Professional Documents

Culture Documents

PFD Stator Line

PFD Stator Line

Uploaded by

akash.research.innovationCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PFD Stator Line

PFD Stator Line

Uploaded by

akash.research.innovationCopyright:

Available Formats

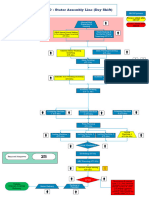

PFD : Stator Assembly Line (1 Shift)

SECOP process

Process added after

SECOP

Manual Roll

Preparing & Process added after

Loading ARETE

NIDE Manual Stack Making Stack Making &

& Insulation Paper Inserting Insulation Paper

(CT-50s) Inserting (CT-17s)

Team Leader

Yahotec Main Winding Main Winding Inserting

Inserting (CT-14s)

(CT-55s)

Quality data

collection & Data

Entry

Main Forming

(CT-13s)

Stator Rework

Yahotec Aux Winding Inserting Auxiliary Winding Inserting

(CT-52s) (CT-13s)

Cluster

Prepare

(CT-17s)

Auxiliary Forming

(CT-11.39s)

Cluster Insert and

Checking (CT- 24s)

Crimping Machine Crimping Machine Crimping Machine

1 (CT-30s) 2 (CT-50s) 3 (CT-50s)

Final Forming

(CT-12s)

Lacing

Lacing Machine 1 Lacing Machine 2 Lacing Machine 3 Machine 4

(CT-44s) (CT-44s) (CT-44s) (CT-54.25s)

Visual Checking 1

Present Manpower 26 ID Rolling (CT-8s)

Standard Manpower 27 ABC Pressing (CT-10s)

Shortage Manpower 1 Vacuum Surge testing

(CT-13s)

Optimization Scope 2

Visual Checking

2 Rechecking all damage

Manual from V.C.1 and checking

Walpha

Packing of damages (Insulation paper

Internal Assembly Stator Delivery damage, up-down & rotate ,

Finished

Delivery Wire damage, connector

Stators damage from ABC press

checking) coming from the

process after V.C.1 .

You might also like

- Atp 57 (B)Document636 pagesAtp 57 (B)yasinmubin100% (2)

- CV For Project Manager - EngineerDocument4 pagesCV For Project Manager - EngineerShaikh Ibrahim0% (1)

- Living From Truth A Manual For Masters of Long Enlightenment IntensivesDocument116 pagesLiving From Truth A Manual For Masters of Long Enlightenment IntensivesZeljko Zex Malinovic100% (1)

- Semi Detailed Lesson Plan On Definition and Functions of ManagementDocument4 pagesSemi Detailed Lesson Plan On Definition and Functions of ManagementSydney Lee Macapelit NavaresNo ratings yet

- Assignment HBEF3703 Introduction To Guidance and Counselling / May 2020 SemesterDocument8 pagesAssignment HBEF3703 Introduction To Guidance and Counselling / May 2020 SemesterSteve SimonNo ratings yet

- Blow Off Valves DescriptionDocument12 pagesBlow Off Valves DescriptionParmeshwar Nath TripathiNo ratings yet

- PFD Stator Line NewDocument2 pagesPFD Stator Line Newakash.research.innovationNo ratings yet

- PFD Shell Welding & WashingDocument1 pagePFD Shell Welding & Washingakash.research.innovationNo ratings yet

- PFD Stator Line SkeletonDocument1 pagePFD Stator Line Skeletonakash.research.innovationNo ratings yet

- Automotive Electronic SystemsDocument62 pagesAutomotive Electronic Systemsyusufsithik100% (3)

- MV Pan IvyDocument1 pageMV Pan IvyOck MarinemosterzNo ratings yet

- 773F PDFDocument216 pages773F PDFPablo Andres Chavez100% (1)

- RBS 6000 HW Familiarization and ConfigurationsDocument71 pagesRBS 6000 HW Familiarization and ConfigurationsAlex Pena100% (3)

- TH-K2AT/K2E/K2ET: Service ManualDocument63 pagesTH-K2AT/K2E/K2ET: Service ManualRds Comunicaciones EirlNo ratings yet

- ASRS Morning Shift Report 08.11.2023Document10 pagesASRS Morning Shift Report 08.11.2023Sikander SaleemNo ratings yet

- OFDC-B8 - (163 X 326 X 102) - Recordsplice, Smouv Ant - 18 - 6 (8 - ) - 8Document2 pagesOFDC-B8 - (163 X 326 X 102) - Recordsplice, Smouv Ant - 18 - 6 (8 - ) - 8BuratNo ratings yet

- Scac Carrier Route (CTT, CPU, Export, or LTL) : Today's Date 4/29/2021 SiteDocument5 pagesScac Carrier Route (CTT, CPU, Export, or LTL) : Today's Date 4/29/2021 SiteHeather BegelmanNo ratings yet

- NH Màn Hình 2023-11-07 Lúc 11.44.21 SADocument1 pageNH Màn Hình 2023-11-07 Lúc 11.44.21 SAtranvietha4384No ratings yet

