Professional Documents

Culture Documents

SCL Model

SCL Model

Uploaded by

beriCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SCL Model

SCL Model

Uploaded by

beriCopyright:

Available Formats

SAFETY RESEARCH

Peer-Reviewed

SAFETY CLAS

& LEARNIN

Defining & Class

Serious Injurie

I

By Matthew R. Hallowell and Carren Spencer

IN THE SAFETY PROFESSION, nothing is more important SIFs are paradoxical for organizational learning.

than preventing serious injuries and fatalities (SIFs). Although SIFs are extraordinarily important, they are

Despite widespread efforts, however, SIFs continue to exceedingly rare and randomly distributed over time

plague every major industry. In 2021 alone, 5,190 fatal and space (Hallowell et al., 2021). Consequently, safety

injuries occurred in U.S. workplaces (BLS, 2022), result- professionals observe a “whack a mole” approach to

ing in $6 billion of direct costs and immeasurable harm learning from SIFs whereby organizations rightfully de-

to the well-being of the workforce and their families ploy significant resources to deeply investigate the few

(NSC, n.d.). Although safety professionals have made cases that occur. The findings are then aggregated using

great strides in the prevention of recordable injuries, the common cause analyses and conclusions are presented

rate of SIFs has generally plateaued and even increased as if they characterize underlying patterns. Unfortu-

in recent years (BLS, 2022). For example, as observed in nately, it is difficult to apply robust statistics to reveal

Figure 1 (p. 20), the rate of OSHA-recordable injuries meaningful trends from the few fatalities that occur

declined in the electric utility sector by approximately within individual companies. Although many compa-

50% over the past decade while the rate of fatal injuries nies may attempt to leverage the information available,

has remained relatively stable. When examining 3.2 the lack of sufficient data means that no single company

trillion worker hours of data across industrial sectors, has enough SIF data to effectively trend, learn from and

Hallowell et al. (2021) found a similar statistical discon- eliminate fatalities on its own.

nect. These trends provide compelling evidence that Progress toward eliminating SIFs requires increasing

reductions in lower-severity injuries do not translate to the number of learning opportunities and community-

proportional reductions in SIFs, which directly contra- level data sharing that transcends traditional company

dicts antiquated theories stemming from the unfortu- boundaries. To expand relevant learning opportunities,

nately ubiquitous Heinrich pyramid (Heinrich, 1931). many organizations have begun to explore potential SIF

Therefore, targeted methods are needed for SIF-specific (PSIF) events. If companies adopt a common method of

learning and prevention. defining and classifying PSIF events and share data within

their respective communities, safety professionals could

KEY TAKEAWAYS transition from the fragmented and isolated analysis of a

•(SIFs)

Understanding how to prevent serious injuries and fatalities

is a priority for the safety profession. Potential SIF (PSIF)

handful of SIF events to an integrated method of learning

from thousands of SIF and PSIF events.

events may be used to significantly broaden learning. However, In pursuit of this vision, the Edison Electric Institute

an experiment revealed that current methods of defining PSIF (EEI), the association that represents all U.S. investor-

events result in so much inconsistency in classification (noise) owned electric companies, formed a team of academic

that they have limited utility. researchers and industry safety professionals to create a ro-

• To address this core limitation, the safety classification and

learning (SCL) model was created by an integrated team of ac-

bust scientific method of defining and classifying PSIFs and

other high-potential learning opportunities, and to initiate

ademic and industry professionals. This model is based on the and maintain a community of practice where EEI members

science of energy-based safety, controls analysis and principles may collaborate to learn and respond to salient trends.

of human performance.

• A community of practice was created to facilitate implemen-

tation and diffusion of the SCL model via calibration, revision,

Background

The goal of this study was to create definitions. Al-

data sharing, sector-level trending and advocacy. though seemingly banal, common definitions are the

18 PSJ PROFESSIONAL SAFETY FEBRUARY 2024 assp.org

SSIFICATION

NG MODEL

sifying Potential

es & Fatalities

foundation of learning because a common understanding definitions still lead to inconsistent classifications and

of a topic influences how people communicate and what is incoherent communication. Therefore, an intensional

perceived as relevant (Vincent, 2022). Precise definitions definition of PSIF is needed to accelerate learning.

afford the ability to classify observations consistently and

reliably, which facilitates communication, hypothesis test- Existing Methods of Assessing PSIFs

ing, trending and innovation. Without shared definitions, The concept of PSIFs is hardly new. Blog posts and

there can be no reliable measurement or trending and, white papers have been published about PSIFs for more

consequently, no scientific advancement. than a decade. Although authors of these publications

When a new phenomenon is observed or conceived, made the case that PSIF events should be studied to ex-

its associated definitions tend to mature over time. The pand learning, they did not offer a definition of the term

process begins with the subjective interpretation of an (e.g., Horan, 2017). To find a more precise definition, the

observer (i.e., “you know it when you see it”). Then, as authors of this study turned to peer-reviewed literature.

a phenomenon is observed more broadly, extensional Unfortunately, a thorough search of the Web of Science,

definitions emerge that explain a term by specifying Scopus and Google Scholar revealed no peer-reviewed

every observed element (i.e., a list-based approach). studies that provide a definition of PSIF. Instead, the

Finally, once conceptual meaning is assigned to a phe- authors’ review revealed that most mature methods of

nomenon, intensional definitions are created, taking assessing PSIFs are extensional (i.e., list-based) definitions

the form of a set of precise rules that can be empirically in reports published by the Campbell Institute (2018) and

examined (i.e., a rule-based approach). Intensional DEKRA (2019). These resources present PSIF classifica-

definitions are preferable because they enable consistent tion schemes that involve a list of SIF exposures such as:

and robust classification. 1) confined space

A case example is the evolution of the term “planet.” 2) lockout/tagout

The term was first coined by the ancient Greeks to 3) work at height

describe a celestial object that appeared to move inde- 4) fall greater than 48 in.

pendently from fixed stars (NASA, n.d.). During the 5) falling into deep water

17th century, an extensional definition formed as a 6) suspended load

comprehensive list of all observed planets. It wasn’t until 7) hot work

2006 that the International Astronomical Union (IAU, 8) arc flash

2006) created an intensional definition. Now, a planet 9) fire

is precisely defined as a celestial body that 1) is in or- 10) explosion

bit around the Sun, 2) is massive enough that it takes a 11) hazardous materials

nearly round shape, and 3) has cleared the neighborhood 12) vehicle collision

COLDSNOWSTORM/E+/GETTY IMAGES

around its orbit. Using this rule-based definition, any 13) struck-by or caught between a vehicle or powered

newly observed celestial object may be consistently clas- equipment

sified, and the findings can be unambiguously shared 14) contact with moving components of stationary

with the scientific community. machinery

In the case of PSIFs, definitions have recently matured 15) barricades or guarding has been defeated or

from personal interpretation (i.e., “you know it when you bypassed

see it”) to extensional definitions (i.e., lists of hazardous 16) contact with moving components of powered

situations that commonly cause a SIF). These extensional equipment

assp.org FEBRUARY 2024 PROFESSIONAL SAFETY PSJ 19

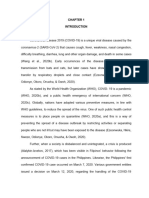

FIGURE 1

POWER GENERATION & DELIVERY INJURY & FATALITY TRENDS

Injury and fatality trends for electric power generation and delivery (rolling 3-year average).

