Professional Documents

Culture Documents

CRE-Project 2324 Sem1

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CRE-Project 2324 Sem1

Copyright:

Available Formats

FACULTY OF CHEMICAL AND ENERGY ENGINEERING

UNIVERSITI TEKNOLOGI MALAYSIA

SEMESTER 1, 2023/2024

CHEMICAL REACTION ENGINEERING PROJECT

SETK 3263/SETB 3223/SETG 3463

Introduction

Students will work together in a team of 4 – 5 members. Each team will work on a slightly

different problem. At the end of the project, each team is required to produce a video

presentation consists of all the important topics of the project.

Project Description

The project objective is to design a reactor for a production of 100 kg/day of a chemical

production. The products are listed in Appendix A. Each group will be assigned only one (1)

chemical product.

The project work will involve the following tasks:

i. Literature review

• Review the processes and typical process conditions (inlet compositions, operating

pressure, and temperature, and typical reactor conversions, and selectivity) for the

manufacture of your chemical product.

• A review of the literature for background on the chemical product.

ii. Synthesis route

• Discuss the synthesis routes of the chemical product.

• Discuss on the most typical reactor types employed to produce the chemical.

iii. Multiple Reactions

• All reactions including the side reactions must be considered.

• Assuming that all reactions are elementary, write the rate law for all components

(species) in the reactions.

iv. Reaction kinetics

• Find the reaction kinetics for your reaction.

• Obtain at least three journal references for possible reaction kinetics for your

reactor. (All references must be listed at the end of your video).

v. Reactor System

• From the literature review, suggest a suitable reactor system (batch or CSTR or PFR

or PBR) that is appropriate to produce the chemical.

• Draw the selected reactor using AutoCAD software with detail dimension.

vi. Calculation and analysis

• Calculate the selectivity (main product) and yield of all products produced in the

process (isothermal and isobaric condition) using numerical methods.

• Simulate your numerical calculations using any computational tools

(MATLAB/Polymath/C++ programming/others software).

• You need to simulate by using different input variables (initial

concentration/flowrate/etc).

• Plot your analysis of input parameter manipulation.

vii. Video

• Each group must produce a video presentation that discusses all the tasks mentioned

above including the engineering drawing.

• Each student should show his/her face video and his/her name during his/her

presentation slot.

• You must also draw a conclusion from your project.

• List of references must also be included at the end of video.

• Maximum duration of video is 10 minutes, if it is more than 10 minutes, your mark

will be deducted.

• Your cover page of video must include program name, course name, section number,

title of project, project group number, your lecturer’s name and all group members’

names.

Project Output

i. Video file

ii. Programming code and simulation file

iii. Name all your files as: group_0#_sect_0#_ChemicalName

iv. Upload and submit all your files using this link:

https://docs.google.com/forms/d/e/1FAIpQLSe1G5INeBmv_zAL-

S7bnqdKeF2VUcP0Pawf8c4mSPgwZ643aQ/viewform?usp=pp_url

v. Only the team leader should submit the work.

Grading

The design project will count as 15% of your final grade. The marks distribution is as follows:

Computer simulation (PLO5) : 5%

Video (PLO3) : 5%

Video (PLO7) : 5%

Submission due date: Not later than 14 January 2024

Appendix A

Group Chemical Synthesis route*

1,7 1,3-Butanediol (1) Hydrogenation of 3-hydroxybutanal gives 1,3-

(Butylene butanediol:

glycol)

CH3CH(OH)CH2CHO + H2 → CH3CH(OH)CH2CH2OH

(2) Dehydration of 1,3-butanediol gives 1,3-butadiene:

CH3CH(OH)CH2CH2OH → CH2=CH-CH=CH2 + 2 H2O

2,8 Caprolactam Caprolactam is synthesized from cyclohexanone (1), which

is first converted to its oxime (2). Treatment of this oxime

with acid induces the Beckmann rearrangement to give

caprolactam (3)

