Professional Documents

Culture Documents

Russo Et Al 2005 Shear Strength Analysis and Prediction For Reinforced Concrete Beams Without Stirrups

Uploaded by

Siva GuruOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Russo Et Al 2005 Shear Strength Analysis and Prediction For Reinforced Concrete Beams Without Stirrups

Uploaded by

Siva GuruCopyright:

Available Formats

Shear Strength Analysis and Prediction for Reinforced

Concrete Beams without Stirrups

Gaetano Russo, M.ASCE1; Giuliana Somma2; and Denis Mitri3

Downloaded from ascelibrary.org by Indian Institute Of Technology Madras on 03/11/24. Copyright ASCE. For personal use only; all rights reserved.

Abstract: The analysis of shear strength of longitudinally reinforced concrete beams, in which a constant shear force acts throughout the

shear span, is performed. The shear mechanism is found to be governed by a second order differential equation linking the internal lever

arm with the distance from the support. The solution of the shear governing equation is provided, and then the corresponding shear

expression is parametrically defined by means of a mechanical analysis. The empirical parameters are determined from more than 900 test

data and results found in the literature. The proposed shear strength formula predicts the experimental behavior in a more accurate and

uniform way than most known expressions. It is also proposed a design formula, which is more consistent and reliable than the Eurocode

one and even than the laborious procedures suggested by ACI Code and AASHTO Standards, since it exhibits a minor number of unsafe

predictions.

DOI: 10.1061/(ASCE)0733-9445(2005)131:1(66)

CE Database subject headings: Beams; High strength concrete; Flexure; Reinforcement; Shear strength.

Introduction ies in this field (Kim and White 1999b; Pendyala and Mendis

2000; Kwak et al. 2002).

Several theoretical and experimental studies (Bresler and Scord- By means of an analytical approach and a mechanical study of

elis 1963; Zsutty 1968; Angelakos et al. 2001) have been carried shear strength and previous experimental results, in this paper a

out to analyze the phenomenon of the shear failure of reinforced semirational and accurate equation is provided for predicting

concrete (RC) beams. This failure is due to the combined action shear strength of RC beams without web reinforcement, as far as

a design formula.

of shear and flexure, and may happen in a brittle way and without

warning signs. Due to shear, beam flexural strength may be

greatly reduced compared with the case of pure flexure.

Failure under flexure and shear interaction may happen in very Analytical Model for Shear Strength

different modes, and the parameters affecting the failure type and

The typical loading arrangement of test beams is shown in Fig.

the beam capacity are several, including the web reinforcement

1(a). Throughout the shear span a, a constant shear force V acts,

(Rajagopalan and Ferguson 1968; Yoon et al. 1996; Russo and

and the bending moment M共x兲, for a constant depth beam, is

Puleri 1997). For this reason a lot of researchers (Bazant and Kim

given by M共x兲 = T共x兲j共x兲d, where x⫽horizontal coordinate start-

1984; Mphonde and Frantz 1984; Russo et al. 1991; Hallgren ing from the support; T共x兲⫽tensile force on the longitudinal rein-

1994; Kim and Park 1994) have concentrated their attention on forcement; d⫽effective beam depth; and j共x兲⫽internal lever arm

the behavior of only longitudinally reinforced beams, also be- to effective depth ratio, defining the location of the compression

cause their strength constitutes the so-called “concrete contribu- resultant C [Fig. 1(d)]. By deriving the bending moment, the

tion” of beams with web reinforcement. Despite numerous studies shear force V is obtained

carried out on this subject over the last 50 years by researchers

from every part of the world, shear failure of longitudinally rein- dT dj

forced concrete beams still remains unresolved, and so of great V= j共x兲d + T共x兲 d 共1兲

dx dx

interest, as it is demonstrated by the great number of recent stud-

By assuming the bond force to be constant in the shear span, it

1

Professor, Dept. of Civil Engineering, Univ. of Udine, Via delle follows a linear variation of T共x兲 in the reinforcement

Scienze, 208, 33100 Udine, Italy.

2

PhD Eng., Dept. of Civil Engineering, Univ. of Udine, Via delle T共x兲 = tx + T1 共2兲

Scienze, 208, 33100 Udine, Italy.

3

PhD Student, Dept. of Civil Engineering, Univ. of Udine, Via delle where t = dt / dx and T1 are constant with respect to x.

Scienze, 208, 33100 Udine, Italy. By means of Eq. (2), Eq. (1) may be written as

Note. Associate Editor: Dat Duthinh. Discussion open until June 1,

2005. Separate discussions must be submitted for individual papers. To

extend the closing date by one month, a written request must be filed with dj

V = tj共x兲d + 共tx + T1兲 d 共3兲

the ASCE Managing Editor. The manuscript for this paper was submitted dx

for review and possible publication on August 13, 2002; approved on

March 18, 2004. This paper is part of the Journal of Structural Engi- Since the external shear force V does not depend on x into the

neering, Vol. 131, No. 1, January 1, 2005. ©ASCE, ISSN 0733-9445/ shear span, the internal shear force provided by Eq. (3) must

2005/1-66–74/$25.00. satisfy the following shear governing equation:

66 / JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JANUARY 2005

J. Struct. Eng., 2005, 131(1): 66-74

Nevertheless, it can be observed that bond strength increases

with cover-to-bar diameter ratio (Gambarova and Rosati 1997). It

follows that bond strength inversely depends on bar diameter, and

hence is proportional to −p, with p⫽constant exponent. Conse-

quently

t = c41/2−p f ⬘c q 共7兲

Tensile Force at the Support, T1

The constant T1, appearing in Eq. (2), evidently represents the

Downloaded from ascelibrary.org by Indian Institute Of Technology Madras on 03/11/24. Copyright ASCE. For personal use only; all rights reserved.

value of the tensile force in the longitudinal reinforcement at the

support. This horizontal force is different from zero because it

must satisfy equilibrium at the node support, with the inclined

force in the compressive concrete and the vertical support reac-

tion. It may be expressed as

Fig. 1. Simply supported beam with no web reinforcement:

(a) loading scheme; (b) shear force diagram; (c) moment diagram; T1 = s0bd 共8兲

and (d) actions in the shear span

where s0⫽steel stress at the support; and b⫽beam width.

Bazant and Kim (1984) assume the steel stress s0 is constant,

for the arch-action shear, for all beams and values of steel rein-

d2 j dj forcement. By contrast in this paper s0 is assumed to be depen-

共tx + T1兲 + 2t = 0 共4兲

dx2 dx dent on , on shear span-to-effective depth ratio a / d, and on

yielding strength of the longitudinal reinforcement f yl. It follows

whose general solution is j共x兲 = c1 / 关t共t x + T1兲兴 + c2. The constants

c1 and c2 are determined by imposing the conditions j共0兲 = 0 and s0 = f共兲g共a/d兲f yl 共9兲

j共a兲 = j0, where j 0⫽internal lever arm-to-effective depth ratio

under flexure only. Therefore the particular solution of Eq. (4) where f共兲 and g共a / d兲⫽positive functions to be determined; and

results a linear dependence on f yl is assumed so that f共兲g共a / d兲 directly

yields the s0 to f yl ratio.

j共x兲 =

j0

ta

冉

共ta + T1兲 1 −

T1

tx + T1

冊 共5兲

For f共兲 an inverse relationship is chosen because s0 is ex-

pected to decrease by increasing the reinforcement area and con-

sequently . Hence

According to the classical bending theory of RC beams with

f共兲 = c5−z 共10兲

only flexural tensile reinforcement and with a negligible tensile

capacity of concrete, j0 = 1 − 共冑共n兲2 + 2n − n兲 / 3, where n where c5⫽positive constant; and z⫽constant exponent. It is well

= Es / Ec, with Es and Ec⫽elastic moduli of steel and concrete; and known that a beam can exhibit flexural overstrength due to steel

⫽geometric percentage of longitudinal reinforcement. For j 0 Ba- strain hardening when the tensile reinforcement is low (Russo

zant and Kim (1984) proposed the simpler expression j0 = k0−m, 1990; Paulay and Priestley 1992). In this case, the increase in

in which k0 and m⫽certain constants. steel stress beyond yielding strength, in the middle span, obvi-

By utilizing for j共x兲 the expression provided by Eq. (5), Eq. ously provides an increase of the tensile stress s0 at the support.

