Professional Documents

Culture Documents

SCOR MySQL

Uploaded by

Edgar EspinozaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SCOR MySQL

Uploaded by

Edgar EspinozaCopyright:

Available Formats

D2.

15

ER.8

P5.4

D1.15

Process Procedures

Installed Product Payment

Invoice

ER.2

Company

Establish & Communicate Return Plans

D2.14

Process Procedures Installed Product Payment

Invoice

Return Rules and Policies

D1.14 Company

ER.1

Process Procedures ER.1

SR1.2

Return Plans Source Return Requirements

DR1.1 P2.1

Return Plans Return Production

Requirements

D2.14

ER.4 P3.1

Return Plans

Deliver Return Requirements Installed Product

Install Product

D1.14

ER.7

P4.1 Product D2.15

Install Product

Return Plans Deliver Return Requirements D2.13 Installed Product

P4.2 Product Installed Product

ER.6

Customer

Return Plans D1.13 D1.15

Product Return Capabilities

DR1.1

ER.5

Return Plans

P5.3

D2.13

Product by Customer

D1.13

Return Resources

Receive & Verify

Product by Customer

P5.3

Supply Chain Performance

with Return Requirements

Balance Return Resources

Receive & Verify

Improvement Plan Advanced Ship Notice Product

EP.2 D2.11 D2.14 Product

Return Requirements D1.14

P5.1

Return Resources

P5.2

P5.2

EP.2

Planning Decision Policies Delivery Plans Return Process Capabilities

EP.1 P4.4 EP.4

Identify, Assess, & Aggregate Return Resources

Production Plans

Inventory Strategy

D2.12

P3.4 EP.3

Return Requirements

D1.12

P5.3

Sourcing Plans

Ship Product

Planning Data

Ship Product

P2.4 EP.1

Return Regulatory Requirements

Planning Decision Policies

ER.8

DR1.3

Return Process Workflow

Return Inventory Transfer Data

Definition and Policies

ER.7

DR1.4

Return Inventory Transfer Data

Return Transportation Guidelines,

P5.1

EP.5

Product Routings Policies & Agreements

ER.6

D2.11

Revised Capital Plan

EP.7

D1.11

Load Product & Generate Shipping Docs

Item Master

EP.5

Delivered End Items Shipping Documents

Load Product & Generate

EP.7 Return Inventory Targets Make/Buy Decision

Customer (Government, Customer, Carrier)

Shipping Export Parameters and

Identify, Prioritize, & Aggregate Return Requirements

Revised Aggregate Forecast and ER.4

Shipping Docs

Advanced Ship Notice

EP.6

Documentation

Projections Data About Return Capabilities

Outsource Plan ED.8 D2.13 Delivered End Items

EP.9 Shipping Export Parameters and

ER.3 Shipping Parameters and Documentation Customer

Shipping History

EP.6

Revised Business Assumptions Capacity

Documentation ED.8 Shipping History

EP.9 ED.6 ED.8 Shipping Parameters and ED.8

Projected Internal and External

Business Rules for Return Shipping Documents

Documentation Order Backlog

Processes ED.6

ER.1 P1.1

Return Regulatory Requirements Shipments

Regulatory Requirements

Business Rules for Return

ER.8 P1.1

Contractual Obligations D1.2

P Load, Shipping, Verify, and

Budget Constraints

Actual Sales History

Revised Aggregate Forecast and D2.2 Credit Information

SR1.5

D2.10

DR1.4

Projections

Actual Sales History Return Inventory Transfer

P

Data

DR1.1

Supply Chain Plans ER.4

Processes

Pack Product

Historical Return Rates

P1.4 DR1.1 Return Inventory Transfer

Sourcing Plans

D1.10

Transfer Defective Product

Data

Historical Return Rates

P2.4 EP.3 Return Inventory for Transfer P5.2

Production Plans Planning Data ER.4 Return Inventory Transfer

Pack Product

ER.1

EP.9

EP.8

Finished Product Release

P3.4

Data

EP.3

Production Plans Sourcing Plans

S1.1

Inventory Availability

Planning Data

P3.4 P2.4

Scheduled Receipts

Defective Products

EP.5

Historical Return Rates

S1.2

Revised Business Assumptions

SR1.3 EP.7 Returned Defective Product

Item Master DR1.3 Return Inventory Transfer

Data

S2.1

Inventory Availability

D2.9

Defective Products

M2.2

S2.2

Finished Product Release

Pick Product

M2.6

M1.6

S1.1

S1.4

D1.8

D1.9

Inventory Availability

Receive Product from Source

S2.4

WIP Location Rules Existing

EM.6 Inventory Availability Inventory Data

Pick Product

Inventory Availability D1.8 ED.4

DR1.3

or Make

M2.1 Inventory

Scheduled Deliveries

Receive Defective Product (includes verify)