2.200

0.145

2.000 0.125

Recordable injury rate

1.800 0.105

Fatality rate

0.085

1.600

0.065

1.400

0.045

1.200

0.025

1.000 0.005

2010 2011 2012 2013 2014 2015 2016 2017 2018 2019 2020 2021

Year

Total recordable injury rate (per 200,000 worker-hours) Fatality rate (per 1,000 workers)

Note. Reprinted from “The Power to Prevent Serious Injuries and Fatalities,” by Edison Electric Institute (EEI), 2020 (www.eei.org/-/media/

Project/EEI/Documents/Issues-and-Policy/Power-to-Prevent-SIF/SCLwebinar.pdf). Copyright 2020 EEI. Reprinted with permission.

17) pinched, caught between, struck by or in the line of fire a technical advisor and a program manager. The profes-

of a moving object with sufficient energy to cause SIF harm sional members of the team were senior safety leaders

18) violent attacks by a person or animal species capa- representing electric companies in North America. To

ble of inflicting SIF harm execute the study, the team met in person for 1 day each

19) electrical contact of sufficient voltage or amperage month for 6 months. Figure 2 provides a high-level sum-

to cause SIF harm mary of the model development process.

20) uncontrolled energy sources like electrical, me- The process began with an inventory of existing methods

chanical, hydraulic, pneumatic, chemical, thermal, high of PSIF classification used by the members of the team.

pressure or potential energy Each team member described the methods used by their

21) any other SIF exposure situation not described company. Most team members (80%) made decisions based

These list-based definitions advance understanding of on the experience and judgment of their internal safety

PSIFs because they provide tangible examples that practi- team. Although approximately 20% of the team used the

tioners can use to begin to calibrate. Unfortunately, some existing reference tools, they all made organization-specific

serious limitations remain. They do not help identify adaptations such as adding, removing or editing categories

when an incident or observation is not a PSIF. For exam- from the lists. Therefore, no two organizations on the team

ple, with a desired conclusion, any incident or condition used the same method to classify PSIF events.

could be classified as a PSIF by citing items 19, 20 or 21 To examine the variability in PSIF assessment, the au-

from the preceding list. In other words, if an analyst be- thors conducted an experiment on 14 recent incident cases

lieves that a case is a PSIF, there are no rules to suggest submitted by the team members using the methods sug-

otherwise. This increases the potential for overinclusion, gested by Kahneman et al. (2021). In the experiment, the

which waters down SIF-specific learning. authors asked the team members to independently review

Honoring the important progress made by others, the each case and draw a conclusion (PSIF or not a PSIF) using

authors’ goal was to mature a PSIF definition by intro- their preferred method of classification. Surprisingly, the

ducing an intensional (rule-based) definition that gives average level of agreement was only 64%, where 50% rep-

meaning via the science of energy-based safety, controls resents perfect disagreement (i.e., a 50/50 split). This small

analysis and principles of human performance. experiment exposed the magnitude of the PSIF classifica-

tion problem and subsequent discussions revealed the root

Study Protocol causes of the variability.

To create and test a new method of PSIF definition and After the cases were independently reviewed and clas-

classification, EEI convened a team of 20 professionals, sified, the team discussed and debated their conclusions.

20 PSJ PROFESSIONAL SAFETY FEBRUARY 2024 assp.org

These discussions revealed two key philosophical differ- the cases that they found most challenging. During the

ences. The first related to assessing the worst possible out- testing procedure, every decision criterion was carefully

come versus the most likely outcome. That is, while some revised to remove ambiguity and potential subjectivity.

focused on whether the event could have possibly caused To ensure that the model would be broadly useful, all

a SIF, others judged whether the condition was likely to decisions related to the model structure and definitions

cause a SIF. Although seemingly inconsequential, the dif- were made by consensus. In each iteration of the model,

ference in these perspectives had a significant impact on the team members individually reviewed and classified

the results. The team reconciled these perspectives, con- 10 cases. The level of agreement was computed for the

cluding that we should not be asking the question “does round and cases with high levels of disagreement were

this incident have SIF potential?” because every hazard discussed. After four rounds of review (i.e., 40 test cases),

has the remote possibility of causing a SIF. Instead, we the model yielded greater than 95% agreement. The final

should ask, “Is the most likely outcome of this event a model, named the safety classification and learning (SCL)

SIF?” The second major philosophical difference related model, is shown in Figure 3 (p. 22).

to controls. Although some team members focused only

on the seriousness of the hazard involved, others consid- Using the SCL Model

ered the presence and adequacy of relevant controls. After This SCL model is based on four questions. The an-

the discussions, the team concluded that cases where an swers to these questions can be complex and hotly de-

adequate control was present were fundamentally differ- bated without clear and compelling rules. Thus, detailed

ent from those with an inadequate level of control. The guidance was created for each question.

team agreed that a new model must address, reflect and

operationalize these positions. Question 1: Was High Energy Present?

The team decided that a hazardous condition is seri-

Model Creation & Refinement ous when the most likely outcome associated with the

The model was designed based on guiding principles. hazard is a SIF. To assist with objective assessments, the

Specifically, the team agreed that a new model of PSIF authors leveraged knowledge from energy-based safety.

classification must: In an experiment based on empirical data, Hallowell et

•align with the team’s collective philosophies and al. (2017) found that the magnitude of physical energy

principles, predicts the most likely severity of an incident. Specifi-

•establish when an event is and is not a PSIF, cally, incidents with energy greater than 500 joules are

•involve objective assessment based on scientific most likely to cause a medical case or more severe inju-

knowledge, ry, and incidents with energy greater than 1,500 joules

•yield consistent classification results regardless of em- are most likely to be fatal. To be conservative and to

ployer, experience or background, conform to imperial units used by most of the team

•include an assessment of controls, and members, the high-energy threshold was set as 500 ft-lb

•result in clear and crisp operational definitions of SIF, (slightly less than 500 joules). Consequently, the term

PSIF, and other event or observation types. “high-energy” in the SCL model refers to a condition

Based upon these principles, a first draft of the new where a SIF is the most likely outcome because the phys-

model was created by the technical advisor. The draft ical energy exceeds 500 ft-lb.

