Professional Documents

Culture Documents

On A Solid Base AutomotiveElectronics 200509 PressArticle EN

Uploaded by

Chaos XiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

On A Solid Base AutomotiveElectronics 200509 PressArticle EN

Uploaded by

Chaos XiaCopyright:

Available Formats

You will find the figures mentioned in this article in the German issue of

Automotive Electronics beginning on page 44.

Auf solider Basis

– Effiziente Entwicklung von

Diagnosefunktionen im Automobil

On a Solid Base

Efficient Development of Diagnostic

Functions in the Automobile

In an effort to meet the challenges posed by the growing

importance of motor vehicle diagnostics, in recent years

Vector Informatik GmbH and DaimlerChryler AG have ex-

panded their strategic partnership in developing diagnos-

tic tools. This relationship is based on many years of col-

laboration in the 1990s related to networking tools for CAN

between these two companies, each with headquarters in

Stuttgart Germany. Vector and DaimlerChrysler now have

tools developed and customized for the special area of mo-

tor vehicle diagnostics. Application of these tools involves

more initial effort, but in the final analysis it proves to be

extremely effective in terms of quality and cost.

1 Introduction rate-wide implementation in development,

production and service. Furthermore, the

At the end of the 1990s DaimlerChrysler center also offers corporate-wide support in

gave new direction to its diagnostic develop- introducing the concepts, processes and

ment tools to accomplish future tasks. One tools in these different business areas.

important goal was to make the new tools

easier to use and understand, and data rele- 2 Universal Implementation of

vant to diagnostics were to be described in a Diagnostic Functions

uniform format. This was the only way to as-

sure a high level of acceptance in its use by As partners in this process,the diagnostic ex-

all involved business units and partners, in- perts at Vector Informatik designed a tool so-

cluding ECU and software suppliers, and to lution based on the “Single Source Princi-

Authors: assure re-usability of the data. ple”. That is, all diagnostic functions are

Simon Stimmler and Christoph Rätz In support of this effort, DaimlerChrysler specified formally just once in machine-

consolidated and focused its diagnostic readable XML description files, and all users

know-how with its GSP/TD Center (Center can then use these data universally.

for Diagnostic and Flash Technologies). At Since DaimlerChrysler wanted to pre-

this center, new diagnostic and flash con- serve its use of the DIOGENES description

cepts are developed comprehensively togeth- format and its proprietary run-time system

er with their associated processes for corpo- CAESAR (internal DC project name for Com-

20 Automotive Electronics II/2005

Diagnostic DEVELOPMENT TOOLS

mon Access to Electronic Systems of Auto- DaimlerChrysler obtains data for its in- SAR Binary Format and are fed into the auto-

motive Requirements) in Development, Pro- ternal DIOGENES format by Export from the motive OEM’s proprietary testing tools, Fig-

duction and Service, Vector designed its ECU description in CANdelaStudio, Figure 1. ure 3. Mercedes-Benz now develops nearly all

CANdela diagnostic product line (CAN diag- The DIOGENES data are transformed into CAN-based ECUs in this manner. The CAN-

nostic environment for lean applications) the run-time optimized binary format CBF dela and DIOGENES combination is also be-

with the flexibility required to integrate (CAESAR Binary Format), and the next step ing used at Smart and MMC (Mitsubishi Mo-

OEM-specific export formats too. utilizes these binary data to parameterize tor Company). Lead projects have been start-

Besides DaimlerChrysler, Vector’s strate- testers. Since a new variant is described ed for the Chrysler, Freightliner, Detroit

gic alliances with OPEL and Claas (producer within the CANdela file whenever a diagnos- Diesel and Mitsubishi Fuso brands.

of agricultural machinery) also influenced tic change is made to the ECU, customized

the development of these tools. In the mean- test environments can be prepared immedi- 5 ODX - Standardized Exchange Format

time Vector has also entered into working re- ately for the latest ECU samples. for Diagnostic Data

lationships with companies such as Fiat, Diagnostic tester functionalities are also