D1.7 Availability

D1.9 Receipt Data

ER.3 Receipt Discrepancy Notification

Receipt Data P, S, ER

D2.8

Receive Product from Source or

ER.4

Return Inventory Transfer Data

D2.7

Return Transportation Guidelines, P5.2

Policies & Agreements

Authorization to Return to Service

Select Carriers & Rate

Delivery Plans ER.6

D2.3 Returned Defective Product

Return Regulatory Requirements

P4.4

Establish Delivery Plans

Delivery Plans DR1.4

Make

Shipments

P5.2

Shipment Routes

D1.7

ER.8

Delivery Plans M1.5 D2.6 Returned Defective Product Return Inventory Transfer Data

ER.4

Authorization to Scrap

Select Carriers & Rate

D1.9

Delivery Plans SR1.5

Production Schedule

D1.3

Scheduled Deliveries

Delivery Plans M2.5 Return Schedule Instructions

Delivery Plans

Shipments

DR1.2

P

P5.1

P1.2 Scheduled Deliveries

Delivery Plans

Delivery Plans

P3.1

Delivery Plans P2.1

Shipment Routes

D1.6

Rated Carrier Data

DR1.2

SR1.2

SR1.2

M1.1

D2.6

Route Shipments

Schedule Defective Return

Company Scheduled Deliveries

P4.3

Resources withDelivery

Delivery Requirements Load Information P

P4.1 D2.5 Shipment Routes

Balance Delivery

Return Schedule Instructions

Requirements

Delivery Resources and Routing Guide Valid Returns Request

Receipt

D2.7

D1.6

Capabilities Company DR1.1 SR1.3

Route Shipments

P4.2 (Carrier) Routing Guide Return Schedule Instructions

Planning Decision Policies Shipment Routes DR1.3

EP.1 (Carrier) Rated Carrier Data D1.7

D1.5

D2.5

Load Information

Build Loads

D1.5 Consolidated Orders Load Information

P4.2

Identify, Assess, & Aggregate Delivery Resources

Year-to-year for Like SKU/ Planning Data D2.4 D2.4 Business Rules for Return

P4.1

DR1.1

Subclass EP.3

Company Sourcing Plans Processes Manage Integrated Supply

ER.1

Authorize Defective Product Return

Product/Category Lifecycle

D1.5

P2.4 Plan and Build Loads Chain Inventory Information

Company Production Plans Product Return Capabilities EP.4

Information

P3.4 SR1.4 P5.4 Historical Return Rates

Stock-out History

Build Loads

Daily Shipment Volume Return Plans

Company Production Plans Load Information P5.1

Delivery Resources D1.4 P5.4

Promotion/Event Plans P3.4 SR1.1 Defective Product Return

Deliver Return Requirements and Capabilities

Company P4.3 Defective Product Disposition Authorization Response

Identify, Prioritize, & AggregateDelivery Requirements

Load Information

D2.4

P5.4

Consolidate Orders

Actual Shrink SR1.3

Inventory Availability/Delivery P4.2 Request

Company SR1.3 Ship-to Data

DC/Vendor Transit Time Date Delivery Date Consolidated Orders Defective Product Return SR1.4

D1.3

Company Inventory Availability/Delivery D2.3 D2.5 Authorization Request

DC/Vendor Lead Time SR1.3 Valid Returns Request

Date DR1.2

Company D2.3 Manage Integrated Supply Chain

EOQ/QSQ Finish Goods Inventory Target Inventory Information

D1.4

Consolidate Orders

Company Levels EP.4

Markdown Plans ED.4

Delivery Requirements

Company Delivery Date Daily Shipment Volume

P4.3

Merchandise Category/ D1.3 D1.5

D2.3

Classification Customer Order

Company ED.2

Reserve Resources & Determine Delivery Date

Order Backlog

Available to promise date

D1.3 Production Schedule

Order Backlog M

M2.1 Inventory Status

D2.3 P, S, M,

Service Levels Sourcing Plans

P2.4 D

EP.1 Order Signal Shipments

D1.3

Planning Data Inventory Availability P2.1 P1.1

Reserve inventory & Determine Delivery

EP.3 S2.4 Order Signal

Item Master Inventory Availability Order Backlog

Booked Order

EP.7 P3.1 S1.4 P1.1

D2.2

Product Routings Delivery Plans Order Backlog Sourcing Plans Order Backlog

EP.7 P4.4 P4.1 P2.4 P4.1

Supply Chain Plans Inventory Availability/Delivery Inventory Availability/Delivery

