Professional Documents

Culture Documents

Preparing For Installation

Uploaded by

jwg94546Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Preparing For Installation

Uploaded by

jwg94546Copyright:

Available Formats

Prepare for Installation

Before you install the Cisco NCS 520, you must prepare your site for the installation.

Preparing your site involves these tasks:

• Site Planning, on page 1

• Receive the Device, on page 8

Site Planning

The following sections describe how to plan the site for installing of the Cisco NCS 520.

General Precautions

Observe the following general precautions when using and working with your chassis:

• Keep your system components away from radiators and heat sources, and do not block cooling vents.

• Do not spill food or liquids on your system components, and never operate the product in a wet

environment.

• Do not push any objects into the openings of your system components. Doing so can cause fire or electric

shock by shorting out interior components.

• Position system cables and power supply cable carefully. Route system cables and the power supply

cable and plug so that they are not stepped on or tripped over. Ensure that nothing is rests on your system

component cables or power cable.

• Do not modify power cables or plugs. Consult a licensed electrician or your power company for site

modifications. Always follow your local and national wiring rules.

• If you turn off your system to avoid damage to the system components, wait at least 30 seconds before

turning it on again.

Site Planning Checklist

Use the following checklist to carry out all site planning tasks:

• The site meets environmental requirements.

Prepare for Installation

1

Prepare for Installation

Site Selection Guidelines

• The site’s air conditioning system can compensate for the heat dissipation of the chassis.

• The floor space that the chassis occupies can support the weight of the system.

• Electrical service to the site complies with the safety with electricity requirements.

• The electrical circuit servicing the chassis complies with the power supply requirements.

• Console port wiring and cabling limitations have been considered in accordance to TIA/EIA-232F.

• The chassis Ethernet cabling distances are within prescribed limits.

• The equipment rack where the chassis is to be installed complies with prescribed requirements.

• The following factors have been carefully considered when selecting rack: location, safety, ease of

maintenance, and proper airflow.

Site Selection Guidelines

The device requires specific environmental operating conditions. Temperature, humidity, altitude, and vibration

can affect the performance and reliability of the device.

The device is designed to meet the industry EMC, safety, and environmental standards.

Airflow for Site Planning

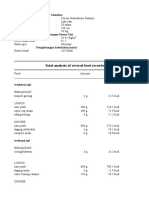

Table 1: Cisco NCS 520 Airflow

Device Feature Maximum System Airflow

(CFM) at Maximum System

Temperature

N520-4G4Z-A Cisco NCS 520 - 4xGE + 4x10GE, 25.0

commercial temp, AC power supply

N520-X-4G4Z-A Cisco NCS 520 - 4xGE + 4x10GE, 28.0

industrial temp, AC power supply

N520-X-4G4Z-D Cisco NCS 520 - 4xGE + 4x10GE,

industrial temp, DC power supply

N520-20G4Z-A Cisco NCS 520 - 20xGE + 4x10GE, 50.0

commercial temp, AC power supply

N520-20G4Z-D Cisco NCS 520 - 20xGE + 4x10GE,

commercial temp, DC power supply

N520-X-20G4Z-A Cisco NCS 520 - 20xGE + 4x10GE, 57.0

industrial temp, AC power supply

N520-X-20G4Z-D Cisco NCS 520 - 20xGE + 4x10GE,

industrial temp, DC power supply

Prepare for Installation

2

Prepare for Installation

Environmental Requirements

Environmental Requirements

Environmental monitoring of the chassis protects the system and components from damage due to excessive

voltage and temperature conditions. To ensure normal operation and avoid unnecessary maintenance, plan

and prepare your site configuration before installation. After installation, ensure that the environmental

characteristics continue to be met.

For an outside plant installation (cell site cabinet, hut, and so on), you require to protect the chassis against

airborne contaminants, dust, moisture, insects, pests, corrosive gases, polluted air, or other reactive elements.

We recommend that you install the unit in a fully sealed enclosure or cabinet. Examples of such cabinets

include IP65 cabinets with heat exchanger complying with Telcordia GR487. Temperature must be maintained

within –40ºC to 70ºC.

Place the device inside a space that is protected from direct weather and environmental stresses by an enclosure.

Ensure the operating climate as defined by Class 2 of GR-3108-CORE for premium variants.

• –40°C (-40°F) and 70°C (158°F)

• 5 and 85% RH

Ensure the operating climate as defined by Class 1 of GR-3108-CORE for base variants.

• –5°C (23°F) and 50°C (122°F)

• < 15 to 85% RH

Physical Characteristics

To set the device at its proper location, be familiar with its physical characteristics.

Airflow Guidelines

Cool air is circulated through the chassis by fans that are located along the back of the device.