3,9 Diisopropyl Diisopropylbenzenes typically arise by alkylation of

benzene benzene or isopropylbenzene with propylene:

C6H6 + 2 CH3CH=CH2 → C6H5CH(CH3)2

C6H5CH(CH3)2 + CH3CH=CH2 → C6H4(CH(CH3)2)2

4 , 10 Methanol CO + 2H2 → CH3OH (1)

CO2 + 3H2 → CH3OH + H2O (2)

5 , 11 Hydrogen Steam reforming of methane (1) and subsequent water-gas-

shift stages (2):

CH4 + H2O → CO + 3H2 (1)

H2O + CO → CO2 + H2 (2)

Alternatively, dry reforming of methane:

CH4 + CO2 → 2CO + 2H2 (1)

6 , 12 Olefin Methanol to Olefin: Methanol (MeOH)/dimethyl ether (DME)

via a dual-cycle mechanism, where ethylene and propylene are

the secondary products.

*The synthesis route is a suggestion. You can choose another synthesis route if you find an

alternative from the literature review.

You might also like

- Phthalic AnhydrideDocument60 pagesPhthalic AnhydrideAnonymous Ksq1dyPRh0% (2)

- Phthalic AnhydrideDocument60 pagesPhthalic AnhydrideSatyam SharmaNo ratings yet

- Acjc 08 Paper 3Document8 pagesAcjc 08 Paper 3Zenaida AtinorNo ratings yet

- Process Creation (Synthesis and Design Alternatives)Document48 pagesProcess Creation (Synthesis and Design Alternatives)Siddharth KrishnanNo ratings yet

- Dr. K. Sivagami, Associate Professor, School of Chemical Engineering, VIT VelloreDocument57 pagesDr. K. Sivagami, Associate Professor, School of Chemical Engineering, VIT VelloreAmol RastogiNo ratings yet

- Main Project Psl360sDocument6 pagesMain Project Psl360sPonatshego Stojaković OnewangNo ratings yet

- Area Six HandoutDocument3 pagesArea Six HandoutspamNo ratings yet

- Process Design Principles I: BITS PilaniDocument39 pagesProcess Design Principles I: BITS PilanividishsaNo ratings yet

- MEB Project Sem II-20162017Document2 pagesMEB Project Sem II-20162017Koogulan ChinnasamyNo ratings yet

- MEB Project Sem I 20232024Document3 pagesMEB Project Sem I 20232024Harshini BaskaranNo ratings yet

- Kuliah 2 PDFDocument51 pagesKuliah 2 PDFusepNo ratings yet

- 56621 Điều văn bản 161021 2 10 20210514Document11 pages56621 Điều văn bản 161021 2 10 20210514Tường DuyNo ratings yet

- Chemical Process Design CHE3202-5-2007-2Document5 pagesChemical Process Design CHE3202-5-2007-2Priyam RamsokulNo ratings yet

- Native File Thesis AkasDocument21 pagesNative File Thesis AkasAkas StevenNo ratings yet

- CHEM 1 Module 8 PDFDocument2 pagesCHEM 1 Module 8 PDFGwen YosheenNo ratings yet

- Exam Chemistry 2014-05-27 StudentsDocument6 pagesExam Chemistry 2014-05-27 StudentsAli PliegoNo ratings yet

- A Study of The Biomass Gasification Process: Year 2 Bridging CourseworkDocument10 pagesA Study of The Biomass Gasification Process: Year 2 Bridging CourseworkDavid ManningNo ratings yet

- Organic Chem Revision Part 1+2Document46 pagesOrganic Chem Revision Part 1+2Thanh Hằng NgôNo ratings yet

- TH Q7Document4 pagesTH Q7Hazel Dela PazNo ratings yet

- B2 6.2.5 Organic Synthesis 2020-21Document27 pagesB2 6.2.5 Organic Synthesis 2020-21noornhhhNo ratings yet