Production Plans Production Plans

P1.4 Date Date

P3.4 P4.2 P3.4

Date

Deliver Return Requirements P4.2

Replenishment Signal Delivery Plans Replenishment Signal

P5.4

S2.1 P4.4 S1.1

Delivery Date Inventory Availability Replenishment Signal

D2.4 M1.2 S1.4

Validated Order Replenishment Signal

D1.2 S2.4

Production Schedule Delivery Date

Optional Payment M1.1 D1.4

D2.2

Company

P3.4

D2.3 Production Plans

Production Plans M1.1 Booked Order Location of Customers

D1.2

Production Plans D2.3 ED.7

Establish Production Plans

Receive, Configure, Enter & Validate Order

EM.1

M1.5 Purchase History Actual Sales History

Production Plans Production Plans ED.3 P5.1

M2.1 Booked Order

EM.5

Production Plans Validated Order

Order Quote (Customer) ED.3

Production Plans

Receive, Enter & Validate Order

M2.5 D1.3

EM.2 D1.2 Credit History

Production Plans Customer Order Customer Order

Configuration Rules

Production Plans

ED.3 ED.2

D1.3 P1.2 ED.1 Customer

Production Plans Shipping Preferences Contract Status

Production Plans Contract Terms

P2.1 ED.3 Deliver Contract Terms ED.3

Customer

P5.2

Production Plans Customer Address Data Customer Credit History

Production Plans Order Rules

P4.2 ED.3 Customer Quote ED.3

ED.1

P5.1

Production Plans Contract Status D1.1 Customer Address Data

ED.3 Order Rules ED.3

ED.1 Shipping Preferences

Customer Order Size, Weight,

and Freight Class Customer Replenish Signal ED.3

ED.6 Customer Customer Order Size, Weight,

Location of Customers and Freight Class

ED.6

ED.7

Optional Payment

P3.3

Production Requirements

Actual Sales History

P5.1 Company

Balance Production

Return Production Requirements

Resources with

P3.1

Production Resources

P3.2

D1.1

D2.1

Planning Decision Policies

Process Inquiry &

Process Inquiry &

EP.1 Order Quote (Customer)

