Professional Documents

Culture Documents

Irin

Irin

Uploaded by

Ariestan SuhendraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Irin

Irin

Uploaded by

Ariestan SuhendraCopyright:

Available Formats

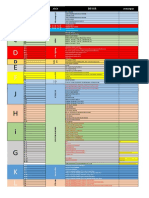

Index

Symbols Activity G-1

$ (US Dollars) 30-6 Activity duration G-1

1 SPEED Actual dates G-1

Hoists (HO) 13-11 AD. See Dryers (AD)

2 STAGE Addendum G-1

Ejectors (EJ) 9-5 Admiralty brass. See Brass

4 STAGE Adsorption towers 8-4

Ejectors (EJ) 9-6 AERATOR

4-STAGE B Water Treatment Systems (WTS) 15-

Ejectors (EJ) 9-5 7

5 SPEED AFC G-1

Hoists (HO) 13-11 AFD G-1

5-STAGE B AFE G-2

Ejectors (EJ) 9-6 Aftercoolers. See Heat Exchangers (HE)

AG. See Agitators (AG)

A Agglomerators. See Mills (M)

Agitated falling film

AACE G-1 Evaporators (E) 12-5

ABC G-1 Agitated kettle. See Agitated Tanks (AT)

Above-grade piping Agitated pan batch dryer

piping plant bulks 18-3 Dryers (D) 12-9

Abrasion resistant Agitated Tanks (AT)

lining materials 28-52 COND-CELL 2-9

Absolute temperatures 29-10 description 2-11

Absorber towers 8-4 FLOAT-CELL 2-9

Absorption towers 8-4 general nomenclature 2-11

ABVGR-TANK impeller materials 2-14

civil plant bulks 19-3 impeller type references 2-14

AC. See Air Compressors (AC) impeller types 2-12, 2-13

AC/DC Transformer MACH-PULP 2-9, 2-10

electrical plant bulks 22-11 MIXER 2-5, 2-6

Accelerated depreciation G-1 OFF-MACH 2-9, 2-10

Accomodations OPEN TOP 2-8

construction overhead 36-59 REACTOR 2-6, 2-7

Account G-1 Agitated thin film evaporator

Account codes. See Code of accounts Wiped Film Evaporators (WFE) 12-7

ACID BRICK Agitators. See Agitated Tanks

Packing, Linings (PAK, LIN) 6-7 (AT); Agitators (AG); Blenders

Acid-resistant brick (BL); Kneaders (K); Mixers (MX)

lining materials 28-51

Acid-test ratio G-1

Action button G-1

Activated aluminas

packing 6-4

Activated carbon

pacing materials 28-55

packing 6-5

G3 © ICARUS Corporation, 1998.

I-2 ICARUS Reference

Agitators (AG) Aluminum ASME design code

ANCHOR 2-3 casting materials 28-54 clad plate materials 28-10

DIRECT 2-3 default piping materials 18-15 ferrous plate materials

FIXED PROP 2-3 non-ferrous plate materials carbon steel 28-3

GEAR DRIVE 2-3 ASME 28-8 heat treated steel 28-4

MECH-SEAL 2-3 BS 28-20 high alloy steel 28-7

PORT-PROP 2-3 DIN 28-44 low alloy steel 28-5, 28-6

procurment lead times 36-11 JIS 28-32 ferrous tube materials

PULP STOCK 2-4 pipe materials 18-18 carbon steel 28-11

side entry 2-4 Amortization G-2 high alloy steel 28-13

top entry 2-4 Analog, process control 36-14 low alloy steel 28-12

Air Analyzers non-ferrous

utility piping services 18-14 sensor loop descriptions 21-12 plate materials 28-8, 28-9

Air Compressors (AC) ANCHOR tube materials 28-14

CENTRIF-M 3-3 Agitators (AG) 2-3 plate materials 28-3

CENTRIF-T 3-3 Angular tube materials 28-11

packaged unit 3-3 units of measure 29-10 ASPHALT

RECIP-GAS 3-4 Anion exchangers site development 25-11

RECIP-MOTR 3-4 DEMINERAL 15-7 Asphalt equipment

SINGLE 1-S 3-4 SOFTENING 15-7 construction equipment 32-9, 32-10

SINGLE 2-S 3-4 Anodes Asphaltic resin lining 28-53

Air conditioning electrical plant bulks 22-7 ASRSN. See Asphaltic resin lining

buildings 26-4 ANSI G-2 Asset structure G-2

AIR COOLER Centrifugal Pumps (CP) 7-4 AT. See Agitated Tanks (AT)

Heat Exchangers (HE) 5-7 ANSI PLAST ATM SUSPEN

Air coolers Centrifugal Pumps (CP) 7-5 Centrifuges (CT) 14-3

procurment lead times 36-11 API G-2 ATM-SYSTEM

AIR DRYER API 610 Tray Drying Systems (TDS) 12-12

Dryers (AD) 12-8 Centrifugal Pumps (CP) 7-3 ATMOS-TRAY

Air Dryers (AD) API 610-IL Dryers (D) 12-9

AIR DRYER 12-8 Centrifugal Pumps (CP) 7-7 Atmospheric

procurment lead times 36-11 API Pipe filtration. See Dust Collectors

Air fan. See Fans, Blowers (FN) piping materials 18-16 (DC); Filters (F)

AIR COOLER (HE) 5-7 Apply G-2 solid/liquid storage

Air, plant/instrument. See Air Compres- Apply & Close G-2 Vertical Tanks (VT) 10-24

sors (AC) APRON Atmospheric tray batch dryer

Alkylation reactor. See Agitated Tanks Conveyors (CO) 13-4 Dryers (D) 12-9

(AT); Agitators (AG); Horizontal Area Atmospheric tray dryer

Tanks (HT) insulation/fireproofing 23-3 Tray Drying Systems (TDS) 12-12

Alkylators units of measure 29-5, 29-11, 29-12 Attributes, database relations

REACTOR (AT) 2-6, 2-7 Area lighting descriptions 35-13

Allocate G-2 electrical plant bulks 22-6 sequence numbers 35-3

Allowances G-2 Area paving ATTRITION

Alloy 20 civil foundation types 19-5 Mills (M) 11-7

pipe materials 18-18 AREA-LIGHT Attrition mill

Alloy steel. See High alloy electrical plant bulks 22-6 Mills (M) 11-7

steel; Intermediate alloy steel; Low Areas AUTOGENOUS

alloy steel introduction 36-3 Mills (M) 11-7

Alloys. See Brass; Capenter 20; High pipe envelope 36-6 Autogenous mill

alloy steel; Inconel; Intermediate process control 36-20 Mills (M) 11-7

alloy steel; Low alloy types 36-4 Automotive

steel; Monel; Nickel; Titanium unreferenced requiring power 36-35 construction equipment 32-4