model was then tested by analyzing actual cases and Because energy assessment can be challenging, two

refined over an iterative process. To enhance the robust- resources were developed. First, the authors created

ness of the model, the team members were asked to bring an energy calculator application that enables precise

FIGURE 2

MODEL CREATION & TESTING PROCESS

Note. Reprinted from “Safety Classification and Learning (SCL) Model,” by M. Hallowell, 2023 (https://bit.ly/3mFRw5C). Copyright 2023

EEI. Reprinted with permission.

assp.org FEBRUARY 2024 PROFESSIONAL SAFETY PSJ 21

computations of energy magnitude based on reasonably control of the worker. Finally, the worker must either have

estimated parameters such as height, weight, speed and contact with the energy or be in proximity to the energy.

voltage. Second, to make energy assessment more fea- “Contact” is defined as an instance when the high energy

sible in the field, the authors also created a set of icons is transmitted to the human body. “Proximity” is defined

that correspond to the different hazardous conditions as a hazardous circumstance where the boundary of the

where the energy magnitude almost always exceeds the high-energy exposure is 1) within 6 ft of the worker; 2)

500-ft-lb threshold (see Table 1). Although these icons within a confined space; or 3) within a situation where

are generally objective, they are not all-inclusive and a worker cannot escape the energy source (restricted

actual energy computations should be made for the most egress). These definitions should be interpreted exactly as

precise assessments. worded to ensure consistent classification.

Question 2: Was There a High-Energy Incident? Question 3: Was a Serious Injury Sustained?

Given that at least one high-energy hazard exists, the When determining whether an injury is serious, the team

next question is whether there was an incident related to deferred to the EEI (n.d.) SIF criteria maintained by the EEI

that energy source. The team first assumed that deciding Recordkeeping Task Force. EEI maintains a definition of

whether an incident had occurred would be obvious. serious injury based on a list of injuries and illnesses that

However, as cases were analyzed, it became apparent that are considered serious. Since there is no single definition of

this is more nuanced than anticipated. The team settled serious injury that transcends all industrial sectors, future

on this definition: research is recommended.

An instance where the high-energy source was Question 4: Was a Direct Control Present?

released and where the worker came in contact A core principle in the SCL model is that the primary

with or proximity to the high-energy source. differentiator between safety success and failure is the

This definition is graphically described in Figure 4 (p. 24). presence or absence of direct controls. The team care-

To ensure consistent application of this definition, the fully defined a direct control as one that 1) is specifically

team defined “energy release” as an instance where the targeted to the high-energy source; 2) effectively miti-

energy source changes state while exposed to the work gates exposure to the high-energy source when installed,

environment. Examples of energy release could be a tool verified and used properly (i.e., a SIF should not reason-

that is dropped and transitions from potential to kinetic ably occur if these conditions are present); and 3) is ef-

energy, or a person who loses control of their balance fective even if there is unintentional human error during

and stumbles. The energy release is always related to an the work (unrelated to the installation of the control).

instance where the energy is no longer contained or in the The first two criteria relate to energy control theory

FIGURE 3

SAFETY CLASSIFICATION & LEARNING (SCL)

Note. Reprinted from “Safety Classification and Learning (SCL) Model,” by M. Hallowell, 2023 (https://bit.ly/3mFRw5C). Copyright 2023

EEI. Reprinted with permission.

22 PSJ PROFESSIONAL SAFETY FEBRUARY 2024 assp.org

TABLE 1

COMMON HIGH-ENERGY HAZARDS

Icon Description

Gravity

Most suspended loads require specialty equipment to lift more than 500 lb of load

higher than 1 ft off the ground. In such a case, the suspended load would exceed

the high-energy threshold.

while the third criterion was included

to align with principles of human per- Suspended load

formance (Conklin, 2019). Since human Gravity

Considering the average weight of a human is more than 150 lb, 4 ft of elevation

error is normal and inevitable, controls ≥ 4 ft

(measured from the ground surface to the bottom of the feet) exceeds the high-

must be effective even when people make energy threshold.

mistakes (Reason, 1990).

Fall from elevation

Examples of direct controls that typ- Because of the mass, most mobile equipment including motor vehicles exceeds

ically correspond to this definition in- Motion

the high-energy threshold when the equipment or vehicle is in motion at any

clude physical lockout/tagout, machine speed. The energy exposure is taken from the point of view of the worker on foot

guarding, hard physical barriers, fall and not the equipment operator or vehicle driver. (Note: For work zone traffic, an

protection and rubber cover-up. Exam- Mobile equipment/ incident occurs only when a vehicle departs from the intended path of travel and

traffic with workers

on foot is within 6 ft of an exposed employee, or if an employee enters the traffic pattern.)

ples that are not direct controls include Estimations of the motor vehicle speed typically involved in serious or fatal crashes

training, warning signs, rules and expe- Motion

vary greatly from the National Transportation Safety Board, National Highway

rience because they are susceptible to un- ≥ 30 mph

Transportation Safety Association and the U.S. Department of Transportation. The

intentional human error. Further, most team selected a conservative estimate of 30 mph as the high-energy threshold.

standard nonspecialized PPE such as Motor vehicle This energy exposure is taken from the point of view of the vehicle occupants,

incident (occupant) including the driver.

hard hats, gloves and boots are not direct Computing mechanical energy can be complex as it requires estimation of

controls because they are not specifically Mechanical

moment of inertia and angular velocity for rotating objects and stiffness and

targeted to a high-energy source. Al- displacement for tension or compression. Thus, all heavy rotating equipment

though many of these safety practices are beyond powered hand tools typically exceed the high-energy threshold and

extremely important, they are not con- Heavy rotating should be considered high energy.

equipment

sidered sufficient as the only protection Temperature

According to the American Burn Association (2023), exposure to any substance

against life-threatening hazards. By con- >150 °F typically causes third-degree burns when contacted for 2 seconds or

trast, some specialized PPE such as rated ≥ 150°F more.

rubber gloves and sleeves, arc-flash suits

High temperature

or a properly rated respirator do meet the According to the American Burn Associa2on (2023), any circumstance with the

definition of a direct control. Temperature

release of steam exceeds the high-energy threshold.

Direct controls can be either absolute

or mitigating. Absolute controls eliminate

high-energy exposure when installed, ver- Steam

According to the North American Combustion Handbook (Reed, 1978), a lightly

ified and used properly, and include tech- Temperature

combustible material such as paper burns at approximately 700 °F, far exceeding

niques such as de-energization, physical the temperature threshold. Fire with a sustained source of fuel exceeds the high-

lockout/tagout or machine guarding. Mit- energy threshold.

igating controls reduce energy exposure Fire with sustained

to below the 500-ft-lb threshold, but do fuel source

Most incidents described as an explosion exceed the high-energy threshold.

not eliminate all exposure to the energy, Pressure

such as a thermal insulation barrier that

reduces heat exposure from a pipe, fall

protection that limits free fall, or airbags Explosion

and seat belts that reduce impact during a Pressure

An exposure to unsupported soil in a trench or excavation more than 5 ft deep

motor vehicle crash. exceeds the high-energy threshold. Typically, for each foot of depth, soil pressure

≥ 5 ft

increases by about 40 lb per square foot. Thus, at a depth of 5ft, the pressure is

approximately 200 lb per square foot.