Ford and many automotive suppliers world- included in the Vector Tools CANoe, Figure 2, ODX is an international standard developed

wide. Today, CANdela tools are used in near- CANape Graph and CANdito. If ECU specifi- within the ASAM advisory body (Association

ly all countries with automotive and suppli- cations exist the user can test ECU samples for Standardisation of Automation- and Mea-

er industries. These tools give users signifi- using these tools. suring Systems); it is currently awaiting fi-

cant support in acquiring and editing diag- With the constantly rising number of nal release as an ISO standard (ISO 22901-1)

nostic data, and exporting them in various electronic functions in the vehicle, the abili- which is expected at the end of 2006. It sup-

data formats. The acquired data can also be ty to perform diagnostics on them is becom- ports automotive OEMs and suppliers in

used to automatically generate diagnostic ing increasingly important. Shifting diag- their work with various test tools [1].

software for ECUs. nostic software development to early devel- In the data-driven, communication sys-

opment stages (“Frontloading”) prevents tems interconnecting ECUs in today’s vehi-

3 Saving Time by Frontloading “last minute” development of diagnostics of cle networks, engineers no longer develop

inferior quality from flowing into the ECU diagnostic software in isolation. Therefore,

The governing principle of the diagnostic software. individual data and description blocks from

development process at DaimlerChrysler is CANdela’s XML database have been designed

to obtain a comprehensive and dependable 4 Developing Quality to be reusable. CANdela’s future ODX Im-

database by creating a complete specifica- port feature will also make it possible to use

tion very early in the process. This database The use of CANdela is firmly anchored in diagnostic data from other sources

prevents misunderstandings and errors in DaimlerChrysler’s development process. Another step by DaimlerChrysler will be

working relationships with suppliers, and The goal is to not only have the ECU supplier to replace its proprietary DIOGENES format

the need for optimization cycles is avoided develop diagnostic functions, but also sup- with the standardized ODX (Open Diagnos-

for the most part as well. As soon as Daimler- ply the associated formal descriptions. In do- tic EXchange) data format for formal de-

Chrysler selects ECU suppliers for a develop- ing so, besides using internal DC diagnostic scription of diagnostic functionalities. By

ment project, engineers from Development, development testers to implement and veri- importing and exporting ODX data into and

Production and Service begin to define diag- fy data descriptions, they can also rely on out of CANdela, DaimlerChrysler will guar-

nostic functions for the ECUs together with proven tools of the Vector tool chain to de- antee a uniform diagnostic data description

these suppliers. velop high-quality ECUs and description that is robust in its processes. The first appli-

The user-friendly input interface of CAN- files. The goal here is to have suppliers fully cation is already in use today in a joint devel-

delaStudio, the requirements engineering test the diagnostics before submitting new opment with a competitor.

tool, allows suppliers and ECU developers ECU samples to DaimlerChrysler. ODX Export has been integrated in CAN-

create the diagnostic specification in the To further enhance software quality, dela since the end of 2004, and it enables

form of a formal description. Representing DaimlerChrysler is requiring suppliers to each automotive OEM and supplier to make

the basis for this description are so-called use standard software components in imple- a smooth transition from proprietary for-

templates that contain the requirements menting diagnostics in ECUs. Such compo- mats to a standardized exchange format.

for the diagnostic protocol and the specific nents can be automatically generated from Nothing changes for the user at the comput-

requirements and data of the vehicle mod- the CANdela data using Vector’s ECU diag- er screen or test bench in this process.

el. The GSP/TDE department, as the devel- nostics software component CANdesc (CAN

opment-oriented department at the Center diagnostic embedded software component). 6 Equipped for Future Requirements

for Diagnostic and Flash Technologies, co- The automatically generated component al-

ordinates and checks parameter configura- lows ECU producers and OEMs to achieve a Vector attaches a lot of importance to diag-

tions based on internal DaimlerChrysler uniform implementation of the diagnostic nostic software and is therefore continually

standards and guidelines. Then the specifi- protocol across products. expanding the CANdela product line. This is

cation is automatically generated from the After the supplier has implemented the because the significance of early integration

formal description in Microsoft Word for- software in the ECU and tested it, Daimler- and reliable verification of diagnostic and

mat. This is how DaimlerChrysler ensures Chrysler conducts tests of all diagnostic serv- flash functions at suppliers will continue to

that ECUs produced by different suppliers ices based on the diagnostic description. grow. Automated hardware-in-the-loop tests

will satisfy all requirements in the same DaimlerChrysler engineers export the re- are on the rise as well. Furthermore, Vector

way. Whenever a new ECU sample is deliv- levant parameters from CANdela to the already supports the new UDS diagnostic

ered its diagnostic specification level can DIOGENES format. Afterwards, the data are protocol (ISO 14229) with its CANoe,

be clearly identified. converted to the run-time optimized CAE- CANape Graph, CANdito and CANdelaStu-