Alternate G-2 ARR. See Average rate of return (ARR) Average collection period G-2

Alumina ASME G-2 Average rate of return (ARR) G-2

packing materials 28-55 Axial

Gas Compressors (GC) 3-5

AXIAL FLOW

Centrifugal Pumps (CP) 7-7

Axial motion

sensor loop descriptions 21-14

Azeotropic distillation system. See

Distillation systems

© ICARUS Corporation, 1998. G3

Index I-3

B Batch tray dryer Book value per share G-2

Tray Drying Systems (TDS) 12-12 BORINGS

BACKFILL BATCH VAC earthwork - site development 25-6

earthwork - site development 25-7 Crystallizers (CRY) 12-3 BOT-UNLOAD

Bag filters. See Dust Collectors (DC) Batch vacuum Centrifuges (CT) 14-3

Baghouse Crystallizers (CRY) 12-3 Bow screen

cloth bay 14-6 BATCH-AUTO Screens (VS) 14-17

Bags Centrifuges (CT) 14-3 BOX

units of measure 29-5 BATCH-BOTM civil foundation types 19-8

Balance sheet G-2 Centrifuges (CT) 14-3 Furnaces, Process Heaters (FU) 5-21

Ball BATCH-TOP Boxes

control valves 21-20 Centrifuges (CT) 14-4 steel plant bulks 20-8

Fisher control valve information 21- BCR. See Benefit-cost ratio (BCR) Boxes, junction

19 BEAM SCALE instrumentation plant bulks 21-4

BALL MILL Scales (S) 13-12 Bracing

Mills (M) 11-7 Beams steel plant bulks 20-7

Ball mill civil foundation types 19-7 Brackets

Mills (M) 11-7 steel plant bulks 20-7 steel plant bulks 20-7

Balloon G-2 Beaters BRADFORD

Balloon payment G-2 Kneaders (K) 2-16 Crushers (CR) 11-5

BAR Mixers (MX) 2-17, 2-18 Brass

Screens (VS) 14-17 BELGR-TANK non-ferrous plate materials

BARBED civil plant bulks 19-3 JIS 28-32

fencing - site development 25-9 BELT non-ferrous tube materials

Barcharts Feeders (FE) 13-10 DIN 28-50

project schedule 36-10 Scales (S) 13-12 JIS 28-38

BAROMETRIC Belt feeder Break-even analysis G-2

Condensers (C) 9-3 Feeders (FE) 13-10 Break-even budget G-2

Barrels BENCH Break-even point G-2

units of measure 29-5 Scales (S) 13-12 BREAKER

Base indices Benefit-cost ratio (BCR) G-2 electrical plant bulks 22-10

construction 33-3 Berl saddle Brick linings 28-51

construction management 33-3 packing 6-4 Bridge crane

country base Berl saddles Cranes (CE) 13-9

JP 33-3 packing materials 28-55 BRIDGE-CRN

UK 33-3 Bid documents G-2 Cranes (CE) 13-9

US 33-3 Bin activator BRUSH

design engineering 33-3 Feeders (FE) 13-10 earthwork - site development 25-6

general materials 33-3 BIN-ACTVTR BS design code

introduction 33-3 Feeders (FE) 13-10 clad plate materials 28-22

BASE-PREP BL. See Blenders (BL) ferrous plate materials

site development 25-11 See Blenders (BL) heat treated steel 28-16

Baseline schedule G-2 BLASTING high alloy steel 28-19

Basic engineering G-2, 36-52, 36-56 earthwork - site development 25-7 low alloy steel 28-17, 28-18

disciplines and wage rates BLENDER ferrous tube materials

JP 31-5 Blenders (BL) 2-15 carbon steel 28-23

UK 31-4 Blenders (BL), 2-15 high alloy steel 28-25

US 31-3 BLENDER 2-15 low alloy steel 28-24

expenses and indirects 31-6 ROTARY 2-15 non-ferrous

man-hour adjustments 36-54 Blocks plate materials 28-20, 28-21

BASIN civil foundation types 19-6 tube materails 28-26

civil foundation types 19-7 Blowers. See Fans, Blowers (FN) tube materials 28-26

BASINS BOILER plate materials 28-15, 28-16

drainage - site development 25-5 Steam Boilers (STB) 15-4 tube materials 28-23

Basins, catch Boilers. See Steam Boilers (STB) BS5500 G-2

drainage - site development 25-5 procurment lead times 36-11 Bubble cap trays 8-4

Batch Bond G-2 Bucket elevator

Centrifuges (CT) 14-3 Bond covenants G-2 Conveyors (CO) 13-7

Batch blending Bond indenture G-2 Budget G-2

Blenders (BL) 2-15 Bond refunding G-2 Budget: -15 to +30 percent estimate G-2

Batch dryer Book value G-2 Building shell 26-4

Dryers (D) 12-9

Tray Dring Systems (TDS) 12-12

G3 © ICARUS Corporation, 1998.

I-4 ICARUS Reference

Buildings CAISSON CASIL. See Calcium silicate

air contitioning 26-4 piling - site development 25-12 Cast iron

construction range adjustements 26-6 Calciners. See Rotary Dryers (RD) casting materials 28-54

cost 26-3 Calcium chloride Cast steel

defaults 26-4 packing materials 28-55 casting materials 28-54

demolish 25-4 Calcium silicate Castable refractories, linings 6-5

electrical 26-4 insulation materials 23-5 Casting materials 28-54

fire protection 26-4 Calculate schedule G-3 Catalyst

floor heights/levels 26-5 Calendars G-3 bed reactor, packed 8-7, 8-12

furniture 26-4 Call provision for a bond G-3 Catch basin

heating 26-4 Call value of a bond G-3 drainage - site development 25-5

heights/levels 26-5 Cancel G-3 Categories

introduction 26-3 CANNED process equipment 1-3

lighting 26-4 Centrifugal Pumps (CP) 7-9 Catering

mill, steel plant bulks 20-5 CANNED RTR construction overhead 36-59

plumbing 26-4 Gear Pumps (GP) 7-10 Cation exchangers

types 26-4 Capital budgeting G-3 DEMINERAL 15-7

types and defaults 26-4 Capital markets G-3 CBD G-3

ventilating 26-4 Capital rationing G-3 CE. See Cranes (CE)

Bulks. See Plant bulks Capital structure G-3 CED G-3

Bulks & adj. G-3 Capitalization rate for leases G-3 Cement

BUMPER Carbon lined steel pipe 18-20

railroads - site development 25-13 packing materials 28-55 CENT-BKT-L

Bundle runs - pneumatic Carbon steel Conveyors (CO) 13-6

instrumentation plant bulks 21-3 ASME ferrous CENT-COMPR

Burdens G-3 plate materials 28-3 Refrigeration Units (RU) 15-5

construction overhead 36-59 tube materials 28-11 CENT-TURBO

Burdens, engineering 31-6 BS ferrous Fans, Blowers (FN) 3-9

Buried pipe plate materials 28-15 CENTRF-PRE

piping plant bulks 18-3, 18-6 tube materials 28-23 Dust Collectors (C) 14-6

Bus duct casting materials 28-54 CENTRIF

electrical plant bulks 22-9 default piping materials 18-15 Centrifugal Pumps (CP) 7-6