- Che502 Mid Term Assessment May 2021 HimDocument3 pagesChe502 Mid Term Assessment May 2021 HimLehbron JemsNo ratings yet

- Production of Acrylonitrile by Ammoxidation of PropyleneDocument33 pagesProduction of Acrylonitrile by Ammoxidation of PropyleneJ José B VelasquezNo ratings yet

- Apr 2008Document9 pagesApr 2008Ismi FadliNo ratings yet

- Hydrogenation of Carbon Dioxide For Methanol Production 2012 Chemical Engineering TransactionsDocument6 pagesHydrogenation of Carbon Dioxide For Methanol Production 2012 Chemical Engineering TransactionssapooknikNo ratings yet

- Practice Exam OC1.1Document9 pagesPractice Exam OC1.1Stella CheaNo ratings yet

- Worksheet On Carboxylic AcidsDocument3 pagesWorksheet On Carboxylic AcidsmalisnotokNo ratings yet

- Biotechnology Engineering 2019 SyllabusDocument139 pagesBiotechnology Engineering 2019 SyllabusprarthanaNo ratings yet

- CRE (Stage 3) GROUP A6Document13 pagesCRE (Stage 3) GROUP A6Danish MughalNo ratings yet

- Revision Organic Tutorial 2 - MSDocument5 pagesRevision Organic Tutorial 2 - MSDanish HamizanNo ratings yet

- Ejercicios QO-I-T6 7Document5 pagesEjercicios QO-I-T6 7dddddNo ratings yet

- 18 Understanding COD TestDocument38 pages18 Understanding COD TestSubhabrata MabhaiNo ratings yet

- MEB Project II 1718Document2 pagesMEB Project II 1718Siti HajarNo ratings yet

- Revision Organic Tutorial 2Document3 pagesRevision Organic Tutorial 2Danish HamizanNo ratings yet

- Assignment Booklet: ST STDocument5 pagesAssignment Booklet: ST STManoj KaushikNo ratings yet

- Organic Chem (With Solution) 2Document75 pagesOrganic Chem (With Solution) 2vlNo ratings yet

- H2 Chemistry 9746/03: Dunman High School (Senior High) Year 6 Preliminary Examination 2008Document8 pagesH2 Chemistry 9746/03: Dunman High School (Senior High) Year 6 Preliminary Examination 2008Ronald McdonaldNo ratings yet

- Petroleum Refinery Hydrogen Production Unit ExergyDocument8 pagesPetroleum Refinery Hydrogen Production Unit ExergylovegrkNo ratings yet

- Che1211 Module 5 PDFDocument5 pagesChe1211 Module 5 PDFMaries San PedroNo ratings yet

- MEC551 Assignment - Design September 2015Document7 pagesMEC551 Assignment - Design September 2015SyafiqAsyrafNo ratings yet

- Bkf1323-Organic Chemistry 21213 PDFDocument8 pagesBkf1323-Organic Chemistry 21213 PDFrushdiNo ratings yet

- Process Synthesis (Process Creation)Document32 pagesProcess Synthesis (Process Creation)Göksu KutluNo ratings yet

- MTA QuestionDocument3 pagesMTA QuestionArissa HaniNo ratings yet

- Tutorial Sheets-CHEM2002-2017-2018 PDFDocument18 pagesTutorial Sheets-CHEM2002-2017-2018 PDFajali1957No ratings yet

- Integrated Design Project (Sept 2020)Document5 pagesIntegrated Design Project (Sept 2020)Meesaa KbaiiNo ratings yet

- HSC June 2009 Paper and Marking Scheme On Same Paper Word DocumentDocument26 pagesHSC June 2009 Paper and Marking Scheme On Same Paper Word DocumentreekoyeNo ratings yet

- An Analysis of The Biomass Gasification Process: Year 2 Bridging CourseworkDocument8 pagesAn Analysis of The Biomass Gasification Process: Year 2 Bridging CourseworkDavid ManningNo ratings yet