Special Edition ATZ and MTZ and AUTOMOTIVE ENGINEERING PARTNERS 21

DEVELOPMENT TOOLS Diagnostic

dio products. Mercedes-Benz will introduce the ECUs. In the future DaimlerChrysler will

this protocol sequentially in all of its model rely on the standardized ODX data format to

changes beginning with the next C-Class; it describe flash data. This data format will re-

will replace the KWP2000 protocol that has place the internal ECU_MEM/FLADEN for-

been used until now. mat.

Today CANdelaFlash already supports ex-

7 Optimizing the Diagnostic port to the ODX format. In the next release

Development Process an ODX Import function will also be avail-

able, so that flash data can be exchanged be-

Using CANdelaStudio Mercedes engineers tween suppliers and DaimlerChrysler in

enter data about 6 to 7 times quicker than ODX format. This facilitates complete de-

before, Figure 4 [2]. It is extremely difficult to scription of the flash data at an early point

reach a conclusion regarding time savings in time. Analogous to the situation in diag-

over the entire development process; this is nostics, in flashing it is also necessary to de-

because processes are constantly adapting scribe the flash data early in the develop-

themselves. However, it is clear that diagnos- ment process. These data are used to check

tic functions today are often already fully de- whether the ECU can be flashed by diagnos-

veloped with B-Samples, while previously tics according to the flash specification.

they were available at the earliest with C-

Samples or even later. This is due to the 9 Outlook

user-friendly diagnostic description and ear-

ly implementation. A positive benefit is that The uniform ODX standard offers the capa-

more intensive tests are possible, and these bility of reusing diagnostic data, i.e. later

can be used to improve the quality of ECUs projects can have access to qualitatively ma-

interconnected in the network even more. ture diagnostic implementations and de-

Semi-automatic translation of diagnostic scriptions. In the future, standardization of

data in CANdelaStudio (e.g. into English, the hardware interface (ISO 22900-2 MVCI

French, Italian or Japanese) guarantees a Part 2: D-PDU API), diagnostic data model

consistent work process, even with globally (ISO 22901-1 ODX Part 1: Data Model Specifi-

distributed development sites. cation) and interface between the run-time

system and test application (ISO/CD 22900-3

8 Implementing CANdela in the Flash MVCI Part 3: D-Server API) will make it possi-

Environment ble to combine the best hardware on the de-

sired run-time system and the best applica-

The CANdela product line includes a CANde- tion for each type of use.

laFlash editor that is available for describing The universality of diagnostics that has

flash data, see Figure 5. The actual software already been achieved with CANdela and

to be flashed, i.e. the HEX or binary data, DIOGENES inspires visionary scenarios: For

must be supplemented by other informa- example, will it be possible in just a few

tion. Some of this information describes the years to automatically send fault reports to a

software to be flashed, e.g. its software ver- central diagnostic center, evaluate the faults

sion and the size of segments. Other infor- there, determine repair needs, initiate con-

mation relates to the process, e.g. part num- tact with the nearest service center and or-

bers. Since most process-related information der the necessary replacement parts?

is OEM-specific, CANdelaFlash templates are

used to represent these individual proper-

ties. References

In designing the user interface for CAN- [1] The ODX Format Committee Draft of ISO/CD 22901-1

delaFlash, special care was taken to making ODX Part 1: Data model specification ASAM (Associ-

ation for Standardization of Automation and Measur-

inputs simple and user-friendly. Therefore

ing Systems, www.asam.net)