Definitions of SCL Model Categories Excavation or trench

The SCL model can yield one of seven Electricity > 50 V is sufficient to result in serious injury or death according to NFPA

Electrical

possible outcomes. A definition and inter- 70E (2024). Note that this icon is conservative, as most medical literature indicates

pretation for each of these classifications

≥ 50 V that a current of 1 A or greater has the likely potential to cause a SIF.

are provided here. The definitions are con-

Electrical contact

sistent with the four SCL model questions. with source

•High-energy SIF: Incident with a re- Electrical Any arc flash exceeds the high-energy threshold because of the voltage exposure

lease of high energy where a serious in- according to NFPA 70E (2024). Also, permissible distances are covered in 29 CFR

jury is sustained. These are high-priority 1910.333, in particular, section 1910.333(c)(3)(ii)(C).

events because a worker, their family, Arc flash

coworkers and the organization are all Exposure to toxic chemicals or radiation. An industrial hygienist, chemist,

deeply affected. The organization must Chemical/ toxicologist, or other competent person should be involved in the assessment of

respond seriously to such events and seek radiation

toxicity and acceptable exposure limits. The following references should be used

to learn to prevent future failures. In al- to judge acceptable exposure limits:

• immediately dangerous to life or health (IDLH) values from NIOSH

most every high-energy SIF event, a direct High dose of toxic • exposures which reduce oxygen levels below 16%

control was absent. chemical or radiation

• corrosive chemical exposures (pH < 2 or > 12.5)

•Low-energy SIF: Incident with a re-

lease of low energy where a serious in- Note. Reprinted from “Safety Classification and Learning (SCL) Model,” by M. Hallowell, 2023

jury is sustained. Typically, low-energy (https://bit.ly/3mFRw5C). Copyright 2023 EEI. Reprinted with permission.

SIF incidents are related to health and

assp.org FEBRUARY 2024 PROFESSIONAL SAFETY PSJ 23

FIGURE 4

COMPONENTS OF HIGH-ENERGY INCIDENT DEFINITION

High energy Energy Contact or High-energy

present released proximity incident

physiology. Unlike high-energy SIF events that mainly Case 1

relate to engineering controls, low-energy SIF events are An employee was on the top of a de-energized trans-

typically best addressed by an industrial hygienist or a former at 25 ft of height with a proper fall arrest sys-

medical professional. Thus, the competencies needed tem. While working, she tripped on a lifting lug and

to learn and the means of preventing future incidents fell from the unguarded edge. She was caught by

may require consultation outside of the safety profes- the fall arrest system, which functioned as designed.

sion. Low-energy SIFs are not less important than high- The employee sprained a wrist in the fall, which was

energy SIFs; they are simply different. treated on site by a medical professional.

•PSIF: Incident with a release of high energy in the Classification decisions:

absence of a direct control where a serious injury is not 1) Was high-energy present? Yes, the worker was at 25 ft of

sustained. PSIF incidents have the same circumstances height, which exceeds 4-ft threshold (see Table 1 icon, p. 23).

and characteristics as high-energy SIF events except 2) Was there a high-energy incident? Yes, the worker

for the SIF outcome. In other words, we were simply tripped and fell.

lucky that a SIF did not occur. These events are excellent 3) Was a serious injury sustained? No, a sprained wrist

learning opportunities because there was no serious out- is not considered serious per the EEI SIF criteria.

come and parties involved in the incident can be includ- 4) Was a direct control present? Yes, a proper fall arrest

ed in the learning team. system was used, which is a mitigating control that reduc-

•Capacity: Incident with a release of high energy in es energy exposure to below 500 ft-lb.

the presence of a direct control where a serious injury Conclusion: Capacity

is not sustained. Unlike PSIF cases, direct controls are

present in capacity cases. Because a high-energy incident

Case 2

occurred in the presence of a direct control, capacity inci-

An employee was working alone and placed an ex-

dents are not inherently positive or negative. Rather, they

tension ladder against the wall. When he reached 10

represent excellent learning opportunities because they

ft of height, the ladder feet slid out and he fell with

provide insight on what triggered the energy release and

the ladder to the floor. The employee was taken

the opportunity to verify the resilience of their controls

to the hospital for a bruise to his right leg and re-

without negative consequences.

mained off duty for 3 days.

•Exposure: Condition where high energy is present in

the absence of a direct control. Unlike incidents, an expo- Classification decisions:

sure is an observable condition. Exposure conditions are the 1) Was high-energy present? Yes, the worker was at 10 ft

same as PSIFs and high-energy SIFs except that an incident of height, which exceeds the 4-ft threshold (see Table 1

has yet to occur. Thus, learning can occur from exposure icon, p. 23).

events before a negative incident occurs. Observations of 2) Was there a high-energy incident? Yes, the energy was

conditions can also be made regularly, resulting in a higher released when the worker fell.

volume of learning opportunities. 3) Was a serious injury sustained? No, the injury does

•Success: Condition where a high-energy incident not meet the EEI SIF criteria.

does not occur because of the presence of a direct con- 4) Was a direct control present? No, there were no con-

trol. The SCL model creates an operational definition of trols that meet the direct control requirements.

success as it applies to SIFs. Here, success is distinguished Conclusion: PSIF

from all other observations by the presence of direct con-

trols. As with exposure cases, success cases are conditions Case 3

that may be regularly observed. Therefore, they can be A crew was closing a 7-ton door on a coal crusher. As

studied in high volume. the door was lowered, an observer noticed that the

•Low severity: These low-priority situations did not jack was not positioned correctly and could tip. The

result in or are unlikely to result in a SIF. Although they observer also noted that workers were nearby, within

should not be ignored, they have minimal relevance for 4 ft of the jack.

SIF prevention. Classification decisions:

1) Was high-energy present? Yes, the 7-ton door far

Example Cases exceeds the 500-ft-lb threshold for gravity per energy

To assist the reader with interpreting and applying the calculations.

SCL model, three example cases are provided. More cases 2) Was there a high-energy incident? No, the observer

are available from EEI (n.d.). intervened before the energy was released.

24 PSJ PROFESSIONAL SAFETY FEBRUARY 2024 assp.org

3) Was a serious injury sustained? No. made instead of collecting all the evidence. All four

4) Was a direct control present? No, the jack was not primary questions (and their subquestions) should be

installed and used properly. answered carefully and completely before a classifica-

Conclusion: Exposure tion is made.