The internal fans maintain acceptable operating temperatures for the internal components by drawing in cool

air through the vents and circulating that air through the chassis.

The direction of airflow is from front-to-back.

To ensure adequate airflow through the equipment rack, we recommend that you always maintain a minimum

clearance distance as mentioned in the following specifications.

• Front clearance—5 inches (12.7 centimeters)

• Rear clearance—3.93 inches (10 centimeters)

Note the following points:

• When installing chassis in a back-to-back position with another device, ensure a minimum of 3.93 inches

(10 centimeters) airflow clearance between them. Also, ensure that the device behind the chassis is not

installed in a way that it blows air into the chassis.

• An over-temperature condition may occur within the rack, if airflow through the rack and the device is

restricted, or if the air that is drawn into the rack is warm.

Prepare for Installation

3

Prepare for Installation

Airflow Guidelines for ETSI Rack Installation

• Ensure that the site is dust free. Dust tends to clog the device fans, reducing the flow of cooling air

through the equipment rack and the devices that occupy it, thus increasing the risk of an over-temperature

condition.

• Enclosed racks must have adequate ventilation. Because each device generates heat, ensure that the racks

are not congested. An enclosed rack must have louvered sides and a fan to provide cool air. Heat that is

generated by the equipment near the bottom of the rack may be drawn upward into the intake ports of

the equipment above.

• When mounting a chassis on an open rack, ensure that the rack frame does not block the exhaust fans.

• When a rack-installed equipment fails, especially equipment on an enclosed rack, if possible try operating

the equipment by itself. Power off all other equipment on the rack (and in adjacent racks) to give the

device maximum cooling air and clean power.

• Avoid installing the chassis in a location in which the chassis air intake vents may draw in the exhaust

air from an adjacent equipment. Consider how the air flows through the device; the airflow direction is

from front to back, with ambient air drawn in from the vents located on the sides of the chassis.

Caution When mounting the device on any type of rack equipment, ensure that the temperature of inlet air to the device

does not exceed the specified operating temperature limits of the product.

Airflow Guidelines for ETSI Rack Installation

When you install a device on a 2 or 4-post rack, the front and rear doors of the cabinet must be removed. We

recommended that you always maintain a minimum clearance distance as mentioned the following.

• Front clearance—5 inches (12.7 centimeters)

• Rear clearance—3.93 inches (10 centimeters)

To mount the chassis in a 4-post enclosed cabinet, ensure a minimum of 3.93 inches (10 centimeters) of

clearance on each side of the chassis.

Floor Loading Considerations

Ensure that the floor under the rack supporting the chassis is able to support the combined weight of the rack

and all the other installed equipment.

For additional information about floor loading requirements, see the GR-63-CORE, Network Equipment

Building System (NEBS) Requirements: Physical Protection document.

Site Power Guidelines

The chassis has specific power and electrical wiring requirements. Adhering to these requirements ensures

reliable operation of the system. Follow these precautions and recommendations when planning your site

power for the chassis:

• The redundant power option provides a second, identical power supply to ensure uninterrupted power

supply.

Prepare for Installation

4

Prepare for Installation

Electrical Circuit Requirements

Note Applicable only to Cisco N540-24Z8Q2C-SYS, N540X-ACC-SYS, and

N540-ACC-SYS routers.

• Connect each power supply to a separate input power source. Otherwise, it results in total power failure

to the system due to a fault in the external wiring or a tripped circuit breaker.

• To prevent loss of input power, ensure that the maximum load on each circuit is within the current ratings

of the wiring and the breakers.

• Check the power at your site before installation, and periodically after installation, to ensure that you are

receiving clean power. If necessary, install a power conditioner.

• Provide proper grounding to avoid personal injury and damage to the equipment due to power surges or

lightning striking power lines. The chassis ground must be attached to a central office or other interior

ground system.

Warning This product requires short-circuit (overcurrent) protection to be provided as part of the building installation.

Install only in accordance with national and local wiring regulations. Statement 1045

Caution This product requires external surge protection device for both AC and DC power feeds to the equipment.

For DC power feed, the surge protective device (SPD) must handle common mode and differential mode

surge as per the local standards.

Note The chassis installation must comply with all the applicable codes, and is approved for use with only copper

conductors. The ground bond-fastening hardware must be compatible and preclude loosening, deterioration,

and electrochemical corrosion of hardware and joined material. Attachment of the chassis ground to a central

office or other interior ground system must be made with a 6-AWG gauge wire copper ground conductor.

Electrical Circuit Requirements

Each chassis requires a dedicated electrical circuit. If you equip the device with dual-power feeds, provide a

separate circuit for each power supply to avoid compromising the power redundancy feature.