CANdelaFlash and CANdelaStudio have sim- [2] Stimmler, S.; Rätz, C.: Vector Kongress 2002,: “Diag-

ilar appearances and user interface philoso- nostic Process for Future Requirements”

phies. It is easy to take flash-relevant diag- [3] Bodensteiner, F., Blanz, M., Feiter, G.: SAE World

nostic data acquired by CANdelaStudio and Congress 2002, ISO, SAE, JSAE, ASAM Standardiza-

apply it in various ways. tion – A Joint Step Forward, “Common Interfaces

and Architecture of Diagnostic & Programming

DaimlerChrysler takes the flash data de-

Tools”

scription in CANdelaFlash and by export ob-

tains the data for their internal XML format

named ECU_MEM/FLADEN. In turn, the

ECU_MEM/FLADEN data are transformed to

the run-time optimized binary format CFF

(CAESAR Flash Format) and are flashed in

22 Automotive Electronics II/2005

Technical Article – Figures

On a Solid Base

Efficient development of diagnostic functions in the Automobile

[Lead photo]

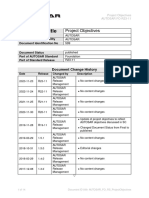

[Figure 1: Description of ECU-specific diagnostic requirements by

CANdelaStudio and export of data to DIOGENES database via CANdela

database]

On a Solid Base 1/3

Technical Article – Figures

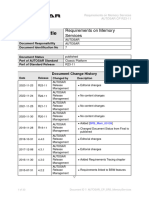

[Figure 2: Testing diagnostic functionality with CANoe, the tool for

professional network development]

[Figure 3: Electronic components for the A-Class vehicle are tested on an

integration test bench]

On a Solid Base 2/3

Technical Article – Figures

[Figure 4: Cost savings by a factor of 6-7 due to description of

diagnostic data using CANdelaStudio and the resulting quicker

implementation of the diagnostic protocol]

[Figure 5: Management of Flash data and generation of ODX Flash

Containers with CANdelaFlash]

Lead photo and Figure 3: DaimlerChrysler AG

Figures 1, 2, 4 and 5: Vector Informatik GmbH

On a Solid Base 3/3

You might also like

- Diagnostics Congress ElektronikAutomotive 200703 PressArticle enDocument7 pagesDiagnostics Congress ElektronikAutomotive 200703 PressArticle enJonatas Xavier SilvaNo ratings yet

- Automatic Validation of Diagnostic ServicesDocument6 pagesAutomatic Validation of Diagnostic ServicesChaos XiaNo ratings yet

- Ewili14 Submission 19Document7 pagesEwili14 Submission 19luongktdtNo ratings yet

- Diagnostics Congress ElektronikAutomotive 200703 PressArticlDocument7 pagesDiagnostics Congress ElektronikAutomotive 200703 PressArticllelamedaNo ratings yet

- Using Dynatrace Monitoring Data For Generating Performance Models of Java EE Applications PDFDocument2 pagesUsing Dynatrace Monitoring Data For Generating Performance Models of Java EE Applications PDFanthony cesar ortiz arteagaNo ratings yet

- 2023 ATZextra Softing Diagnostic Systems Accelerate the Development en-تم التحريرDocument8 pages2023 ATZextra Softing Diagnostic Systems Accelerate the Development en-تم التحريرgh6975340No ratings yet

- CIMdata Commentary Siemens SSE Product Definition 5jan2021Document5 pagesCIMdata Commentary Siemens SSE Product Definition 5jan2021wafabouzid23kNo ratings yet

- Kraemer2008-Model Based Testing of Automotive SystemsDocument10 pagesKraemer2008-Model Based Testing of Automotive SystemssanketNo ratings yet

- Model-Based Approach To Automated Calculation of Key Performance Indicators For Industrial TurbinesDocument8 pagesModel-Based Approach To Automated Calculation of Key Performance Indicators For Industrial TurbinesarchNo ratings yet

- 0712 Atz Elektronik Autosar ETAS enDocument4 pages0712 Atz Elektronik Autosar ETAS enAbdessamad BnaneNo ratings yet

- Radar Target Simulation For Vehicle-in-the-Loop TestingDocument15 pagesRadar Target Simulation For Vehicle-in-the-Loop TestingmakkieNo ratings yet

- Android-Based Universal Vehicle Diagnostic and Tracking SystemDocument8 pagesAndroid-Based Universal Vehicle Diagnostic and Tracking SystemjavoverdugoNo ratings yet

- Two Case Studies On Collobarative Manufacturing With Respect To Automobile Industries by Angadi.VDocument7 pagesTwo Case Studies On Collobarative Manufacturing With Respect To Automobile Industries by Angadi.VNikhil Raj TNo ratings yet