Customer Inquiry D2.2 Customer Inquiry Customer Quote

Quote

Quote

Customer Order Quote (Customer) Customer D1.2

Customer

Equipment and Facilities

P3.2

Replacement and Disposition Plans

EM.5

Planning Data

P3.1

Identify, Assess, & Aggregate

Identify, Prioritize, & Aggregate Production

EP.3 Planning Data

Production Resources

Bill of Materials EP.3

EP.7

M2.6

Product to Deliver

Production Schedule

Release Finished

Item Master M1.1 Production Resources Information Feedback

EP.7 Inventory Availability P3.3 M2.1

Product Routings Finished Product Release

Requirements

Return Production M1.2

EP.7 Production Schedule D2.9

Supply Chain Plans Requirements

P3.3 M2.1

P1.4 Inventory Availability

Delivery Plans M2.2

M1.6

Product to Deliver

P4.4

Release Finished

Sourcing Plans Information Feedback

Return Production Requirements P2.4 M1.1

P5.4

M2.5

Finished Product Release

Order Signal Delivery Plans

Stage Product

D1.8

D2.3 P4.4 Information Feedback

Production Plans M2.1

P3.4

M1.5

Stage Product Information Feedback

Delivery Plans

M1.1

M2.4

P4.4

Information Feedback

Package

M2.1

Sourcing Plans

D2.3

P2.4

Sourcing Plans

DR1.4

M1.4

Sourcing Plans

Information Feedback

Package

ES.3

M2.3

Produce and Test

Sourcing Plans M1.1

ES.4 Information Feedback

Sourcing Plans

P1.2 M2.1

Sourcing Plans

Establish Sourcing Plans

P3.2

Sourcing Plans

M1.3

Produce and

P4.2

Sourcing Plans Information Feedback

Test

P5.1 Product Location Information M1.1

M2.2

Sourcing Plans EM.6

P5.2 Information Feedback

Sourcing Plans M2.1

S1.1 Production Schedule

Sourcing Plans WIP Handling Rules, Move M2.3

Information and Methods Product Location Information

M1.2

S1.1 EM.4 Production Schedule

Sourcing Plans EM.6

WIP Location Rules P3.2 Information Feedback

S2.1

EM.6 WIP Location Rules M1.1

Issue Product

Product Sources Inventory Availability

P2.3 Production Schedule P3.2 EM.6 Inventory Availability

Sourcing Plans M2.1 Production Schedule P3.2

Replenishment Signal

M1.1

Issue Product

D1.3 Inventory Availability Replenishment Signal

S1.1

S1.4 Inventory Availability S1.1

Inventory Availability Replenishment Signal

S1.4 Replenishment Signal

S2.4 S1.4

Inventory Availability S1.4

Replenishment Signal

S2.4 Replenishment Signal

S2.1 WIP Handling Rules, Move

P2.3

S2.1

Resources with Product

Product Requirements Replenishment Signal Information and Methods Replenishment Signal

P2.1 EM.4

Balance Product

S2.4

Requirements

S2.4

Product Sources Inventory Availability Inventory Availability

P2.2 D2.9 D1.3

Planning Decision Policies

EP.1

Scheduled Receipts Production Schedule

Preventative Maintenance and

M2.1

D2.9

M1.1

S2.1 Calibration Schedule

Production Schedule EM.5

Information Feedback

S1.1 P3.2 Information Feedback

Production Schedule M1.2 Production Schedule

Production Plans

Schedule Production Activities

Schedule Production Activities

Product Inventory Target Levels P3.4 S1.1 Information Feedback D1.8

Order Signal

P2.2

P2.1

ES.4 Production Schedule M1.3 Production Schedule

Identify, Assess, & Aggregate

D2.3 Information Feedback Information Feedback

Identify, Prioritize, & Aggregate Product Requirements

Product On Order S2.1 M1.2

Planning Data M2.6 M1.4 Production Schedule

Product Resources

S1.1 Information Feedback Production Schedule

EP.3 Information Feedback P3.2

Inventory Availability Product Sources M2.5 D2.3 Production Schedule

Product Routings S1.4 M1.5

P2.3 Information Feedback Production Schedule Information Feedback S1.1

EP.7 Product On Order M2.2 Production Schedule

M2.4 M1.6

Item Master S2.1 Production Plans S2.1

Information Feedback Production Schedule

EP.7 P3.4

Planning Data M2.3 S1.1

Scheduled Receipts D1.3

Product Equipment and Facilities

EP.3

Scheduled Receipts

Bill of Materials Schedules and Plans S1.1

Requirements EM.5 Scheduled Receipts

EP.7 P2.3 EM.5

Calibration Schedule S2.1

Information Feedback Preventative Maintenance and Equipment and Facilities

Supply Chain Plans M2.2 Schedules and Plans

P1.4 EM.5

Production Plans

P3.4

Delivery Plans Return Inventory Availability

SR1.5

Return Defective Product

P4.4 ER.4

S1.5

Authorize Supplier

Payment terms Scheduled Defective Product Returned Defective Product

Source Return Requirements

P5.4 ES.9 Return DR1.3

SR1.4

Payment

Transferred Product Returned Defective Product Shipping Documents

S1.4 SR1.4 (Government, Customer, Carrier)

Load, Shipping, Verify, and Credit

Information

D1.11

Inventory Availability

S1.4

D1.8

Replenishment Signal Existing Inventory Data Credit/Exchange Options

SR1.4

D1.3 ES.4 SR1.3

WIP Inventory Location Inventory Availability

Schedule Defective Product

Supply Chain Plans Ship-to Data

P1.4

Transfer Product

P3.1 EM.6 ES.4 DR1.1

Establish & Communicate

Supply Chain Plans Product Inventory Location Inventory Availability Validated Return Material

