Professional Documents

Culture Documents

Power Operated Chucks: Closed Centre Standard Stroke

Uploaded by

Navdeep SinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Power Operated Chucks: Closed Centre Standard Stroke

Uploaded by

Navdeep SinghCopyright:

Available Formats

WC

Power Operated Chucks

Closed Centre Standard Stroke

Manufactured from high-grade alloy steel, all the sliding surfaces of these chucks are hardened and ground for

accurate running and long service. Lubrication facility provided on each base jaw, ensures better gripping force

output.

The Wedge design of the chuck has a self-locking feature, that prevents accidents and it does not loose its

gripping power even at cutting loads.

These compact and sturdy chucks offer powerful grip together with high repeatability. Their stable gripping

power even at higher speeds make them ideal for CNC applications.

The base jaw design is such that in the event of breakage it is retained within the jaw ways of the chuck.

The chuck is actuated by a rear mounted hydraulic or pneumatic cylinder via a draw bar passing through the

machine spindle bore. Since it is important that the cylinder should provide the correct operating force to match

the chuck, the supply of line pressure to the cylinder should be adjusted accordingly.

These chucks are offered both in two-jaw and three-jaw versions. Standard hard and soft jaws can be replaced

with special hard and soft jaws for chucking different components.

Power Operated Chucks

28

WC

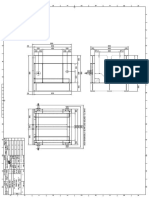

U

L

M

G pcd

O

S

ØZ

N

ØA

ØC

ØV

ØY

Y

T

ØE

P X

H

a

R

Q

K

D

0

15 0 15

F B

Fig. 1 * Fig. 2

Dimensions

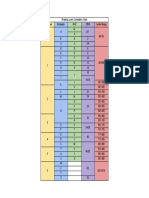

Model * 125WC 160WC 200WC 250WC 315WC 400WC 530WC 630WC 800WC 900WC 1000WC

A 125 169 210 254 304 400 530 635 800 900 1000

B 42 76 77 89 101 112 117.5 119 141 165 165

C (H6) 105 140 170 220 220 300 380 380 460 520 520

D 14 16 16 21 22 30 31 31 35 45 32

E (H7) 70 72 90 100 140 175 186 210.5 220 290 290

F 3 5 5 5 6 6 6 8 8 10 10

G 90 116 150 190 190 260 340 340 - - -

H 82.6 104.78 133.35 171.45 171.45 235 330.2 330.2 380 463.6 463.6

K 3 x M10 3 x M10 6 x M12 6 x M16 6 x M16 6 x M20 6 x M22 6 x M22 9 x M24 6 x M24 6 x M24

L 35 48 61 75 96 127.5 177 219 302 320 370

M 12 20 25 30 30 43 60 60 60 60 60

N (Max) 29.8 37 43 50.1 54 72 86.7 97 97.5 130 130.7

N (Min) 25.8 33 38.5 45.4 48.2 62 78.7 89 87 119.5 120.2

O (Max) 14.5 20.5 24.1 34 52 64.5 93.5 136.5 220 234 284

O (Min) 5 8.5 10.5 14 11.5 17 23.1 23.1 22.5 25 25

P - 40 40 36 50 57 54 60 65 75 75

Q 28 32 37 40 50 65 65 65 70 85 85

R (H6) 10 12 14 16 18 24 25 25 25 30 30

S (Max) 39 43 45 54 61 43 65.5 66 67 70 70

S (Min) 20 23 25 31 36 8 30.5 31 27 30 30

T - M16 M20 M20 M24 M24 M30 M30 M30 M30 M30

U 7 4 4 5 5 9 3 8 6 9 9

V - 32 40 50 55 52 60 60 60 65 65

W 3 x M6 3 x M6 6 x M6 6 x M8 6 x M8 6 x M10 3 x M12 6 x M12 - - -

X - 23 23 26 32 32 35 35 35 30 30

Y M20 x 1.5P 40 52 60 60 63 78 85 85 90 90

Z 50 78 90 100 105 135 156 175 180 250 250

a 6 x M4 3 x M5 3 x M6 3 x M6 3 x M8 3 x M8 3 x M6 3 x M6 3 x M8 3 x M8 3 x M8

b 58 56 75 80 124 155 171.4 190 200 270 270

c 2.5 2.5 3 3 3 6 6 6 4 4 3.5

d 6 x M6 6 x M10 6 x M12 6 x M12 6 x M14 6 x M20 6 x M20 6 x M20 6 x M20 6 x M24 6 x M24

e 1/16” x 90º 1/16” x 90º 1/16” x 90º 1/16” x 90º 1/16” x 90º 1/16” x 90º 3/32” x 90º 3/32” x 90º 3/32” x 90º 3/32” x 90º 3/32” x 90º

