Professional Documents

Culture Documents

SCHMIDT

SCHMIDT

Uploaded by

rt.polymer.afraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SCHMIDT

SCHMIDT

Uploaded by

rt.polymer.afraCopyright:

Available Formats

Automation’s Best Friend Solution Chronicles

TM

TM

T E C H N O L O G I E S

Kepware Technologies Automation’s Best Friend 1.888.Kepware sales@kepware.com www.kepware.com

SCHMIDT Technology

chooses LinkMaster to link PLC data to ServoPress

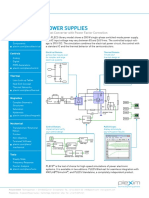

SCHMIDT Technology Corp. a wholly owned subsidiary of SCHMIDT Technology - Germany, offers a comprehensive line of precision Manual,

Air-Powered, and Hydro-Pneumatic presses for manufacturing industries in the United States, Mexico, and Canada.

idt idt idt involvement of providing status of force monitoring, sequence information,

SecrhvomPress SecrhvomPress SecrhvomPress and real-time access to additional force and position data from two

S #1 S #2 S #3

ServoPress modules.

Since SCHMIDT does not support a direct driver link to a GE Fanuc

PLC, SCHMIDT engineers decided to review Kepware’s OPC server suite

(KEPServerEX) as well as Kepware’s OPC system bridging software package

(LinkMaster). KEPServerEX would provide the Ethernet connection to the

GE Fanuc PLC, and LinkMaster would bridge or “link” the OPC data between

c

anu the SCHMIDT OPC server and KEPServerEX. During the development stage

GE FLC

P of this project, the fully functioning 2-hour demo packages of KEPServerEX

and LinkMaster were downloaded from the Kepware website.

It is important to note that, during this process, SCHMIDT engineers did not

aster have a GE PLC in-house to test the data transfer. However, they did have

M

Link

Serv

erEX several Allen Bradley Micrologix PLCs on hand. Because KEPServerEX also

KEP

provides connectivity to Allen Bradley PLCs, the SCHMIDT team was able to

idt

SchSmerver install the KEPServerEX OPC server suite and the LinkMaster application on

OPC

the PRC4000 controller. They used Kepware’s Allen Bradley DF1 connectivity

to communicate directly to the PLC through a serial port. Next, LinkMaster

With its most recent introduction of (5) five ServoPress Models, certain

was quickly configured to acquire the data to/from the SCHMIDT OPC

challenges were presented to the SCHMIDT Technology control engineering

server, and map the integer and Boolean data directly to available Integers

staff in how to communicate electronic data between control systems.

and bits within the AB PLC. Due to the reliability and ease of use of the

The SCHMIDT Technology PRC4000 6-axis ServoPress controller is an “open in-house evaluation system, SCHMIDT engineers made the decision to use

source” logic and servo control unit that provides sequencing, calculating, Kepware’s solution at the customer site. Kepware’s OPC server provides a

process monitoring, SPC, and motion control, as well as a built-in HMI. This single consistent interface to a variety of industrial protocols. This made the

controller also contains an OPC server that is used as an interface to allow for transition from the in-house AB to the on-site GE connectivity fast and easy.

real-time exchanging of data with OPC clients. By using an OPC interface, any KEPServerEX with GE connectivity and the bridge application LinkMaster

word or Boolean information can be easily exchanged between the SCHMIDT were installed on the PRC4000 controller allowing a successful and seamless

controller and another PC-based control, HMI, or PLC. exchange of data through the on-board Ethernet port.

In a recent medical application, the PRC4000 ServoPress controller was This fast, easy, and reliable solution provided by LinkMaster prompted a

required to provide force data to a GE Fanuc PLC that was functioning as final configuration featuring the use of LinkMaster to transfer data and

a master controller on an assembly line. This application also required the status/control bits between three PRC4000 controllers and the GE PLC.

Kepware is the leading provider of communications software for automation with annual shipments exceeding 100,000 units.

You might also like

- Power BI Interview Questions For FreshersDocument13 pagesPower BI Interview Questions For Fresherschandrakant mehtreNo ratings yet

- S7 Password Crack PDFDocument47 pagesS7 Password Crack PDFNikhil Narang100% (1)

- Mitsubishi IQ F PLCDocument192 pagesMitsubishi IQ F PLCChi Nguyen NgocNo ratings yet

- Mathematics 9 Teaching Guide - Revised 2020Document382 pagesMathematics 9 Teaching Guide - Revised 2020Santy Enril Belardo Jr.100% (1)

- Universidad Tecnologica de DurangoDocument6 pagesUniversidad Tecnologica de DurangoVictor CenicerosNo ratings yet