BUS-DUCT DIN ferrous Fans, Blowers (FN) 3-8

electrical plant bulks 22-9 plate materials 28-39 Gas Compressors (GC) 3-5

Business risk G-3 JIS ferrous CENTRIF-IG

Butterfly plate materials 28-27 Gas Compressors (GC) 3-6

control valves 21-20 tube materials 28-35 CENTRIF-M

Fisher control valve information 21- lining materials 28-51, 28-53 Air Compressors (AC) 3-3

19 packing materials 28-56 CENTRIF-T

Button G-3 pipe materials 18-16 Air Compressors (AC) 3-3

Butyl rubber Carpenter 20 Centrifugal

lined steel pipe 18-20 ASME non-ferrous Fans, Blowers (FN) 3-8

Butyl rubber lining 28-53 tube materials 28-14 filters

BW G-3 BS non-ferrous Centrifuges (CT) 14-3

plate materials 28-21 Dust Collectors (DC) 14-6

C tube materials 28-26 Filters (F) 14-9

casting maeterials 28-54 Gas Compressors (GC) 3-5

C. See Condensers (C) DIN non-ferrous pumps (CP) 7-3

Cable, control plate materials 28-45 Centrifugal precipitator

electrical plant bulks 22-7 tube materials 28-50 Dust Collectors (DC) 14-6

Cable, data-highway JIS non-ferrous Centrifugal Pumps (CP)

instrumentation plant bulks 21-6 plate materials 28-33 ANSI 7-4

CABLE DUCT tube materials 28-38 ANSI PLAST 7-5

electrical plant bulks 22-8 CARTRIDGE API 610 7-3

Cable runs Filters (F) 14-9 API 610-IL 7-7

electrical plant bulks 22-3 Cartridge filter AXIAL FLOW 7-7

Cable tray Filters (F) 14-9 CANNED 7-9

electrical plant bulks 22-4 Cash budget G-3 CENTRIF 7-6

instrumentation plant bulks 21-3 Cash discount and EOM G-3 GEN-SERV 7-6

CAFE, buildings 26-4 Cash flow cycle G-3 IN LINE 7-8

Cafeteria 26-4 Cash reserves G-3 MAG DRIVE 7-9

Caged ladders 20-7 PULP STOCK 7-9

steel plant bulks 20-3 pump efficiencies 7-13

TURBINE 7-7

© ICARUS Corporation, 1998. G3

Index I-5

Centrifuges (CT) Clad plate materials modifying 34-3

ATM SYSPEN 14-3 ASME design code 28-10 other project costs 34-5

BATCH-AUTO 14-3 BS design code 28-22 output reports 34-4

BATCH-BOTM 14-3 DIN design code 28-46 paint 34-13

BATCH-TOP 14-4 JIS design code 28-34 piping 34-8

BOT-UNLOAD 14-3 Clad vessels steel 34-10

DISK 14-4 default piping materials 18-15 summary reports 34-4

INVERTING 14-5 Cladding material Coincident indicator G-4

procurment lead times 36-11 ASME design code 28-10 Coke

RECIP-CONV 14-4 BS design code 28-22 paking materials 28-55

SCREEN-BWL 14-5 DIN design code 28-46 Collateral G-4

SCROLL-CON 14-4 JIS design code 28-34 Collection costs G-4

SOLID BOWL 14-4 Clarifiers. See Centrifuges (CT); Dust Collection system. See Dust Collectors

TOP UNLOAD 14-3 Collectors (DC); Filters (DC)

TUBULAR 14-5 (F); Thickeners (T) Collectors, dust. See Dust Collectors

VIBRATORY 14-5 Class (DC)

Ceramic electrical 22-15 COLM/BM

packing materials 28-55 Classifications of drawings 31-9 civil foundation types 19-7

CERATE relation 35-8 Classified-suspension crystallizer Columns. See Double Diameter Towers

Certainty equivalent G-3 Crystallizers (CRY) 12-4 (DDT); Single Diameter Towers

Certificates of deposit G-3 Classifiers. See Screens (VS); Separation (TW); Towers

Chain conveyors. See Conveyors (CO) Equipment (SE) civil foundation types 19-7, 19-8

Chain drivers CLEAD. See Chemical lead lining packed 8-7, 8-12

variable speed motor reducer 4-5 Clear G-3 steel plant bulks 20-3, 20-7

CHAIN-LINK Clear brush tray towers 8-9, 8-14

fencing - site development 25-9 earthwork - site development 25-6 washers 14-8

Chance event G-3 CLEAR-GRUB Combustible

Change G-3 earthwork - site development 25-6 electrical class/division

Change order G-3 Clearing dust 22-15

Chemical lead lining 28-53 earthwork - site development 25-6 fibers or particles 22-15

Chemical sewer Click G-3 Combustion equipment

utility piping services 18-14 Close G-3 Flares (FLR) 16-3

CHEST-CYL CLOSED, buildings 26-4 Furnaces, Process Heaters (FU) 5-21

Vertical Tanks (VT) 10-27 CLOSED-BLT Heating Units (HU) 15-5

CHEST-MTL Conveyors (CO) 13-4 Stacks (STK) 16-9

Vertical Tanks (VT) 10-28 Closed-end mortgage bond G-4 Commercial paper G-4

CHEST-REC CLOTH BAY Commissioning

Vertical Tanks (VT) 10-25 Dust Collectors (DC) 14-6 disciplines and wage rates

Chests, tile Cloth bay baghouse JP 31-5

Vertical Tanks (VT) 10-25 Dust Collectors (DC) 14-6 UK 31-4

Chillers. See Condensers (C); Heat CM G-4 US 31-3

Exchangers (HE); Refrigeration CNTRCT relation 35-11 expenses and indirects 31-6

Units (RU) CO. See Conveyors (CO) Common equity G-4

Chimneys. See Flares (FLR); Stacks COA. See Code of account COMPACT

(STK) COAT+WRAP earthwork - site development 25-7

Chlorinated polyvinyl piping plant bulks 18-9 Compaction

pipe materials 18-19 Coatings construction equipment 32-5

Choose G-3 Packing, Linings (PAK, LIN) 6-7 Comparative analysis G-4

Chutes. See Conveyors (CO) COD G-4 Compensating balance G-4

steel plant bulks 20-8 Code of account G-4 COMPONENT relation 35-11

Circuit breakers Code of accounts Components G-4

electrical plant bulks 22-10 civil 34-9 Composition G-4

Circular ring construction indirect costs 34-5, 35- COMPR, buildings 26-4

civil foundation types 19-6 12 Compressed air systems. See Compres-

Civil contingencies 34-5, 35-12 sors

code of accounts 34-9 creating 34-3, 34-4 Compressor

concrete foundations 19-3 directs 34-6 construction equipment 32-7

concrete tanks 19-3 electrical 34-12 Compressor building 26-4

foundation types 19-5 equipment and setting 34-6, 34-7 Compressors. See also Air Compressors

plant bulks 19-3 indirects 34-5, 35-12 (AC); Fans, Blowers (FN); Gas

soil types 19-9 instrumentation 34-11 Compressors (GC)

structures 19-3 insulation 34-13 procurment lead times 36-11

typical structure live loads 19-9 introduction 34-3

G3 © ICARUS Corporation, 1998.