- Versatile Approach For ISO 26262 Compliant Hardware-Software InterfaceDocument8 pagesVersatile Approach For ISO 26262 Compliant Hardware-Software InterfaceAleksandr VasilevNo ratings yet

- Metrics in Automotive Software DevelopmentDocument39 pagesMetrics in Automotive Software DevelopmentRaviNo ratings yet

- Ae 201709 PDFDocument45 pagesAe 201709 PDFParaz EngineerNo ratings yet

- Paper DLRK - 01Document8 pagesPaper DLRK - 01M Hassaan KhalidNo ratings yet

- PLM Softwares: American Motors CorporationDocument5 pagesPLM Softwares: American Motors CorporationAkansha KalraNo ratings yet

- SPE 84821 Decision and Risk Analysis Tools For The Oil and Gas IndustryDocument7 pagesSPE 84821 Decision and Risk Analysis Tools For The Oil and Gas IndustryrezaNo ratings yet

- CIMAC Paper 009Document11 pagesCIMAC Paper 009김민욱No ratings yet

- Automotive EngineeringDocument57 pagesAutomotive EngineeringAndreNo ratings yet

- Automotive Embedded Application DevelopmentDocument15 pagesAutomotive Embedded Application DevelopmentminaNo ratings yet

- Xiong 2016Document2 pagesXiong 2016VengadeshNo ratings yet

- Vendor Selection Matrix™ Application Release Orchestration (Aro) Saas and SoftwareDocument16 pagesVendor Selection Matrix™ Application Release Orchestration (Aro) Saas and SoftwareSonia Herrera UribeNo ratings yet

- PLM ComponentsDocument16 pagesPLM ComponentsMurali KrishNo ratings yet

- Safety-Critical Software Development Using Automatic Production Code GenerationDocument13 pagesSafety-Critical Software Development Using Automatic Production Code GenerationganeshNo ratings yet

- MADO - Software Package For High Order Multidisciplinary Aircraft Design and OptimizationDocument10 pagesMADO - Software Package For High Order Multidisciplinary Aircraft Design and OptimizationmegustalazorraNo ratings yet

- Task-Specific Decision Support Systems in Multi-Level Production Systems Based On The Digital ShadowDocument6 pagesTask-Specific Decision Support Systems in Multi-Level Production Systems Based On The Digital ShadowAna MaríaNo ratings yet

- Preprints201709 0145 v1Document21 pagesPreprints201709 0145 v1saurabhsubhuNo ratings yet

- Digital Twins at Work in Maritime and EnergyDocument7 pagesDigital Twins at Work in Maritime and Energyjwpaprk1No ratings yet

- Automation Solution Guide 2008 by Schneider Electric 1655790068Document300 pagesAutomation Solution Guide 2008 by Schneider Electric 1655790068Lacramioara VisnyeiNo ratings yet

- Automation Hand BookDocument310 pagesAutomation Hand BookPul50No ratings yet

- Blackberry IVY in DepthDocument12 pagesBlackberry IVY in Depthhongyuan.capitalchenNo ratings yet

- AUTOSAR Brochure EN PDFDocument4 pagesAUTOSAR Brochure EN PDFTadNaodNo ratings yet

- Transport and Marine 060902-Out EcDocument223 pagesTransport and Marine 060902-Out EcAhmad ElsheemyNo ratings yet

- Brochure Wiring Harness Engineering SolutionsDocument12 pagesBrochure Wiring Harness Engineering Solutionsarun.nagarkarNo ratings yet

- Sae Technical Paper Series: Khawar M. Zuberi, Padmanabhan Pillai and Kang G. ShinDocument9 pagesSae Technical Paper Series: Khawar M. Zuberi, Padmanabhan Pillai and Kang G. ShinmuradbashirNo ratings yet

- Implementing The CAN Calibration Protocol (CCP) in An SAE J1939 ApplicationDocument6 pagesImplementing The CAN Calibration Protocol (CCP) in An SAE J1939 ApplicationPrem NathNo ratings yet

- Evaluate Measurement Data With jBEAMDocument4 pagesEvaluate Measurement Data With jBEAMRodrigo MargaritNo ratings yet

- Machine Vision StandardsDocument5 pagesMachine Vision StandardsNaresh KumarNo ratings yet