The chassis supports both DC source or an AC source. Ensure that equipment grounding is present and observe

power-strip ratings. Make sure that the total ampere rating of all the products plugged into the power strip

does not exceed 80% of the rating.

Site Cabling Guidelines

This section contains guidelines for wiring and cabling at your site. When preparing your site for network

connections to the chassis, consider the type of cable that is required for each component and cable limitations.

Consider the distance limitations for signaling, electromagnetic interference (EMI), and connector compatibility.

Possible cable types are fiber, thick or thin coaxial, foil twisted-pair, or unshielded twisted-pair cabling.

Prepare for Installation

5

Prepare for Installation

Asynchronous Terminal Connections

Also, consider any additional interface equipment that you need, such as transceivers, hubs, switches, modems,

channel service units (CSU), or data service units (DSU).

Before you install the chassis, have on hand all additional external equipment and cables. For information

about ordering, contact a Cisco customer service representative.

The extent of your network and the distances between the network interface connections depend, in part, on

the following factors:

• Signal type

• Signal speed

• Transmission medium

The distance and rate limits that are referenced in the following sections are the IEEE-recommended maximum

speeds and distances for signaling purposes. Use this information as a guideline when planning your network

connections before installing the chassis.

If wires exceed the recommended distances, or if wires pass between buildings, give special consideration to

the possibility of a lightning strike in your vicinity. The electromagnetic pulse due to lightning or other

high-energy phenomena can easily couple enough energy into unshielded conductors to destroy electronic

devices. If you have had problems of this sort in the past, you may want to consult experts in electrical surge

suppression and shielding.

Asynchronous Terminal Connections

The chassis provides a console port to connect a terminal or computer for local console access. The port has

an RJ-45 connector and supports RS-232 asynchronous data with distance recommendations that are specified

in the IEEE RS-232 standard. The available baud rate is 115200 bauds.

Interference Considerations

When wires are run for any significant distance, there is a risk of receiving stray signals on the wires as

interference. If interference signals are strong, it results in data errors or equipment damage.

The following sections describe the sources of interference and how to minimize their effects on the chassis.

Electromagnetic Interference

All the equipment that is powered by AC current can propagate electrical energy that can cause EMI and

possibly affect the operation of other equipment. The typical sources of EMI are equipment power cords and

power service cables from electric utilities.

Strong EMI can destroy the signal drivers and receivers in the chassis. It can even create an electrical hazard

by causing power surges through the power lines into installed equipment. These problems are rare, but could

be catastrophic.

To resolve these problems, you need specialized knowledge and equipment that could consume substantial

time and money. However, you can ensure that you have a properly grounded and shielded electrical

environment, paying special attention to the need for electrical surge suppression.

Radio Frequency Interference

When electromagnetic fields act over a long distance, radio frequency interference (RFI) may be propagated.

Building wiring can often act as an antenna, receiving the RFI signals and creating more EMI on the wiring.

Prepare for Installation

6

Prepare for Installation

Lightning and AC Power Fault Interference

If you use a twisted-pair cable in your plant wiring with a good distribution of grounding conductors, the plant

wiring is unlikely to emit radio interference. If you exceed the recommended distances, use a high-quality

twisted-pair cable with one ground conductor for each data signal.

Lightning and AC Power Fault Interference

If signal wires exceed the recommended cabling distances, or if signal wires pass between buildings, you may

encounter a lightning strike on the chassis.

The electromagnetic pulse (EMP) generated by lightning or other high-energy phenomena can couple enough

energy into unshielded conductors and damage or destroy electronic equipment. For such problems, you must

consult with RFI and EMI experts to ensure adequate electrical surge suppression and shielding of signal

cables in your operating environment.

Warning This product requires surge protection as part of the building installation. To comply with the Telcordia

GR-1089 NEBS standard for electromagnetic compatibility and safety, an external surge protective device

(SPD) is required at the AC or DC power service equipment.

Rack-Mounting Guidelines

The following sections provide guidelines for selecting racks and precautions for mounting the chassis on a

rack:

Precautions for Rack-Mounting

Follow these rack-mount guidelines to ensure your safety:

• Ensure that the rack is level and stable before extending a component from the rack.

• Ensure that proper airflow is provided to the components on the rack.

• Do not step on or stand on any component or system when servicing other systems or components on a

rack.

• If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing the

chassis.

Rack Selection Guidelines

Ensure the 2 or 4-post, 19 inches (48.3 centimeters) or 23 inches (58.42 centimeters) rack that you select

complies with the Electronic Industries Association (EIA) standard for equipment racks (EIA-310-D). The

rack must have at least two posts with mounting flanges to mount the chassis.

Caution When mounting a chassis in any type of rack equipment, ensure that the temperature of the inlet air to the

chassis does not exceed the specified operating temperature of the chassis.