Specifications

Model 125WC 160WC 200WC 250WC 315WC 400WC 530WC 630WC 800WC 900WC 1000WC

Jaw stroke(dia) mm 7 9.2 9.2 10.6 11.6 18.5 16 16 21 21 21

Plunger stroke mm 14 20 20 23 25 35 35 35 40 40 40

Max draw bar pul kgf 900 1800 2500 3100 4000 5000/9000 5000/9000 5000/9000 10000 13500 13500

Max gripping force kgf 1500 5000 6800 9500 12500 18000/28000 18000/28000 18000/28000 32000 37500 37500

Max speed rpm 3000 3800 3100 2800 2300 2000 1500 1000 800 750 630

Weight without

Jaws (approx.) kg 5 13.0 20.5 30.0 50.0 105 163 315 560 750 950

Matching hydraulic HCHSA HCHSA HCHSA HCHSA HCHSA HCHSA HCHSA HCHSA HCHSA HCHSA HCHSA

cylinder 80 105 120 120 160 160/200 160/200 160/200 250 250 250

AIR/WC/2017

Note: Metric serrations on request for base jaw

The information set out in this catalogue is subject to any changes made since its publication. Further changes may be made without giving any notice.

29

You might also like

- Каталог FOTON BJ3251DLPJBDocument335 pagesКаталог FOTON BJ3251DLPJBГригорий КлименкоNo ratings yet

- M57tu Eu4 enDocument33 pagesM57tu Eu4 enIongornistu50% (2)

- Sk75ur-3e - Sk130ur-1e HanbookDocument134 pagesSk75ur-3e - Sk130ur-1e HanbookPHÁT NGUYỄN THẾ96% (51)

- 10 Easy Ways To Increase Engine PerformanceDocument9 pages10 Easy Ways To Increase Engine PerformanceRajes SaraNo ratings yet

- Module 11.2 EM2Document7 pagesModule 11.2 EM2BenNo ratings yet

- Abb Frame SizeDocument2 pagesAbb Frame Sizeप्राजक्ताएकनाथसाटमNo ratings yet

- Steel Road PlateDocument1 pageSteel Road Platejklo12No ratings yet

- Reverse Circulation Junk Basket: Instruction Manual 3100Document14 pagesReverse Circulation Junk Basket: Instruction Manual 3100walter acero orpesaNo ratings yet

- Types of Storage Tank and Their Design1Document30 pagesTypes of Storage Tank and Their Design1Raunak Jangid100% (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Sole PlatesDocument12 pagesSole Platesjonodo89No ratings yet

- 360 Degree Fire Fighting Protection SystemDocument20 pages360 Degree Fire Fighting Protection Systempramo_dass100% (5)

- Abb Frame SizeDocument2 pagesAbb Frame Sizeप्राजक्ताएकनाथसाटम100% (4)

- Viscosity LabDocument15 pagesViscosity LabM. Fatih Doğan50% (2)

- Open Centre Power ChucksDocument2 pagesOpen Centre Power ChucksSrinivas MurthyNo ratings yet

- TDL GB 0810 DimDocument1 pageTDL GB 0810 DimAlfredo LacompoenganNo ratings yet

- Krups Ea8105 Coffe MakerDocument34 pagesKrups Ea8105 Coffe MakerBranislav UhricNo ratings yet

- AL Series Pumps: Keyway Details X: Length Y: WidthDocument4 pagesAL Series Pumps: Keyway Details X: Length Y: WidthJuan PulidoNo ratings yet

- A2 Mybmrchuc: VDP-1507-G0011-D01-01Document1 pageA2 Mybmrchuc: VDP-1507-G0011-D01-01tênchỉđểgọiNo ratings yet

- Moment Connection-1Document37 pagesMoment Connection-1rohitnrgNo ratings yet

- Wall Mounted Ventilating Fans: FeaturesDocument1 pageWall Mounted Ventilating Fans: FeaturesttyNo ratings yet

- Wall Mounted Ventilating Fans: FeaturesDocument1 pageWall Mounted Ventilating Fans: FeaturesTYNo ratings yet

- Chinese 2Document1 pageChinese 2yamin.liNo ratings yet

- Ceiling Mounted Ventilating Fans: FeaturesDocument1 pageCeiling Mounted Ventilating Fans: FeaturesTYNo ratings yet

- SpoteDocument5 pagesSpoteEni BreguNo ratings yet

- MS Series Dimensions DetailsDocument1 pageMS Series Dimensions DetailsDesaiNo ratings yet