(3) gives By taking into account an actual to specified yield strength ratio

equal to 1.15, and a potential strength increase resulting from

j 0d strain hardening equal to 1.25 (Paulay and Priestley 1992), the

V = 共ta + T1兲 共6兲 maximum value for s0 is taken as 1.4 f yl.

a

The attainment of this value is assumed to occur for the

which evidently does not depend on x, because j共x兲 [Eq. (5)] value just equal to the minimum provided by ACI Code (2002),

satisfies the governing equation (4). min = 1.4/ f yl, with f yl expressed in MPa. Hence Eqs. (9) and (10)

For the sake of comparison with other previous formulas, it give

can be observed that the first addendum of Eq. (6) represents the

beam action, while the second one the arch action. 1

c5 = 1.4z+1 f −z

yl 共11兲

g共a/d兲

Rate of Change of Tensile Force, t Finally Eq. (10), by means of Eq. (11) and for g共a / d兲 = 1, yields

The rate of change of tensile force t may be expressed in terms of f共兲 = 1.4z+1−z f −z 共12兲

yl

the bond stress b transmitted by concrete to the steel bars (Bazant

and Kim 1984), as t = c3共 兺 Dbb兲, in which c3⫽constant; and To find the g共a / d兲 function, T1 and V versus a / d variation

兺Db⫽sum of the diameters of all bars in the transverse section. must be evaluated, because of Eqs. (9), (8), and (6). Therefore

The beam section being constant, 兺Db is proportional to 冑. from Eq. (6) it is obtained

Moreover, bond stress in the ultimate condition is proportional to

f c⬘q, where f ⬘c ⫽cylindrical concrete compressive strength and q is

a constant exponent. By taking into account these considerations

V

=

T1

j0

共a/d兲 共a/d兲 d

a

冉冊 −1

− T1 j 0 冉冊

a

d

−2

共13兲

Bazant and Kim (1984) expressed t as t = c41/2 f ⬘c q, in which since t does not depend on a / d. As the shear decreases with a / d

c4⫽constant. (Kani 1967), V / 共a / d兲 ⬍ 0, and hence Eq. (13) provides

JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JANUARY 2005 / 67

J. Struct. Eng., 2005, 131(1): 66-74

冋

vuc = k0k1 1/2−p−m f ⬘c q + k21−m−z f 1−z

yl 冉冊 册

a

d

−s−1

共21兲

The foregoing analysis has not yet taken into account the size

effect, which is appropriate for brittle fracture due to concrete

cracking. In fact fracture mechanics indicates that the nominal

stress at failure decreases as the structure size increases, for a

given maximum aggregate size da (Bazant and Kim 1984). This

size effect may be described by the simple size-effect function

(Bazant and Sun 1987)

Downloaded from ascelibrary.org by Indian Institute Of Technology Madras on 03/11/24. Copyright ASCE. For personal use only; all rights reserved.

1 + 冑5.08/da

= 共22兲

冑1 + d/共25da兲

Fig. 2. Plots of g共a / d兲 function versus a / d, for c6 = 1

According to Bazant and Kim (1984), Eq. (21) has to be mul-

tiplied for .

T1 a

共a/d兲 d

− T1 ⬍ 0

Eq. (14), by means of Eqs. (8) and (9), yields

共14兲

冋

vuc = k0k1 1/2−p−m f ⬘c q + k21−m−z f 1−z

yl 冉冊 册

a

d

−s−1

共23兲

冉冊

The parameters k1, k2, p, q, z, s0, and s1 should be determined

dg a on the basis of experimental shear strength results. By contrast k0

−g⬍0 共15兲

d共a/d兲 d and m are not affected by shear strength results, but only depend

on the equilibrium in flexure, without shear. They must be chosen

which is always verified for dg / d共a / d兲 ⬍ 0. Consequently, g共a / d兲

so that the j 0 values given by the classical bending theory and

must be a decreasing function, as the following hyperbola

Bazant and Kim are almost indistinguishable. It follows that k0

g共a/d兲 = c6 冉冊

a

d

−s

共16兲

and m will be determined on the basis of n and values of the

considered tested beams.

with c6⫽positive constant. For s it is chosen

Considered Beam Test Specimen

a

s = s0 + s1 共17兲

d With the purpose of identifying in the best way the unknown

with s0 and s1⫽positive constants, to allow for the T1 versus a / d parameters, 917 beams, all with only longitudinal reinforcement,

relation a variability greater than in the case of s constant. By have been taken into consideration. This collection is the most

utilizing Eq. (16) for g, and Eq. (17) for s, dg / d共a / d兲 ⬍ 0 is numerous ever collected for shear, in the literature.

verified when The test data specimens, here considered, have been collected

from 67 papers (Clark 1951; Moody et al. 1954; Morrow and

s0 ⬎ 0.135 s1 共18兲 Viest 1957; Watstein and Mathey 1958; Diaz de Cossio and Siess

1960; Taylor 1960; Taub and Neville 1960; Van Den Berg 1962;

The relation g共a / d兲 versus a / d is shown in Fig. 2 for c6 = 1, Bresler and Scordelis 1963; Mathey and Watstein 1963; Acharya

s0 = 1.5, and s1 equal to 1, 0.5, or 0, the last value leading to a and Kemp 1965; Kani 1966; Krefeld and Thurston 1966; Kani

constant exponent. It has to be stressed that, for s0 and s1 values 1967; Rajagopalan and Ferguson 1968; Mattock 1969; Swamy et

satisfying Eq. (18), the assumed function g共a / d兲 [Eq. (16) with al. 1970; Placas and Regan 1971; Suter and Manuel 1971; Taylor

Eq. (17)] verifies the differential inequality (14), and hence cor- 1972; Mphonde and Frantz 1984; Elzanaty et al. 1986; Ahmad

rectly describes the dependence of the tensile force at the support and Lue 1987; Chana 1987; Lim et al. 1987; Narayanan and Dar-

on a / d. wish 1987; Johnson and Ramirez 1989; Lambotte and Taerwe

Finally, Eqs. (8), (9), (12), and (16) provide 1990; Thorenfeldt and Drangsholdt 1990; Bazant and Kazemi

冉冊 −s 1991; Hallgren 1994; Kim and Park 1994; Xie et al. 1994; Ahmad

a

T1 = c61.4z+11−z f 1−z

yl bd 共19兲 et al. 1995; Desai 1995; Adebar and Collins 1996; Yoon et al.

d 1996; Tan et al. 1997; Foster and Gilbert 1998; Islam et al. 1998;

Kulkarni and Shah 1998; Muller and Reid 1998; Collins and

Kuchma 1999; Jelic et al. 1999; Kim et al. 1999; Kim and White

1999a,b; Russo et al. 1999; Shin et al. 1999; Tan and Lu 1999;

Parametric Shear Strength Expression

Gale and Ibell 2000; Pendyala and Mendis 2000; Teng et al.

Eqs. (6), (7), and (19) provide 2000; Angelakos et al. 2001; Oh and Shin 2001; Somma and

Russo 2001; Cladera and Marì 2002; Fujita et al. 2002; Hayashi

冋

V = k0k1bd 1/2−p−m f ⬘c q + k21−m−z f 1−z

yl 冉冊 册a

d

−s−1

共20兲

et al. 2002; Kwak et al. 2002; Matsuo et al. 2002; Pellegrino et al.

2002; Rahal and El-Hawary 2002; Takaki et al. 2002; Tompos

and Frosch 2002; Tureyen and Frosch 2002; Cho 2003).

where k1 and k2⫽positive constants. By calculating the nominal Among the considered beams, 250 are made with high

shear stress at failure as vuc = V / 共bd兲, from Eq. (20) it is obtained strength concrete (HSC), with f ⬘c from 50 up to 143.7 MPa.

68 / JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JANUARY 2005

J. Struct. Eng., 2005, 131(1): 66-74

Downloaded from ascelibrary.org by Indian Institute Of Technology Madras on 03/11/24. Copyright ASCE. For personal use only; all rights reserved.

Fig. 3. Comparison between two j0共兲 approximating functions and Fig. 4. Plots of: (a) j共x兲d; (b) T共x兲; and (c) M共x兲, relevant to three

917 j0 flexural values (each computed for its own n) Kani (1966) beams (3.8-1.88-12P)

Mean Internal Lever Arm to Effective Depth Ratio Internal Bending Moment Based on Shear Strength

under Flexure Only, j0

As a consequence of the function introduction in Eq. (23), Eqs.

To obtain reliable values for the parameters k0 and m that appear (7) and (19), respectively, result in

in Bazant and Kim’s expression, j0 = k0−m, the following approxi-

t = 1.670.46 f ⬘c 0.39b 共26兲

mate procedure is utilized: (1) calculate the mean value nmean of

冉冊

the 917 n values relevant to all the beams under consideration,

each obtained with Es = 200,000 MPa, and Ec = 4,700冑 f c⬘ (ACI

−0.2–0.45 a/d

a

T1 = 0.830.89 f 0.89

yl bd 共27兲

Code 2002); and (2) find k0 and m so that the j 0 values given by d

the classical bending theory, computed for nmean, and by j0 The j共x兲d and T共x兲 functions, respectively, provided by Eqs.