The distance between the center lines of the mounting holes on the two mounting posts must be 18.31 inches

(46.50 centimeters) ± 0.06 inch (± 0.15 centimeter). The rack-mounting hardware included with the chassis

is suitable for most 19 inches (48.3 centimeters) equipment racks.

Install the chassis on a rack with the following features:

• NEBS-compliant, 19 inches (48.3 centimeters) rack or 23 inches (58.42 centimeters).

Prepare for Installation

7

Prepare for Installation

Receive the Device

• EIA or European Telecommunications Standards Institute (ETSI) hole patterns in the mounting rails.

The required mounting hardware is shipped with the chassis. If the rack on which you plan to install the

chassis has metric-threaded rails, you must provide your own metric-mounting hardware.

• Perforated top and open bottom for ventilation to prevent overheating.

• Leveling feet for stability.

Do not install the device on an enclosed rack because the chassis requires an unobstructed flow of cooling air

to maintain the acceptable operating temperature. If you use an enclosed rack, ensure that the airflow

requirements are maintained as discussed in the Airflow Guidelines section.

Receive the Device

Each device is shipped in a container that is strapped to a pallet.

Figure 1: Chassis Package

Prepare for Installation

8

Prepare for Installation

Unpack and Verify Shipped Contents

Label Description Label Description

1 Packing carton 3 Assembly packaging material

2 Accessories tray 4 Chassis

Unpack and Verify Shipped Contents

Procedure

Step 1 Inspect the shipping container for any shipping damage. If there is obvious physical damage, contact your

Cisco service representative, else continue with the remaining steps.

Step 2 Unpack the device.

Step 3 Inspect the device.

Step 4 Use the following table to verify the contents of the container. Do not discard the shipping container. You

will need the container in the future if you move or ship the device.

What to do next

Table 2: Default Shipping Container Contents

Component Description

Device Cisco NCS 520

ESD, wrist strap (disposable) One disposable wrist strap (optional)

Documentation Cisco NCS 500 Series Services Routers Pointer Card

Optional equipment Check the container for the following optional equipment:

• Power cord if an AC power supply is shipped.

• Lugs if a DC power supply is shipped.

Note If you do not specify the type of power cable, US power cable for the AC device variant

is supplied.

Note Most Cisco documentation is available online. The chassis Pointer Card that is shipped with your Cisco NCS

500 Series Services Routers contains links and information to other online documentation.

Note If the product is not in use, store the device in the initial packaged condition or in an ESD PE sealed bag with

silica gel.

Prepare for Installation

9

Prepare for Installation

Tools and Equipment

Table 3: Accessories Kit

Variant Category PID Accessories

N520-4G4Z-A 19 inches N520-RCKMT-19-D2A / Yes

N520-RCKMT-19-D2D

N520-X-4G4Z-A

N520-X-4G4Z-D 23 inches N520-RCKMT-23-D2A / Yes

N520-RCKMT-23-D2D

N520-20G4Z-A

ETSI N520-RMT-ETSI-D2A / Yes

N520-20G4Z-D

N520-RMT-ETSI-D2D

N520-X-20G4Z-A

Wall mount N520-WALLMT Yes

N520-X-20G4Z-D

Desktop NA Applicable only for

N520-4G4Z-A

Cable bracket N520-CBL-BRKT Yes

Tools and Equipment

You need the following tools and equipment to install and upgrade the device and its components:

• ESD-preventive cord and wrist strap

• Antistatic mat or antistatic foam

• Number 1 and Number 2 Phillips-head screwdrivers

• #12-24 pan-head screws to secure the device to the equipment rack.

• Cables for connecting to network ports (based on the configuration)

• Ethernet hub, switch, or PC with a network interface card for connecting to the Ethernet ports

• Console terminal that is configured for 9600 baud, 8 data bits, no parity, no flow control, and 1 stop bit.

• Console cable for connecting to the console port

• Ratcheting torque screwdriver with a Phillips head that exerts up to 30-pound force per square inch

(0.02-kilograms force per square millimeter (kgf/mm2)) of pressure.

• Crimping tool as specified by the ground lug manufacturer

• Wire-stripping tools for stripping both 6 and 14-AWG wires

• Tape measure and level

• Ratcheting torque screwdriver with a Phillips head that exerts up to 15 inch-pounds (1.69 newton meters)

of torque for attaching the ground wire to the device.