Supply-Chain Plans

ES.4 Returned Defective Product

Shipment

P4.1 M1.2 Authorization

Replenishment Signal Inventory Availability SR1.3 SR1.5

Supply Chain Plans M1.2 M2.2 Returned Defective Product

Replenishment Signal Scheduled Defective Product

P5.1 Inventory Availability SR1.3

M2.2 Return

Supply Chain Plans Receipt Verification P2.2 SR1.5

Plan and Build Loads Information

Customer S1.3 Transferred Product D1.5

Supply Chain Plans Finished Goods Inventory S1.5 Return Inventory Availability

P2.1 Location Inventory Availability ER.4

ED.4 D1.3

Validated Return Material

SR1.3

S1.3

Request Defective Product Return Authorization

Supply Chain Resources Authorization

P1.3

with Supply-Chain Requirements

Balance Supply-Chain Resources

Receipt Verification SR1.4

P1.2

S1.4

Verify Product

Ship-to Data

Supply Chain Requirements Receipt Verification Receipt Verification SR1.4

P1.1 S1.2 ES.2

Return Schedule Instructions Credit/Exchange Options

Receipt Verification SR1.4

ES.1 DR1.2

Inventory Strategy

EP.4 Returned Defective Product Defective Product Disposition

SR1.2 Request

Supply Chain Performance Defective Product Return DR1.1

Improvement Plan Authorization Response Returned Defective Product

EP.2 DR1.1

Receipt Verification SR1.4

S1.2

S1.3 Historical Return Rates

Receipt Verification

P5.1

Scheduled Receipts ES.8

Receive Product

S1.1 Defective Product Return

Receipt Verification

Defective Products Authorization Request

P1.2

ES.6 DR1.1

Revised Capital Plan DR1.4

Product Receipt Verification

EP.5

Supplier ES.2

Identify, Assess, & Aggregate Supply-Chain Resources

Revised Capital Plan

Receipt Verification

EP.6

Revised Aggregate Forecast and ED.8

P1.1

Outsource Plan

SR1.2

Projections Receipt Verification Authorization to Return to

EP.6

Disposition Defective Product

EP.9

Identify, Prioritize, & Aggregate Supply-Chain

Regulatory Requirements ES.1 Service

ED.4

Revised Business Assumptions EP.8

Returned Defective Product Return Product Location

EP.9 Sourcing Plans

P2.4 SR1.1 ED.4

Shipments Supply Chain Replenishment Signal

S1.1

D1.11 Production Plans Resources Return Plans Returned Defective Product

D1.3

Requirements

P1.3 P5.4

Shipments Supply Chain Requirements P3.4 SR1.3

Return Inventory Transfer Data Return Inventory Availability

D1.3 P1.3 Make/Buy Decision DR1.4 D1.8

Order Backlog EP.5 Supplier Performance Procurement Signal

Schedule Product Deliveries

D1.3 Authorization to Scrap

Outsource Plan ES.2 Supplier D1.8

Planning Data EP.5 Logistics Selection Scheduled Receipts

EP.3

Planning Data ES.6 S1.2

Revised Business Assumptions EP.3 Production Schedule Product On Order

EP.5 M1.1 P2.2

Order Backlog Inventory Replenishment Signal

SR1.1

Scheduled Receipts

D1.11 Customer M1.2 Manage Regulatory Return Policy

Product Condition

Identify Defective

M2.1 ER.8

Delivery Plans Production Schedule

M2.1 Scheduled Receipts

P4.4 Warranty Data Supply Chain Resources

M1.1 ER.8

Replenishment Signal Product On Order P1.3

M2.2 Business Rules for Return

ES.9

Sourcing Plans Processes

Scheduled Receipts ER.1

P2.4 D1.8

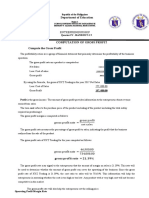

You might also like

- IAQG SCMH-3.4.3-FOD-Risk-Assessment-FOD-Prevention-Program-Assessment-Dated-17APR2018Document4 pagesIAQG SCMH-3.4.3-FOD-Risk-Assessment-FOD-Prevention-Program-Assessment-Dated-17APR2018LiherNo ratings yet

- Curb Your EnthusiasmDocument1 pageCurb Your EnthusiasmL Gecko100% (1)

- Bobcat - 325 - 328Document1 pageBobcat - 325 - 328Laboratorio IP50% (2)

- ISO 9000 Internal Audit Checklist Clause WiseDocument26 pagesISO 9000 Internal Audit Checklist Clause Wisesajid waqas100% (1)

- Peer-e-Kamil - Umera AhmedDocument550 pagesPeer-e-Kamil - Umera AhmedsaraNo ratings yet