I-6 ICARUS Reference

CONC-PAVNG Construction engineering Construction overhead & fees

site development 25-11 country base construction overhead 36-59

Concentrators JP 31-5 Construction overhead and fees G-4

REACTOR UK 31-4 Construction range adjustment

Agitated Tanks (AT) 2-6 US 31-3 buildings 26-6

THICKENER Construction eqiupment Construction rental equipment

Thickeners (T) 14-15 introduction 32-3 construction overhead 36-59

CONCRETE reporting 32-3 Consumables G-4

civil plant bulks 19-3 Construction equipment 32-4 construction overhead 36-59

Concrete asphalt equipment 32-9, 32-10 Consumer survey method for

construction equipment 32-7 automotive 32-4 forecasting G-4

pipe, piping plant bulks 18-6 compaction 32-5 CONT-BKT-L

tanks, civil plant bulks 19-3 compressor 32-7 Conveyors (CO) 13-7

Concrete drainage concrete 32-7 CONTAINMNT

civil 19-4 crane 32-6 civil plant bulks 19-4

Concrete paving crane attachment 32-6 Contingencies

site development 25-11 derrick 32-7 code of accounts 34-5, 35-12

COND-CELL drilling 32-5 Contingency G-4

Agitated Tanks (AT) 2-9 earthmoving 32-4, 32-5 construction overhead 36-59

Condensers (C) electric equipm/tool 32-9 Continuous spray drying system

BAROMETRIC 9-3 hoist 32-9 Dryers (D) 12-9

CONDENSING miscellaneous equipment 32-9 Contract documents G-4

Turbines (TUR) 4-7 piling 32-7 Contracts

Conditioners. See Water Treatment piping equipment 32-8, 32-10 concepts 36-61, 36-62

Systems (WTS) pneumatic port. tool 32-9 construciton - home office construction

Conditioning cell pump 32-9 services 36-65

Agitated Tanks (AT) 2-9 site/office equipment 32-10 construction 36-64

Conductivity tractor 32-5 construction - direct field man-

sensor loop descriptions 21-16 trailer 32-5, 32-6 power 36-64

CONDUIT truck 32-4 construction - field erected ves-

civil foundation types 19-6 welding equipment 32-7, 32-8 sels 36-64

electrical plant bulks 22-3 Construction indirect costs construction - field indirects 36-64

CONE code of accounts 34-5, 35-12 construction - field supervision 36-65

Crushers (CR) 11-3 Construction management cost benefits 36-62

Cone bottom base indices 33-3 cost elements 36-62

Vertical Tanks (VT) 10-22 disciplines and wage rates description 36-60, 36-61

CONE BTM JP 31-5 engineering 36-53, 36-63

Vertical Tanks (VT) 10-22 UK 31-4 impact on other user input 36-66

Cone crusher US 31-3 introduction 36-60

Crushers (CR) 11-3 expenses and indirects 31-6 materials 36-63

Cone roof tank (storage) Construction overhead overheads 36-65

Vertical Tanks (VT) 10-18 accomodations 36-59 prime contractor defaults 36-60

Conglomerate merger G-4 burdens 36-59 procurement 36-63

Conical hopper. See Vertical Tanks (VT) catering 36-59 CONTRL, buildings 26-4

Conical rotary vacuum dryer construction overhead & fees 36-59 Control G-4

Rotary Dryers (RD) 12-11 construction rental equipment 36-59 Control cable

Coning 8-4 consumables 36-59 electrical plant bulks 22-7

Connstruction overhead contingency 36-59 Control centers 36-14, 36-15, 36-16

engineering 36-59 demobilization 36-59 analog 36-16

CONSET (contract set number) 36- field services 36-59 default 36-17

21, 36-23, 36-25 fringe benefits 36-59 defining 36-23, 36-24

Constants indirects 36-59 digital 36-17

units of measure 29-10 introduction 36-58 electrical plant bulks 22-10

Construction miscellaneous 36-59 PLC 36-25, 36-26

base indices 33-3 mobilization 36-59 redundant control 36-24

contracts 36-64 project costs 36-59 requirements 36-17

direct field manpower 36-64 scaffolding 36-59 spares 36-24

field office 36-53 small tools 36-59 types 36-23

field supervision 36-65 temporary construction 36-59 Control process G-4

home office 36-53 travel 36-59 Control room 26-4

home office construction services 36- utilities 36-59 Control valve

65 vendor representatives 36-59 Fisher information 21-19

management 36-50, 36-53 instrumentation options 21-20

© ICARUS Corporation, 1998. G3

Index I-7

Control valve size Cost of capital G-4 Crossflow trays

piping 18-4 Cost reporting bubble cap 8-4

Controllers currency and escalation 36-39 sieve 8-4

Fisher Control International, Inc. 37- currency and system base indices 36- valve 8-4

5 39 CROSSING

Controllers, multifunction COST® G-4 railroads - site development 25-13

instrumentation plant bulks 21-4 Counter flow trays 8-4 Crossing signal

Conversion premium G-4 Country base railroads - site development 25-13

Converters. See Reactors; Vessels default values 36-38 Crushed limestone

Convertible security G-4 JP 30-5 packing materials 28-55

Conveyor belt scale project definition 36-37 Crushed stone

Scales (S) 13-12 UK 30-4 packing materials 28-55

Conveyor transfer tower US 30-3 Crushers (CR)

