Professional Documents

Culture Documents

Cecomp Gas Kits

Cecomp Gas Kits

Uploaded by

basarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cecomp Gas Kits

Cecomp Gas Kits

Uploaded by

basarCopyright:

Available Formats

Ult ra- Ru g ged ized Digital Pre ssure Gauge s for

Nat u ral Gas Pre ssure Me asure me nts

± 0.25% Test Gauge Accuracy Tool Box Tough

C E C OMP

OO OO

OO 316L Stainless Steel Sensor OO Easy to Use, Setup, and Calibrate

OO All Metal Housing OO Long Term Stability and Reliability Div. of ABSOLUTE PROCESS INSTRUMENTS

OO FM Class I Div. 1 Intrinsically Safe OO Extra-Long Recalibration Cycle

OO Protective Coating on Circuit Boards OO Serviceable and Repairable cecomp.com

H H H H H H

H H H H H

H H H H H H

H H H H H

H H H H H H

H H H H H

H H H H H H

H H H H H

H H H H H H

Made in USA

3-1/2 Digit 4-Digit, Min/Max Memory, 4-Digit, Min/Max Memory, Specifications

Range Range Range

No Memory 1 Button/Internal Buttons 3-Button Keypad See cecomp.com/is for complete specifications

DPG2000BBL85INH2O 85.0 inH2O DPG2000BBL85INH2O-D4 85.0 inH2O DPG2000BBL85INH2O-D4-M2 85.0 inH2O FM Approved Intrinsically Safe Class I, Div. 1, Groups A, B, C, D

DPG2000BBL15PSIG 15.00 psig DPG2000BBL15PSIG-D4 15.00 psig DPG2000BBL15PSIG-D4-M2 15.00 psig Display 3-1/2 or 4 digit LCD updated 3 reading/second

DPG2000BBL30PSIG 30.0 psig DPG2000BBL30PSIG-D4 30.00 psig DPG2000BBL30PSIG-D4-M2 30.00 psig Backlight Keypress activated red LED

DPG2000BBL60PSIG 60.0 psig DPG2000BBL60PSIG-D4 60.00 psig DPG2000BBL60PSIG-D4-M2 60.00 psig Accuracy ±0.25% of full scale, ±1 LSD, ±0.1% optional

DPG2000BBL100PSIG 100.0 psig DPG2000BBL100PSIG-D4 100.0 psig DPG2000BBL100PSIG-D4-M2 100.0 psig Batteries Two 1.5 V AAA included

DPG2000BBL200PSIG 199.9 psig DPG2000BBL200PSIG-D4 200.0 psig DPG2000BBL200PSIG-D4-M2 200.0 psig Battery Life Up to 1000 hours depending on back light usage

DPG2000BBL300PSIG 300 psig DPG2000BBL300PSIG-D4 300.0 psig DPG2000BBL300PSIG-D4-M2 300.0 psig Auto Shutoff 5 minutes. D4: user configurable on/off to 8 hrs

DPG2000BBL500PSIG 500 psig DPG2000BBL500PSIG-D4 500.0 psig DPG2000BBL500PSIG-D4-M2 500.0 psig D4 Controls Min/max memory, push button zero

DPG2000BBL1000PSIG 1000 psig DPG2000BBL1000PSIG-D4 1000 psig DPG2000BBL1000PSIG-D4-M2 1000 psig D4 Setup Units, shutoff time, memory, calibration, pass code

DPG2000BBL2000PSIG 2000 psig DPG2000BBL2000PSIG-D4 2000 psig DPG2000BBL2000PSIG-D4-M2 2000 psig Connection 1/4" NPT male fitting

DPG2000BBL3000PSIG-D4 3000 psig DPG2000BBL3000PSIG-D4-M2 3000 psig Sensor 316L stainless steel

DPG2000BBL5000PSIG-D4 5000 psig DPG2000BBL5000PSIG-D4-M2 5000 psig Operating Amb. –4 to 185°F (–20 to 85°C)

Field Service

OO Cases for Service Kits

OO 2, 3 or 6 Gauge Versions

OO Pelican ® Brand Case

OO Storage for Pete’s Plugs ® and Fittings

OO High Visibility Orange

OO Custom Heavy Duty Foam Interior

OO Optional Heavy Duty Gauge Boot

Model Service Kit Case Interior Size

DPG-OK2 1 or 2 gauges 9.2" x 7.1" x 4.1"

DPG-OK3 1 to 3 gauges 11.8" x 8.8" x 5.2"

DPG-OK6 1 to 6 gauges 16.7" x 11.2" x 6.1"

Model Protective Boot Size

RB Orange rubber boot 3.5" x 3" x 2" H H H H H H

H H H H H

H H H H H H

H H H H H

H H H H H H

H H H H H

H H H H H H

H H H H H

H H H H H H

Pelican–Reg TM Pelican Products, Inc.