- Cost Control Techniques PDFDocument3 pagesCost Control Techniques PDFHosamMohamedNo ratings yet

- Quetta MapDocument1 pageQuetta MapSal AtNo ratings yet

- Accounting For Special Transactions Part 3 Course AssessmentDocument31 pagesAccounting For Special Transactions Part 3 Course AssessmentRAIN ALCANTARA ABUGANNo ratings yet

- 3512B & 3516B Engines With Premium Electrical System Wiring Harness For Marine PropulsionDocument2 pages3512B & 3516B Engines With Premium Electrical System Wiring Harness For Marine PropulsionMehdi Chakroune100% (2)

- GAAP Graded Questions 2022Document377 pagesGAAP Graded Questions 2022Mika-eel100% (4)

- Chart - Poster - PMBOK 6th Ed Data Flow DiagramDocument1 pageChart - Poster - PMBOK 6th Ed Data Flow DiagramPatelVKNo ratings yet

- How Cure Fit Does Marketing: Business Case-StudyDocument11 pagesHow Cure Fit Does Marketing: Business Case-StudyACNo ratings yet

- Samsung sm-j110h PDFDocument73 pagesSamsung sm-j110h PDFHenry Tamayo33% (3)

- Mar 11 Tax CasesDocument13 pagesMar 11 Tax CasesMeg PalerNo ratings yet

- SCHEMA HYDRAULIQUE TN122 159P325420 Ind B HA41PX GEMINI PDFDocument3 pagesSCHEMA HYDRAULIQUE TN122 159P325420 Ind B HA41PX GEMINI PDFHanin Bouziane100% (1)

- Quarter 4 Entrep Handout 2 With WW PTDocument5 pagesQuarter 4 Entrep Handout 2 With WW PTRodalyn Pang-ot100% (1)

- Ethernet Routing Switch 2500 Series Quick Install Guide: Powering UpDocument1 pageEthernet Routing Switch 2500 Series Quick Install Guide: Powering UpTárcio LunaNo ratings yet

- Material Point Method: Theory and Applica3onsDocument35 pagesMaterial Point Method: Theory and Applica3onsyin hoe ongNo ratings yet

- 2006 07 Dsrposter.5cf575ce43e3fDocument1 page2006 07 Dsrposter.5cf575ce43e3fSriram KumaranNo ratings yet

- Sample Maintenance Schedule-A4Document1 pageSample Maintenance Schedule-A4premquilonNo ratings yet

- Convenciones: ColegioDocument1 pageConvenciones: ColegioCristina MedinaNo ratings yet

- Revisions: Research in MotionDocument2 pagesRevisions: Research in MotionIntel_Pentium_INo ratings yet

- Revisions: Research in MotionDocument2 pagesRevisions: Research in MotionAshardgsm kroyaNo ratings yet

- POP 46302 009 - Rev2Document2 pagesPOP 46302 009 - Rev2Hari AshdikaNo ratings yet

- A11-L1d - Lower Ground Level-Part DDocument1 pageA11-L1d - Lower Ground Level-Part Dconsultnadeem70No ratings yet

- SCALE 1: 400: Denah Rencana Ac Lantai 4 Perancangan Bangunan Mixed Use (Shopping Mall, Hotel, Office)Document1 pageSCALE 1: 400: Denah Rencana Ac Lantai 4 Perancangan Bangunan Mixed Use (Shopping Mall, Hotel, Office)najiha salsabilaNo ratings yet

- SCALE 1: 400: Denah Rencana Ac Lantai 3 Perancangan Bangunan Mixed Use (Shopping Mall, Hotel, Office)Document1 pageSCALE 1: 400: Denah Rencana Ac Lantai 3 Perancangan Bangunan Mixed Use (Shopping Mall, Hotel, Office)najiha salsabilaNo ratings yet

- Fire Window Form 17-D Annual Inspection, Tests, and MaintenanceDocument2 pagesFire Window Form 17-D Annual Inspection, Tests, and MaintenanceMYSTerBNo ratings yet

- Derivacion 2Document3 pagesDerivacion 2Nicoll YarpasNo ratings yet

- A13-L1b - Lower Ground - Part B (Finish Plan)Document1 pageA13-L1b - Lower Ground - Part B (Finish Plan)consultnadeem70No ratings yet