2) Avoid what-if scenarios when classifying. When

Community of Practice beginning to use the SCL model, analysts tend to consid-

The author’s team was motivated to create the SCL er how changes in hazard circumstances and proximity

model to 1) improve consistency in the assessment of PSIF would change the classification of the event. Although

and other high-value learning opportunities and 2) create interesting, what-if scenarios should not be considered

a mechanism by which the EEI community could share in the formal classification of the event or observation.

and learn from relevant data. The authors perceived the Instead, the analyst should consider only the facts and

risk that without some form of moderation, companies avoid fabrications.

would begin to customize and adapt the SCL model to 3) The SCL model should be used for learning, not

align with their individual company philosophies. Such for the creation of new metrics. There is often an initial

alterations would erode the ability to share and collab- desire to create metrics from the SCL model. For example,

orate across organizational some organizations have con-

boundaries. Thus, EEI creat- sidered measuring a PSIF rate.

ed a community of practice Learning from SIFs is challenging Unfortunately, such a metric

(COP) to assist with training, because they are so rare that is problematic for two reasons.

First, PSIF rates are not unidi-

calibration, revision, data

sharing and trending. it is virtually impossible for one rectional. That is, a high PSIF

The SCL model’s rate of rate could equally be the result

implementation and the at- company to uncover meaningful of poor safety performance

tendance and participation or the presence of a strong

in the COP was surprisingly

trends alone. Thus, the safety reporting culture, and a low

high. Monthly COP meetings profession must expand learning PSIF rate could be the result of

for the first 2 years averaged strong performance or under-

more than 50 attendees who opportunities and create reporting. Second, if PSIF rates

represented most of the U.S. are tracked and directly or in-

electric power generation mechanisms to share directly incentivized, learning

and delivery sector. In the data across traditional may be severely compromised.

4) Provide strong training

meetings, the COP group re-

viewed challenging incidents organizational boundaries. and the opportunity to cali-

to arrive at a group consensus, brate. Effective use of the SCL

developed implementation resources, and discussed and model requires both training and practice. Specifically,

voted on proposed changes to the model. After 2 years analysts should be trained on how to estimate energy mag-

of implementation, no major changes were made to the nitude and assess direct controls. The authors have found

model beyond a few minor clarifications and the addi- that learning is accelerated and performance improves

tion of external references for toxic chemical exposure when challenging cases are reviewed as a group with a

analysis. This stability is a testament to the robustness of knowledgeable facilitator. Several companies saw value in

the SCL model and the veracity of the underlying deci- having both widespread training across the safety team

sion framework. and deeper expertise for a smaller group of internal sub-

The adoption of the model has been remarkable. A ject matter experts.

survey of the EEI membership at the end of 2022 revealed 5) Develop a reporting and learning process that

that more than 70% of responding companies (n = 32) aligns with the SCL categories. SCL model questions

began integrating the SCL model and 20% planned to use can be added into the reporting logic in most safety

the model in 2023. More than 14,000 SCL model cases management systems. Specifically, logic associated with

have been submitted to the EEI repository and a live dash- the four yes/no questions can be programmed to auto-

board has been created so that the COP members may matically classify incidents. Further, since the SCL mod-

inspect and interrogate the data. el is designed to support learning, organizations may

wish to develop a learning response program that aligns

Lessons Learned From Implementation with the SCL categories. For example, full learning

The COP group convened to document lessons learned teams may be deployed for high-energy SIF, low-energy

from 2 years of implementation. These findings are based SIF, and PSIF events and lower levels of investigation

on general trends but do not represent a complete consen- may be deployed in higher volume for success and expo-

sus of experience. Five key lessons are shared because they sure observations. Although many EEI companies are

may be helpful to an organization considering or begin- aligning their systems accordingly, remember that some

ning to use the SCL model. impactful events such as high-energy SIF events may be

1) Follow the SCL model exactly and answer all relatively weak learning opportunities while success and

questions before reaching a decision. One of the most exposures may provide rich opportunities. Therefore,

common sources of confusion and misclassification companies should maintain a degree of flexibility to op-

occurs when questions are skipped or assumptions are timize learning.

assp.org FEBRUARY 2024 PROFESSIONAL SAFETY PSJ 25

Matthew R.

Hallowell is the

executive director of

the Construction Safe-

ty Research Alliance.

He is also a President’s

Conklin, T.E. (2019) The 5 principles Teaching Scholar and

Conclusion an endowed professor

Many safety professionals share the same vision: elim- of human performance: A contemporary

update of the building blocks of Human of construction en-

ination of SIFs. Unfortunately, despite significant ef- gineering at the Uni-

Performance for the new view of safety.

forts, SIF rates have plateaued or even increased over the PreAccident Media. versity of Colorado.

past decade. Learning from SIFs is challenging because DEKRA. (2019). Determining serious Outside academia, he

they are so rare that it is virtually impossible for one injury and fatality potential [White pa- is the is the founder

company to uncover meaningful trends alone. Thus, the per]. https://bit.ly/3vLtbPX and executive director

safety profession must expand learning opportunities Edison Electric Institute (EEI). (n.d.). of Safety Function

and create mechanisms to share data across traditional Issues and policies: The power to prevent LLC, and serves as a

organizational boundaries. To this end, a team of safety serious injuries and fatalities. https://bit technical advisor to

.ly/3SgtpGi the Edison Electric

leaders and academic researchers was convened by EEI Institute (EEI) and

to define PSIF in the context of other high-potential Hallowell, M.R., Alexander, D. &

Gambatese, J.A. (2017). Energy-based Interstate Natural

learning opportunities. The result was a classification Gas Association of

safety risk assessment: Does magnitude

model and a corresponding set of intensional (objective and intensity of energy predict injury America. Hallowell is

and rule-based) definitions. severity? Construction Management and a professional mem-

The SCL model incorporates elements from energy- Economics, 35(1-2), 1-14. https://doi.org/ ber of ASSP’s Rocky

based safety, controls assessment and human perfor- 10.1080/01446193.2016.1274418 Mountain Chapter.

mance. As compared to existing list-based definitions of Hallowell, M., Quashne, M., Salas, Carren Spencer

PSIF, the model enables objective, consistent and reliable R., Jones, M., MacLean, B. & Quinn, E. serves as director,

classification of incidents and observations. The model’s (2021, April). The statistical invalidity safety and health pol-

structure also facilitates robust data sharing and trending. of TRIR as a measure of safety perfor- icy, with EEI. Spencer

Since the inception of the SCL model, EEI has created mance. Professional Safety, 66(4), 28-34. manages industry