steel plant bulks 20-7 Coupon rate G-4 BRADFORD 11-5

Conveyors (CO) Covenants G-4 CONE 11-3

APRON 13-4 CP. See Centrifugal Pumps (CP) ECCENTRIC 11-3

CENT-BKT-L 13-6 CR. See Crushers (CR) GYRATORY 11-3

CLOSED-BLT 13-4 Crackers. See Reactors; Towers; Vessels HAMMER-MED 11-5

CONT-BKT-L 13-7 Cracking furnaces. See JAW 11-4

OPEN BELT 13-3 Crackers; Furnaces, Process Heaters procurment lead times 36-11

PNEUMATIC 13-5 (FU); Heating Units (HU) PULVERIZER 11-6

procurment lead times 36-11 Craft REV-HAMR 11-5

ROLLER 13-5 codes 30-3, 30-4, 30-5 reversible hammermill 11-5

SCREW 13-5 country base ring granulator 11-6

section types 13-8 JP 30-5 ROLL RING 11-6

VIBRATING 13-6 UK 30-4 ROTARY 11-4

Cookers. See Drum Dryers (DD); Dryers US 30-3 rotary breaker 11-5

(D); Rotary Dryers (RD); Tray helper 30-3, 30-5 S-IMPACT 11-5

Drying Systems (TDS) names 30-3, 30-4, 30-5 S-ROLL-HVY 11-4

COOLING Craftmen's mate S-ROLL-LT 11-4

Cooling Towers (CTW) 15-3 craft names and wage rates 30-4 S-ROLL-MED 11-4

Cooling Towers (CTW) Crafts SAWTOOTH 11-5

COOLING 15-3 labor 36-8 single roll 11-4

COOLING-WP 15-3 names 36-42 size reduction 11-5

factory assembled 15-3 productivity 36-48 swing jaw 11-4

PACKAGED 15-3 wage rates 36-41 SWING-HAMR 11-5

procurment lead times 36-11 Crane Crushers, mills and stock treatments. See

Cooling water and return line construction equipment 32-6 Crushers (CR); Flakers (FL); Mills

utility piping services 18-14 Crane attachment (M); Stock Treatment (ST)

Cooling water systems. See Centrifugal construction equipment 32-6 Crushing rolls. See Crushers (CR); Mills

Pumps (CP); Cooling Towers Cranes (CE) (M)

(CTW); Piston, Other Positive BRIDGE-CRN 13-9 CRWSCH relation 35-9

Displacement Pumps (P) HOIST 13-9 CRY. See Crystallizers (CRY)

COOLING-WP hoist trolley 13-9 CRYOGENIC

Cooling Towers (CTW) 15-3 travelling bridge crane 13-9 Vertical Tanks (VT) 10-20

Copper Create G-4 Cryogenic storage tank

ASME non-ferrous Credit discount G-5 Vertical Tanks (VT) 10-20

tube materials 28-14 Credit period G-5 Crystallizers (CRY)

BS non-ferrous Credit period only G-5 BATCH VAC 12-3

plate materials 28-20 Credit policy G-5 batch vacuum 12-3

tube materials 28-26 Crew mixes classified-suspension 12-4

default piping materials 18-15 workforce 36-42 growth 12-4

DIN non-ferrous Critical activity G-5 MECHANICAL 12-3

plate materials 28-44 Critical path G-5 mechanical scraped-surface crystal-

tube materials 28-50 CROSS BORE lizer 12-3

JIS non-ferrous Heat Exchangers (HE) 5-11 OSLO 12-4

plate materials 28-32 Cross gutter scraped surface 12-3

tube materials 28-38 site development 25-11 CS G-5

pipe materials 18-18 CROSS-GUTT CSTCTRL relation 35-10

Copy & change G-4 site development 25-11 CT. See Centrifuges (CT)

Cost G-4 CTRL-CABLE

Cost index G-4 electrical plant bulks 22-7

Cost modeling G-4 CTW. See Cooling Towers (CTW)

G3 © ICARUS Corporation, 1998.

I-8 ICARUS Reference

CURB Decision tree G-5 DEMOL

site development 25-11 Decolorizers. See demolition - site development 25-4

Curb and gutter Demineralizers; Packed columns DEMOLITION

site development 25-11 Decomposers. See Agitated Tanks (AT) demolition - site development 25-4

Currency base Dedusters. See Dust Collectors (DC) Demolition

conversion 36-37 DEEP-ANODE site development 25-4

project definition 36-37 electrical plant bulks 22-7 Densifiers. See Mixers (MX)

Current ratio G-5 Default piping materials 18-15 Deodorizers. See Distillation

Current yield G-5 Deferred call provision G-5 systems; Dryers (D); Reactors

CUSSPC relation 35-10 Defiberizers. See Crushers (CR); Mills DERRICK

CUT-FILL (M) Flares (FLR) 16-4

earthwork - site development 25-7 Definitive: -5 to +15 percent estimate G- Derrick

CYCLONE 5 construction equipment 32-7

Dust Collectors (DC) 14-7 DEFLAKE-CN Desiccators. See Demineralizers; Dryers

Cyclones Stock Treatment (ST) 11-8 (D); Packed columns; Packing,

liquid. See Separation Equipment (SE) DEFLAKE-DK Linings (PAK, LIN)

separation. See Dust Collectors (DC) Stock Treatment (ST) 11-8 Design basis G-5

water only. See Separation Equipment Deflakers Design codes. See ASME design

(SE) Stock Treatment (ST) code; BS design code; DIN design

CYLINDER concentric conical type 11-8 code; JIS design code

Heating Units (HU) 15-5 plate type 11-8 Design engineering

Vertical Tanks (VT) 10-8 Deflocculators. See Crushers (CR); Mills base indices 33-3

Cylindrical chests (M) country base

Vertical Tanks (VT) 10-27 Defoamers. See Agitators (AG); Mixers JP 31-5

(MX) UK 31-4

D Degasifiers. See Mixers (MX) US 31-3

Degree of financial leverage G-5 DESIGN relation 35-7

D. See Dryers (D) Degree of operating leverage G-5 Desludgers. See Centrifuges (CT); Filters

Data-highway cable Degummers. See Centrifuges (F); Thickeners (T)

instrumentation plant bulks 21-6 (CT); Evaporators (E); Wiped Film Desmoggers. See Dust Collectors

Database G-5 Evaporators (WFE) (DC); Filters (F)

Database relations Dehumidifiers. See Air Dryers Desolventizers. See Distillation

attribute descriptions 35-13 (AD); Dryers (D) systems; Drum Dryers

CERATE relation 35-8 Dehydrators. See Distillation (DD); Dryers (D); Evaporators

CNTRCT relation 35-11 systems; Drum Dryers (E); Rotary Dryers (RD); Tray

COMPONENT 35-11 (DD); Dryers (D); Evaporators Drying Systems (TDS)

CRWSCH relation 35-9 (E); Rotary Dryers (RD); Tray Desorbers. See

CSTCTRL relation 35-10 Drying Systems (TDS); Wiped Film Columns; Reactors; Towers; Vessels

CUSSPC relation 35-10 Evaporators (WFE) Desorption towers 8-4

DESIGN relation 35-7 Deionizers. See Desulferization reactors

DETAILS relation 35-6 Demineralizers; Softeners packed 8-7, 8-12

EQRENT relation 35-9 Deisobutanizers. See Distillation systems Desulfurization reactors. See