- 159P328750 Ind A - Gemini 2 Et 2bis Schema HydrauliqueDocument3 pages159P328750 Ind A - Gemini 2 Et 2bis Schema HydrauliqueDaniel Peña VergaraNo ratings yet

- Corte Eje 2-2: Especificaciones TécnicasDocument1 pageCorte Eje 2-2: Especificaciones TécnicasRonaldo TorrejonNo ratings yet

- CorellaDocument2 pagesCorellamikey434No ratings yet

- Av. 450 Años-Model5 PDFDocument1 pageAv. 450 Años-Model5 PDFPablo Helio Mieles PoloNo ratings yet

- Kai Tak 6 Bed Room For VMUDocument2 pagesKai Tak 6 Bed Room For VMUJason IeongNo ratings yet

- TDS - D37D - Extension FR FDR RH LHDocument1 pageTDS - D37D - Extension FR FDR RH LHYuliantoNo ratings yet

- 2.00 PLANIMETRIA GGG-ModelDocument1 page2.00 PLANIMETRIA GGG-ModelROSAHNo ratings yet

- Juventus Inno MediumDocument2 pagesJuventus Inno MediumIlaria LopezNo ratings yet

- Inverter Air/Water Heat Pump Chillers With Axial Fans User'S and Installer'S Manuals Pre Series ModelsDocument56 pagesInverter Air/Water Heat Pump Chillers With Axial Fans User'S and Installer'S Manuals Pre Series ModelsDirt FilterNo ratings yet

- Terminal Second FloorDocument1 pageTerminal Second FloorRaphael AustriaNo ratings yet

- Samsung SM j110hDocument73 pagesSamsung SM j110hPersona xNo ratings yet

- P 6Document1 pageP 6REA CONSTRUCTIONNo ratings yet

- Ramp For Temporary Access Layout Plan Enoc SD)Document1 pageRamp For Temporary Access Layout Plan Enoc SD)zubair khanNo ratings yet

- H021011001P00Document1 pageH021011001P00MohammadNo ratings yet

- Limit EsDocument8 pagesLimit Esenmanuel sanchezNo ratings yet

- A11-00a - Ground Level - Part ADocument1 pageA11-00a - Ground Level - Part Aconsultnadeem70No ratings yet

- A11-L1c - Lower Ground Level-Part CDocument1 pageA11-L1c - Lower Ground Level-Part Cconsultnadeem70No ratings yet

- A13-L1d - Lower Ground - Part D (Finish Plan)Document1 pageA13-L1d - Lower Ground - Part D (Finish Plan)consultnadeem70No ratings yet

- A11-00b - Ground Level - Part BDocument1 pageA11-00b - Ground Level - Part Bconsultnadeem70No ratings yet

- Existing Land Us E Map Planning District: 9Document5 pagesExisting Land Us E Map Planning District: 9gopal shindeNo ratings yet

- Nai NaiDocument7 pagesNai Nair8ygcqrpr9No ratings yet

- PR-06 CommercialDocument1 pagePR-06 CommercialMoiz Aijaz MemonNo ratings yet

- S-Curve For Jayapura (3.20) RevDocument1 pageS-Curve For Jayapura (3.20) RevFauzan TriandiNo ratings yet

- Formato IIa (L-E 5.1)Document1 pageFormato IIa (L-E 5.1)Erika AnguloNo ratings yet

- Formato Ii - A Hoja de Trabajo de Requisición: Req./OcDocument1 pageFormato Ii - A Hoja de Trabajo de Requisición: Req./Ocarmando0212-1No ratings yet

- Pablo Fernando Ramirez TesissDocument1 pagePablo Fernando Ramirez TesissAngel MedinaNo ratings yet

- Revisions: Research in MotionDocument2 pagesRevisions: Research in Motionzulkafli othmanNo ratings yet

- Pop 44860 106 - Rev1Document2 pagesPop 44860 106 - Rev1Muhammad NURMANNo ratings yet

- FM - 2 - PC - 21636 - 0 - BB Skb02 Hub Sukabumi To Skb021 - Page 1Document1 pageFM - 2 - PC - 21636 - 0 - BB Skb02 Hub Sukabumi To Skb021 - Page 1Tauco integraNo ratings yet

- MD-RA-1.1: Issued For ConstructionDocument1 pageMD-RA-1.1: Issued For ConstructionEmmanuel BahenaNo ratings yet