Prepare for Installation

10

You might also like

- Installing The Server: Preparing For InstallationDocument18 pagesInstalling The Server: Preparing For InstallationopekozNo ratings yet

- Aironet 3600 SeriesDocument40 pagesAironet 3600 SeriesvictorrangelsanderoNo ratings yet

- Standalone 90KW Modular Data Center Specification V1.0Document17 pagesStandalone 90KW Modular Data Center Specification V1.0tekatiwariNo ratings yet

- Manual Cisco Systems Cisco Aironet 3700 Series AIRCAP3702IAK9Document44 pagesManual Cisco Systems Cisco Aironet 3700 Series AIRCAP3702IAK9pabloNo ratings yet

- 6300P DC Powered Panel PCS: Installation InstructionsDocument8 pages6300P DC Powered Panel PCS: Installation InstructionsmgptecnologyNo ratings yet

- IDHBIDHE SpecDocument4 pagesIDHBIDHE SpechtanhNo ratings yet

- AP 1040 Get StartDocument34 pagesAP 1040 Get StartjachamonsterNo ratings yet

- P9egm 914 924Document106 pagesP9egm 914 924Billy NormanNo ratings yet

- Cisco Implementation PlanningDocument13 pagesCisco Implementation PlanningrhisyamNo ratings yet

- VRV Technical SpecificationDocument7 pagesVRV Technical Specificationdheerajdorlikar100% (2)

- Installation: This Chapter Describes The Setup of The Access Point and Includes The Following SectionsDocument8 pagesInstallation: This Chapter Describes The Setup of The Access Point and Includes The Following SectionsAngel Bernardo Gomez LizanaNo ratings yet

- 5-20 Ton Capacity: Packaged Wall Mounted Industrial-Grade Air Conditioners For General Purpose ApplicationsDocument20 pages5-20 Ton Capacity: Packaged Wall Mounted Industrial-Grade Air Conditioners For General Purpose ApplicationsYhonny OviedoNo ratings yet

- PCB Assembly Considerations When Designing For The Aerospace IndustryDocument9 pagesPCB Assembly Considerations When Designing For The Aerospace IndustryMentholNo ratings yet

- Design, Installation and Maintenance Manual: Industrial Electric Heat Tracing SystemsDocument24 pagesDesign, Installation and Maintenance Manual: Industrial Electric Heat Tracing SystemsJohn BeaconNo ratings yet

- Safety Instructions-Rack Mount ENDocument4 pagesSafety Instructions-Rack Mount ENdeniwahyud channelNo ratings yet

- 1769-L32C, 1769-L35Cr Compactlogix Controllers: Installation InstructionsDocument48 pages1769-L32C, 1769-L35Cr Compactlogix Controllers: Installation Instructionsnio756No ratings yet

- 1769-1769-L32C, 1769-L35CR CompactLogixDocument48 pages1769-1769-L32C, 1769-L35CR CompactLogixVÕ QUỐC HIỆUNo ratings yet

- Essential Rack System Requirements For Next Generation Data CentersDocument10 pagesEssential Rack System Requirements For Next Generation Data Centers(unknown)No ratings yet

- Fan Control 3Document35 pagesFan Control 3Franz JW MontezaNo ratings yet

- P9hak 980Document66 pagesP9hak 980MiftahNo ratings yet

- Biamp Manual Tesira Hd-1 Oct15-1Document16 pagesBiamp Manual Tesira Hd-1 Oct15-1Rachmat Guntur Dwi PutraNo ratings yet

- Saes P 100Document20 pagesSaes P 100hamzah MajedNo ratings yet

- 05di-Hiecbxx-19 (1) (2016 - 09 - 14 20 - 59 - 34 Utc)Document14 pages05di-Hiecbxx-19 (1) (2016 - 09 - 14 20 - 59 - 34 Utc)Dhanushka RathnasooriyaNo ratings yet

- Antenna Data SheetDocument56 pagesAntenna Data SheetlinkdenovaNo ratings yet

- Cisco Aironet 1140 Series AP Getting Started GuideDocument44 pagesCisco Aironet 1140 Series AP Getting Started GuideMohd Faizal RezaNo ratings yet

- Deutsch Français: Operating Instructions and SpecificationsDocument28 pagesDeutsch Français: Operating Instructions and SpecificationsrmspNo ratings yet

- PCK, PHK Packaged Unit IO ManualDocument15 pagesPCK, PHK Packaged Unit IO ManualChad HensonNo ratings yet

- Design, Installation and Maintenance Manual: Industrial Electric Heat Tracing SystemsDocument24 pagesDesign, Installation and Maintenance Manual: Industrial Electric Heat Tracing SystemsMekaNo1DNo ratings yet

- Ap3700g EtstartedDocument46 pagesAp3700g EtstartedblablaNo ratings yet

- Intertek IEC EN 60079 25 Intrinsically Safe Electrical SystemsDocument2 pagesIntertek IEC EN 60079 25 Intrinsically Safe Electrical Systemssofiane mokhtariNo ratings yet