= k0−m, are almost indistinguishable. (5), (24), (26), and (27), and by Eqs. (2), (26), and (27), are

It is obtained nmean = 7.3, and the interpolating function results plotted along the shear span in Figs. 4(a and b), for three Kani

j0 = 0.68−0.06 共24兲 (1966) beams, which differ only for a / d value. By means of Eqs.

(2) and (5), the bending moment results

The functions provided by Eq. (24) and that relevant to the

flexural theory with n = 7.3 are plotted in Fig. 3. The 9.17 j0 val- j 0d

M共x兲 = 共ta + T1兲x 共28兲

ues relevant to the flexural theory, each corresponding to its own a

n value, are shown in Fig. 3 with points. The average value

with j0 provided by Eq. (24). The moment provided by Eq. (28),

(AVG) of the ratios between these j0 values and the correspond-

by means of Eqs. (24), (26), and (27), is plotted in Fig. 4(c) for

ing ones provided by Eq. (24), is 1.00, while the coefficient of

the three Kani beams considered above. According to the linear

variation (COV), given by the ratio between the standard devia-

variation of the external moment, the internal moment [Eq. (28)]

tion (STD) and AVG, is 0.02.

is linear with x along the overall shear span, in spite of the very

nonlinear j共x兲 expression (5) [Fig. 4(a)]. This important result,

obtained for the first time, is a consequence of having imposed

Shear Strength Formula

the analytical condition of constancy of the internal shear force

[Eq. (4)].

On the basis of the analysis of the 917 beams considered, the

values of the parameters k1, k2, p, q, z, s0, and s1, appearing in Eq.

(23), have been iteratively changed, with the aim to attain the best

prediction uniformity of shear strength. This aim has been pur-

Model Reliability

sued by minimizing the coefficient of variation (COV) relevant to

To evaluate the proposed model, five well-known expressions for

the measured to calculated shear strength ratios. These ratios have

computing the ultimate beam shear strength have been selected

been calculated for each beam by means of Eq. (23) computed for

for comparison with respect to the overall number (917) of

the trial values k1i, k2i, pi, qi, zi, s0i, and s1i assumed in the ith

beams.

iteration. At the end of the iterations the minimum COV is 0.21,

1. Zsutty (1968)

which corresponds to the following parameter values: k1 = 1.67,

k2 = 0.5, p = 0.04, q = 0.39, z = 0.11, s0 = 0.2, and s1 = 0.45. It can be

observed that the last two parameters verify the analytically ob-

tained inequality (18).

冉 冊

vuc = 2.2 f ⬘c

d

a

1/3

共29兲

Hence the shear strength formula for beams with no transverse Eq. (29) must be multiplied by 2.5共d / a兲, for a / d ⬍ 2.5.

reinforcement is 2. Bazant and Sun (1987)

冋 冉冊

vuc = 1.13 0.4 f ⬘c 0.39 + 0.50.83 f 0.89

yl

a

d

−1.2–0.45 a/d

册 共25兲 vuc = 0.541/3 冋冑 f ⬘c + 249 冑 册

共a/d兲5

共30兲

where is expressed by Eq. (22). where is expressed by Eq. (22).

JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JANUARY 2005 / 69

J. Struct. Eng., 2005, 131(1): 66-74

3. Kim and Park (1996)

冉

vuc = 3.5f c⬘␣/33/8 0.4 +

d

a

冊 共31兲

where = 共1 + 0.008 d兲−1/2 + 0.18, ␣ = 1 for a / d 艌 3, or ␣ = 2

− a / 共3d兲 for a / d ⬍ 3.

4. Nielsen (1998)

a. First expression

vuc = 0.5f ⬘c

d

冋冑4⌽共1 − ⌽兲 + 冉冊 册a 2

−

a

Downloaded from ascelibrary.org by Indian Institute Of Technology Madras on 03/11/24. Copyright ASCE. For personal use only; all rights reserved.

h h h

As f yl

for ⌽ = 艋 0.5 共32兲

bhf c⬘

where h⫽beam depth. For ⌽ ⬎ 0.5, 4⌽共1 − ⌽兲 is re-

placed by 1.

Nielsen has also introduced in Eq. (32) an effectiveness

factor, keff, which should better fit the experimental re-

sults, hence providing

b. Second expression

vuc = 0.5keff f ⬘c

d

h

冋冑 冉 冊 冉 冊 册

4

⌽

keff

1−

⌽

keff

+

a

h

2

−

a

h

for ⌽ 艋 0.5keff 共33兲

where Fig. 5. Measured to calculated shear strength ratios versus a / d, for

917 tested beams

keff =

0.76

冑 f ⬘c 冉 冑 冊冉

1+

1

h

d

0.15 + 0.58

h

冊 共34兲

the 631 beams on which Eq. (33) is applicable, Eq. (25) exhibits

with 5 ⬍ f ⬘c ⬍ 60 MPa, 0.08⬍ h ⬍ 0.7 m, and AVG= 1.01 and COV= 0.18, while Nielsen’s expression provides

d / h ⬍ 4.5% with in %. For ⌽ ⬎ 0.5 keff, 4⌽共1 AVG= 1.42 and COV= 0.30.

− ⌽ / keff兲 / keff is replaced by 1. The three conditions de-

fining Eq. (34) are respected only by 631 of the 917

considered beams. Proposed Design Formula for Shear Strength

5. Rebeiz (1999) and Its Reliability

vuc = 0.4 + 冑 d

f ⬘c 共10 – 3Ad兲

a

共35兲

Eq. (25) cannot be used for design without a safety factor because

it corresponds to the average value of the measured to computed

shear strength ratio equal to 1. The AVG value may be modified

where Ad = a / d for a / d ⬍ 2.5, and Ad = 2.5 for a / d 艌 2.5. by multiplying by a factor the right member of Eq. (25), and this

In Fig. 5 the ratio between the measured shear strength value modification does not change the COV value. Since the COV

and the calculated one by means of each of the five above- value provided by Eq. (25) is the lowest one, this formula is

mentioned expressions [Eqs. (29)–(32) and (35)] and the pro- suitable for design for the shear strength.

posed formula [Eq. (25)] is plotted versus the shear span-to- A characteristic expression is chosen as the design formula.

effective depth ratio a / d for the 917 beams. The horizontal bold The multiplying factor is obtained on statistical bases, and it is

lines represent the perfect correspondence between experimental chosen so that there is a 95-in-100 probability that the computed

and computed shear strength values. So, the closer to this line the design shear strength results on the favorable side. This factor, on

points are, the more accurate the shear strength prediction is. The the basis of 917 beams, results 0.64. Therefore the proposed de-

thinner the width of the strip including the points is, the greater sign formula for shear strength is

冋 冉冊 册

the prediction uniformity. The AVG and COV values are also

−1.2–0.45 a/d

reported in Fig. 5. AVG is the index of the mean accuracy of the a

considered formula, and the closer to one its value is, the more vuc,d = 0.72 0.4 f c⬘0.39 + 0.50.83 f 0.89

yl 共36兲

d

accurate the expression. COV is the index of the uniformity in the

prediction, with variation in beam geometrical and mechanical To check the proposed design formula reliability and safety in

characteristics or the loading position, and the lower it is, the the shear strength prediction, Eq. (36) has been compared with

better the prediction capability of the experimental results. From three Code shear strength computing models.

Fig. 5 it is apparent that the proposed formula for computing 1. Eurocode (CEN 1992)

shear strength of beams without stirrups is better than the other

vuc,d = Rdk共1.2 + 40兲 共37兲

ones, in terms of accuracy and uniformity of prediction.

It must be observed that the proposed expression [Eq. (25)] is where k = 1.6− d 艌 1 (d in m),  = 1 fora / d 艌 2.5 or

also better than the second one provided by Nielsen [Eq. (33)]: of = 2.5d / a 艋 5 for a / d ⬍ 2.5, = min关As / 共bd兲 ; 0.02兴, and Rd

70 / JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JANUARY 2005

J. Struct. Eng., 2005, 131(1): 66-74

Downloaded from ascelibrary.org by Indian Institute Of Technology Madras on 03/11/24. Copyright ASCE. For personal use only; all rights reserved.