Pete's Plug–Reg TM Peterson Equipment Co., Inc.

Pete's Plugs not included. See petesplug.com Made in USA

CE C O MP Div. of ABSOLUTE PROCESS INSTRUMENTS 1220 American Way Libertyville, IL 60048

800-942-0315 cecomp.com © 01-18

Cecomp Digital Pressure Gauge Applications

Application: Accurately monitoring pressure in a gas distribution system

Type Of company: Public Utility

Location: Washington

Problem

Natural gas utilities require operators and technicians to check the gas pressures at the various “Stops” (regulator locations) along the local

utility transmission line. Analog pressure gauges were used to check pressure, but often had accuracy errors due to mechanical shock, wear,

and field conditions. Reading errors were also caused by using the gauges outside of their rated 2/3 accuracy band width.

Some gas utility managers advised that 3 different analog gauges yielded 3 significantly different pressure readings on the same line. Since

gas is billed by volume and that volume is calculated from their temperature / pressure formula, the pressure needs to be accurately measured

and recorded at each stop.

Solution

A kit with three Cecomp DPG2000BBL series digital pressure gauge is the solution. The ranges required were 85 InH2O, 100 PSIG, and a 1000

PSIG. The Cecomp Digi Max gauges have ±0.25% accuracy over the full pressure range and can handle the abuse because of its rugged

design. These are supplied in a rugged Pelican brand case that can hold three gauge and Pete's Plug accessories.

Many utilities use a pressure testing system called a “Pete’s Plug”. This uses rubber seals that are penetrated by a needle, much like a football

inflator. This allow quick pressure checks without needing a shutoff valve. The Pete’s Plug probe can be mounted to the 1/4" NPT fitting on

the gauge.

LDC—Local Distribution Companies

Supplemental storage

LNG, propane

Stop #1 230 psig typical Stop #2 Stop #3 Stop #4

Citygate pressure reduction station 30 psig typical up to 60 psig 30 psig typical 30 psig typical

100-150 psig typical Metering & Regulator Station Sampling & Regulator Station Residential Transfer Station

Power generator plants

Stop #6

2 psig typical

Stop #5 Images and pressures are representa- Stop #7 Residential Service Line

30 psig typical tive and are not intended to reflect actual .25 psig (7 inH2O)

Industrial User Transfer Station equipment or pressures used. Residential service

Application: Test and check calibration of in-place analog gauges

Type Of company: Natural Gas Pipeline Service

Location: Wisconsin

Problem

The customer provides routine maintenance and modification of metering stations for natural gas pipeline distribution companies. The general

goal of their program is to increase system reliability and lower system costs which provides tangible benefits to their customers. Part of

the technician’s routine maintenance is to perform a field test on the installed analog pressure gauge to ensure that the gauge is operating

properly and reading correctly.

This requires the technician to have a “working standard” gauge. A “working standard” is a pressure gauge that is calibrated from a “primary

standard” and is used to check and field calibrate other pressure gauges. The customer needs an accurate and reliable digital pressure gauge

to use as the “working standard” for their technicians.

Solution

The customer purchased an Ultra-Ruggedized F16B5000PSIG gauge. They did not require an Intrinsically Safe gauge for this application. This

model gives the technician an accurate visual readout to check the reading and operation of the in-place analog gauge.

CECOMP See cecomp.com for latest product information. Call 800-942-0315 for questions or quotes.