- Instrument Connectivity - by RavindraDocument16 pagesInstrument Connectivity - by RavindraPinaki Chakraborty100% (1)

- Industrial Automation Communication ProtocolsDocument7 pagesIndustrial Automation Communication ProtocolsNeshvar DmitriNo ratings yet

- Garweeze Wurld AtlasDocument44 pagesGarweeze Wurld AtlasJosé Miguel Henarejos100% (1)

- Joints in Concrete ConstructionDocument4 pagesJoints in Concrete ConstructionRavi TejaNo ratings yet

- Siemens S7-300 - 400 CP-343-1 Ethernet Connection GuideDocument5 pagesSiemens S7-300 - 400 CP-343-1 Ethernet Connection GuideSandeep YadavNo ratings yet

- Sppa T3000Document6 pagesSppa T3000Dipti BhanjaNo ratings yet

- Tracing A Number: //CELLID// // LACDocument7 pagesTracing A Number: //CELLID// // LACMahamadou Ousseini BarkiréNo ratings yet

- IEC 60870-5 RTU SimulatorDocument4 pagesIEC 60870-5 RTU Simulatorjimmy004155525No ratings yet

- EPB Short Course 2010Document94 pagesEPB Short Course 2010sCoRPion_trNo ratings yet

- Conveyor Belt Motor Using Control Grafcet As Programming ToolDocument27 pagesConveyor Belt Motor Using Control Grafcet As Programming Toolcacung100% (3)

- Verilog AMS TutorialDocument29 pagesVerilog AMS TutorialSiva KrishnaNo ratings yet

- Report On PLC & ScadaDocument30 pagesReport On PLC & ScadaRajmal Menariya60% (10)

- How To Setup Your Lab - Step by Step InstructionsDocument10 pagesHow To Setup Your Lab - Step by Step InstructionsDhananjai SinghNo ratings yet

- Kepserverex: Opc Server Software - Maximize The Promise of OpcDocument50 pagesKepserverex: Opc Server Software - Maximize The Promise of OpcsukasnoNo ratings yet

- APSIDocument1 pageAPSIrt.polymer.afraNo ratings yet

- PLC Based Real Time Process Control Using Scada and Matlab: C.B.Kadu P.S.VikheDocument5 pagesPLC Based Real Time Process Control Using Scada and Matlab: C.B.Kadu P.S.VikheGoutam ChandraNo ratings yet

- D351528X012 OpenEnterprise v3 SCADA SystemDocument16 pagesD351528X012 OpenEnterprise v3 SCADA Systemadesa2013No ratings yet

- Rapid Prototyping Real-Time Simulation Platform For Digital Electronic Engine ControlDocument5 pagesRapid Prototyping Real-Time Simulation Platform For Digital Electronic Engine ControlTuan AnhNo ratings yet

- Rapid Control Prototyping Using MATLAB/Simulink and A DSP-based Motor ControllerDocument10 pagesRapid Control Prototyping Using MATLAB/Simulink and A DSP-based Motor ControllerSaid MerengueNo ratings yet

- Power Supplies: Boost Converter With Power Factor CorrectionDocument2 pagesPower Supplies: Boost Converter With Power Factor CorrectionhvworldcupNo ratings yet

- CX Lite Opc en Int01Document8 pagesCX Lite Opc en Int01fdfdfdfrtmNo ratings yet

- Silvaco EDA DemoDocument11 pagesSilvaco EDA DemobhataviNo ratings yet

- 05Document42 pages05tt_aljobory3911No ratings yet

- CV-Faisal Tahir Automation EngineerDocument2 pagesCV-Faisal Tahir Automation EngineerFaisal KhanNo ratings yet

- CloudEngine 6850 Series Data Center Switches Data SheetDocument13 pagesCloudEngine 6850 Series Data Center Switches Data SheetTrckNo ratings yet

- Deltav PK Controller: Powerful Standalone. Easily IntegratedDocument2 pagesDeltav PK Controller: Powerful Standalone. Easily IntegratedfantoniriskaNo ratings yet

- CV ResumeDocument2 pagesCV ResumeSachin KumarNo ratings yet

- Industrial Training Report: Sri.B.SharanappaDocument40 pagesIndustrial Training Report: Sri.B.SharanappaKollu dhruvaNo ratings yet

- Sy/Max PLC Upgrade Kit: Easy, Inexpensive and CompleteDocument2 pagesSy/Max PLC Upgrade Kit: Easy, Inexpensive and CompleteNour BenNo ratings yet

- ResumeDocument3 pagesResumeAdnan HayatNo ratings yet

- Projects and ExperienceDocument4 pagesProjects and Experienceapi-466523420No ratings yet