- Alkanes, Alkenes, Alkynes and Their Alicyclic Couterparts: 1. What Is The IUPAC Name For CHDocument17 pagesAlkanes, Alkenes, Alkynes and Their Alicyclic Couterparts: 1. What Is The IUPAC Name For CHEllaŠtrbac100% (1)

- Catalyst Design and PreparationDocument16 pagesCatalyst Design and PreparationErika de la RosaNo ratings yet

- Tutorial Kit (Chemistry-200 L) - Vol. 2 PDFDocument84 pagesTutorial Kit (Chemistry-200 L) - Vol. 2 PDFLucienne IrianaNo ratings yet

- Tutorial Sheet 1: Chem 2002 - Process Systems Analysis - 2016-2017Document20 pagesTutorial Sheet 1: Chem 2002 - Process Systems Analysis - 2016-2017ajali1957No ratings yet

- Unit 4 Industrial ChemistryDocument23 pagesUnit 4 Industrial ChemistryYidaZhou100% (1)

- Essential Organic Chemistry 2nd Edition Bruice Test Bank Full Chapter PDFDocument41 pagesEssential Organic Chemistry 2nd Edition Bruice Test Bank Full Chapter PDFbasilthoatuis6100% (13)

- Lec#4 FLOW SHEET SYNTHESIS AND DEVELOPMENT PDFDocument76 pagesLec#4 FLOW SHEET SYNTHESIS AND DEVELOPMENT PDFSaidNo ratings yet

- 412512sp10hw3 635731752264840564 PDFDocument1 page412512sp10hw3 635731752264840564 PDFTrường TùngNo ratings yet

- 2 Synthesis of PFDDocument65 pages2 Synthesis of PFDMelissa HuynhNo ratings yet

- Essential Organic Chemistry 2nd Edition Bruice Test BankDocument20 pagesEssential Organic Chemistry 2nd Edition Bruice Test Banknhiamandat4uvr100% (31)

- Reactions of Alkanes: Radicals: Essential Organic Chemistry (Bruice)Document43 pagesReactions of Alkanes: Radicals: Essential Organic Chemistry (Bruice)tyron9520100% (2)

- Sec 4 Alkenes NotesDocument12 pagesSec 4 Alkenes Notesanya de silvaNo ratings yet

- Introduction to Supercritical Fluids: A Spreadsheet-based ApproachFrom EverandIntroduction to Supercritical Fluids: A Spreadsheet-based ApproachNo ratings yet

- Cement Grinding and StorageDocument24 pagesCement Grinding and StorageMarzuki UkiNo ratings yet

- Expperiment 1a Ras1132a Group 2Document7 pagesExpperiment 1a Ras1132a Group 2Salazar ZawawiNo ratings yet

- B - SC - Chemistry (I To VI Semesters) W - e - F - 2014-15 in Phased MannerDocument30 pagesB - SC - Chemistry (I To VI Semesters) W - e - F - 2014-15 in Phased MannerNatish JaglanNo ratings yet

- Lab Assignment 1: Small Molecule Diffusion: Model DevelopmentDocument5 pagesLab Assignment 1: Small Molecule Diffusion: Model DevelopmentSaurabh GuptaNo ratings yet

- Quality PlanDocument3 pagesQuality PlanhjgajjarNo ratings yet

- Extraction of Anthocyanin Pigments From Malabar Spinach Fruits As A Potential Photosensitizer For Dye-Sensitized Solar CellDocument11 pagesExtraction of Anthocyanin Pigments From Malabar Spinach Fruits As A Potential Photosensitizer For Dye-Sensitized Solar CellMani kumarNo ratings yet

- Techniques OF Drip Irrigation and FertigationDocument25 pagesTechniques OF Drip Irrigation and FertigationBhuvnesh Kumar100% (2)