Fig. 7. Measured to design shear strength ratios (with a = l / 4) versus

l / d, for 56 uniformly loaded tested beams.

do not provide direct equations for computing shear strength and

hence are difficult to use in practice, while Eq. (36) is an explicit

Fig. 6. Measured to design shear strength ratios versus a / d, for 779 expression.

tested beams. The comparison of 917 tested beams between the proposed

design formula [Eq. (36)] and Eurocode [Eq. (37)] has shown a

better consistency for Eq. (36), which exhibits AVG= 1.57,

= 0.25f ctk0.05 / ␥c, with ␥c = 1.5, f ctk0.05 = 0.7f ctm, and f ctm COV= 0.21, and 26 unconservative predictions, while Eurocode

= 0.3f ⬘c 2/3. provides AVG= 1.75, COV= 0.41, and 80 unconservative predic-

2. AASHTO Standards (1999) tions.

These standards are based on the modified compression field

theory (Collins et al. 1996) for slender beams 共a / d ⬎ 2兲, and

the strut-and-tie model with special provisions for deep Applicablity of the Proposed Model to Uniform

beams 共a / d 艋 2兲. Loading

3. ACI Code (2002)

Kani (1966) showed that a uniformly distributed load compares

vuc,d =

1

7

冋冑 f ⬘c + 120

V ud

Mu

册艋 0.3冑 f ⬘c 共38兲

best with a point loading arrangement of two point loads at the

quarter points. Consequently, the shear arm of a beam with uni-

formly distributed load has been defined by a = l / 4, with l the

For beams with a / d 艋 2, the shear strength has been computed beam length.

with the strut-and-tie model described in Appendix A of this On the basis of Kani’s (1966) conclusion, the greatest number

Code. of researchers have tested beams under point loads. As a proof of

The diagrams representing vuc,meas / vuc,d versus a / d, relative to this there has been found in literature 917 beams tested with point

AASHTO and ACI Code shear strength computing models and loading and only 56 beams uniformly loaded. For these reasons

the proposed design formula [Eq. (36)] are shown in Fig. 6, to- almost all the shear strength expressions proposed by various

gether with AVG and COV values, and the number of unsafe writers and Codes are functions of a / d, and accordingly the

predictions. AASHTO, ACI Code, and Eq. (36) have been evalu- model proposed here is referred to as a loading arrangement with

ated only for 779 beams because the strut-and-tie model, recom- pointing loads.

mended by the two Standards, requires the bearing plate dimen- Moreover, among the shear strength models here taken into

sion, which is not always provided by the experimenters. From account, only ACI Code and AASHTO are applicable to every

Fig. 6, it is apparent that the proposed design formula is better loading type, as the first depends on M u / 共Vud兲, and the second on

than the other ones, since it leads to more uniform prediction and M u and Vu.

to the lowest number of unconservative predictions. To verify Kani’s assumption and hence the applicability of the

To highlight the consistency of MCFT and strut-and-tie mod- proposed formula to the case of uniformly distributed load, test

els slender and deep beams have been considered separately. By results of 56 beams were collected from two papers (Diaz de

considering only the 711 slender beams with a / d ⬎ 2 AASHTO Cossio and Siess 1960; Krefeld and Thurston 1966).

(based on MCFT) gives AVG= 1.43 and COV= 0.27, while the The proposed design formula has been compared with the ACI

proposed design formula [Eq. (36)] provides AVG= 1.56 and Code and AASHTO. By considering a / d = l / 共4d兲 the proposed

COV= 0.19. Instead, by considering only the 68 deep beams with equation [Eq. (39)] gives AVG= 2.03 and COV= 0.14, while ACI

a / d 艋 2 and bearing plate dimension known, AASHTO (based on Code [Eq. (38)] provides AVG= 3.75 and COV= 0.44 (Fig. 7).

strut-and-tie model) gives AVG= 1.96 and COV= 0.28, while Eq. For M u and Vu referred to a distance d from face of support Eq.

(36) provides AVG= 1.60 and COV= 0.29. These results evidence (38) exhibits AVG= 3.63 and COV= 0.46, while AASHTO gives

that the proposed formula [Eq. (36)] is much more consistent than AVG= 3.14 and COV= 0.48.

AASHTO both considering the overall number of beams (31% of It results that the proposed formula is consistent and reliable

COV reduction) and the slender ones (30% of COV reduction). It not only for point loading but also for uniformly distributed load

must be stressed that AASHTO MCFT and strut-and-tie models arrangement. It follows that the here proposed expression is ap-

JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JANUARY 2005 / 71

J. Struct. Eng., 2005, 131(1): 66-74

plicable also to a beam with uniformly distributed load, simply Db ⫽ diameter of longitudinal bar;

putting a / d = l / 共4d兲. d ⫽ effective beam depth;

da ⫽ maximum aggregate size;

E c, E s ⫽ elastic moduli of concrete and steel;

Conclusions f ⬘c ⫽ cylindrical concrete compressive strength;

f yl ⫽ yielding strength of longitudinal reinforcement;

From the above provided analysis and considerations relevant to f共兲 ⫽ function given by Eq. (12);

RC beams with only longitudinal reinforcement, it can be con- g共a / d兲 ⫽ function given by Eq. (16);

cluded that: h ⫽ beam depth;

1. A shear strength analysis can be performed on the basis that j共x兲 ⫽ internal lever arm-to-effective depth ratio;

in the shear span: (1) the tensile force in the longitudinal j0 ⫽ internal lever arm-to-effective depth ratio,

Downloaded from ascelibrary.org by Indian Institute Of Technology Madras on 03/11/24. Copyright ASCE. For personal use only; all rights reserved.

reinforcement is linearly increasing with the distance from under flexure only;

the support, and (2) the internal shear force must have the keff ⫽ effectiveness factor [Eq. (34)];

same value whatever the distance from the support. l ⫽ beam length;

2. The failure under flexure and shear is governed by a differ- M共x兲 ⫽ bending moment;

ential equation in the internal lever arm. m, p, q, z ⫽ constant exponents;

3. The internal lever arm expression obtained from the govern- n ⫽ ratio of elastic moduli of steel and concrete

ing equation is to be used for computing beam and arch 共Es / Ec兲;

action shear contributions, since it yields an internal shear s ⫽ exponent, function of a / d [Eq. (17)];

force constant along the shear span. T共x兲 ⫽ tensile force on the longitudinal reinforcement;

4. The shear expression analytically obtained may be trans- T1 ⫽ tensile force at the support;

formed in a parametric expression, by means of a mechanical t ⫽ rate of change of tensile force T共x兲;

analysis. The unknown coefficients and exponents appearing V ⫽ shear force;

in the corresponding shear strength expression have been de- vuc ⫽ concrete contribution to shear strength;

termined, in this paper, on the basis of the shear strength of x ⫽ horizontal coordinate starting from the

already tested 917 beams (the largest statistical sample con- support;

sidered in the literature until now). By contrast the param- ⫽ size-effect function [Eq. (22)];

eters relevant to the mean internal lever arm-to-effective ⫽ geometric percentage of longitudinal

depth ratio under flexure only, must be determined on the reinforcement [As / 共bd兲, with As area of steel in

basis of the geometrical and mechanical characteristics of the tension];

beams considered. s0 ⫽ steel stress at the support; and

5. A consistent expression of the internal bending moment b ⫽ bond stress.

based on shear strength must be linear, consistent with the

Subscripts

linear variation of external moment, as the one obtained.

6. The proposed semirational shear strength expression is the calc ⫽ calculated;

most uniform in the prediction, with respect to the expres- d ⫽ design;

sions provided by various writers. Moreover, it has the value mean ⫽ mean;

to be continuous in the overall shear span-to-effective depth meas ⫽ measured; and

ratio range. min ⫽ minimum.

7. On the basis of the above derived shear strength formula, a

design (conservative) formula has been proposed, which is

more consistent than Eurocode, AASHTO, and ACI Code, References

and exhibits the fewest unconservative predictions.

8. On the basis of 56 uniformly loaded beams found in the

Acharya, D. N., and Kemp, K. O. (1965). “Significance of dowel forces

literature, the proposed expression may be applied to the case on the shear failure of rectangular reinforced concrete beams without

of uniformly loaded beams by considering the conventional web reinforcement.” ACI J., 62(10), 1265–1279.

shear span proposed by Kani, equal to a quarter of beam Adebar, P., and Collins, M. P. (1996). “Shear strength of members with-

length. out transverse reinforcement.” Can. J. Civ. Eng., 23(1), 30–41.

Ahmad, S. H., and Lue, D. M. (1987). “Flexure-shear interaction of re-

inforced high-strength concrete beams.” ACI Struct. J., 84(4), 330–

Acknowledgment

341.

Ahmad, S. H., Park, F., and El-Dash, K. (1995). “Web reinforcement

Support of this research by the Ministero dell’Istruzione, effects on shear capacity of reinforced high-strength concrete beams.”

dell’Università e della Ricerca is gratefully acknowledged. Mag. Concrete Res., 47(172), 227–233.

American Association of State Highway and Transportation Officials

Notation (AASHTO). (1999). AASHTO LRFD bridge specification, 2nd Ed.,

Washington, D.C.