- FSE-DS2013 CameraReady DajsurenDocument5 pagesFSE-DS2013 CameraReady DajsurenAbu MSNo ratings yet

- 3 A Review of Power System Modelling Platforms and CapabilitiesDocument13 pages3 A Review of Power System Modelling Platforms and CapabilitiesArjun SECINo ratings yet

- Doip Protocol 2011Document6 pagesDoip Protocol 2011valangelofNo ratings yet

- Sensores Basilea SuizaDocument17 pagesSensores Basilea SuizaXAILA ROB RONo ratings yet

- Vehicle Diagnostic Competence Boosts Your Business.: OEM Partner For Diagnostic SolutionsDocument12 pagesVehicle Diagnostic Competence Boosts Your Business.: OEM Partner For Diagnostic SolutionsMarjan Stojanov100% (1)

- Desktop Gear EngineeringDocument5 pagesDesktop Gear EngineeringAdam FoltzNo ratings yet

- Data-Driven Development A Complementing Approach For Automotive Systems EngineeringDocument6 pagesData-Driven Development A Complementing Approach For Automotive Systems Engineering1730203No ratings yet

- Paper 2Document15 pagesPaper 2sashankknjsNo ratings yet

- Tetra Pak: A Digitally Enabled Supply Chain As A Competitive AdvantageDocument6 pagesTetra Pak: A Digitally Enabled Supply Chain As A Competitive AdvantageChirag KocharNo ratings yet

- MTZ. .Transient - Simulation.in - The.diesel - Engine.development - Process.retail - Ebook PDF WritersDocument7 pagesMTZ. .Transient - Simulation.in - The.diesel - Engine.development - Process.retail - Ebook PDF Writersfuel4hatredNo ratings yet

- Manufacturing Process Optimization Using Data Mining TechniquesDocument4 pagesManufacturing Process Optimization Using Data Mining TechniquesIIR indiaNo ratings yet

- Automated Test Outlook: ArchitectureDocument9 pagesAutomated Test Outlook: ArchitectureMuraleetharan_BNo ratings yet

- The Application of Process Automation and Optimisation in The Rapid Development of New Passenger Vehicles at SAIC MotorDocument15 pagesThe Application of Process Automation and Optimisation in The Rapid Development of New Passenger Vehicles at SAIC MotorAltairEnlightenNo ratings yet

- Comprehensive Evaluation of Logging Frameworks For Future Vehicle DiagnosticsDocument12 pagesComprehensive Evaluation of Logging Frameworks For Future Vehicle Diagnosticsbalazs.grillscripbd1No ratings yet

- MSC Software Company OverviewDocument28 pagesMSC Software Company OverviewadneneNo ratings yet

- Vehicle Fault Detection SystemDocument19 pagesVehicle Fault Detection SystemHrudhay LuckyNo ratings yet

- Master Thesis Ketan BavaliaDocument89 pagesMaster Thesis Ketan Bavaliaxlrider530100% (1)

- Product DevelopmentDocument3 pagesProduct Developmentabdullah nadhifNo ratings yet

- Book Series Increasing Productivity of Software Development, Part 2: Management Model, Cost Estimation and KPI ImprovementFrom EverandBook Series Increasing Productivity of Software Development, Part 2: Management Model, Cost Estimation and KPI ImprovementNo ratings yet

- AUTOSAR FO RS ProjectObjectivesDocument14 pagesAUTOSAR FO RS ProjectObjectivesChaos XiaNo ratings yet

- VN5650 VN5240 10BASE T1S PressRelease 202307 ENDocument2 pagesVN5650 VN5240 10BASE T1S PressRelease 202307 ENChaos XiaNo ratings yet

- AUTOSAR FO PRS NetworkManagementProtocolDocument28 pagesAUTOSAR FO PRS NetworkManagementProtocolChaos XiaNo ratings yet

- AUTOSAR FO RS IPsecProtocolDocument19 pagesAUTOSAR FO RS IPsecProtocolChaos XiaNo ratings yet

- AUTOSAR FO RS HealthMonitoringDocument29 pagesAUTOSAR FO RS HealthMonitoringChaos XiaNo ratings yet