- HousingDocument1 pageHousingCaripahNo ratings yet

- Jet DiffusersDocument4 pagesJet DiffusersYapKJNo ratings yet

- Isarc - Tec PDFDocument20 pagesIsarc - Tec PDFPham Khoa100% (1)

- Data-Sheet Drum Brake RT - 200220 - enDocument1 pageData-Sheet Drum Brake RT - 200220 - enRFTNo ratings yet

- Catalogue Tsubaki ChainDocument2 pagesCatalogue Tsubaki ChainHien TốngNo ratings yet

- SGB 20152 05 00Document2 pagesSGB 20152 05 00phong viNo ratings yet

- UGH Drain PipeDocument2 pagesUGH Drain PipeQuoc LeHoaiNo ratings yet

- BL Bls Ma Msa MotorsDocument50 pagesBL Bls Ma Msa Motorsen262No ratings yet

- OK Series Vice - GerardiDocument1 pageOK Series Vice - Gerardi...No ratings yet

- Backup GB III.1 l.2 (Pengurangan Besi Siku 100.100.10 + Angkur)Document1 pageBackup GB III.1 l.2 (Pengurangan Besi Siku 100.100.10 + Angkur)Alif SyarifudinNo ratings yet

- Servo Actuator POS 100Document2 pagesServo Actuator POS 100haggNo ratings yet

- Yay Baskılı Frenler YBF Serisi: Spring Applied Brakes YBF SeriesDocument1 pageYay Baskılı Frenler YBF Serisi: Spring Applied Brakes YBF SeriesKamer YıldızNo ratings yet

- BZCT DimensionsDocument1 pageBZCT Dimensionshasan 31No ratings yet

- Keystone Gear Unit F422Document2 pagesKeystone Gear Unit F422Robi KeiNo ratings yet

- Avk Y-Strainer, PN 16 910/21: N50-300, A2 Plug and Fasteners 001Document3 pagesAvk Y-Strainer, PN 16 910/21: N50-300, A2 Plug and Fasteners 001AgieYogaswaraNo ratings yet

- Clutches Technical DataDocument7 pagesClutches Technical DataNicolás CarboniNo ratings yet

- Gs 51Document1 pageGs 51danielmacayNo ratings yet

- Section 2.0 - Specifications Square Drive Tools: W ENG-5525-056 AD) Page 6 of 40 Eng UsDocument3 pagesSection 2.0 - Specifications Square Drive Tools: W ENG-5525-056 AD) Page 6 of 40 Eng UsTiago FreireNo ratings yet

- Bushed Pin Type Flanged CouplingDocument1 pageBushed Pin Type Flanged CouplingabhiNo ratings yet

- 300p9010038e - BZS HydroDocument1 page300p9010038e - BZS HydroEng-Mohammed SalemNo ratings yet

- For Butterfly Valve Manual Gear Box: (Tecfly and Teclarge) - General Use: Mounts On The Full Range of Butterfly ValveDocument1 pageFor Butterfly Valve Manual Gear Box: (Tecfly and Teclarge) - General Use: Mounts On The Full Range of Butterfly Valvevicenteiii miderNo ratings yet

- Reading Level Comparison ChartDocument1 pageReading Level Comparison ChartGreg JamesonNo ratings yet

- Y Strainer 2Document1 pageY Strainer 2scarpredator5No ratings yet

- CNC Collet Chuck CatalagueDocument6 pagesCNC Collet Chuck CatalaguethingsneededforNo ratings yet

- Elk FJM 30 630 1Document1 pageElk FJM 30 630 1kajian19 juniNo ratings yet

- Section C-C Scale 1: 5: LADDER LENGTH: 4839 Mm. Finish: Hot Dip Galvanized Qty - 2 No'sDocument1 pageSection C-C Scale 1: 5: LADDER LENGTH: 4839 Mm. Finish: Hot Dip Galvanized Qty - 2 No'sNeil SoansNo ratings yet

- Rollers: With RingsDocument4 pagesRollers: With RingsVijay BhureNo ratings yet

- Sdja Manual StackerDocument17 pagesSdja Manual Stackergerardo cruz100% (1)

- Ass 2 - 602Document9 pagesAss 2 - 602farishaNo ratings yet

- HAWLE - Flap Valve CatalogueDocument1 pageHAWLE - Flap Valve Cataloguefasil tkNo ratings yet

- Vertical Hold Down Action Toggle Clamps 101 Series: ApplicationDocument1 pageVertical Hold Down Action Toggle Clamps 101 Series: ApplicationSaurabh NarkhedeNo ratings yet