American Concrete Institute (ACI). (2002). “Building code requirements

The following symbols are used in this paper:

for structural concrete (ACI 318-02) and commentary (ACI 318R-

a ⫽ shear span length; 02).” ACI 318-02, Farmington Hills, Mich.

b ⫽ beam width; Angelakos, D., Bentz, E. C., and Collins, M. P. (2001). “Effect of con-

C ⫽ compression resultant; crete strength and minimum stirrups on shear strength of large mem-

ci共i=1,2,3,4,5,6兲, ki共i=0,1,2兲, si共i=0,1兲 bers.” ACI Struct. J., 98(3), 290–300.

⫽ constants; Bazant, Z. P., and Kazemi, M. T. (1991). “Size effect on diagonal shear

72 / JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JANUARY 2005

J. Struct. Eng., 2005, 131(1): 66-74

failure of beams without stirrups.” ACI Struct. J., 88(3), 268–276. 63(6), 675–692.

Bazant, Z. P., and Kim, J. K. (1984). “Size effect in shear failure of Kani, G. N. J. (1967). “How safe are our large reinforced concrete

longitudinally reinforced beams.” ACI J., 81(5), 456–468. beams?” ACI J., 64(3), 128–141.

Bazant, Z. P., and Sun, H. H. (1987). “Size effect in diagonal shear Kim, D., Kim, W., and White, R. N. (1999). “Arch action in reinforced

failure: Influence of aggregate size and stirrups.” ACI Mater. J., concrete beams—A rational prediction of shear strength.” ACI Struct.

84(4), 259–271. J., 96(4), 586–593.

Bresler, B., and Scordelis, A. C. (1963). “Shear strength of reinforced Kim, J. K., and Park, Y. D. (1994). “Shear strength of reinforced high

concrete beams.” ACI J., 60(1), 51–74. strength concrete beams without web reinforcement.” Mag. Concrete

Chana, P. S. (1987). “Investigation of the mechanism of shear failure of Res., 46(166), 7–16.

reinforced concrete beams.” Mag. Concrete Res., 39(141), 196–204. Kim, J. K., and Park, Y. D. (1996). “Prediction of shear strength of

Cho, S. H. (2003). “Shear strength prediction by modified plasticity reinforced concrete beams without web reinforcement.” ACI Mater. J.,

theory for short beams.” ACI Struct. J., 100(1), 105–112. 93(3), 213–222.

Downloaded from ascelibrary.org by Indian Institute Of Technology Madras on 03/11/24. Copyright ASCE. For personal use only; all rights reserved.

Cladera, A., and Marì, A. R. (2002). “Shear strength of reinforced high- Kim, W., and White, R. N. (1999a). “Shear-critical cracking in slender

strength concrete beams.” Proc., 6th Int. Symposium on “Utilization reinforced concrete beams.” ACI Struct. J., 96(5), 757–765.

of High Strength/High Performance Concrete,” Leipzig, Germany, Kim, W., and White, R. N. (1999b). “Hypothesis for localized horizontal

Gert König and Frank Dehn (Leipzig University), Thorsten Faust, shearing failure mechanism of slender RC beams.” J. Struct. Eng.,

König Heunisch und Partner (Consulting Engineers, Frankfurt), 205– 125(10), 1126–1135.

219. Krefeld, W. J., and Thurston, C. W. (1966). “Studies of the shear and

Clark, A. P. (1951). “Diagonal tension in reinforced concrete beams.” diagonal tension strength of simply supported reinforced concrete

ACI J., 48(10), 145–156. beams.” ACI J., 63(4), 451–476.

Collins, M. P., and Kuchma, D. (1999). “How safe are our large, lightly Kulkarni, S. M., and Shah, S. P. (1998). “Response of reinforced concrete

reinforced concrete beams, slabs, and footings?” ACI Struct. J., 96(4), beams at high strain.” ACI Struct. J., 95(6), 705–715.

482–490. Kwak, Y. K., Eberhard, M. O., Kim, W. S., and Jubum, K. (2002). “Shear

Collins, M. P., Mitchell, D., Adebar, P., and Vecchio, F. J. (1996). “A strength of steel fiber-reinforced concrete beams without stirrups.”

general shear design method.” ACI Struct. J., 93(1), 36–45. ACI Struct. J., 99(4), 530–538.

Comité Européen de Normalization (CEN). (1992). “Eurocode Lambotte, H., and Taerwe, L. R. (1990). “Deflection and cracking of

2—Design of concrete structures—Part 1-1: General rules and rules high-strength concrete beams and slabs.” Proc., 2nd Int. Symp. on

for buildings.” ENV 1992-1-1. High-Strength Concrete, Berkely, Calif. [ACI SP-121(11.)]

Desai, S. B. (1995). “Horizontal web steel as shear reinforcement.” Mag. Lim, T. Y., Paramasivam, P., and Lee, S. L. (1987). “Shear and moment

Concrete Res., 47(171), 143–152. capacity of reinforced steel-fibre-concrete beams.” Mag. Concrete

Diaz de Cossio, R., and Siess, C. P. (1960). “Behavior and strength in Res., 39(140), 148–160.

shear of beams and frames without web reinforcement.” ACI J., Mathey, R. G., and Watstein, D. (1963). “Shear strength of beams without

56(8), 695–735. web reinforcement containing deformed bars of different yield

Elzanaty, A. H., Nilson, A. H., and Slate, F. O. (1986). “Shear capacity of strengths.” ACI J., 60(2), 183–208.

reinforced concrete beams using high-strength concrete.” ACI Struct. Matsuo, M., Lertsrisakulrat, T., Yanagawa, A., and Niwa, J. (2002). “Ef-

J., 83(2), 290–296. fect of shear reinforcement on mechanical behavior of RC deep

Foster, S. J., and Gilbert, R. I. (1998). “Experimental studies on high- beams.” Proc., 1st fib Congress on “Concrete Structures in the 21st

strength concrete deep beams.” ACI Struct. J., 95(4), 382–390.

Century,” Osaka, Japan, Japan Prestessed Concrete Engineering As-

Fujita, M., Sato, R., Matsumoto, K., and Takaki, Y. (2002). “Size effect

sociation, Japan Concrete Institute, 199–206.

on shear capacity of RC beams using HSC without shear reinforce-

Mattock, A. H. (1969). “Diagonal tension cracking in concrete beams

ment.” Proc., 6th Int. Symposium on “Utilization of High Strength/

with axial forces.” J. Struct. Div. ASCE, 95(9), 1887–1900.

High Performance Concrete,” Leipzig, Germany, Gert König and Moody, K. G., Viest, I. M., Elstner, R. C., and Hognestad, E. (1954).

Frank Dehn (Leipzig University), Thorsten Faust, König Heunisch “Shear strength of reinforced concrete beams, Part 1—Tests of simple

und Partner (Consulting Engineers, Frankfurt), 235–245. beams.” ACI J., 51(4), 317–332.

Gale, L., and Ibell, T. J. (2000). “Effect of compression reinforcement on Morrow, J., and Viest, I. M. (1957). “Shear strength of reinforced con-

the shear strength of reinforced concrete bridge beams.” Mag. Con- crete frame members without web reinforcement.” ACI J., 53(9),

crete Res., 52(4), 275–285.

833–870.

Gambarova, P. G., and Rosati, G. P. (1997). “Bond and splitting in bar

Mphonde, A. G., and Frantz, G. C. (1984). “Shear tests of high- and

pull-out: Behavioural laws and concrete cover role.” Mag. Concrete

low-strength concrete beams without stirrups.” ACI J., 81(4), 350–

Res., 49(179), 99–110.

357.

Hallgren, M. (1994). “Flexural and shear capacity of reinforced high

Müller, G., and Reid, R. (1998). “Shear resistance of beams with shallow-

strength concrete beams without stirrups.” Licentiate thesis, Depart-

angle bent-up bars.” J. Struct. Build., 128, 385–393.

ment of Structural Engineering, Royal Institute of Technology, Stock-

Narayanan, R., and Darwish, I. Y. S. (1987). “Use of steel fibers as shear

holm, Sweden, 49.

reinforcement.” ACI Struct. J., 84(3), 216–227.

Hayashi, K., Oriji, K., Yamaguchi, T. and Ikeda, S. (2002). “The mecha-

nism of size effect on the shear strength of reinforced concrete mem- Nielsen, M. P. (1998). Limit analysis and concrete plasticity, 2nd Ed.,

bers.” Proc., 1st fib Congress on “Concrete Structures in the 21st CRC, Boca Raton, Fla., 908.