- NI PXIe-6544 - Getting Starter GuideDocument20 pagesNI PXIe-6544 - Getting Starter Guide차지형No ratings yet

- P10eai src2cDocument1,168 pagesP10eai src2cwillianalvespereira1988No ratings yet

- Design, Installation and Maintenance Manual: Industrial Electric Heat Tracing SystemsDocument24 pagesDesign, Installation and Maintenance Manual: Industrial Electric Heat Tracing SystemssuhasNo ratings yet

- P10eai srn1bDocument304 pagesP10eai srn1bwillianalvespereira1988No ratings yet

- 174Document24 pages174Janko ArtukovićNo ratings yet

- ASHRAE TC9.9 Pergravis - Data Center Standards-Overview 2013 v1.2Document43 pagesASHRAE TC9.9 Pergravis - Data Center Standards-Overview 2013 v1.2Au Psl FightFor GreatVictoryNo ratings yet

- Samsung X20 ManualDocument328 pagesSamsung X20 ManualoztronixNo ratings yet

- AED HD1000 Quick Start CardDocument4 pagesAED HD1000 Quick Start CardNicolásHerreraNo ratings yet

- Operating InstructionsDocument6 pagesOperating InstructionsJagix85No ratings yet

- Inrow RC (ASTE-6Z5S8Z - R1 - ENDocument40 pagesInrow RC (ASTE-6Z5S8Z - R1 - ENjoseNo ratings yet

- 3 - Thermal Guide For Control PanelsDocument70 pages3 - Thermal Guide For Control PanelsMAKANNo ratings yet

- P9eab 914 924Document52 pagesP9eab 914 924Billy NormanNo ratings yet

- P 9 HCDDocument292 pagesP 9 HCDBilly NormanNo ratings yet

- DC TieringDocument32 pagesDC TieringUntuk DiaNo ratings yet

- Nu - 23 6500 - Cooling TowersDocument16 pagesNu - 23 6500 - Cooling Towersjia wangNo ratings yet

- Dsi 700Document30 pagesDsi 700mahh1234No ratings yet

- Manual Instalacion 900CRDocument16 pagesManual Instalacion 900CRgeovanyhazellopezsixtosNo ratings yet

- Honeywell Web600 PDFDocument16 pagesHoneywell Web600 PDFMarcello PorrinoNo ratings yet

- Cisco SwitvhDocument31 pagesCisco SwitvhTiina TammNo ratings yet

- PowerBeam PBE-5AC-500 QSGDocument24 pagesPowerBeam PBE-5AC-500 QSGMaria Clara MendesNo ratings yet

- P9hal 914 924Document92 pagesP9hal 914 924Billy NormanNo ratings yet

- MT-500 Series: MT-510T, MT-508T Installation Instruction 1.0 Installation and Startup GuideDocument8 pagesMT-500 Series: MT-510T, MT-508T Installation Instruction 1.0 Installation and Startup GuideTRITRONIX INDUSTRIAL SOLUTIONNo ratings yet

- Etting Tarted Uide: First Published: April 29, 2015Document44 pagesEtting Tarted Uide: First Published: April 29, 2015Tuấn ĐoànNo ratings yet

- Sony PVM 14L5 - 20L5 Operation ManualDocument80 pagesSony PVM 14L5 - 20L5 Operation ManualJosh MinnichNo ratings yet

- RFP Data CenterDocument7 pagesRFP Data CenterAbdul RafaeNo ratings yet

- Site PlaningDocument213 pagesSite Planingrostik gromykNo ratings yet

- RX1500 Hardware-Installation-Guide en 16Document1 pageRX1500 Hardware-Installation-Guide en 16harrypotter 05No ratings yet

- Socomec EN61439 PDFDocument8 pagesSocomec EN61439 PDFdesportista_luisNo ratings yet

- PTACMANUALDocument8 pagesPTACMANUALshhyeNo ratings yet

- 03 - Air Ticket Request & Claim Form 2018Document1 page03 - Air Ticket Request & Claim Form 2018Danny SolvanNo ratings yet

- Education - Khóa học IELTS 0đ Unit 3 - IELTS FighterDocument19 pagesEducation - Khóa học IELTS 0đ Unit 3 - IELTS FighterAnna TaoNo ratings yet

- Hijama Cupping A Review of The EvidenceDocument5 pagesHijama Cupping A Review of The EvidenceDharma Yoga Ayurveda MassageNo ratings yet

- Tool 10 Template Working Papers Cover SheetDocument4 pagesTool 10 Template Working Papers Cover Sheet14. Đỗ Kiến Minh 6/5No ratings yet