- Training Report: Bachelor of TechnologyDocument46 pagesTraining Report: Bachelor of TechnologyHelloprojectNo ratings yet

- Smart Production Line: Deogratias Mzurikwao, Zhijun PeiDocument4 pagesSmart Production Line: Deogratias Mzurikwao, Zhijun PeiqwertyukahNo ratings yet

- PLC To Hmi Communication ProtocolDocument7 pagesPLC To Hmi Communication Protocolganesh sNo ratings yet

- PLCDocument11 pagesPLCGeorge PaulNo ratings yet

- CV Mohamed AwadDocument7 pagesCV Mohamed AwadMohamed HassanNo ratings yet

- DDC Controller - Jci - XPMDocument15 pagesDDC Controller - Jci - XPMolingga92No ratings yet

- (Ixjil), ( W,: Advanced Ecu Software Development Method For Fuel Cell SystemsDocument8 pages(Ixjil), ( W,: Advanced Ecu Software Development Method For Fuel Cell SystemsJoshua sam jNo ratings yet

- CloudEngine 6881 Series Data Center Switches Data SheetDocument14 pagesCloudEngine 6881 Series Data Center Switches Data SheetEduardo SoberanisNo ratings yet

- Communication by PLC PDFDocument2 pagesCommunication by PLC PDFJoshuaNo ratings yet

- EkipLink BrochureDocument4 pagesEkipLink BrochureMarceloNo ratings yet

- Advantages and Disadvantages of PLCDocument3 pagesAdvantages and Disadvantages of PLCMayank ShahabadeeNo ratings yet

- CloudEngine 6881 Series Data Center Switches Data SheetDocument14 pagesCloudEngine 6881 Series Data Center Switches Data SheetwhocaresscribdNo ratings yet

- CloudEngine 6881 Series Data Center Switches Data SheetDocument14 pagesCloudEngine 6881 Series Data Center Switches Data SheetRiqo SetyoNo ratings yet

- Beckhoff PackML 5423 Full Document PDFDocument69 pagesBeckhoff PackML 5423 Full Document PDFVictor Duran MuñozNo ratings yet

- Huawei CloudEngine 6881 Switch DatasheetDocument14 pagesHuawei CloudEngine 6881 Switch DatasheetJoelinho CrushNo ratings yet

- AWC Series Handout UKDocument4 pagesAWC Series Handout UKelectrotehnicaNo ratings yet

- 32.051 - Kit1 RNDocument6 pages32.051 - Kit1 RNyoquins22No ratings yet

- Project PLCDocument12 pagesProject PLCmajumderabhijit85No ratings yet

- MVI56E-MNET MNETXT DatasheetDocument3 pagesMVI56E-MNET MNETXT DatasheetSeon CharlesNo ratings yet

- PLCBased Real Time Process Controlusing MATLABDocument6 pagesPLCBased Real Time Process Controlusing MATLABusmankhalid6854No ratings yet

- PLC 1Document9 pagesPLC 1عبدالسلام الهبوبNo ratings yet

- Nor-Par Online A/S: Scada/Hmi/Dcs Visualization Integration With Chemstations' SoftwareDocument26 pagesNor-Par Online A/S: Scada/Hmi/Dcs Visualization Integration With Chemstations' SoftwareMaulik JoshiNo ratings yet

- Bro ibaPDA-PLC-Xplorer v1.7 enDocument4 pagesBro ibaPDA-PLC-Xplorer v1.7 enhajhdjNo ratings yet

- CloudEngine 6881 Series Data Center Switches Data SheetDocument13 pagesCloudEngine 6881 Series Data Center Switches Data SheetDaniel DoyharzabalNo ratings yet

- Motion Control Solution For New PLC-based Standard Development Platform For VLT Instrument Control SystemsDocument12 pagesMotion Control Solution For New PLC-based Standard Development Platform For VLT Instrument Control SystemsMinh Nhut LuuNo ratings yet

- Data Transmission With Simulink On 6-Dof Platform On Can BusDocument9 pagesData Transmission With Simulink On 6-Dof Platform On Can BusRafik OassidiNo ratings yet

- Thesis Programmable Logic ControllerDocument5 pagesThesis Programmable Logic Controllerfjh1q92b100% (2)

- Programmable Logic Controller: From Wikipedia, The Free EncyclopediaDocument10 pagesProgrammable Logic Controller: From Wikipedia, The Free EncyclopediaAlda LopezNo ratings yet

- SEL-3505/SEL-3505-3 Real-Time Automation Controller: Major Features and BenefitsDocument16 pagesSEL-3505/SEL-3505-3 Real-Time Automation Controller: Major Features and BenefitsHectorNo ratings yet