- Sammary of Instrumentation Installation and Monitoring For Sat 2nd GI WorkDocument3 pagesSammary of Instrumentation Installation and Monitoring For Sat 2nd GI WorkJarugit PoonchaiNo ratings yet

- Pantalla Anterior Bienvenido: Cr463spexplaDocument3 pagesPantalla Anterior Bienvenido: Cr463spexplahenotharenasNo ratings yet

- HSE Statistics Report FormatDocument23 pagesHSE Statistics Report FormatBrijgopal YadavNo ratings yet

- Scape 2004 Tipo 1Document1 pageScape 2004 Tipo 1Rogelio ArenasNo ratings yet

- APN BA6-7 Book 部分25Document3 pagesAPN BA6-7 Book 部分25蒋文政No ratings yet

- EMR-3000 User Manual Eaton enDocument774 pagesEMR-3000 User Manual Eaton enSergio Robles CastroNo ratings yet

- CFS 02 MDB 06-01Document2 pagesCFS 02 MDB 06-01fahamida joyaNo ratings yet

- SBCF Ils-T-Rwy16 Iac 20160303Document1 pageSBCF Ils-T-Rwy16 Iac 20160303Rodrigo HalzenthNo ratings yet

- RINA LV Relay Settings-11062021Document4 pagesRINA LV Relay Settings-11062021rahul patraNo ratings yet

- SAS Automation: Lightweight Gripper System ComponentsDocument6 pagesSAS Automation: Lightweight Gripper System ComponentsMichael KrummNo ratings yet

- Routine Task CardDocument17 pagesRoutine Task CardLuis miguel SanchezNo ratings yet

- Pro Sys12a 03 002Document3 pagesPro Sys12a 03 002hyderNo ratings yet

- Audio Corolla VersoDocument20 pagesAudio Corolla VersoAliyineNo ratings yet

- Connector: C175T: Powertrain Control Module (PCM) 15525 12A650Document2 pagesConnector: C175T: Powertrain Control Module (PCM) 15525 12A650Matias MartinezNo ratings yet

- S1-YFCE18B - 1 (Chassis Vol 1 Euro 2)Document942 pagesS1-YFCE18B - 1 (Chassis Vol 1 Euro 2)irwan yuniardiNo ratings yet

- TEstfier 1Document1 pageTEstfier 1Marlos LucasNo ratings yet

- Triton Workcentre 2000Document28 pagesTriton Workcentre 2000MiraNo ratings yet

- 777F (JRP) OFF - Highway TruckDocument224 pages777F (JRP) OFF - Highway TruckArturo Casas ArenasNo ratings yet

- LN - 10 - 55 - Paper V-Satellite Meteorology - IMDPSDocument36 pagesLN - 10 - 55 - Paper V-Satellite Meteorology - IMDPSASNMURTYNo ratings yet

- Kdc-c717 Service ManualDocument28 pagesKdc-c717 Service ManualWayne TwerkNo ratings yet

- Thk20a Kenwood HTDocument40 pagesThk20a Kenwood HTzaenal abidinNo ratings yet

- It Sty Pcda SendDocument4 pagesIt Sty Pcda Send533ascbnhisarNo ratings yet

- Annex For CHWP AreaDocument3 pagesAnnex For CHWP AreaJanaka KarunarathnaNo ratings yet

- How The Starting System Works - Blog - TeknisiDocument24 pagesHow The Starting System Works - Blog - TeknisiSetiawan Tuhu basukiNo ratings yet

- Ford CVT TransmissionDocument3 pagesFord CVT TransmissionIonut-alexandru Iordache100% (1)

- Aircraft Weight & BalanceDocument14 pagesAircraft Weight & BalanceEduardoMCraft PLUSNo ratings yet

- KPC Maunong Daily Inventory Report As of March 21, 2021Document3 pagesKPC Maunong Daily Inventory Report As of March 21, 2021DenisNo ratings yet

- Kenwwod DMC g7rDocument30 pagesKenwwod DMC g7rkong2550No ratings yet

- Manual-Book-Kijang-Inova-Diesel (Google Tranlated Indonesian To English)Document508 pagesManual-Book-Kijang-Inova-Diesel (Google Tranlated Indonesian To English)Orly Palomar Jr.100% (5)

- 2015 - Spare Parts List (AWT Mechanism)Document6 pages2015 - Spare Parts List (AWT Mechanism)Luciano Lopez CastroNo ratings yet

- 硬皮鯊 進氣系統組裝Document69 pages硬皮鯊 進氣系統組裝qazwsxedc4430No ratings yet

- Site ID 6229 Site Name: BSC Name BSC16 Site On-Air Date: Cell ID 62291,62292,62293 Drive Test Date: ALT (M)Document21 pagesSite ID 6229 Site Name: BSC Name BSC16 Site On-Air Date: Cell ID 62291,62292,62293 Drive Test Date: ALT (M)Mohamed RizviNo ratings yet