Oh, J. K., and Shin, S. W. (2001). “Shear strength of reinforced high-

Century,” Osaka, Japan, 69–78.

strength concrete deep beams.” ACI Struct. J., 98(2), 164–173.

Islam, M. S., Pam, H. J., and Kwan, A. K. H. (1998). “Shear capacity of

high-strength concrete beams with their point of inflection within the Paulay, T., and Priestley, M. J. M. (1992). Seismic design of reinforced

shear span.” J. Struct. Build., 128, 91–99. concrete and masonry buildings, Wiley, New York.

Jelic, I., Pavlovic, M. N., and Kotsovos, M. D. (1999). “A study of dowel Pellegrino, C., Bernardini, A., and Modena, C. (2002). “Shear failure of

action in reinforced concrete beams.” Mag. Concrete Res., 51(2), HSC beams with variable shear span-to-depth ratios.” Proc., 6th Int.

131–141. Symposium on “Utilization of High Strength/High Performance Con-

Johnson, M. K., and Ramirez, J. A. (1989). “Minimum shear reinforce- crete,” Leipzig, Germany, Gert König and Frank Dehn (Leipzig Uni-

ment in beams with higher strength concrete.” ACI Struct. J., 86(4), versity), Thorsten Faust, König Heunisch und Partner (Consulting En-

376–382. gineers, Frankfurt), 473–484.

Kani, G. N. J. (1966). “Basic facts concerning shear failure.” ACI J., Pendyala, R. S., and Mendis, P. (2000). “Experimental study on shear

JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JANUARY 2005 / 73

J. Struct. Eng., 2005, 131(1): 66-74

strength of high-strength concrete beams.” ACI Struct. J., 97(4), 564– Japan Concrete Institute, 217–224.

571. Tan, K. H., Kong, F. K., Teng, S., and Weng, L. W. (1997). “Effect of web

Placas, A., and Regan, P. E. (1971). “Shear failure of reinforced concrete reinforcement on high-strength concrete deep beams.” ACI Struct. J.,

beams.” ACI J., 68(10), 763–773. 94(5), 572–582.

Rahal, K. N., and El-Hawary, M. M. (2002). “Experimental investigation Tan, K. H., and Lu, H. Y. (1999). “Shear behavior of large reinforced

of shear strength of epoxy-modified longitudinally reinforced concrete concrete deep beams and code comparisons.” ACI Struct. J., 96(5),

beams.” ACI Struct. J., 99(1), 90–97. 836–845.

Rajagopalan, K. S., and Ferguson, P. M. (1968). “Exploratory shear tests Taub, J., and Neville, A. M. (1960). “Resistance to shear of reinforced

emphasizing percentage of longitudinal steel.” ACI J., 65(8), 634– concrete beams. Part 1—Beams without web reinforcement.” ACI J.,

638. 57(11), 193–220.

Rebeiz, K. S. (1999). “Shear strength prediction for concrete members.” Taylor, H. P. J. (1972). “Shear strength of large beams.” J. Struct. Div.

J. Struct. Eng., 125(3), 301–308.

ASCE, 98(11), 2473–2490.

Downloaded from ascelibrary.org by Indian Institute Of Technology Madras on 03/11/24. Copyright ASCE. For personal use only; all rights reserved.

Russo, G. (1990). “Beam strength enhancement at design ductility factor

Taylor, R. (1960). “Some shear tests on reinforced concrete beams with-

demands.” J. Struct. Eng., 116(12), 3402–3416.

out web reinforcement.” Mag. Concrete Res., 12(36), 145–154.

Russo, G., Biolzi, L., and De Cillia, F. (1999). “Resistenza a flessione-

Teng, S., Ma, W., and Wang, F. (2000). “Shear strength of concrete deep

taglio di travi in c.a. ordinario e ad alta resistenza.” Industria Italiana

beams under fatigue loading.” ACI Struct. J., 97(4), 572–580.

del Cemento, 744, 498–507.

Thorenfeldt, E., and Drangsholdt, G. (1990). “Shear capacity of rein-

Russo, G., and Puleri, G. (1997). “Stirrup effectiveness in reinforced

concrete beams under flexure and shear.” ACI Struct. J., 94(3), 451– forced high-strength concrete beams.” Proc., 2nd Int. Symposium on

476. High-Strength Concrete, Berkeley, Calif. [ACI SP-121(11), 129–154].

Russo, G., Zingone, G., and Puleri, G. (1991). “Flexure-shear interaction Tompos, E. J., and Frosch, R. J. (2002). “Influence of beam size, longi-

model for longitudinally reinforced beams.” ACI Struct. J., 88(1), tudinal reinforcement, and stirrup effectiveness on concrete shear

60–68. strength.” ACI Struct. J., 99(5), 559–567.

Shin, S. W., Lee, K. S., Moon, J., and Ghosh, S. K. (1999). “Shear Tureyen, A. K., and Frosch, R. J. (2002). “Shear tests of FRP-reinforced

strength of reinforced high-strength concrete beams with shear span- beams without stirrups.” ACI Struct. J., 99(4), 427–434.

to-depth ratios between 1.5 and 2.5.” ACI Struct. J., 96(4), 549–556. Van Den Berg, F. J. (1962). “Shear strength of reinforced concrete beams

Somma, G., and Russo, G. (2001). “Shear tests of high-performance con- without web reinforcement, Part 2—Factors affecting load at diagonal

crete beams without stirrups.” Proc., 7th European Conf. on Advanced cracking.” ACI J., 59(11), 1587–1600.

Materials and Processes, Rimini, Italy. Watstein, D., and Mathey, R. G. (1958). “Strains in beams having diag-

Suter, G. T., and Manuel, R. F. (1971). “Diagonal crack control in short onal cracks.” ACI Struct. J., 55(6), 717–728.

beams.” ACI J., 68(6), 451–455. Xie, Y., Ahmad, S. H., Yu, T., Hino, S., and Chung, W. (1994). “Shear

Swamy, R. N., Andriopoulos, A., and Adepegba, D. (1970). “Arch action ductility of reinforced concrete beams of normal and high-strength

and bond in concrete shear failures.” J. Struct. Div. ASCE, 96(6), concrete.” ACI Struct. J., 91(2), 140–149.

1069–1091. Yoon, Y., Cook, W. D., and Mitchell, D. (1996). “Minimum shear rein-

Takaki, Y., Fujita, M., and Matsumoto, K. (2002). “Diagonal tension forcement in normal, medium, and high-strength concrete beams.”

failure of reinforced concrete beam without shear reinforcement.” ACI Struct. J., 93(5), 576–584.

Proc., 1st fib Congress on “Concrete Structures in the 21st Century,” Zsutty, T. C. (1968). “Beam shear strength prediction by analysis of ex-

Osaka, Japan, Japan Prestressed Concrete Engineering Association, isting data.” ACI J., 65(11), 943–951.

74 / JOURNAL OF STRUCTURAL ENGINEERING © ASCE / JANUARY 2005

J. Struct. Eng., 2005, 131(1): 66-74

You might also like

- Rational Approach To Prediction of Shear Capacity of RC Beam-Column ElementsDocument13 pagesRational Approach To Prediction of Shear Capacity of RC Beam-Column ElementsRayan MahgoubNo ratings yet

- Numerical Investigation of The Shear Strength of RC DeepDocument13 pagesNumerical Investigation of The Shear Strength of RC DeepJoão Paulo MendesNo ratings yet

- Analytical Calculation Model For Predicting Cracking Behavior of Reinforced Concrete TiesDocument17 pagesAnalytical Calculation Model For Predicting Cracking Behavior of Reinforced Concrete TiesSalim AwadNo ratings yet

- (Asce) 0733-9445 (2001) 127 7Document11 pages(Asce) 0733-9445 (2001) 127 7abadittadesseNo ratings yet

- Load Capacity of Reinforced Concrete Continuous Deep Beams: K. H. Yang and A. F. AshourDocument11 pagesLoad Capacity of Reinforced Concrete Continuous Deep Beams: K. H. Yang and A. F. AshourJoão Paulo MendesNo ratings yet

- Effect of Seismic Load History On Deformation Limit States For Longitudinal Bar Buckling in RC Circular ColumnsDocument13 pagesEffect of Seismic Load History On Deformation Limit States For Longitudinal Bar Buckling in RC Circular ColumnsAristotle MedinaNo ratings yet

- MD Shahnewaz Ahmad Rteil Sharia Alam - Shear Strength of Reinforced Concrete Deep Beams - A Review With ImprovedDocument15 pagesMD Shahnewaz Ahmad Rteil Sharia Alam - Shear Strength of Reinforced Concrete Deep Beams - A Review With ImprovedJoão Paulo MendesNo ratings yet

- Aashto Excerpt Specification CH9Document8 pagesAashto Excerpt Specification CH9CyrilNo ratings yet