Hallowell, M. (2023). Safety classifi- safety and health

a COP where cases are reviewed, revisions to the model

cation and learning (SCL) model (White benchmarking and

are considered, and data are shared and analyzed for the paper). Edison Electric Institute. https:// research initiatives

greater good. More than 14,000 SCL model cases have bit.ly/3mFRw5C and provides advocacy

been submitted and are being analyzed. The work has Heinrich, H.W. (1931). Industrial ac- for EEI members on

garnered attention from external stakeholders. For ex- cident prevention: A scientific approach. national policies and

ample, the Interstate Natural Gas Association of America McGraw-Hill. standards impact-

Foundation (INGAA Foundation, 2021) includes the Horan, R.J., Jr. (2017). Learning from ing the safety and

model in its Guidance for Serious Injury and Fatality Pre- potential serious injuries and fatalities. health of the industry

vention report, the American Gas Association has hosted Incident Prevention. https://bit.ly/ workforce. Spencer is

workshops, and the California Public Utility Commission 3ue9Kib a member of ASSP’s

International Astronomical Union National Capital

(CPUC, 2022) now mandates PSIF reporting and explicit- (IAU). (2006). Resolution B5: Definition

ly cites the SCL model as an acceptable option. Chapter and Utilities

of a planet in the solar system. https://bit Practice Specialty.

Every model has flaws, and the SCL model is certainly .ly/42bsDyO

no exception. Therefore, the EEI COP will continue to re- Interstate Natural Gas Association of

visit and revise the model as new knowledge and creative America Foundation (INGAA Foundation). (2021). Guidance on

ideas emerge. The authors present the model after 2 years serious injury and fatality prevention. https://bit.ly/3SxR31p

of implementation in hopes that it will reach a broader au- Kahneman, D., Sibony, O. & Sunstein, C.R. (2021). Noise: A

dience and transcend industrial sectors and geographies. flaw in human judgment. William Collins.

If the learning community expands, so will the chances of National Aeronautics and Space Administration (NASA). (n.d.).

What is a planet? https://solarsystem.nasa.gov/planets/in-depth

eventually eliminating SIFs from workplaces. PSJ

National Fire Protection Association (NFPA). (2024). Standard

for electrical safety in the workplace (NFPA 70E). https://bit.ly/

Acknowledgments 3SuRMBy

The authors thank the following EEI team members who NIOSH. (2019, Oct. 8). Immediately dangerous to life or health

participated in the creation of the SCL model: Brian Bailey, (IDLH) values. www.cdc.gov/niosh/idlh/intridl4.html

Jenny Bailey, Joe Cissna, Sarah Czarnowski, Tom Dyson, National Safety Council (NSC). (n.d.). All injuries. https://

David Flener, Todd Gallaher, Cliff Gibson, Terry Halford, injuryfacts.nsc.org/all-injuries/overview

Chad Lockhart, Paul Mackintire, Paul McDonald, Terri Reason, J. (1990). Human error. Cambridge University Press.

McGee, Heidi Meyer-Bremer, David Myers, Marguerite Reed, R.J. (1978). North American combustion handbook: A

Porsch, Joe Quartemont, Jamie Rottmann, Bob Spencer basic reference on the art and science of industrial heating with

and Clifford Tegart. The authors also thank Fred Sherratt, gaseous and liquid fuels. North American Manufacturing.

U.S. Bureau of Labor Statistics (BLS). (2022, Dec. 16). Census of

Siddharth Bhandari and Michael Quashne for their valu-

fatal occupational injuries news release. www.bls.gov/news.release/

able contributions to the writing of this article. archives/cfoi_12162022.htm

Vincent, J. (2022). Beyond measure: The hidden history of mea-

References surement. W.W. Norton.

American Burn Association. (2023). Scald injury prevention

educator’s guide. https://bit.ly/48PjM8E

California Public Utilities Commission (CPUC). (2022). Safety This article is an adaptation of a white paper originally pub-

performance metric reports. https://bit.ly/3Sy9DaT lished by Edison Electric Institute (EEI). The white paper is avail-

Campbell Institute. (2018, Nov. 14). Serious injury and fatality able at https://bit.ly/3mFRw5C. Copyright 2023 EEI. Reprinted

prevention: Perspectives and practices. National Safety Council. with permission.

https://bit.ly/3HwuTXV

26 PSJ PROFESSIONAL SAFETY FEBRUARY 2024 assp.org

You might also like

- DKL Installation Manual (English)Document58 pagesDKL Installation Manual (English)류성하No ratings yet

- Ebook SIFDocument9 pagesEbook SIFmondi123No ratings yet

- J Ssci 2020 105076Document10 pagesJ Ssci 2020 105076Taufik SiregarNo ratings yet

- Hse Literature ReviewDocument7 pagesHse Literature Reviewc5ryek5a100% (1)

- Failure To Learn From Safety Incidents - Status, Challenges and OpportunitiesDocument13 pagesFailure To Learn From Safety Incidents - Status, Challenges and OpportunitiesEmy Ariviana100% (2)

- Psychosocial Safety Behavior - A Scoping Review of Behavior-Based Approaches To Workplace Psychosocial SafetyDocument8 pagesPsychosocial Safety Behavior - A Scoping Review of Behavior-Based Approaches To Workplace Psychosocial SafetyErnesto González VegasNo ratings yet

- Safety Culture TransformationDocument17 pagesSafety Culture TransformationLuqman MuhammadNo ratings yet

- Eq 2Document9 pagesEq 2eganNo ratings yet

- Literature Review Safety CultureDocument7 pagesLiterature Review Safety Culturegw11pm8h100% (1)

- Constructs of Leading Indicators - A Synthesis of Safety LiteratureDocument16 pagesConstructs of Leading Indicators - A Synthesis of Safety Literaturece23s002No ratings yet

- What Is A Serious Serious Injury? Injury?Document9 pagesWhat Is A Serious Serious Injury? Injury?Muhammad Shakeel AttariNo ratings yet

- Safety Culture Literature ReviewDocument7 pagesSafety Culture Literature Reviewfvg6kcwy100% (1)

- Parsons 2017Document12 pagesParsons 2017GonzoNo ratings yet

- 2021 Freidin Et Al., Field Observations CovidDocument20 pages2021 Freidin Et Al., Field Observations CovidFabricio CarballoNo ratings yet

- Patient Safety Culture Literature ReviewDocument7 pagesPatient Safety Culture Literature Reviewgvytgh3b100% (1)

- II. Revisiting Information Security Risk Management Challenges - A Practice PerspectiveDocument15 pagesII. Revisiting Information Security Risk Management Challenges - A Practice PerspectiveBattoussaii BattoussaiiNo ratings yet

- PHD Thesis On Safety CultureDocument4 pagesPHD Thesis On Safety Culturekimtagtowsiouxfalls100% (1)

- Occupational Safety, Health LiteratureDocument33 pagesOccupational Safety, Health LiteratureshamanthkumarNo ratings yet