- Kat Double Inlet Centrifugal Fans: DimensionsDocument2 pagesKat Double Inlet Centrifugal Fans: DimensionsPrestoneKNo ratings yet

- 12 Gas Spring End FittingsDocument4 pages12 Gas Spring End FittingsVikky HariNo ratings yet

- Praktikum CADDocument1 pagePraktikum CADAndika AdityaNo ratings yet

- Cadenas KMCDocument16 pagesCadenas KMCJhonny GuzmanNo ratings yet

- 004 Sheet No 1 Seprator AsslyDocument1 page004 Sheet No 1 Seprator AsslyMehul5070No ratings yet

- TB-55-106 - Cylinder Pin CollerDocument1 pageTB-55-106 - Cylinder Pin CollerAnuj BhardwajNo ratings yet

- Calplas CatalogueDocument59 pagesCalplas CatalogueMorris MorrisonNo ratings yet

- Series: Corrosion Resistant Centrifugal FanDocument8 pagesSeries: Corrosion Resistant Centrifugal Fansuan170No ratings yet

- Dimmension of Hoval Max-3Document1 pageDimmension of Hoval Max-3rachman hardianNo ratings yet

- YEZ-Conical Brake MotorDocument3 pagesYEZ-Conical Brake MotorMech MallNo ratings yet

- Elec QuasarDocument30 pagesElec QuasarIH MedranoNo ratings yet

- Effect of Soil Reinforcement On Shear Strength and Settlement of Cohesive-Frictional SoilDocument6 pagesEffect of Soil Reinforcement On Shear Strength and Settlement of Cohesive-Frictional SoilAbdikani SaidNo ratings yet

- IMEE-6 Maintenance PDFDocument8 pagesIMEE-6 Maintenance PDFHirakNo ratings yet

- Paper WTC2020 - ID 639 FINAL PDFDocument6 pagesPaper WTC2020 - ID 639 FINAL PDFTayo RobertsNo ratings yet

- Turbine Supervisory Instrumentation - ModDocument4 pagesTurbine Supervisory Instrumentation - ModJay Pritchett100% (1)

- Preschool Exercises PDFDocument69 pagesPreschool Exercises PDFSHAHBAZ KHALIDNo ratings yet

- Cutting Force Thrust ForceDocument1 pageCutting Force Thrust ForcepmagrawalNo ratings yet

- Tor 31Document1 pageTor 31carlitoNo ratings yet

- DEA 300/600 Weighbelt Feeders: For More Information, Please Contact Us at 1-800-558-0184 or Fax: 262-473-4384Document2 pagesDEA 300/600 Weighbelt Feeders: For More Information, Please Contact Us at 1-800-558-0184 or Fax: 262-473-4384shadi22No ratings yet

- Compare Honda CB Trigger Cbs Vs CB Hornet 160rDocument4 pagesCompare Honda CB Trigger Cbs Vs CB Hornet 160rAvk SanjeevanNo ratings yet

- E 384 - 99 Rtm4nc05oq - PDFDocument24 pagesE 384 - 99 Rtm4nc05oq - PDFJose SotoNo ratings yet

- SECTION 413-01 Instrument ClusterDocument6 pagesSECTION 413-01 Instrument Clustermail4281No ratings yet

- Problems Related To Pure BendingDocument15 pagesProblems Related To Pure BendingMuhammad Fazeel Khan0% (1)

- Omnidirectional Pig SignallerDocument2 pagesOmnidirectional Pig SignallermsjadejaNo ratings yet

- Topic Wise Analysis: Unit & Topic Name No of Questions Total Marks % WeightageDocument6 pagesTopic Wise Analysis: Unit & Topic Name No of Questions Total Marks % WeightageSagar TiwariNo ratings yet

- SA1Document6 pagesSA1Raj BisenNo ratings yet

- Sac3500 All-Terrain Crane 350 Tons Lifting Capacity: Quality Changes The WorldDocument27 pagesSac3500 All-Terrain Crane 350 Tons Lifting Capacity: Quality Changes The WorldRaza AidanNo ratings yet

- Last Modified:4/3/2014 Page 1 of 4Document4 pagesLast Modified:4/3/2014 Page 1 of 4Manjunath HrmNo ratings yet

- SMSS™: Single Monolithic Stationary SealDocument8 pagesSMSS™: Single Monolithic Stationary Sealnarayan rajuNo ratings yet

- Ebara DW VoxDocument2 pagesEbara DW Voxmarckalhi100% (1)

- ISO 2768 1 & 2 StandardDocument5 pagesISO 2768 1 & 2 StandardRafael CastroNo ratings yet

- Aluminum Duct machine-ACT1Document1 pageAluminum Duct machine-ACT1tubeformerNo ratings yet