Professional Documents

Culture Documents

Tute - 2

Uploaded by

sajeevanrs12160 ratings0% found this document useful (0 votes)

1 views1 pageOriginal Title

tute -2

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1 views1 pageTute - 2

Uploaded by

sajeevanrs1216Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

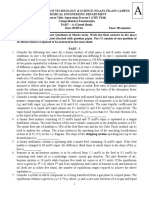

CP202- Separation Process Principles

Tutorial -2

01). 1000 kg/hr of a mixture containing 40 mole percent heptane and 60 mole percent ethyl

benzene is to be fractionated to a distillate containing 97 mole percent heptane and a residue

containing 99 mole percent ethyl benzene using a total condenser and feed at its saturated liquid

condition. The enthalpy-concentration data for the heptane-ethyl benzene at 1 atm pressure are as

follows:

xheptane 0 0.08 0.18 0.25 0.49 0.65 0.79 0.91 1.0

yheptane 0 0.28 0.43 0.51 0.73 0.83 0.90 0.96 1.0

Hl (kJ/kmol) x 10-3 24.3 24.1 23.2 22.8 22.05 21.75 21.7 21.6 21.4

Hv (kJ/kmol) x 10-3 61.2 59.6 58.5 58.1 56.5 55.2 54.4 53.8 53.3

Calculate the following:

a. Minimum reflux ratio

b. Minimum number of stages at total reflux

c. Number of stages at Ropt =1.5 * Rmin

d. Number of stages at reflux ratio of 2.5

e. Condenser heat duty

f. Reboiler heat duty

g. Composition of the stream leaves the top plate

h. Composition of the stream enters the top plate

You might also like

- CH138P WS 1.2 Geromo HALDocument11 pagesCH138P WS 1.2 Geromo HALLora Bell100% (1)

- Mass Transfer Tutorial: Distillation Example Problem 2: Mccabe-Thiele MethodDocument11 pagesMass Transfer Tutorial: Distillation Example Problem 2: Mccabe-Thiele MethodTapiwa KapondaNo ratings yet

- Equilibrium.2 ExampleDocument14 pagesEquilibrium.2 Examplekindenew50% (2)

- Distillation Aspen HysysDocument66 pagesDistillation Aspen HysysCzarina MasicatNo ratings yet

- Sample Problem 16 PDFDocument9 pagesSample Problem 16 PDFJoshua Arrojo100% (1)

- Problems in Mass TransferDocument3 pagesProblems in Mass TransferAngelica Joyce BenitoNo ratings yet

- DistillationDocument40 pagesDistillationEbook Download100% (2)

- #Separation Tut2Document1 page#Separation Tut2ibtihal esamNo ratings yet

- Assignment Problems Batch I (R.No. 102117001 To 102117011)Document7 pagesAssignment Problems Batch I (R.No. 102117001 To 102117011)Nishanth ChandranNo ratings yet

- Ponchon-Savarit MethodDocument5 pagesPonchon-Savarit MethodSamantha SwiftNo ratings yet

- Assignment MTO 2 - Unit 1, Unit 2 and Part of Unit 3Document4 pagesAssignment MTO 2 - Unit 1, Unit 2 and Part of Unit 3Shane MandarinNo ratings yet

- MTO AssignmentDocument4 pagesMTO AssignmentBishal LamichhaneNo ratings yet

- D D D D DDocument5 pagesD D D D Drazzee yuchengkoNo ratings yet

- HOMEWORK NO. 9 Che422 Ponchon Savarit MethodDocument2 pagesHOMEWORK NO. 9 Che422 Ponchon Savarit MethodMohamed ElbehlilNo ratings yet

- Che F244 1183 C 2015 2Document4 pagesChe F244 1183 C 2015 2shubhamNo ratings yet

- Activity 3 DistillationDocument2 pagesActivity 3 DistillationMaria Hazel AbayaNo ratings yet

- Che 246 - Mass Transfer and Unit Operations Tutorial-Chapter 2 (Distillation)Document5 pagesChe 246 - Mass Transfer and Unit Operations Tutorial-Chapter 2 (Distillation)fatien zakariaNo ratings yet

- Set 4Document3 pagesSet 4Ibtisam FarhaniNo ratings yet

- FALLSEM2015-16 CP3149 04-Aug-2015 RM01 Tutorial-1Document2 pagesFALLSEM2015-16 CP3149 04-Aug-2015 RM01 Tutorial-1ShashwatAgarwalNo ratings yet

- Individual Assignment 200412Document2 pagesIndividual Assignment 200412Zaidi ZakariaNo ratings yet

- Assignment 4 (7332)Document8 pagesAssignment 4 (7332)Musa KaleemNo ratings yet

- Chapter 11Document12 pagesChapter 11kumar_chemicalNo ratings yet

- Tutorial in MT 2Document3 pagesTutorial in MT 2mohanraj1990No ratings yet

- Separation Processes - I (CHE F244) Total Marks - 15 Due Date & Time: 01/07/2020, 5:00 PM AssignmentDocument4 pagesSeparation Processes - I (CHE F244) Total Marks - 15 Due Date & Time: 01/07/2020, 5:00 PM AssignmentElliot AldersonNo ratings yet