- XxxMechanical Equipment List - RevDocument9 pagesXxxMechanical Equipment List - RevACRILYC ACID i-III NSI PROJECTNo ratings yet

- FINALDocument7 pagesFINALZhiger TuleushNo ratings yet

- C.50.HW - TP2.02+Document338 pagesC.50.HW - TP2.02+yassineguenfoud412No ratings yet

- Angel Test Automation Line Program Description: Technology - InnovationDocument29 pagesAngel Test Automation Line Program Description: Technology - Innovationsunil NepalNo ratings yet

- Advanced Load-Pull and Time-Domain MeasurementsDocument18 pagesAdvanced Load-Pull and Time-Domain MeasurementsstepannpNo ratings yet

- Tajima TME-DC (Type D2)Document62 pagesTajima TME-DC (Type D2)marcos ortizNo ratings yet

- Conector PCMDocument2 pagesConector PCMAlirio VilchezNo ratings yet

- Yahotec PFD Stator LineDocument1 pageYahotec PFD Stator Lineakash.research.innovationNo ratings yet

- G3606 & G3608 Engine Electrical System Schematic, (Two Vol) - Caterpillar Machinery Repair & TroubleshootingDocument10 pagesG3606 & G3608 Engine Electrical System Schematic, (Two Vol) - Caterpillar Machinery Repair & Troubleshootingartemio CardosoNo ratings yet

- Ser. No. 1 2 3 4 5Document4 pagesSer. No. 1 2 3 4 5subhash_chander100% (2)

- V60N en PDFDocument64 pagesV60N en PDFY.EbadiNo ratings yet

- IXL - Fifth Grade Language Arts PracticeDocument3 pagesIXL - Fifth Grade Language Arts PracticeJanderson Barroso0% (1)

- Neil Armstrong BiographyDocument4 pagesNeil Armstrong Biographyapi-232002863No ratings yet

- Keyboard ShortcutsDocument11 pagesKeyboard Shortcutsashscribd_idNo ratings yet

- High Availability Cluster - Proxmox VEDocument4 pagesHigh Availability Cluster - Proxmox VEDhani MultisolutionNo ratings yet

- The Times ProjectionDocument5 pagesThe Times ProjectionBelinda NiuNo ratings yet

- Compiler LabDocument63 pagesCompiler LabAbhishek YadavNo ratings yet

- The Sultan S Harem in The Ottoman Empire PDFDocument19 pagesThe Sultan S Harem in The Ottoman Empire PDFZara AhmedNo ratings yet

- Ncert Summary Class 12th PhysicsDocument29 pagesNcert Summary Class 12th Physicsmeghraj.socialNo ratings yet

- Arts 6 Module 1Document18 pagesArts 6 Module 1Elexthéo JoseNo ratings yet

- DCC 240 MinutesDocument138 pagesDCC 240 MinutesMuhammadAmdadulHoqueNo ratings yet

- FAQ Cork Fabric Folclore Crafts 2018Document7 pagesFAQ Cork Fabric Folclore Crafts 2018gabrielampNo ratings yet

- ATV61 Communication Parameters en V5.8 IE29Document126 pagesATV61 Communication Parameters en V5.8 IE29Anonymous kiyxz6eNo ratings yet

- Mathematics Grade 10 Weeks 1-5 - Term 3Document63 pagesMathematics Grade 10 Weeks 1-5 - Term 3Daniel Dowding100% (1)

- Paths, Path Products and Regular Expressions: UNIT-3Document70 pagesPaths, Path Products and Regular Expressions: UNIT-3ranjithNo ratings yet

- Dhi NVR2108 8P 4KS2 - A&e - 20211201145323Document4 pagesDhi NVR2108 8P 4KS2 - A&e - 20211201145323Augustin CatineanNo ratings yet

- ARCS and ORCS User Guide: Revision HistoryDocument17 pagesARCS and ORCS User Guide: Revision HistoryHasain AhmedNo ratings yet

- CRSBS BrochureDocument2 pagesCRSBS BrochureKarthik PalaniswamyNo ratings yet

- Ashray Online Child Abuse DatabaseDocument2 pagesAshray Online Child Abuse Databaseअमन झाNo ratings yet

- Review of Status of Advanced Materials (Cost)Document60 pagesReview of Status of Advanced Materials (Cost)enriquesantaolallaNo ratings yet

- Fairview Terminal PhaseII Expansion Project Report - Oct2012Document436 pagesFairview Terminal PhaseII Expansion Project Report - Oct2012NewsroomNo ratings yet

- Automatic Bottle Filling SystemDocument3 pagesAutomatic Bottle Filling Systemvidyadhar GNo ratings yet

- Eligible Students - SoCDocument39 pagesEligible Students - SoCaaqilumri20No ratings yet

- Fat Loss Plan - Week 4Document2 pagesFat Loss Plan - Week 4John RohrerNo ratings yet

- Crafting The Brand Positioning: Marketing Management, 13 EdDocument21 pagesCrafting The Brand Positioning: Marketing Management, 13 Edannisa maulidinaNo ratings yet