- Safety Literature ReviewDocument6 pagesSafety Literature Reviewe9xy1xsv100% (1)

- Final ManuscriptDocument42 pagesFinal ManuscriptKevin RamanNo ratings yet

- A Literature Review On Global Occupational Safety and Health Practice & Accidents SeverityDocument32 pagesA Literature Review On Global Occupational Safety and Health Practice & Accidents SeverityPallavi PalluNo ratings yet

- Research and Development Activities of Life Insurance CompaniesDocument15 pagesResearch and Development Activities of Life Insurance CompaniesHtet Lynn HtunNo ratings yet

- Research Paper On Safety CultureDocument6 pagesResearch Paper On Safety Culturevagipelez1z2100% (1)

- Safety and Health at Work: Elisabeth Wischlitzki, Nadja Amler, Julia Hiller, Hans DrexlerDocument12 pagesSafety and Health at Work: Elisabeth Wischlitzki, Nadja Amler, Julia Hiller, Hans DrexlerESTERNo ratings yet

- Literature Review On Health and SafetyDocument7 pagesLiterature Review On Health and Safetyeygyabvkg100% (1)

- First Principles Information SafetyDocument71 pagesFirst Principles Information SafetyHuayi HuangNo ratings yet

- Wearable Systems For Unveiling Collective Intelligence in Clinical SettingsDocument29 pagesWearable Systems For Unveiling Collective Intelligence in Clinical SettingsjjNo ratings yet

- J of Nursing Scholarship - 2021 - Sim - Contextualization of Psychological First Aid An Integrative Literature ReviewDocument9 pagesJ of Nursing Scholarship - 2021 - Sim - Contextualization of Psychological First Aid An Integrative Literature ReviewJoelNo ratings yet

- Cybersecurity Culture Behaviour Framework Pre-PrintDocument32 pagesCybersecurity Culture Behaviour Framework Pre-Printwinibo3452No ratings yet

- Towards An Integrated Debiasing Framework For Consumer Financial Decisions: A Reflection On Debiasing ResearchDocument25 pagesTowards An Integrated Debiasing Framework For Consumer Financial Decisions: A Reflection On Debiasing Researchpkdhu22No ratings yet

- 1610 Cybersecurity CurriculumDocument74 pages1610 Cybersecurity CurriculumAdrian SanjoseNo ratings yet

- A Practice-Based Approach To Learning Nature of Science Through Socioscientific IssuesDocument27 pagesA Practice-Based Approach To Learning Nature of Science Through Socioscientific IssuesJim MorrisonNo ratings yet

- A Literature Review On Global Occupational Safety and Health Practice & Accidents SeverityDocument32 pagesA Literature Review On Global Occupational Safety and Health Practice & Accidents SeverityandyNo ratings yet

- Safety Measurement of Inmates Chapte 1 4Document44 pagesSafety Measurement of Inmates Chapte 1 4Mark Jayson VergaraNo ratings yet

- Do HR Systems and Relational Climates Affect Knowledge H 2022 Journal of BusDocument15 pagesDo HR Systems and Relational Climates Affect Knowledge H 2022 Journal of BusAmir ElkassasNo ratings yet

- Jurnal Internasional 2Document13 pagesJurnal Internasional 2Ilham Nur AziziNo ratings yet

- Safety Culture and PerformanceDocument8 pagesSafety Culture and Performanceshane.ramirez1980No ratings yet

- Safety Science: William D. Taylor, Lori A. SnyderDocument9 pagesSafety Science: William D. Taylor, Lori A. SnyderDedy ChemistNo ratings yet

- Vaccine: Musonda Kasonde, Pamela SteeleDocument7 pagesVaccine: Musonda Kasonde, Pamela SteeleULFI KHADJIBAHNo ratings yet

- Process-Based Functional Analysis Can Help Behavioral Science Step Up ToDocument19 pagesProcess-Based Functional Analysis Can Help Behavioral Science Step Up ToGabriel TalaskNo ratings yet

- Information Security Awareness-Haeussinger Kranz 2013Document18 pagesInformation Security Awareness-Haeussinger Kranz 2013LuterNo ratings yet

- Learning From AccidentsDocument16 pagesLearning From AccidentsAmisha YadavNo ratings yet

- A Practical Guide To Reflexivity in Qualitative Research - AMEE Guide No. 149Document12 pagesA Practical Guide To Reflexivity in Qualitative Research - AMEE Guide No. 149Elfie SamaniegoNo ratings yet

- Educational Interventions For Imposter - Phenomenon in Healthcare - A Scoping ReviewDocument11 pagesEducational Interventions For Imposter - Phenomenon in Healthcare - A Scoping Reviewmoralesemily990No ratings yet

- CDC 11793 DS1Document4 pagesCDC 11793 DS1NouracNo ratings yet

- Safeguarding Vulnerable Adults Exploring The ChallengesDocument12 pagesSafeguarding Vulnerable Adults Exploring The ChallengesDeepaNo ratings yet

- Fauzan Nurrahman 11210810000189UTS Manajemen Pengetahuan Tugas 2023-2024Document19 pagesFauzan Nurrahman 11210810000189UTS Manajemen Pengetahuan Tugas 2023-2024Zulham Muhammad HusainNo ratings yet

- AntigoIN - 2012 - Questões Fundamentais em Matéria de Avaliação e Gestão de RiscosDocument10 pagesAntigoIN - 2012 - Questões Fundamentais em Matéria de Avaliação e Gestão de RiscoscaiopetroniosNo ratings yet

- SdasdDocument19 pagesSdasdDorin CascavalNo ratings yet

- Cheung (2016) - How Methodological Features Affect Effect Sizes in EducationDocument10 pagesCheung (2016) - How Methodological Features Affect Effect Sizes in EducationEduardo Salgado EnríquezNo ratings yet

- Organizational Resilience ThesisDocument6 pagesOrganizational Resilience ThesisWriteMyApaPaperUK100% (2)

- HSE Culture in The Petroleum Industry Lost in TranslationDocument9 pagesHSE Culture in The Petroleum Industry Lost in TranslationBryan Gates AvengedformyvalentineNo ratings yet

- Literature Review Safety PerformanceDocument4 pagesLiterature Review Safety Performanceea68afje100% (1)

- Concept AnalysisDocument27 pagesConcept Analysissokhib930No ratings yet

- Literature Review Health and SafetyDocument7 pagesLiterature Review Health and Safetyafdtxmwjs100% (1)

- Occupational Injuries: Injury Prevention March 2007Document3 pagesOccupational Injuries: Injury Prevention March 2007peternor1No ratings yet

- Chapter 1Document20 pagesChapter 1Jolie Mar ManceraNo ratings yet

- Po Burka 1998Document14 pagesPo Burka 1998Felipe MuñozNo ratings yet

- A Best Evidence Systematic Review of Interprofessional Education BEME Guide No 9Document18 pagesA Best Evidence Systematic Review of Interprofessional Education BEME Guide No 9NAYITA_LUCERONo ratings yet