INDIRECTS 35-12 Deisopentanizers. See Distillation Reactors; Towers; Vessels

NEWCOA relation 35-8 systems Detail engineering 36-52, 36-56

PROJDATA relation 35-7 Delete G-5 disciplines and wage rates

relationships 35-5 Delivery times JP 31-5

REMARKS relation 35-7 process equiment procurement 36-11 UK 31-4

REPGRP relation 35-10 Delphi method for forecasting G-5 US 31-3

sequence numbers of attributes 35- Delumpers. See Crushers (CR); Mills expenses and indirects 31-6

3, 35-4 (M); Mixers (MX) man-hour adjustments 36-54

DC. See Dust Collectors (DC) Demand-diversity factor G-5 Detailed engineering G-5

DC HE TW DEMINERAL DETAILS relation 35-6

Single Diameter Towers (TW) 8-16 Water Treatment Systems (WTS) 15- Dewaterers. See Centrifuges

DD. See Drum Dryers (DD) 7 (CT); Dryers (D); Filters

DDT. See Double Diameter Towers Demineralizers (F); Rotary Dryers (RD)

(DDT) packed towers 8-7, 8-12 DEWATERING

Deaerators. See Mixers (MX) Packing (PAK) 6-7 drainage - site development 25-5

Debenture G-5 Demineralizing system

Debutanizers. See Distillation systems Water Treatment Systems (WTS) 15-

Decanter. See Centrifuges 7

(CT); Separators Demobilization G-5

Decision engineering G-5 construction overhead 36-59

Decision point G-5

© ICARUS Corporation, 1998. G3

Index I-9

Dewatering systems. See Air Dryers Disconnect switches DRAINS

(AD); Centrifugal Pumps electrical plant bulks 22-9 drainage - site development 25-5

(CP); Conveyors (CO); Drying Discount period G-6 Drawing types 31-8

systems; Dust Collectors Discount rate G-6 Drawings

(DC); Filters (F); Hoppers; Piston, DISK classifications 31-9

Other Positive Displacement Pumps Centrifuges (CT) 14-4 engineering 31-8

(P); Receivers; Screens Disk filter Drilling

(VS); Vacuum Pumps (VP) Filters (F) 14-10 construction equipment 32-5

Dewatering wells Dispersers. See Agitators (AG); Blenders Driver power

drainage - site development 25-5 (BL); Mixers (MX) units of measure 29-3

DFC. See Direct field cost Displacement pumps. See Piston, Other Drivers. See Electrical Motors

DH (Direct hire) G-5 Positive Displacement Pumps (P) (MOT); Turbines (TUR)

Dialog box G-5 Display G-6 DRUM

Diameter DISPOSAL Flakers (FL) 11-6

piping standard equations 18-13 demolition - site development 25-4 Drum. See Horizontal Tanks (HT)

diameters Dissolvers. See Mixers (MX) Drum blenders. See Blenders (BL)

piping 18-12 Distillation systems. See Centrifugal Drum Dryers (DD)

DIAPHRAGM Pumps (CP); Condensers DOUBLE ATM 12-10

Piston, Other Positive Displacement (C); Double Diameter Towers SINGLE ATM 12-10

Pumps (P) 7-11 (DDT); Heat Exchangers single atmospheric 12-10

Differential pressure (HE); Piston, Other Positive SINGLE VAC 12-10

sensor loop descriptions 21-8 Displacement Pumps (P); Reboilers vacuum rotary 12-10

Diffusers. See Mixers (MX) (RB); Single Diameter Towers Drum filter

Digesters. See Reactors; Vessels (TW); Vacuum Pumps (VP) Filters (F) 14-11

Digital, process control 36-14 Distillation towers 8-3. See also Double Drum flaker

Digital/electrical Diameter Towers (DDT); Single Flakers (FL) 11-6

instrumentation report details 21-24 Diameter Towers (TW) Dry chemical feeders. See Conveyors

pneumatic instrumentation report Distributable G-6 (CO); Feeders (FE)

details 21-25 Distribution of assets G-6 DRY SAND

DIKE Ditching civil soil types 19-9

earthwork - site development 25-6 earthwork - site development 25-8 Dryers (D). See also Air Dryers

DIKE-MEMBR Dividend declaration date G-6 (AD); Drum Dryers (DD); Rotary

civil plant bulks 19-4 Dividend payment date G-6 Dryers (RD); Tray Drying Systems

DIN G-5 Dividend payout ratio G-6 (TDS)

DIN design code Dividend policy G-6 agitated pan batch 12-9

clad plate materials 28-46 Dividend yield G-6 ATMOS-TRAY 12-9

ferrous plate materials Dividends G-6 atmospheric tray-type batch 12-9

carbon steel 28-39 Division continuous spray system 12-9

heat treated steel 28-40 electrical 22-15 PAN 12-9

low alloy steel 28-41 Dollars SPRAY 12-9

ferrous tube materials currency base 36-37, 36-38 VAC-TRAY 12-9

low alloy steel 28-48 DOUBLE ATM vacuum tray-type batch 12-9

plate materials 28-39 Drum Dryers (DD) 12-10 Drying systems. See Air Dryers

tube materials 28-47 Double Diameter Towers (DDT). See also (AD); Crystallizers (CRY); Drum

DIRECT Towers Dryers (DD); Dryers

Agitators (AG) 2-3 PACKED 8-7 (D); Evaporators (E); Rotary

Rotary Dryers (RD) 12-11 TRAYED 8-9 Dryers (RD); Tray Drying Systems

Direct contact heat exchanger tower 8- Double-arm (TDS); Wiped Film Evaporators

16 Kneaders (K) 2-16 (WFE)

Direct costs G-5 Mixers (MX) 2-17 Duct, bus

Direct feld fanpower DOW Plastic-Lined Piping Products 37- electrical plant bulks 22-9

construction 36-64 4 DUCT-RD

Direct field cost (DFC) G-6 Dowtherm unit piping plant bulks 18-6

Direct hire. See DH (Direct hire) Heating Units (HU) 15-5 DUCT-SQ

Directs Drain field piping plant bulks 18-7

code of accounts 34-6 drainage - site development 25-5 Ductwork

Dirt DRAINAGE piping 18-6

packing materials 28-55 drainage - site development 25-5 DUPLEX

Discharge elevator Drainage Piston, Other Positive Displacement

Conveyors (CO) 13-6 civil 19-4 Pumps (P) 7-11

Disciplines. See Engineering disciplines site development 25-5 Duration G-6

DISCNCT-SW Drainage piping

electrical plant bulks 22-9 drainage - site development 25-5

G3 © ICARUS Corporation, 1998.