- AUTOSAR FO RS SOMEIPServiceDiscoveryProtocolDocument21 pagesAUTOSAR FO RS SOMEIPServiceDiscoveryProtocolChaos XiaNo ratings yet

- Monday OBD Symposium PresentationsDocument10 pagesMonday OBD Symposium PresentationsChaos XiaNo ratings yet

- AUTOSAR FO TR PredefinedNamesDocument20 pagesAUTOSAR FO TR PredefinedNamesChaos XiaNo ratings yet

- AUTOSAR FO EXP SecurityOverviewDocument25 pagesAUTOSAR FO EXP SecurityOverviewChaos XiaNo ratings yet

- AUTOSAR RS FeaturesDocument87 pagesAUTOSAR RS FeaturesChaos XiaNo ratings yet

- AUTOSAR FO EXP SWArchitecturalDecisionsDocument38 pagesAUTOSAR FO EXP SWArchitecturalDecisionsChaos XiaNo ratings yet

- AUTOSAR CP SRS FlashDriverDocument24 pagesAUTOSAR CP SRS FlashDriverChaos XiaNo ratings yet

- AUTOSAR FO RS MainDocument41 pagesAUTOSAR FO RS MainChaos XiaNo ratings yet

- Autosar Exp VFBDocument109 pagesAutosar Exp VFBChaos XiaNo ratings yet

- AUTOSAR CP SRS EEPROMDriverDocument22 pagesAUTOSAR CP SRS EEPROMDriverChaos XiaNo ratings yet

- AUTOSAR CP RS DiagnosticExtractTemplateDocument48 pagesAUTOSAR CP RS DiagnosticExtractTemplateChaos XiaNo ratings yet

- Electronic Systems For Vehicle Propulsion: Tuesday, December 10Document5 pagesElectronic Systems For Vehicle Propulsion: Tuesday, December 10Chaos XiaNo ratings yet

- AUTOSAR CP SWS MemoryMappingDocument104 pagesAUTOSAR CP SWS MemoryMappingChaos XiaNo ratings yet

- AUTOSAR CP EXP FirmwareOverTheAirDocument41 pagesAUTOSAR CP EXP FirmwareOverTheAirChaos XiaNo ratings yet

- AUTOSAR CP SWS MemoryAccessDocument87 pagesAUTOSAR CP SWS MemoryAccessChaos XiaNo ratings yet

- AUTOSAR CP SRS MemoryServicesDocument33 pagesAUTOSAR CP SRS MemoryServicesChaos XiaNo ratings yet

- AUTOSAR CP RS FirmwareOverTheAirDocument23 pagesAUTOSAR CP RS FirmwareOverTheAirChaos XiaNo ratings yet

- AUTOSAR CP SRS FlashTestDocument20 pagesAUTOSAR CP SRS FlashTestChaos XiaNo ratings yet

- AUTOSAR CP RS SystemTemplateDocument44 pagesAUTOSAR CP RS SystemTemplateChaos XiaNo ratings yet

- Autosar Srs RamtestDocument16 pagesAutosar Srs RamtestIvanNo ratings yet

- AUTOSAR SRS GPTDriverDocument19 pagesAUTOSAR SRS GPTDriverD.Saikrishna ReddyNo ratings yet

- AUTOSAR CP SRS MCUDriverDocument17 pagesAUTOSAR CP SRS MCUDriverChaos XiaNo ratings yet

- AUTOSAR CP SWS BFXLibraryDocument46 pagesAUTOSAR CP SWS BFXLibraryChaos XiaNo ratings yet

- AUTOSAR CP SWS IFLLibraryDocument40 pagesAUTOSAR CP SWS IFLLibraryChaos XiaNo ratings yet

- AUTOSAR CP SWS BSWMulticoreLibraryDocument34 pagesAUTOSAR CP SWS BSWMulticoreLibraryChaos XiaNo ratings yet

- 10-CU30 Brochure With SpecsDocument4 pages10-CU30 Brochure With Specsagus widodoNo ratings yet

- Logic Inside AION 500 MK2 Proposal - 2023Document19 pagesLogic Inside AION 500 MK2 Proposal - 2023logicinsideNo ratings yet

- GMG-CP05 HowTo CreateMX3 enDocument24 pagesGMG-CP05 HowTo CreateMX3 enMárcio DiuriNo ratings yet