- Mastering Siemens S7: A Comprehensive Guide to PLC ProgrammingFrom EverandMastering Siemens S7: A Comprehensive Guide to PLC ProgrammingNo ratings yet

- WAN TECHNOLOGY FRAME-RELAY: An Expert's Handbook of Navigating Frame Relay NetworksFrom EverandWAN TECHNOLOGY FRAME-RELAY: An Expert's Handbook of Navigating Frame Relay NetworksNo ratings yet

- Theory of Elasticity Question PaperDocument2 pagesTheory of Elasticity Question PaperDESHMUKH ANKIT PRAKASHRAONo ratings yet

- Simcenter STAR-CCM+ Combustion-Heat Transfer (Furnaces,Heaters,Kilns) – Application Spotlight PresentationDocument80 pagesSimcenter STAR-CCM+ Combustion-Heat Transfer (Furnaces,Heaters,Kilns) – Application Spotlight Presentationvivek shajiNo ratings yet

- Jurnal Kloramfenikol KLT Densito JejesDocument4 pagesJurnal Kloramfenikol KLT Densito JejesShin YosugaraNo ratings yet

- H013-E-EQP-STS-DE-I-E-024 Inteligent Mechanical Device Monitoring SystemDocument27 pagesH013-E-EQP-STS-DE-I-E-024 Inteligent Mechanical Device Monitoring SystemRushabh ShahNo ratings yet

- Class 11 - Physics - Mechanical Properties of FluidsDocument22 pagesClass 11 - Physics - Mechanical Properties of FluidsSha HNo ratings yet

- The Memory Hierarchy: CS 105 Tour of The Black Holes of ComputingDocument39 pagesThe Memory Hierarchy: CS 105 Tour of The Black Holes of ComputinggaurabNo ratings yet

- Ps 5Document1 pagePs 5Dawit B Melka100% (1)

- La Glaciacion Puna Durante El Wisconsin, Desglaciacion y Máximo Lacustre en La Transicion Wisconsin Holoceno y Refugios de Megafauna Postglaciales en La Puna y Desierto de AtacamaDocument30 pagesLa Glaciacion Puna Durante El Wisconsin, Desglaciacion y Máximo Lacustre en La Transicion Wisconsin Holoceno y Refugios de Megafauna Postglaciales en La Puna y Desierto de AtacamaGonzalo Galvez Cardenas100% (1)

- Sabbagh PDFDocument14 pagesSabbagh PDFHaYa RamadanNo ratings yet

- Ud923 Birrell PaperDocument38 pagesUd923 Birrell PaperBurtNo ratings yet

- Governing, Ignition System, Fire OrderDocument33 pagesGoverning, Ignition System, Fire OrderProf. Jignesh Sohaliya100% (1)

- ReadmeDocument6 pagesReadmeMayck VargasNo ratings yet

- WORKSHEET 2 Graph of Rational FunctionDocument9 pagesWORKSHEET 2 Graph of Rational Functiongina coNo ratings yet

- Table No. 1 Frequency Distribution of Entrance Examination ScoresDocument5 pagesTable No. 1 Frequency Distribution of Entrance Examination ScoresRose Ann PaduaNo ratings yet

- Anatomija Istezanja PDF FreeDocument2 pagesAnatomija Istezanja PDF FreeNikola JasikaNo ratings yet

- Adhikari 2018Document7 pagesAdhikari 2018Leylanie JassoNo ratings yet

- Best 50 Data Visualization MCQ Class 12 IP - CS-IP-Learning-HubDocument20 pagesBest 50 Data Visualization MCQ Class 12 IP - CS-IP-Learning-HubArif HussainNo ratings yet

- 4 Pillars of OOPS CONCEPTDocument9 pages4 Pillars of OOPS CONCEPTAjay Kumar ChimmaniNo ratings yet

- Peer-to-Peer File Sharing SystemDocument7 pagesPeer-to-Peer File Sharing SystemakanshaNo ratings yet

- Basic Linux InfoDocument156 pagesBasic Linux Inforkpolu100% (1)

- Summative Test 3 Q 3 Gen - Chem 2 SY 2022 2023 Copy - Edited Copy - Edited.edited Copy - EditedDocument12 pagesSummative Test 3 Q 3 Gen - Chem 2 SY 2022 2023 Copy - Edited Copy - Edited.edited Copy - EditedJV Subang PatindolNo ratings yet

- Electrospinning A Fascinating Fiber Fabrication TechniqueDocument23 pagesElectrospinning A Fascinating Fiber Fabrication TechniqueIvan TotoNo ratings yet

- Iit Ashram MaDocument10 pagesIit Ashram Mawasat59979No ratings yet