- Strength Prediction For Discontinuity Regions by Softened Strut-and-Tie ModelDocument8 pagesStrength Prediction For Discontinuity Regions by Softened Strut-and-Tie ModelAbi IlamvazhuthiNo ratings yet

- Infill of HCBDocument17 pagesInfill of HCBTesfayeNo ratings yet

- 2002c-Dhakal Maekawa PDFDocument10 pages2002c-Dhakal Maekawa PDFdmep25No ratings yet

- Shearwall Damage ReplicationsDocument8 pagesShearwall Damage ReplicationsmohansanjayNo ratings yet

- Tekban Lanjut 4Document7 pagesTekban Lanjut 4Bastian Artanto AmpangalloNo ratings yet

- Bayrak SeikhDocument13 pagesBayrak SeikhArthur DahokloryNo ratings yet

- 10 1061@ascebe 1943-5592 0000456Document11 pages10 1061@ascebe 1943-5592 0000456jiang31No ratings yet

- 6.-Structural Testing and Design of Wire Arc Additively Manufactured Square Hollow SectionsDocument19 pages6.-Structural Testing and Design of Wire Arc Additively Manufactured Square Hollow SectionsJosé RiquelmeNo ratings yet

- Improved Seismic Performance of Gusset Plate ConnectionsDocument12 pagesImproved Seismic Performance of Gusset Plate ConnectionsPrateek PandaNo ratings yet

- Cable VibrationDocument15 pagesCable VibrationStructureClassNo ratings yet

- Engineering Structures Rahman Et Al 2021Document22 pagesEngineering Structures Rahman Et Al 2021José GomesNo ratings yet

- Determination of Actual Design Moment in Ultradeep Reinforced Concrete RaftsDocument3 pagesDetermination of Actual Design Moment in Ultradeep Reinforced Concrete RaftsklllNo ratings yet

- Ej 2023 q2 IssueDocument66 pagesEj 2023 q2 IssueIoannis MitsisNo ratings yet

- Diagonal Tension Failure of RC Beams Without Stirrups: Guray ArslanDocument10 pagesDiagonal Tension Failure of RC Beams Without Stirrups: Guray ArslanHeru P SoehardjoNo ratings yet

- Nenadović, A. Tensegrity PDFDocument10 pagesNenadović, A. Tensegrity PDFPatrickNo ratings yet

- 1984 Malley - Popov - 1984 - Design Methodology (Continuation With Popov (1983) )Document21 pages1984 Malley - Popov - 1984 - Design Methodology (Continuation With Popov (1983) )Saurabh TakNo ratings yet

- (Asce) 0733 9445 (2001) 127 11 (1266)Document10 pages(Asce) 0733 9445 (2001) 127 11 (1266)Seyed Mohamad Mehdi SajediNo ratings yet

- Improved Seismic Performance of Gusset Plate ConnectionsDocument12 pagesImproved Seismic Performance of Gusset Plate ConnectionsGokul PrabuNo ratings yet

- Shear Strength Prediction For Deep Beams: Aci Structural Journal Technical PaperDocument10 pagesShear Strength Prediction For Deep Beams: Aci Structural Journal Technical PaperpicottNo ratings yet

- 1 Shear fb73Document10 pages1 Shear fb73Dr.K.Rajeswara RaoNo ratings yet

- Ajassp 2008 248 262Document15 pagesAjassp 2008 248 262krishnanunniNo ratings yet

- Geometrical Nonlinearity and Length of External Tendons: Marco A. Pisani, M.ASCEDocument10 pagesGeometrical Nonlinearity and Length of External Tendons: Marco A. Pisani, M.ASCEAli OmarNo ratings yet

- Bennett - 2015 - Design Parameters For Masonry Wall - Stiffness PredictionDocument14 pagesBennett - 2015 - Design Parameters For Masonry Wall - Stiffness PredictionJhon Smit Gonzales UscataNo ratings yet

- 1998 - Polyzois and Raftoyiannis - Lateral-Torsional Stability of Steel Web-Tapered I-BeamsDocument9 pages1998 - Polyzois and Raftoyiannis - Lateral-Torsional Stability of Steel Web-Tapered I-BeamsJosé Ferreira FilhoNo ratings yet

- Sustainability 14 05238Document22 pagesSustainability 14 05238mahdiNo ratings yet

- Analysis of FRP-Strengthened RC Beam-Column JointsDocument11 pagesAnalysis of FRP-Strengthened RC Beam-Column JointsCu ToànNo ratings yet

- 2.18-Displacement Estimates For Performance-Based Seismic DesignDocument8 pages2.18-Displacement Estimates For Performance-Based Seismic DesignWangyhNo ratings yet

- Structural Health Monitoring of Exterior Beam-Column Subassemblies (Feb 2022)Document17 pagesStructural Health Monitoring of Exterior Beam-Column Subassemblies (Feb 2022)Hamid GoodarziNo ratings yet

- Chan 1994Document13 pagesChan 1994fahmi aballiNo ratings yet

- (Building Code 1983), For Instance, Which Treats The Problem of ComputationDocument11 pages(Building Code 1983), For Instance, Which Treats The Problem of ComputationabadittadesseNo ratings yet

- Llaves de CorteDocument12 pagesLlaves de CorteJose Luis Martinez SaavedraNo ratings yet

- Behavioral Study of Reinforced Concrete Beams Designed For Shear Using Compressive Force Path and ACI Code ModelsDocument5 pagesBehavioral Study of Reinforced Concrete Beams Designed For Shear Using Compressive Force Path and ACI Code ModelsStefania RinaldiNo ratings yet

- Semi-Rigid Connection Structural ResponsesDocument15 pagesSemi-Rigid Connection Structural Responsesankurshah1986No ratings yet

- 11-Flexural Behavior of SFRC - Testing and ModelingDocument9 pages11-Flexural Behavior of SFRC - Testing and ModelingTùng HìNo ratings yet

- 2016 Evaluation of Simplified and State-of-the-Art Analysis Procedures For Steel Frame Buildings Equipped With Supplemental Damping DevicesDocument17 pages2016 Evaluation of Simplified and State-of-the-Art Analysis Procedures For Steel Frame Buildings Equipped With Supplemental Damping Devicesryan rakhmat setiadiNo ratings yet

- Exploring Buckling and Post-Buckling Behavior of Incompressible Hyperelastic Beams Through Innovative Experimental and Computational ApproachesDocument21 pagesExploring Buckling and Post-Buckling Behavior of Incompressible Hyperelastic Beams Through Innovative Experimental and Computational ApproachesGogyNo ratings yet

- Punching Capacity Nguyen-Minh2012Document12 pagesPunching Capacity Nguyen-Minh2012Ashraf Gomah Mohamed ElshamandyNo ratings yet

- (Lim Et Al., 2016) Finite-Element Modeling of Actively Confined Normal-Strength and High-Strength Concrete Under CompressionDocument12 pages(Lim Et Al., 2016) Finite-Element Modeling of Actively Confined Normal-Strength and High-Strength Concrete Under CompressionJose ManuelNo ratings yet

- Rilem TC 162-Tdf: Test and Design Methods For Steel Fibre Reinforced ConcreteDocument17 pagesRilem TC 162-Tdf: Test and Design Methods For Steel Fibre Reinforced ConcreteJaniele MoreiraNo ratings yet

- 21853Document13 pages21853saeedNo ratings yet

- Jp26 Suwal Guner Joints Ann 2024 2Document23 pagesJp26 Suwal Guner Joints Ann 2024 2Enzo SantosNo ratings yet

- (Asce) ST 1943-541X 0001789Document11 pages(Asce) ST 1943-541X 0001789surafel abebawNo ratings yet

- Ref 10Document15 pagesRef 10SHEIK MASTANNo ratings yet

- 21-0027 Mante SO22Document15 pages21-0027 Mante SO22AgileNo ratings yet

- Seismic Behavior of Symmetric and Asymmetric Steel Structures With Rigid and Semirigid DiaphragmsDocument12 pagesSeismic Behavior of Symmetric and Asymmetric Steel Structures With Rigid and Semirigid DiaphragmsAristotle MedinaNo ratings yet

- Behavior of Cold-Formed Steel Built-Up Sections With Intermediate Stiffeners Under Bending. II: Parametric Study and DesignDocument11 pagesBehavior of Cold-Formed Steel Built-Up Sections With Intermediate Stiffeners Under Bending. II: Parametric Study and Designviveksp99No ratings yet

- Interactive Mechanical Model For Shear Strength of Deep-TanDocument11 pagesInteractive Mechanical Model For Shear Strength of Deep-TanmunnaiitrNo ratings yet