- MD-RA-1.1: Issued For ConstructionDocument1 pageMD-RA-1.1: Issued For ConstructionEmmanuel BahenaNo ratings yet

- Yuyo Verde - Didáctico - (5365)Document2 pagesYuyo Verde - Didáctico - (5365)Santiago PiñeyroNo ratings yet

- Ecu Toyota Rav4Document4 pagesEcu Toyota Rav4Enrico BoglioliNo ratings yet

- 230620-Mesin Olah J2-Jalur Ladder & Cable TrayDocument1 page230620-Mesin Olah J2-Jalur Ladder & Cable TrayWulan NursyifaNo ratings yet

- Akrapovic ABE RSV Mille 200-2004Document2 pagesAkrapovic ABE RSV Mille 200-2004Max MustermannNo ratings yet

- Cancontrol List 2022-07-27 enDocument115 pagesCancontrol List 2022-07-27 enAndrés Felipe Matamala QuezadaNo ratings yet

- Terex Genie Rl4000 Parts ManualDocument5 pagesTerex Genie Rl4000 Parts Manualwesley100% (30)

- 5f-Management and OperationsDocument17 pages5f-Management and OperationsMak PussNo ratings yet

- United The Business of A Better WorldDocument39 pagesUnited The Business of A Better WorldAndrés Barquero RodríguezNo ratings yet

- Dseclzg628T: Birla Institute of Technology & Science, Pilani Second Semester 2021-22 DissertationDocument5 pagesDseclzg628T: Birla Institute of Technology & Science, Pilani Second Semester 2021-22 DissertationnayarzNo ratings yet

- Ankita Knit Wear Ltd.Document209 pagesAnkita Knit Wear Ltd.VikasNo ratings yet

- Purple and Cream Illustrated Technology Pitch Deck PresentationDocument17 pagesPurple and Cream Illustrated Technology Pitch Deck Presentationgovind royNo ratings yet

- Presentation 1Document10 pagesPresentation 1Ahnaf Tahmid ProttoyNo ratings yet

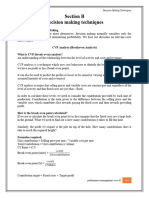

- Section B. Decision Making Techniques - TutorDocument73 pagesSection B. Decision Making Techniques - TutorNirmal ShresthaNo ratings yet

- CHAP 3-5 OMT BooksDocument16 pagesCHAP 3-5 OMT Booksbae joohyunNo ratings yet

- Fundamentals of Corporate Finance Australian 2nd Edition Berk Test BankDocument25 pagesFundamentals of Corporate Finance Australian 2nd Edition Berk Test BankAdamKellyqkjtn100% (56)

- K ServicoDocument32 pagesK ServicoPaola Aquino50% (2)

- Please Refer To Our Contract of CarriageDocument11 pagesPlease Refer To Our Contract of CarriagekarinaNo ratings yet

- Business Cycles (Economics) : Did You Understand The Text?Document2 pagesBusiness Cycles (Economics) : Did You Understand The Text?Moussa CoulibalyNo ratings yet

- Computations of VATDocument21 pagesComputations of VATMikee TanNo ratings yet

- AVSY - Task 2 - 2 - B13 - Assessment - BookDocument7 pagesAVSY - Task 2 - 2 - B13 - Assessment - BookJonathan MerksNo ratings yet

- Company Analysis of Apple Inc. and Capital Budgeting TechniquesDocument19 pagesCompany Analysis of Apple Inc. and Capital Budgeting TechniquesDellNo ratings yet

- Avenue Dmart PDFDocument74 pagesAvenue Dmart PDFdarshanmadeNo ratings yet

- In Strategy, Project Leadership and Pmos: WWW - Sbs.EduDocument8 pagesIn Strategy, Project Leadership and Pmos: WWW - Sbs.EduDiana KilelNo ratings yet

- SHS EntrepreneurshipDocument56 pagesSHS EntrepreneurshipKc Joy Agana FerrerNo ratings yet

- External Environment and Organizational StructureDocument11 pagesExternal Environment and Organizational StructurePrajna DeyNo ratings yet

- USA v. Goodwin, InformationDocument6 pagesUSA v. Goodwin, InformationBillboardNo ratings yet

- FMChap 1Document46 pagesFMChap 1Khang NguyễnNo ratings yet

- Unit3 Logistics Concepts StudentsDocument39 pagesUnit3 Logistics Concepts Studentstriplej189No ratings yet