I-10 ICARUS Reference

Dust collection system. See Dust Elbows VARY-SPEED 4-5

Collectors (DC); Fans, Blowers piping 18-12 Electronic signal wire

(FN) ELC-H-VOLT instrumentation plant bulks 21-3

Dust Collectors (DC). See also Filters Dust Collectors (DC) 14-8 Electrostatic precipitators. See Dust

(F); Separation Equipment (SE) ELC-L-VOLT Collectors (DC)

CENTRF-PRE 14-6 Dust Collectors (DC) 14-8 Elevated access platforms

CLOTH BAY 14-6 ELEC-CABLE steel plant bulks 20-6

CYCLONE 14-7 electrical plant bulks 22-3 Elevated slab

ELC-H-VOLT 14-8 ELEC-TRAY civil foundation types 19-7

ELC-L-VOLT 14-8 electrical plant bulks 22-4 Elevators, Lifts (EL). See also Conveyors

MULT-CYCLO 14-8 Electrical (CO)

procurment lead times 36-11 buildings 26-4 FREIGHT 13-9

PULSE SHKR 14-8 bus duct 22-9 PASSENGER 13-9

WASHERS 14-8 cable runs 22-3 procurment lead times 36-11

Dust, combustible cable tray 22-4 Ellipsoidal towers 8-5

electrical class/division 22-15 circuit breakers 22-10 Elliptical towers 8-5

class/division 22-15 EM-PWR-SET

E code of accounts 34-12 electrical plant bulks 22-12

construction equipment 32-9 Emergency diesel generator

E. See Evaporators (E) control cable 22-7 electrical plant bulks 22-12

E-P-C (Engineering, procurement and disconnect switches 22-9 Emergency eyewash and shower

construction) G-6 galvanic anode 22-7 units 18-11

Early finish G-6 general plant bulks 22-3 Emergency light

Early start G-6 ground grid 22-5 electrical plant bulks 22-8

Earned surplus G-6 group of anodes in deep well 22-7 Emulsifiers. See Mixers (MX)

Earnings per share G-6 group of anodes in shallow surface ENCLOSED

Earth (dirt) bed 22-7 Electrical Motors (MOT) 4-4

packing materials 28-55 motor control center 22-10 Enclosed building 26-4

Earthmoving oil circuit breakers 22-9 Engineering. See Basic

construction equipment 32-4, 32-5 overhead transmission line 22-9 engineering; Commissioning; Construction

EARTHWORK plant bulks 22-3 engineeirng; Construction

earthwork - site development 25-6 potential measurement test station 22- management; Detail

Earthwork 8 engineering; Engineering

site development 25-6 rigid conduit 22-3 disciplines; Engineering

Ebonite solar panel 22-8 management; Field office; Head

lined steel pipe 18-20 steel for substation structure 22-9 office; Procurement; Startup

ECCENTRIC substation plant bulks 22-9 accounts 36-52

Crushers (CR) 11-3 tracing (existing equipment) 22-4 adjustements to costs 36-56

Economic forecast G-6 tracing (existing piping run) 22-4 adjustments to costs 36-55

Economic indicator G-6 transformer/rectifier 22-8 basic 36-52

Economic order quantity G-6 uninterupted power supply 22-12 code of accounts 35-12

Economizers. See Condensers units of measure 29-9, 29-17 connstruction overhead 36-59

(C); Evaporators (E); Heat wire sizes 22-14 construction management 36-53

Exchangers (HE); Reboilers Electrical Generators (EG). See also contracts 36-53

(RB); Water Treatment Systems Turbines (TUR) contracts assignment 36-50

(WTS) PORTABLE 15-6 detail 36-52

Eductors. See Ejectors (E) procurment lead times 36-11 discipline adjustments 36-51

Efficiency G-6 TURBO-GEN 15-6 drawing types 31-8

Efficiency ratios G-6 Electrical instrumentation expenses 31-6

EG. See Electrical Generators (EG) report details 21-22 field office construction supervi-

EJ. See Ejectors (EJ) Electrical Motors (MOT) sion 36-53

Ejectors (E) ENCLOSED 4-4 home office construction services 36-

Ejectors (EJ) EXP-PROOF 4-4 53

2 STAGE 9-5 explosion proof 4-4 indirects 31-6, 36-53

4 STAGE 9-6 OPEN 4-3 introduction 36-50

4-STAGE B 9-5 power level 4-5 man-hour adjustments 36-54

5-STAGE B 9-6 standard motor sizes 4-6 management 36-53

SINGLE STG 9-4 SYNCHRON 4-3 miscellanious expenses 36-53

TWO STAGE 9-4 synchronous motor speeds (RPM) 4- organization 36-54

EL. See Elevators, Lifts (EL) 6 payroll burdens 36-53

EL SLAB Synchronous motors 4-3 phase adjustments 36-51

civil foundation types 19-7 TEFC 4-4 prime contractor 36-50, 36-53

Elapsed time G-6 TEWAC 4-4 procurement 36-53

© ICARUS Corporation, 1998. G3

Index I-11

reports 36-51, 36-53 long tube rising film 12-5 Factored estimating G-7

SPAN* 36-57 long tube vertical 12-6 FALL-FILM

start-up 36-53 LONG-VERT 12-5 Evaporators (E) 12-5

support personnel 36-53 STAND-HOR 12-6 Fans. See Fans, Blowers (FN)

tasks 36-52 STAND-VERT 12-6 Fans, Blowers (FN). See also Air

work products 36-52 standard horizontal tube 12-6 Compressors (AC); Gas Compres-

workforce 36-51 standard vertical tube 12-6 sors (GC); Piston, Other Positive

Engineering disciplines EWF G-7 Displacement Pumps (P)

country base EWF (engineering work force) 36-51 CENT-TURBO 3-9

JP 31-5 Excavation CENTRIF 3-8

UK 31-4 earthwork - site development 25-7 general purpose blower 3-9

US 31-3 machine 25-8 heavy duty, low noise blower 3-9

Engineering management 36-50 manual 25-7 procurment lead times 36-11

disciplines and wage rates Exchange resin PROPELLER 3-8

JP 31-5 demineralizer 15-7 ROT-BLOWER 3-9

UK 31-4 packed towers 8-7, 8-12 VANEAXIAL 3-8

US 31-3 Packing (PAK) 6-7 Fast tracking G-7

expenses and indirects 31-6 Water Treatment Systems (WTS) 15- FB. See Fringe benefits

Engineering, procurement and 7 FE. See Feeders (FE)

construction. See E-P-C Exchangers Feed heaters. See Furnaces, Process

Engines. See Electrical Generators Condensers (C) 9-3 Heaters (FU); Heat Exchangers

(EG); Electrical Motors Evaporators (E) 12-5 (HE); Heating Units (HU)

(MOT); Turbines (TUR) Heat Exchangers (HE) 5-3 Feed pumps. See Piston, Other Positive

EOM G-6 Reboilers (RB) 5-15 Displacement Pumps (P)