- Khalfallah-Guerdouh2014 Article TensionStiffeningApproachInCon PDFDocument6 pagesKhalfallah-Guerdouh2014 Article TensionStiffeningApproachInCon PDFyanimuhammadNo ratings yet

- Prediction of Axial Compressive Strength For FRP-Confined Concrete Compression MembersDocument12 pagesPrediction of Axial Compressive Strength For FRP-Confined Concrete Compression MembersDoua AbdouNo ratings yet

- Efficient Seismic Design of 3D Asymmetric and Setback RC Frame Buildings For Drift and Strain LimitationDocument12 pagesEfficient Seismic Design of 3D Asymmetric and Setback RC Frame Buildings For Drift and Strain LimitationAristotle MedinaNo ratings yet

- Civil Engineering: A Takagi-Sugeno Fuzzy Model For Predicting The Clean Rock Joints Shear StrengthDocument6 pagesCivil Engineering: A Takagi-Sugeno Fuzzy Model For Predicting The Clean Rock Joints Shear StrengthyutefupNo ratings yet

- Matrix Structural Analysis: Pergamon Unified Engineering SeriesFrom EverandMatrix Structural Analysis: Pergamon Unified Engineering SeriesRating: 3 out of 5 stars3/5 (2)

- 1 s2.0 S0141029618314214 MainDocument9 pages1 s2.0 S0141029618314214 MainSiva GuruNo ratings yet

- 1 s2.0 S0360319920317857 MainDocument20 pages1 s2.0 S0360319920317857 MainSiva GuruNo ratings yet

- 1 s2.0 S1568494616305348 MainDocument7 pages1 s2.0 S1568494616305348 MainSiva GuruNo ratings yet

- 1 s2.0 S0141029604000604 MainDocument10 pages1 s2.0 S0141029604000604 MainSiva GuruNo ratings yet

- Reexamination of Dowel Behavior of Steel Bars Embedded in ConcreteDocument21 pagesReexamination of Dowel Behavior of Steel Bars Embedded in ConcreteSiva GuruNo ratings yet

- Shear Strength of Steel Fiber-Reinforced ConcreteDocument10 pagesShear Strength of Steel Fiber-Reinforced ConcreteSiva GuruNo ratings yet

- 2185 4 2008 Reff2019Document16 pages2185 4 2008 Reff2019Siva GuruNo ratings yet

- 1 s2.0 S1359835X17302804 MainDocument10 pages1 s2.0 S1359835X17302804 MainSiva GuruNo ratings yet

- Foaming Agents For Use in Producing Cellular Concrete Using Preformed FoamDocument6 pagesFoaming Agents For Use in Producing Cellular Concrete Using Preformed FoamSiva GuruNo ratings yet

- 1 s2.0 S095006181932402X MainDocument9 pages1 s2.0 S095006181932402X MainSiva GuruNo ratings yet

- 1 s2.0 S0008884614001343 MainDocument10 pages1 s2.0 S0008884614001343 MainSiva GuruNo ratings yet

- 1 s2.0 S0143974X1100023X MainDocument10 pages1 s2.0 S0143974X1100023X MainSiva GuruNo ratings yet

- 83 - Ex - III - 1a - 2023 - Compassionate Ground RulesDocument10 pages83 - Ex - III - 1a - 2023 - Compassionate Ground RulesSiva GuruNo ratings yet

- Journal of Constructional Steel Research: Saeed Gholizadeh, Akbar Pirmoz, Reza AttarnejadDocument10 pagesJournal of Constructional Steel Research: Saeed Gholizadeh, Akbar Pirmoz, Reza AttarnejadSiva GuruNo ratings yet

- Influence of Shear Wall Openings On Behaviour of Structure: Sumegh S. Patne Harshal M. BanubakodeDocument6 pagesInfluence of Shear Wall Openings On Behaviour of Structure: Sumegh S. Patne Harshal M. BanubakodeSiva GuruNo ratings yet

- Parametric Study of Castellated Beam With Circular and Diamond Shaped OpeningsDocument8 pagesParametric Study of Castellated Beam With Circular and Diamond Shaped OpeningsSiva GuruNo ratings yet

- BUS 8375 Lec. 11 Assignment 4 Qualitative Analysis v.1 1Document8 pagesBUS 8375 Lec. 11 Assignment 4 Qualitative Analysis v.1 1Jaspal SinghNo ratings yet

- FLUID-MECHANICSDocument49 pagesFLUID-MECHANICSBong DuterteNo ratings yet

- Equations of Order One: Differential Equations Module 2ADocument5 pagesEquations of Order One: Differential Equations Module 2AJuvilee RicoNo ratings yet

- Naval Aviation News - Dec 1950Document36 pagesNaval Aviation News - Dec 1950CAP History Library100% (1)

- Yan Li 2016Document10 pagesYan Li 2016Hendy Dwi WarmikoNo ratings yet

- Overtaking Assistant System (OAS) With Fuzzy Logic Method Using Camera SensorDocument7 pagesOvertaking Assistant System (OAS) With Fuzzy Logic Method Using Camera SensorJustamNo ratings yet

- Brainware University: Practice Set ofDocument4 pagesBrainware University: Practice Set ofDeep TarafdarNo ratings yet

- Original PDFDocument7 pagesOriginal PDFPriyaKumarNo ratings yet

- Choice TheoryDocument2 pagesChoice Theoryginabonieve100% (1)

- Free Mechanical Aptitude Questions AnswersDocument12 pagesFree Mechanical Aptitude Questions Answerswhriyj177No ratings yet

- Stratos DR. DMS D.esintrometroDocument14 pagesStratos DR. DMS D.esintrometroRosa Aldiris Garcia MedranoNo ratings yet

- English 7 ASDocument16 pagesEnglish 7 ASAh RingNo ratings yet

- Anquamine 728: Curing AgentDocument4 pagesAnquamine 728: Curing AgentGreg PanganNo ratings yet

- Chemical WarfareDocument18 pagesChemical WarfareUnited States Militia100% (2)

- The System by Todd Valentine - Review & Summary - Power Dynamics™ PDFDocument33 pagesThe System by Todd Valentine - Review & Summary - Power Dynamics™ PDFshadowzack 509No ratings yet

- Conflicted City: Hypergrowth, Urban Renewal and Urbanization in IstanbulDocument45 pagesConflicted City: Hypergrowth, Urban Renewal and Urbanization in IstanbulElif Simge FettahoğluNo ratings yet

- Logical ReasoningDocument11 pagesLogical Reasoning8yjq64s5shNo ratings yet

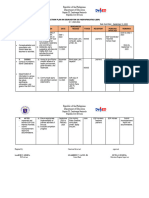

- Action Plan ESP 2023 24Document2 pagesAction Plan ESP 2023 24Je-Ann EstriborNo ratings yet

- Hydration of Calcium Aluminate Cement Phase Ca and Ca2 in Refractory ApplicationsDocument4 pagesHydration of Calcium Aluminate Cement Phase Ca and Ca2 in Refractory Applicationsakanksha.kumariNo ratings yet

- Chapter IiDocument13 pagesChapter IiEmerson CruzNo ratings yet

- Raju ComparativePhilosophySpiritual 1963Document16 pagesRaju ComparativePhilosophySpiritual 1963Kent Jerson CasianoNo ratings yet

- Kiyora Catlog SeiresDocument6 pagesKiyora Catlog SeiresMd SazadNo ratings yet

- Analysis of The Story The AwakeningDocument7 pagesAnalysis of The Story The AwakeningAary Rathod100% (1)

- CHEM1701-lab3-202341 - 202341.12623-CHEM-1701-08 - PRE-HEALTH CHEMISTRY IDocument1 pageCHEM1701-lab3-202341 - 202341.12623-CHEM-1701-08 - PRE-HEALTH CHEMISTRY IMartha ChalmenageNo ratings yet

- Uplift ModelingDocument4 pagesUplift ModelingMatthew ChengNo ratings yet

- Automatic Design of Compliant Surgical Forceps With Adaptive Grasping FunctionsDocument9 pagesAutomatic Design of Compliant Surgical Forceps With Adaptive Grasping FunctionsFarjad KhanNo ratings yet

- Issue: 3D at Depth: The Future Is GreenDocument72 pagesIssue: 3D at Depth: The Future Is GreenPepeNo ratings yet

- Failure Modes of RCC Beams Strengthened With NSM FRP TechniquesDocument9 pagesFailure Modes of RCC Beams Strengthened With NSM FRP TechniquesfelixNo ratings yet

- Exercise 7 Mineral Oil EmulsionDocument3 pagesExercise 7 Mineral Oil EmulsionFreya AvellanoNo ratings yet

- Procedure of CrossingDocument68 pagesProcedure of Crossingrizalbaso100% (4)