Div. of ABSOLUTE PROCESS INSTRUMENTS 1220 American Way Libertyville, IL 60048

You might also like

- H-100 User ManualDocument30 pagesH-100 User ManualBivaria Grup100% (2)

- Industrial Training Report (ADTPS)Document16 pagesIndustrial Training Report (ADTPS)Shahid Tavar100% (1)

- Hitachi EXC5 Operators Manual - oDocument252 pagesHitachi EXC5 Operators Manual - ofahim100% (1)

- Tennant t17 Rider Floor Scrubber Service ManualDocument308 pagesTennant t17 Rider Floor Scrubber Service ManualTirta Budiawan100% (1)

- Yamaha CLP 170 Service ManualDocument122 pagesYamaha CLP 170 Service ManualicaroheartNo ratings yet

- Coiled Tubing Introduction-Part 1Document109 pagesCoiled Tubing Introduction-Part 1qazim786100% (3)

- Technolog Gas Pressure ProfilerDocument3 pagesTechnolog Gas Pressure ProfilerzenerdiodeNo ratings yet

- 3D - DPG-6600 - DatasheetDocument2 pages3D - DPG-6600 - DatasheetJames GeorgeNo ratings yet

- Oxigen RegulatorDocument6 pagesOxigen RegulatorCENEMEM ANDRADENo ratings yet

- Pressure Transmitter Selection GuideDocument2 pagesPressure Transmitter Selection Guideابزار دقیق0% (1)

- Koolkare EN 6 PDFDocument8 pagesKoolkare EN 6 PDFAriel SanchezNo ratings yet

- HI98193 ManualDocument64 pagesHI98193 ManualSidhion.AzarozNo ratings yet

- Leaflet H-80 Series High Flow HumidifierDocument2 pagesLeaflet H-80 Series High Flow HumidifierRico AnandaNo ratings yet

- SensoNODE Blue Pressure Sensors 8 9Document2 pagesSensoNODE Blue Pressure Sensors 8 9Marlon Enrique Hernandez FonsecaNo ratings yet

- CA Overview Temperature en 111123Document38 pagesCA Overview Temperature en 111123Avik BhaiNo ratings yet

- Oillab 715 Reid Vapour Pressure: Automatic Analysers: Oillab RangeDocument1 pageOillab 715 Reid Vapour Pressure: Automatic Analysers: Oillab RangeOmar SaaedNo ratings yet

- Bios Defender 500 Series Spec SheetDocument2 pagesBios Defender 500 Series Spec SheetAnonymous G6ceYCzwtNo ratings yet

- SM Gsi 38Document96 pagesSM Gsi 38Miguel Angel LaraNo ratings yet

- Service Manual: Colour Television Chassis: Cm-905 F Model DTD-29U8ME 29U8MT 29U8MP 29U8MZDocument49 pagesService Manual: Colour Television Chassis: Cm-905 F Model DTD-29U8ME 29U8MT 29U8MP 29U8MZОлег ОзеровNo ratings yet

- Dpi 705 Datasheet EnglishDocument4 pagesDpi 705 Datasheet Englishsec.ivbNo ratings yet

- DocLib 492 SanitrxLPXDatasheetDocument2 pagesDocLib 492 SanitrxLPXDatasheetWormInchNo ratings yet

- Fire Hydrant Pressure Logger - TelogDocument3 pagesFire Hydrant Pressure Logger - TelogBrian McMorrisNo ratings yet

- D Imr4000 en GermanyDocument3 pagesD Imr4000 en Germanyputera instrumenNo ratings yet

- Manual Omega CT87P DatasheetDocument1 pageManual Omega CT87P DatasheetPubcrawlNo ratings yet

- Miniature Tank Level TransmittersDocument2 pagesMiniature Tank Level TransmittersAngel PetrovNo ratings yet

- CC4 50 ACT Controller ManualDocument29 pagesCC4 50 ACT Controller ManualAyub SetiawanNo ratings yet

- Magnetic Stirrer HotplateDocument4 pagesMagnetic Stirrer HotplateumarNo ratings yet

- MEDICA 2020 BMC Medical Co. Ltd. Product Medcom2020.2664582 1Y5SlFXDQZWUyDQKCgo8qADocument2 pagesMEDICA 2020 BMC Medical Co. Ltd. Product Medcom2020.2664582 1Y5SlFXDQZWUyDQKCgo8qAGiovanni BalderramaNo ratings yet

- Operating Instructions Manual: Series 1800C & 1800C-HC Service RegulatorsDocument4 pagesOperating Instructions Manual: Series 1800C & 1800C-HC Service RegulatorsManuel NiñoNo ratings yet

- LPG Sensor TechnologyDocument20 pagesLPG Sensor Technologyeddie eddNo ratings yet

- 3/4-Inch Combination PH and ORP Sensor KitsDocument8 pages3/4-Inch Combination PH and ORP Sensor KitsCowdrey IlanNo ratings yet