- Bituminous Mixes 2Document9 pagesBituminous Mixes 2danielNo ratings yet

- Sartocool PS 0.45 UmDocument2 pagesSartocool PS 0.45 UmHector Serrano MagañaNo ratings yet

- Topic 3: Periodicity (6 Hours) : Assessment Statement Obj Teacher's NotesDocument2 pagesTopic 3: Periodicity (6 Hours) : Assessment Statement Obj Teacher's NotesAtharva SatputeNo ratings yet

- 1 PhET Interactive Simulation - States of MatterDocument2 pages1 PhET Interactive Simulation - States of MatterSophia SinghNo ratings yet

- JR VSA Q and A Wtih Star Marks (2023) PDFDocument42 pagesJR VSA Q and A Wtih Star Marks (2023) PDFShaik irfan basha Shaik irfan bashaNo ratings yet

- Test Bank For Organic Chemistry 8th Edition McmurryDocument19 pagesTest Bank For Organic Chemistry 8th Edition McmurryXavierKimydfj100% (41)

- Chem 11 Expt10Document6 pagesChem 11 Expt10Annet KemumaNo ratings yet

- Cambridge IGCSE: Biology 0610/22Document16 pagesCambridge IGCSE: Biology 0610/22jad obaidNo ratings yet

- AEC - Community Service Project Report - FormatDocument47 pagesAEC - Community Service Project Report - FormatLakshmi PithaniNo ratings yet

- Darryl L Ulrich - Association For Finishing Processes of SME - User's Guide To Powder Coating-Society of Manufacturing Engineers (1993)Document132 pagesDarryl L Ulrich - Association For Finishing Processes of SME - User's Guide To Powder Coating-Society of Manufacturing Engineers (1993)PhucNo ratings yet

- Jui MandalDocument14 pagesJui MandalSudip SahaNo ratings yet

- Bab 2 Solid State Structure - 2.3 - Simple Ionic Solid State StructureDocument32 pagesBab 2 Solid State Structure - 2.3 - Simple Ionic Solid State StructurePutrik AgustinaNo ratings yet

- 6.3 Enzyme Kinetics LabDocument3 pages6.3 Enzyme Kinetics LabSiegNo ratings yet

- Hydrocarbons - DPP 02 (Of Lec 03) - Arjuna JEE Fastrack 2024Document3 pagesHydrocarbons - DPP 02 (Of Lec 03) - Arjuna JEE Fastrack 2024abdthecricketgoatNo ratings yet

- Technical Specification - ACDocument7 pagesTechnical Specification - ACRabin ShresthaNo ratings yet

- Sigma 533 Datasheet 1Document1 pageSigma 533 Datasheet 1benoitNo ratings yet

- MSDS (SALACOS PG-180) Ver.2010Document4 pagesMSDS (SALACOS PG-180) Ver.2010Vinicio AstudilloNo ratings yet

- Poly (Vinyl Chloride) (PVC) Plastic Drain, Waste, and Vent (DWV) Pipe and Fittings Having Post-Industrial Recycle ContentDocument7 pagesPoly (Vinyl Chloride) (PVC) Plastic Drain, Waste, and Vent (DWV) Pipe and Fittings Having Post-Industrial Recycle Contentastewayb_964354182No ratings yet

- Notes 221006 051612Document30 pagesNotes 221006 051612Ramitha . VNo ratings yet

- USP-NF Alginic AcidDocument2 pagesUSP-NF Alginic AcidK.m. Ehsan Morshed RanaNo ratings yet

- Masterclass Shopping ListDocument1 pageMasterclass Shopping ListKiraNo ratings yet

- Organic DPPDocument11 pagesOrganic DPPRahul KumarNo ratings yet

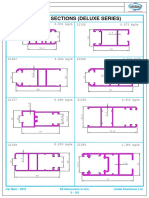

- Slidingwindowsections (Deluxe)Document14 pagesSlidingwindowsections (Deluxe)Farseena O.MNo ratings yet