- APACFPDocument5 pagesAPACFPFaten NajarNo ratings yet

- HSE PlanDocument52 pagesHSE PlanberiNo ratings yet

- 3M™ PELTOR™ WS™ LiteCom Pro III Ex HeadsetDocument2 pages3M™ PELTOR™ WS™ LiteCom Pro III Ex HeadsetberiNo ratings yet

- Layout Saluran Drainase & Oil Trap WorkshopDocument1 pageLayout Saluran Drainase & Oil Trap WorkshopberiNo ratings yet

- 3M Protecta Comfort Belt StyleDocument2 pages3M Protecta Comfort Belt StyleberiNo ratings yet

- BF CMT Diesel Fume ShowDocument12 pagesBF CMT Diesel Fume ShowberiNo ratings yet

- ScaffoldingDocument54 pagesScaffoldingberiNo ratings yet

- Worksho Pencegahan Dan Pengendalian Penyakit MonkeypoxDocument64 pagesWorksho Pencegahan Dan Pengendalian Penyakit MonkeypoxberiNo ratings yet

- Pengembangan Aplikasi Monitoring Penyakit Hipertensi Dan Diabetes Mellitus TerintegrasiDocument15 pagesPengembangan Aplikasi Monitoring Penyakit Hipertensi Dan Diabetes Mellitus TerintegrasiberiNo ratings yet

- 7 Steps To IH Success - EbookDocument18 pages7 Steps To IH Success - EbookberiNo ratings yet

- NickelDocument134 pagesNickelberiNo ratings yet

- Guidance Noise Control Practicability Assessment 2023Document19 pagesGuidance Noise Control Practicability Assessment 2023beriNo ratings yet

- Validation of The Bahasa Version of The COPSOQ IIIDocument39 pagesValidation of The Bahasa Version of The COPSOQ IIIberiNo ratings yet

- Hazard Identification and Risk Assessments Sample (HIRARC)Document8 pagesHazard Identification and Risk Assessments Sample (HIRARC)beriNo ratings yet

- FSQ in Food Storage and Distribution PracticesDocument19 pagesFSQ in Food Storage and Distribution PracticesberiNo ratings yet

- Regional Framework For NATECH - FinalDocument64 pagesRegional Framework For NATECH - FinalberiNo ratings yet

- Hazard Control - High Risk Electrical TasksDocument7 pagesHazard Control - High Risk Electrical TasksberiNo ratings yet

- Heat Stroke Safety PosterDocument4 pagesHeat Stroke Safety PosterberiNo ratings yet

- Root Cause Analysis Presentation (RCA)Document21 pagesRoot Cause Analysis Presentation (RCA)beriNo ratings yet

- Manual On Ambient Water Quality MonitoringDocument231 pagesManual On Ambient Water Quality MonitoringberiNo ratings yet

- All Essential NFPA CodesDocument29 pagesAll Essential NFPA CodesberiNo ratings yet

- Meat HygieneDocument50 pagesMeat HygieneberiNo ratings yet

- Pcse 100 Et X 000 1Document15 pagesPcse 100 Et X 000 1carlos BeltranNo ratings yet

- A. Diana - 2023 Jun 21Document3 pagesA. Diana - 2023 Jun 21Bon Jovy SegunlaNo ratings yet

- Kumar Project 1 VoiloetDocument63 pagesKumar Project 1 VoiloetRohanPuthalathNo ratings yet

- Core Java Meterial PDFDocument203 pagesCore Java Meterial PDFrajesh gantaNo ratings yet

- 8051Document6 pages8051Ravindra SainiNo ratings yet

- P01511January2024 2Document11 pagesP01511January2024 2tholoana sentiNo ratings yet

- Japanese Candlestick ChartingDocument15 pagesJapanese Candlestick ChartingAlex WongNo ratings yet

- Lab 13Document3 pagesLab 135377773No ratings yet

- CH 2 - Essential Requisites of A ContractDocument16 pagesCH 2 - Essential Requisites of A ContractNobel Vince Richillieu NoelNo ratings yet

- DPWH Tranformer PadDocument1 pageDPWH Tranformer PadAl-fin KaytingNo ratings yet

- Job Hazard Analysis: How To Use This FormDocument4 pagesJob Hazard Analysis: How To Use This FormZul Atfi100% (1)

- Oracle EBS Succession Planning Deploying Talent Matrix ADF ComponentDocument18 pagesOracle EBS Succession Planning Deploying Talent Matrix ADF ComponentAhmed HelmyNo ratings yet

- Power BI Beyond The Basics PublicDocument74 pagesPower BI Beyond The Basics Publicsharas77No ratings yet

- Grammer - 1Document21 pagesGrammer - 1Moch Bachtiar KamalNo ratings yet

- Chapter 7Document46 pagesChapter 7Deivasigamani SubramaniyanNo ratings yet

- Predicting Box Compression Strength - 3 PDFDocument37 pagesPredicting Box Compression Strength - 3 PDFTajuddin ShaikNo ratings yet

- Kito ER2 EnglishDocument40 pagesKito ER2 Englishkristina618No ratings yet

- BS4486 1980 Alloy Steel BarDocument13 pagesBS4486 1980 Alloy Steel BarRed FolderNo ratings yet

- Flange Leak Testing ProgramDocument5 pagesFlange Leak Testing Programromedic36No ratings yet

- 5060 Asm1Document20 pages5060 Asm1Nguyen Thanh Tam (FGW HN)No ratings yet

- HikCentral-Workstation64-I5 V2.2.1 Datasheet 20220512Document8 pagesHikCentral-Workstation64-I5 V2.2.1 Datasheet 20220512Pongsakorn ChanyorsaengNo ratings yet

- MASDocument7 pagesMASHelen IlaganNo ratings yet

- Assignment AgricultureDocument5 pagesAssignment AgricultureSiLLa ÀntoNyNo ratings yet

- International Training: Arpana F. Gawade Dhanashri SDocument8 pagesInternational Training: Arpana F. Gawade Dhanashri SAny KadamNo ratings yet

- Buscom Quiz 2 MidtermDocument2 pagesBuscom Quiz 2 MidtermRafael Capunpon VallejosNo ratings yet

- Research Paper On SCARA DRAW-BOTDocument5 pagesResearch Paper On SCARA DRAW-BOTAshok GaikwadNo ratings yet

- UUCMS - Unified University College Management SystemDocument1 pageUUCMS - Unified University College Management Systemanusha.19cs808No ratings yet

- 1-58 Feeder CableDocument2 pages1-58 Feeder CableJason MendozaNo ratings yet

- !gedpublicreports PDFDocument2 pages!gedpublicreports PDFwaleed mosalamNo ratings yet