- School: Sta. Maria Integrated School Group No. Names: Energy Forms & Changes Virtual LabDocument3 pagesSchool: Sta. Maria Integrated School Group No. Names: Energy Forms & Changes Virtual LabNanette Morado0% (1)

- GCU 0103 Computer PlatformsDocument5 pagesGCU 0103 Computer PlatformsArani NavaratnarajahNo ratings yet

- Recognizing Fractures and Dislocations: Corpuz, Rachella Nicole PDocument46 pagesRecognizing Fractures and Dislocations: Corpuz, Rachella Nicole PRachella Nicole CorpuzNo ratings yet

- Materials Management in Hospital Industry Nandi ProjectDocument27 pagesMaterials Management in Hospital Industry Nandi Projectkumaraswamy226No ratings yet

- DefibrillatorDocument2 pagesDefibrillatorVasanth VasanthNo ratings yet

- Governance, Business Ethics, Risk Management and Internal ControlDocument4 pagesGovernance, Business Ethics, Risk Management and Internal ControlJosua PagcaliwaganNo ratings yet

- Accomplishment Report Rle Oct.Document7 pagesAccomplishment Report Rle Oct.krull243No ratings yet

- Adhi Wardana 405120042: Blok PenginderaanDocument51 pagesAdhi Wardana 405120042: Blok PenginderaanErwin DiprajaNo ratings yet

- B028-Sayli Kapse B029-Surya Teja B030-Taranum Kaur B032-Yashesh Kothari B034-Sathish Kumar B035-ManeeshDocument24 pagesB028-Sayli Kapse B029-Surya Teja B030-Taranum Kaur B032-Yashesh Kothari B034-Sathish Kumar B035-ManeeshTaranum RandhawaNo ratings yet

- Emissivity Table E4Document11 pagesEmissivity Table E4Mekro Permana PinemNo ratings yet

- AD Oracle ManualDocument18 pagesAD Oracle ManualAlexandru Octavian Popîrțac100% (2)

- Wax Depilation ManualDocument17 pagesWax Depilation ManualAmit Sharma100% (1)

- FRMUnit IDocument17 pagesFRMUnit IAnonNo ratings yet

- Task 2: Health Services Survey: School Community 1. What Are The Health Services Provided?Document1 pageTask 2: Health Services Survey: School Community 1. What Are The Health Services Provided?Bernadeth BaiganNo ratings yet

- CITEC Genesis & GenXDocument45 pagesCITEC Genesis & GenXPutra LangitNo ratings yet

- Dryden, 1994Document17 pagesDryden, 1994Merve KurunNo ratings yet

- Adult Survivors Act Summons Against Mayor Eric AdamsDocument3 pagesAdult Survivors Act Summons Against Mayor Eric AdamsCity & State New York100% (1)

- Energies: Numerical Simulations On The Application of A Closed-Loop Lake Water Heat Pump System in The Lake Soyang, KoreaDocument16 pagesEnergies: Numerical Simulations On The Application of A Closed-Loop Lake Water Heat Pump System in The Lake Soyang, KoreaMvikeli DlaminiNo ratings yet

- API Filter Press - Test ProcedureDocument8 pagesAPI Filter Press - Test ProcedureLONG LASTNo ratings yet

- BU2508DFDocument3 pagesBU2508DFRaduNo ratings yet

- Tugas Gizi Caesar Nurhadiono RDocument2 pagesTugas Gizi Caesar Nurhadiono RCaesar 'nche' NurhadionoNo ratings yet

- Case Analysis of Vishal Jeet V. Union of India Trafficking of Women and ChildrenDocument7 pagesCase Analysis of Vishal Jeet V. Union of India Trafficking of Women and ChildrenTrishani NahaNo ratings yet

- Selectivities in Ionic Reductions of Alcohols and Ketones With Triethyisilane - Trifluoroacetic AcidDocument4 pagesSelectivities in Ionic Reductions of Alcohols and Ketones With Triethyisilane - Trifluoroacetic AcidJan Andre EriksenNo ratings yet

- GASESDocument55 pagesGASESja_QuinineNo ratings yet

- - 50 Đề Thi Học Sinh Gioi Lớp 12Document217 pages- 50 Đề Thi Học Sinh Gioi Lớp 12Nguyễn Thanh ThảoNo ratings yet

- Catalogo StafsjoDocument12 pagesCatalogo StafsjoBruno Bassotti SilveiraNo ratings yet

- Evaluation of Some Websites that Offer Virtual Phone Numbers for SMS Reception and Websites to Obtain Virtual Debit/Credit Cards for Online Accounts VerificationsFrom EverandEvaluation of Some Websites that Offer Virtual Phone Numbers for SMS Reception and Websites to Obtain Virtual Debit/Credit Cards for Online Accounts VerificationsRating: 5 out of 5 stars5/5 (1)