- Sheet 8 McCabe ThieleDocument2 pagesSheet 8 McCabe ThieleMohamed Fateem0% (1)

- CHE311 Practice Problems 2012Document9 pagesCHE311 Practice Problems 2012Albert HuynhNo ratings yet

- 2023 SPU260S Tutorial 3 QuestionsDocument6 pages2023 SPU260S Tutorial 3 QuestionsMABUKE NDINAINWI INNOCENTIANo ratings yet

- Recycle. Process EngineeringDocument20 pagesRecycle. Process EngineeringDarel WilliamsNo ratings yet

- Diploma Examination, May 2015: (Petroleum Refining Engineering) 110. DistillationDocument2 pagesDiploma Examination, May 2015: (Petroleum Refining Engineering) 110. DistillationgebremichaelNo ratings yet

- #Separation TUT1Document1 page#Separation TUT1ibtihal esamNo ratings yet

- Tutorial-Chapter 2 (June - Oct 2013)Document5 pagesTutorial-Chapter 2 (June - Oct 2013)paulineanakmawatNo ratings yet

- Distillation TutorialDocument17 pagesDistillation TutorialXin-YiWoon100% (1)

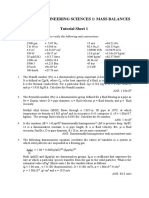

- Peme1025: Engineering Sciences 1: Mass Balances Tutorial Sheet 1Document4 pagesPeme1025: Engineering Sciences 1: Mass Balances Tutorial Sheet 1Kwasi NuamahNo ratings yet

- New Problems Chapter 26Document3 pagesNew Problems Chapter 26KaakmmNo ratings yet

- Chaper 4 Non-Reactive Multi Units ProcessDocument48 pagesChaper 4 Non-Reactive Multi Units Processجنات الغبيراءNo ratings yet

- Sheet 4 AbsorptionDocument4 pagesSheet 4 AbsorptionMohamed FateemNo ratings yet

- Simulation Lab Problem-1: Chem 2002 - Process Systems Analysis - 2016-2017Document5 pagesSimulation Lab Problem-1: Chem 2002 - Process Systems Analysis - 2016-2017ajali1957No ratings yet

- Excel (Comp Aps)Document5 pagesExcel (Comp Aps)api-3728602No ratings yet

- Additional Problems On Material Balances PDFDocument4 pagesAdditional Problems On Material Balances PDFEliot Kh0% (1)

- 3A Total Feed of 200 MolDocument2 pages3A Total Feed of 200 Molgebre0% (1)

- Separo Quiz No. 2Document1 pageSeparo Quiz No. 2Bench GuecoNo ratings yet

- Separation ProcessesDocument3 pagesSeparation ProcessesJoshua SolomonNo ratings yet

- Sample Problems On Gas AbsorptionDocument2 pagesSample Problems On Gas AbsorptionKevin Laganao67% (3)

- Distillation Exercises - Set 1Document3 pagesDistillation Exercises - Set 1Fred VoNo ratings yet

- MT IDocument5 pagesMT IParth Desai100% (1)

- Separation Processes IDocument3 pagesSeparation Processes IAmesh Chiyogami100% (1)

- HW 5 A 2017Document3 pagesHW 5 A 2017maxmNo ratings yet

- Assignment TestDocument1 pageAssignment TestChemical NITTNo ratings yet

- 1 - Prob Kinet 11-12 1-13 EnglishDocument4 pages1 - Prob Kinet 11-12 1-13 EnglishYenNo ratings yet

- Chemical Reaction Set4ansDocument4 pagesChemical Reaction Set4ansffffffNo ratings yet

- Ert 313/4 - Bioseparation Engineering Assignment 1 Date of Submission: 20 Jan 2011Document2 pagesErt 313/4 - Bioseparation Engineering Assignment 1 Date of Submission: 20 Jan 2011Muzammil IqbalNo ratings yet

- TutrealDocument2 pagesTutrealsaint deanNo ratings yet

- Volume of Batch ReactorDocument3 pagesVolume of Batch ReactorEeHuey ChooNo ratings yet

- Assignment 1Document3 pagesAssignment 1Gaurav Rathore0% (1)

- Tutorial DistillationDocument3 pagesTutorial DistillationManu Indivare Nundoolall100% (1)

- MT Assignment - Jan - 2023Document1 pageMT Assignment - Jan - 2023tenguria samriddh100% (1)

- A Modern Course in Statistical PhysicsFrom EverandA Modern Course in Statistical PhysicsRating: 3.5 out of 5 stars3.5/5 (2)

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- E20 025 Junker's CalorimeterDocument9 pagesE20 025 Junker's Calorimetersajeevanrs1216No ratings yet

- Applications of HPLCDocument2 pagesApplications of HPLCsajeevanrs1216No ratings yet

- Non Ideal Binary DistillationDocument23 pagesNon Ideal Binary Distillationsajeevanrs1216No ratings yet

- EM203 2024 E20 2ndLabSessionDocument1 pageEM203 2024 E20 2ndLabSessionsajeevanrs1216No ratings yet