16207

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE UNIT>INSTALLATION

39.TEMPORARILY INSTALL TURBO OIL INLET PIPE SUB-ASSEMBLY 15407

Click hereEngine / Hybrid System>1GD-FTV INTAKE / EXHAUST>EXHAUST MANIFOLD W/

TURBOCHARGER>INSTALLATION

om

40.TEMPORARILY INSTALL EXHAUST MANIFOLD WITH TURBOCHARGER SUB- 17141

ASSEMBLY

Click hereEngine / Hybrid System>1GD-FTV INTAKE / EXHAUST>EXHAUST MANIFOLD W/

TURBOCHARGER>INSTALLATION

t.c

41.INSTALL TURBO OIL OUTLET PIPE 15474

Click hereEngine / Hybrid System>1GD-FTV INTAKE / EXHAUST>EXHAUST MANIFOLD W/

TURBOCHARGER>INSTALLATION

ke

42.TEMPORARILY INSTALL TURBOCHARGER STAY 17293

Click hereEngine / Hybrid System>1GD-FTV INTAKE / EXHAUST>EXHAUST MANIFOLD W/

TURBOCHARGER>INSTALLATION

ar

43.TIGHTEN EXHAUST MANIFOLD WITH TURBOCHARGER SUB-ASSEMBLY 17141

m

Click hereEngine / Hybrid System>1GD-FTV INTAKE / EXHAUST>EXHAUST MANIFOLD W/

TURBOCHARGER>INSTALLATION

44.TIGHTEN TURBOCHARGER STAY 17293

io

Click hereEngine / Hybrid System>1GD-FTV INTAKE / EXHAUST>EXHAUST MANIFOLD W/

TURBOCHARGER>INSTALLATION

ix

45.INSTALL NO. 1 VISCOUS HEATER BRACKET SUB-ASSEMBLY (w/ Viscous 87101

Heater)

.p

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE UNIT>INSTALLATION

w

46.CONNECT NO. 1 AND NO. 2 TURBO WATER HOSE 16284

Click hereEngine / Hybrid System>1GD-FTV INTAKE / EXHAUST>EXHAUST MANIFOLD W/

TURBOCHARGER>INSTALLATION

w

47.INSTALL NO. 1 WATER BY-PASS PIPE 16268

w

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE UNIT>INSTALLATION

48.INSTALL NO. 3 WATER BY-PASS PIPE 16279

Click hereEngine / Hybrid System>1GD-FTV INTAKE / EXHAUST>EXHAUST MANIFOLD W/

TURBOCHARGER>INSTALLATION

49.INSTALL PCV HOSE (except Cold Area Specification Vehicles) 12261

Click hereEngine / Hybrid System>1GD-FTV INTAKE / EXHAUST>EXHAUST MANIFOLD W/

https://toyotamanuals.com.au/docs/hilux-service-repair-manual…anual/repair/contents/RM100000000M7TG.html?PUB_TYPE=RM&MODE=1 Page 12 of 17

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(42 pm

TURBOCHARGER>INSTALLATION

50.INSTALL EXHAUST MANIFOLD CONVERTER SUB-ASSEMBLY 25051

· w/ DPF:

Click hereEngine / Hybrid System>1GD-FTV EMISSION CONTROL>MONOLITHIC CONVERTER(w/

DPF)>INSTALLATION

· w/o DPF:

Click hereEngine / Hybrid System>1GD-FTV EMISSION CONTROL>MONOLITHIC CONVERTER(w/o

DPF)>INSTALLATION

51.INSTALL NO. 2 EXHAUST PIPE SUPPORT STAY

om

· w/ DPF:

Click hereEngine / Hybrid System>1GD-FTV EMISSION CONTROL>MONOLITHIC CONVERTER(w/

DPF)>INSTALLATION

· w/o DPF:

Click hereEngine / Hybrid System>1GD-FTV EMISSION CONTROL>MONOLITHIC CONVERTER(w/o

DPF)>INSTALLATION

t.c

52.INSTALL NO. 1 TURBO INSULATOR 17271

ke

· w/ DPF:

Click hereEngine / Hybrid System>1GD-FTV EMISSION CONTROL>MONOLITHIC CONVERTER(w/

DPF)>INSTALLATION

· w/o DPF:

Click hereEngine / Hybrid System>1GD-FTV EMISSION CONTROL>MONOLITHIC CONVERTER(w/o

ar

DPF)>INSTALLATION

53.INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR 17167

m

· w/ DPF:

Click hereEngine / Hybrid System>1GD-FTV EMISSION CONTROL>MONOLITHIC CONVERTER(w/

io

DPF)>INSTALLATION

· w/o DPF:

Click hereEngine / Hybrid System>1GD-FTV EMISSION CONTROL>MONOLITHIC CONVERTER(w/o

DPF)>INSTALLATION

ix

54.INSTALL AIR FUEL RATIO SENSOR (w/ DPF) 89467B

.p

Click hereEngine / Hybrid System>1GD-FTV ENGINE CONTROL>AIR FUEL RATIO SENSOR>INSTALLATION

w

55.INSTALL NO. 1 INJECTOR HOLDER (w/ DPF) 23295D

Click hereEngine / Hybrid System>1GD-FTV EMISSION CONTROL>EXHAUST FUEL ADDITION

w

INJECTOR>INSTALLATION

56.CONNECT NO. 4 WATER BY-PASS HOSE (w/ DPF) 16281

w

Click hereEngine / Hybrid System>1GD-FTV EMISSION CONTROL>EXHAUST FUEL ADDITION

INJECTOR>INSTALLATION

57.INSTALL NO. 5 WATER BY-PASS HOSE (w/ DPF) 16282

Click hereEngine / Hybrid System>1GD-FTV EMISSION CONTROL>EXHAUST FUEL ADDITION

INJECTOR>INSTALLATION

58.INSTALL PCV PIPE (for Cold Area Specification Vehicles) 12229

https://toyotamanuals.com.au/docs/hilux-service-repair-manual…anual/repair/contents/RM100000000M7TG.html?PUB_TYPE=RM&MODE=1 Page 13 of 17

Find more manuals on: www.pixiomarket.com

Find more manuals on: www.pixiomarket.com

Print-Toyota Service Information 11/3/17, 6(42 pm

Click hereEngine / Hybrid System>1GD-FTV INTAKE / EXHAUST>EXHAUST MANIFOLD W/

TURBOCHARGER>INSTALLATION

59.INSTALL IDLER PULLEY ASSEMBLY (w/o Air Conditioning System) 16630D

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE UNIT>INSTALLATION

60.INSTALL NO. 1 COMPRESSOR MOUNTING BRACKET (w/ Air Conditioning 88431

System)

Click hereEngine / Hybrid System>1GD-FTV ENGINE MECHANICAL>ENGINE UNIT>INSTALLATION

61.INSTALL HOSE BRACKET 44781

om