- Hacking: A Beginners Guide To Your First Computer Hack; Learn To Crack A Wireless Network, Basic Security Penetration Made Easy and Step By Step Kali LinuxFrom EverandHacking: A Beginners Guide To Your First Computer Hack; Learn To Crack A Wireless Network, Basic Security Penetration Made Easy and Step By Step Kali LinuxRating: 4.5 out of 5 stars4.5/5 (67)

- Microsoft Azure Infrastructure Services for Architects: Designing Cloud SolutionsFrom EverandMicrosoft Azure Infrastructure Services for Architects: Designing Cloud SolutionsNo ratings yet

- Microsoft Certified Azure Fundamentals Study Guide: Exam AZ-900From EverandMicrosoft Certified Azure Fundamentals Study Guide: Exam AZ-900No ratings yet

- Cybersecurity: A Simple Beginner’s Guide to Cybersecurity, Computer Networks and Protecting Oneself from Hacking in the Form of Phishing, Malware, Ransomware, and Social EngineeringFrom EverandCybersecurity: A Simple Beginner’s Guide to Cybersecurity, Computer Networks and Protecting Oneself from Hacking in the Form of Phishing, Malware, Ransomware, and Social EngineeringRating: 5 out of 5 stars5/5 (40)

- AWS Certified Solutions Architect Study Guide: Associate SAA-C02 ExamFrom EverandAWS Certified Solutions Architect Study Guide: Associate SAA-C02 ExamNo ratings yet

- Cybersecurity: The Beginner's Guide: A comprehensive guide to getting started in cybersecurityFrom EverandCybersecurity: The Beginner's Guide: A comprehensive guide to getting started in cybersecurityRating: 5 out of 5 stars5/5 (2)

- Set Up Your Own IPsec VPN, OpenVPN and WireGuard Server: Build Your Own VPNFrom EverandSet Up Your Own IPsec VPN, OpenVPN and WireGuard Server: Build Your Own VPNRating: 5 out of 5 stars5/5 (1)

- The Compete Ccna 200-301 Study Guide: Network Engineering EditionFrom EverandThe Compete Ccna 200-301 Study Guide: Network Engineering EditionRating: 5 out of 5 stars5/5 (4)

- Alcatel-Lucent Service Routing Architect (SRA) Self-Study Guide: Preparing for the BGP, VPRN and Multicast ExamsFrom EverandAlcatel-Lucent Service Routing Architect (SRA) Self-Study Guide: Preparing for the BGP, VPRN and Multicast ExamsNo ratings yet

- Networking Fundamentals: Develop the networking skills required to pass the Microsoft MTA Networking Fundamentals Exam 98-366From EverandNetworking Fundamentals: Develop the networking skills required to pass the Microsoft MTA Networking Fundamentals Exam 98-366No ratings yet

- Azure Networking: Command Line Mastery From Beginner To ArchitectFrom EverandAzure Networking: Command Line Mastery From Beginner To ArchitectNo ratings yet

- ITIL® 4 Create, Deliver and Support (CDS): Your companion to the ITIL 4 Managing Professional CDS certificationFrom EverandITIL® 4 Create, Deliver and Support (CDS): Your companion to the ITIL 4 Managing Professional CDS certificationRating: 5 out of 5 stars5/5 (2)

- Concise Guide to OTN optical transport networksFrom EverandConcise Guide to OTN optical transport networksRating: 4 out of 5 stars4/5 (2)

- AWS Certified Cloud Practitioner Study Guide: CLF-C01 ExamFrom EverandAWS Certified Cloud Practitioner Study Guide: CLF-C01 ExamRating: 5 out of 5 stars5/5 (1)

- Computer Networking: The Complete Guide to Understanding Wireless Technology, Network Security, Computer Architecture and Communications Systems (Including Cisco, CCNA and CCENT)From EverandComputer Networking: The Complete Guide to Understanding Wireless Technology, Network Security, Computer Architecture and Communications Systems (Including Cisco, CCNA and CCENT)No ratings yet

- Computer Systems and Networking Guide: A Complete Guide to the Basic Concepts in Computer Systems, Networking, IP Subnetting and Network SecurityFrom EverandComputer Systems and Networking Guide: A Complete Guide to the Basic Concepts in Computer Systems, Networking, IP Subnetting and Network SecurityRating: 4.5 out of 5 stars4.5/5 (13)

- Internet of Things: Principles and ParadigmsFrom EverandInternet of Things: Principles and ParadigmsRating: 4.5 out of 5 stars4.5/5 (6)

- Open Radio Access Network (O-RAN) Systems Architecture and DesignFrom EverandOpen Radio Access Network (O-RAN) Systems Architecture and DesignNo ratings yet