- IOQM 2022 Practice Test-05Document2 pagesIOQM 2022 Practice Test-05AkashNo ratings yet

- Algebra 2 End of Course Test Preparation WorkbookDocument7 pagesAlgebra 2 End of Course Test Preparation Workbookafiwjkfpc100% (2)

- Mathematical Statistics and Data Analysis 3rd Edition - Chapter8 Solutions PDFDocument54 pagesMathematical Statistics and Data Analysis 3rd Edition - Chapter8 Solutions PDFnewpersia81% (32)

- SpaceClaim - Developers Guide-5-6Document2 pagesSpaceClaim - Developers Guide-5-6Alexgh1993No ratings yet

- CSE 441 On Job Training Presentation: Submitted By: Submitted ToDocument14 pagesCSE 441 On Job Training Presentation: Submitted By: Submitted Tosiddharth guptaNo ratings yet

- AI For Business Leaders Executive Program Syllabus PDFDocument12 pagesAI For Business Leaders Executive Program Syllabus PDFLab xNo ratings yet

- Whiplash-Drumset Sheet Music For Drum Group (Solo) Download and Print in PDF or MIDI Free Sheet Music For Whiplash by Hank LevDocument1 pageWhiplash-Drumset Sheet Music For Drum Group (Solo) Download and Print in PDF or MIDI Free Sheet Music For Whiplash by Hank LevJimtim LeeNo ratings yet

- A Fault Analysis Perspective of Logic Encryption in Memristor Based Combinational Circuits Using Key GatesDocument5 pagesA Fault Analysis Perspective of Logic Encryption in Memristor Based Combinational Circuits Using Key GatesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Mobile Applications Development Unit - 1Document25 pagesMobile Applications Development Unit - 1Arpit Gaur100% (1)

- L12-Principles of Message Passing1Document10 pagesL12-Principles of Message Passing1Mohamadi YNo ratings yet

- 4.4.1.2 - Configure Ip Acls To Mitigate Attacks: TopologyDocument85 pages4.4.1.2 - Configure Ip Acls To Mitigate Attacks: TopologyCamylytho GonzalezNo ratings yet

- User Manual (89v51rd2)Document4 pagesUser Manual (89v51rd2)rahul_kumbhar05No ratings yet

- FARO Focus S350 Spec SheetDocument2 pagesFARO Focus S350 Spec SheetRanti Dev VishwakarmaNo ratings yet

- Instagram Guide Vanessa LauDocument13 pagesInstagram Guide Vanessa LauA FalcoNo ratings yet

- XXXDocument4 pagesXXXEugenio HernánNo ratings yet

- Free Download Flirting Formula - Attract and Date Women Instantly and EasilyDocument2 pagesFree Download Flirting Formula - Attract and Date Women Instantly and EasilyabhijeetbishnoiNo ratings yet

- En 54-3 2001Document28 pagesEn 54-3 2001erhanNo ratings yet

- MP 8086Document2 pagesMP 8086Abhay Shankar BharadwajNo ratings yet

- Ramdump Wcss Msa0 2022-11-13 03-28-59 PropsDocument14 pagesRamdump Wcss Msa0 2022-11-13 03-28-59 PropsYoussef MahmoudNo ratings yet

- DBMS Project Report - $#$&Document22 pagesDBMS Project Report - $#$&Rati Shankar100% (1)

- S120 Control Unit Equip Man 0619 en-US-2Document360 pagesS120 Control Unit Equip Man 0619 en-US-2DmitriyNo ratings yet

- UpdatedM.A.D Practical AssignmentDocument12 pagesUpdatedM.A.D Practical AssignmentABCNo ratings yet

- Contact Tachometer: Model: DT-2235BDocument2 pagesContact Tachometer: Model: DT-2235Bnisne0730No ratings yet

- LOGARITHMSDocument23 pagesLOGARITHMSAERGATLA LAXMINo ratings yet

- Chamomile - GO FLOWERDocument4 pagesChamomile - GO FLOWER4g9mz26r8rNo ratings yet

- Uber Partner Agreement November 10 2014Document19 pagesUber Partner Agreement November 10 2014Prasad ShriyanNo ratings yet

- Resigned Staff and Data BackupDocument18 pagesResigned Staff and Data BackupBryan ChooiNo ratings yet