- Model RSP Sanitary Electronic Pressure TransmitterDocument2 pagesModel RSP Sanitary Electronic Pressure Transmittergrincheu70No ratings yet

- Operator'S Manual Px05P-Xxx-Xxx-Bxxx: 1/2" Diaphragm PumpDocument12 pagesOperator'S Manual Px05P-Xxx-Xxx-Bxxx: 1/2" Diaphragm PumpjarosNo ratings yet

- Samsung GT-N8000 Service ManualDocument84 pagesSamsung GT-N8000 Service ManualMario DeejayNo ratings yet

- Daewoo dtd-14d3, d4, d6, d7, U6,20d3,21d3 Chassis cm-905s, cm-905sf SMDocument56 pagesDaewoo dtd-14d3, d4, d6, d7, U6,20d3,21d3 Chassis cm-905s, cm-905sf SMnartea_narcisNo ratings yet

- Tapping Saddle DimensionsDocument4 pagesTapping Saddle DimensionsAnonymous IgzACaiNo ratings yet

- Hartip 1600Document1 pageHartip 1600N & C LINCE SASNo ratings yet

- B1052 InstrumentationDocument240 pagesB1052 InstrumentationJose Valencia0% (1)

- Polyken Utility Tape 900 910 908 911 920Document2 pagesPolyken Utility Tape 900 910 908 911 920Tracy EvansNo ratings yet

- GrothCorporationIndustrialCatalog (TTT)Document194 pagesGrothCorporationIndustrialCatalog (TTT)Huynh Thanh TamNo ratings yet

- Viscosimetros Ku2Document11 pagesViscosimetros Ku2jeremiasNo ratings yet

- EBT720 Series Electronic Balancing ToolsDocument4 pagesEBT720 Series Electronic Balancing Toolsdavid messierNo ratings yet

- CV-Product ListDocument151 pagesCV-Product ListVickram ChopraNo ratings yet

- Catalogo Tecnico Valvula y Actuador GEMU 656Document6 pagesCatalogo Tecnico Valvula y Actuador GEMU 656Ronulfo GutierrezNo ratings yet

- SPEC Pulsatron E PLUS SeriesDocument2 pagesSPEC Pulsatron E PLUS SeriesAlfonso Javier Medina PernethNo ratings yet

- API 6a Valves LomisaDocument5 pagesAPI 6a Valves LomisaJulio CNo ratings yet

- Calibradores Fluke PresionDocument9 pagesCalibradores Fluke PresionreycardoNo ratings yet

- FLFM600W144 9PLDocument3 pagesFLFM600W144 9PLJuan Enrique Castillo CanoNo ratings yet

- De400001 SM-6Document3 pagesDe400001 SM-6seve1No ratings yet

- High Flow MachineDocument2 pagesHigh Flow MachineJinesh GeorgeNo ratings yet

- Druck - Dpi 705 SeriesDocument4 pagesDruck - Dpi 705 Seriesbugoff700No ratings yet

- ARO 2019 PX20X 2 Inch Metallic Diaphragm Pump Manual Fluid SectionDocument12 pagesARO 2019 PX20X 2 Inch Metallic Diaphragm Pump Manual Fluid Sectionduc tranNo ratings yet

- Mroy Pump Catalogue PDFDocument6 pagesMroy Pump Catalogue PDFTitus FelixNo ratings yet

- Digital Test GaugeDocument3 pagesDigital Test GaugejamaluddinNo ratings yet

- 440Document3 pages440Magabata GoguNo ratings yet

- ARO Pump ManualDocument8 pagesARO Pump Manualrazaq athabNo ratings yet

- Product Overview UK BDDocument28 pagesProduct Overview UK BDNaser Jahangiri100% (1)

- Kphj720pro GlobalDocument132 pagesKphj720pro Globalsleepy.dogNo ratings yet

- Split SleeveDocument3 pagesSplit Sleeveast654No ratings yet

- Suntex Online Measurement & Control Brochure-2020-CDocument32 pagesSuntex Online Measurement & Control Brochure-2020-CMohammad Al-TamimiNo ratings yet

- Impedianciometro Gsi - 38Document96 pagesImpedianciometro Gsi - 38jmillan.ibermansaNo ratings yet

- Microcomputers for Process Control: The Pergamon Materials Engineering Practice SeriesFrom EverandMicrocomputers for Process Control: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- TYBOX 137 - 237 - 337: Important Product Information ( )Document6 pagesTYBOX 137 - 237 - 337: Important Product Information ( )Colete GroenewegenNo ratings yet

- JA Solar - JA SolarDocument2 pagesJA Solar - JA SolarRobert SchweikleNo ratings yet

- Drilling EngineeringDocument11 pagesDrilling EngineeringEssam AnanyNo ratings yet

- Psa Nitrogen Generators: Standard Product RangeDocument3 pagesPsa Nitrogen Generators: Standard Product RangeTiar_Rahman_9553No ratings yet

- The Industrial Symbiosis at KalundborgDocument7 pagesThe Industrial Symbiosis at KalundborgRose SocietyNo ratings yet

- Tech Spec Bhel PheDocument55 pagesTech Spec Bhel PheYasmin 2021No ratings yet

- Bslbattlfp OF Performance: TheheightDocument3 pagesBslbattlfp OF Performance: TheheightCamilo PérezNo ratings yet

- APC WP 138 Energy Impact of Increasing Server Inlet Temperature JBEN-7KTR88 - R1 - ENDocument12 pagesAPC WP 138 Energy Impact of Increasing Server Inlet Temperature JBEN-7KTR88 - R1 - ENSargurusivaNo ratings yet

- 7sj80 Overcurrent Relay For Transformer ProtectionDocument30 pages7sj80 Overcurrent Relay For Transformer ProtectionMahmudNo ratings yet

- Fastfill Catalogue 2016 - 11.10.16 Technical CatalogDocument24 pagesFastfill Catalogue 2016 - 11.10.16 Technical CatalogRohmanNo ratings yet

- Analysis of Gas Sector in Cote D'ivoire: History, Current Status and PolicyDocument7 pagesAnalysis of Gas Sector in Cote D'ivoire: History, Current Status and PolicyPalak LimbachiyaNo ratings yet

- Hernandez-Padilla Etal 2017Document15 pagesHernandez-Padilla Etal 2017Mohsin ModiNo ratings yet

- Tender Documents - LOCI 5Document15 pagesTender Documents - LOCI 5SomeshNo ratings yet

- MPPT Based Solar String InverterDocument5 pagesMPPT Based Solar String InverterIJRASETPublicationsNo ratings yet

- RAB MEIA MechanicalDocument362 pagesRAB MEIA MechanicalArif BinorikaNo ratings yet

- KORJO Adapter Guide BrochureDocument2 pagesKORJO Adapter Guide BrochureVicente R EdañoNo ratings yet

- Annex B 2 - 02 - Kfar Hanasi - FS3V-12°-24 - DUODocument1 pageAnnex B 2 - 02 - Kfar Hanasi - FS3V-12°-24 - DUOmatan dvirNo ratings yet

- Gems E-4m17 Air Fin CoolersDocument19 pagesGems E-4m17 Air Fin CoolersMochamad TaufikNo ratings yet

- Community Working Group MTG 3 v2Document12 pagesCommunity Working Group MTG 3 v2David IbanezNo ratings yet

- Current Energy Scenario and Future Prospect of Renewable Energy in BangladeshDocument15 pagesCurrent Energy Scenario and Future Prospect of Renewable Energy in Bangladeshfahim asifNo ratings yet

- Gujarat BOE 2015 Paper 1 SolutionDocument7 pagesGujarat BOE 2015 Paper 1 SolutionSaravana Prasad100% (1)

- Solid Waste Management Practices and Review of Recovery and Recycling Operations in TurkeyDocument8 pagesSolid Waste Management Practices and Review of Recovery and Recycling Operations in TurkeyMahat AnjalNo ratings yet

- Piko 10-20 - Ba - enDocument158 pagesPiko 10-20 - Ba - enAlexander BoleyNo ratings yet

- Ielts Reading Practice 2Document4 pagesIelts Reading Practice 2Nguyenn HonggNo ratings yet

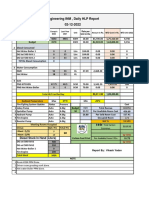

- Daily HLP 02 Report Dec 2022Document1 pageDaily HLP 02 Report Dec 2022Vicky YadavNo ratings yet

- Mtu ModbusDocument6 pagesMtu ModbusOrhan DenizliNo ratings yet

- Ugrd Nsci6101 Calculus Based Physics Prelim FinalsDocument105 pagesUgrd Nsci6101 Calculus Based Physics Prelim FinalsDina SchaubNo ratings yet