EPLCS. See Epoxy resin lining Exercise price G-7 Feed tanks. See Tanks; Vessels

Epoxy Exhausters. See Centrifugal Pumps Feed water treaters. See Water Treatment

default piping materials 18-15 (CP); Compressors; Ejectors Systems (WTS)

lined steel pipe 18-20 (E); Fans, Blowers (FN); Gear Feeders (FE). See also Conveyors (CO)

Epoxy resin lining 28-53 Pumps (GP); Piston, Other Positive BELT 13-10

EQPT-TRACE Displacement Pumps (P); Vacuum BIN-ACTVTR 13-10

electrical plant bulks 22-4 Pumps (VP) ROTARY 13-10

piping plant bulks 18-8 EXIST, buildings 26-4 VIBRATING 13-10

EQRENT relation 35-9 Existing building 26-4 WT-LOSS 13-10

Equipment. See Process equipment Exit G-7 FENCE-WOOD

Equipment and setting EXP-PROOF fencing - site development 25-9

code of accounts 34-6, 34-7 Electrical Motors (MOT) 4-4 FENCING

Equipment fabricate/ship times 36-11 Expected return G-7 fencing - site development 25-9

Equipment hire. See Construction EXPL-DEMOL Fencing

equipment demolition - site development 25-4 site development 25-9

Equipment model library 27-3 Explosion-proof motors Fiber optic cables

Equipment procurement lead times 36- Electrical Motors (MOT) 4-4 instrumentation plant bulks 21-6

11 Exponential smoothing G-7 Fiberglass

Equipment rental. See Construction Export G-7 pipe materials 18-19

equipment Extension G-7 Fiberizers. See Mills (M)

Equity G-6 Extract furnaces. See Furnaces, Process Fibers, combustible

Equity ratios G-6 Heaters (FU); Heating Units (HU) electrical class/division 22-15

Equivalent dividend return G-7 Extraction columns. See Agitated Tanks Field costs G-7

EROSION (AT); Reactors; Towers; Vessels Field erected vessels

landscaping - site development 25-10 Extraction towers 8-4 agitated open tanks

Erosion control Extractors. See Agitated Tanks Agitated Tanks (AT) 2-8

landscaping - site development 25-10 (AT); Centrifuges (CT); Vessels cone roof tanks 10-18

Escalation G-7 EXTRUDER construction 36-64

Escalation, cost reporting 36-39 Mixers (MX) 2-17 floating roof tanks 10-18

Evaporators (E). See also Furnaces, gas holders 10-22

Process Heaters (FU); Heat F lifter roof tanks 10-18

Exchangers (HE); Heating Units open top tanks 10-18

(HU); Wiped Film Evaporators F. See Filters (F) storage tanks 10-18

(WFE) FABR-PLATE Thickeners (T) 14-15

agitated falling film 12-5 steel plant bulks 20-8 tray towers 8-9, 8-14

FALL-FILM 12-5 Fabric filters Field Manpower Summary report

FORCED CIR 12-5 Dust Collectors (DC) 14-6 workforce 36-42

forced circulation 12-5 Fabricated plate items Field manpower titles 30-3, 30-4, 30-5

LONG TUBE 12-5 steel plant bulks 20-8

G3 © ICARUS Corporation, 1998.

I-12 ICARUS Reference

Field mounted solenoid Fire process equipment. See Dryers Floating roof tank (storage)

sensor loop descriptions 21-17 (D); Furnaces, Process Heaters Vertical Tanks (VT) 10-18

Field office 36-56 (FU); Heating Units (HU); Rotary Floor heights/levels, buildings 26-5

disciplines and wage rates Dryers (RD); Stacks (STK); Steam Flow

JP 31-5 Boilers (STB) sensor loop descriptions 21-10

UK 31-4 Fire protection Flow rate

US 31-3 buildings 26-4 units of measure 29-8, 29-16

expenses and indirects 31-6 Firebrick FLR. See Flares (FLR)

Field office construction supervision 36- llining materials 28-51 Flue gas scrubbing systems

53 Fireclay Dust Collectors (DC) 14-6

Field services G-7 lining materials 28-51 Fans, Blowers (FN) 3-8

construction overhead 36-59 FIREP-AREA Filters (F) 14-9

Field shop piping for various materi- insulation plant bulks 23-3 packed towers 8-7, 8-12

als 18-23 FIREP-SSTL Packing (PAK) 6-7

Field warehouse receipt G-7 insulation plant bulks 23-3, 23-4 Fluid heat tracing

Filter Fireproofing existing equipment 18-8

bags. See Dust Collectors insulation plant bulks 23-3 existing pipe runs 18-8

(DC); Filters (F) plant bulks 23-3 Fluidized bed reactors

cloths. See Dust Collectors Firewater demineralizers (WTS) 15-7

(DC); Filters (F) lateral - utility piping services 18-14 SPHERE 10-15

leaves. See Filters (F) loop - utility piping services 18-14 SPHEROID 10-17

presses FIRM CLAY WASHERS (DC) 14-8

PLATE+FRAM 14-9 civil soil types 19-9 Fluidizing conveyor systems. See

Screens (VS) 14-17 Fisher Controls International, Inc. 37-5 Conveyors (CO)

Filters (F) valve information 21-19 Fluorocarbon linings 6-5

CARTRIDGE 14-9 Fixed costs G-7 FN. See Fans, Blowers (FN); Froude

LEAF-DRY 14-9 Fixed mount agitators (AG) 2-3 number

LEAF-WET 14-9 FIXED PROP FOAM. See Foam glass

PLATE+FRAM 14-9 Agitators (AG) 2-3 Foam glass

procurment lead times 36-11 Mixers (MX) 2-17 insulation materials 23-5

ROTY-DISK 14-10 Fixed tube Foam spray systems

ROTY-DRUM 14-11 Heat Exchangers (HE) 5-5 FOAM 18-11

SCROLL 14-12 FIXED-T-S FOOTING

SEWAGE 14-12 Heat Exchangers (HE) 5-5 civil foundation types 19-8

SPARKLER 14-12 FL. See Flakers (FL) Footings

TUBULAR 14-12 Flakers (FL). See also Drum Dryers (DD) civil foundation types 19-8

WHITEWATER 14-12 DRUM 11-6 Footings, wall

Filtrate tanks. See Flammable gasses or vapors civil foundation types 19-7

Receivers; Tanks; Vessels electrical class/division 22-15, 22-16 FORCED CIR

Filtration. See Centrifuges (CT); Dust Flare line Evaporators (E) 12-5

Collectors (DC); Filters (F) utility piping services 18-14 Forced circulation

Fin fan coolers Flares Evaporators (E) 12-5

AIR COOLER (HE) 5-7 John Zink Company 37-7 Foreman

FIN TUBE Flares (FLR), 16-3 craft names and wage rates 30-3, 30-

Heat Exchangers (HE) 5-11 DERRICK 16-4 4, 30-5

Financial forecasting G-7 GUYED 16-5 Foundation subdrain

Financial lease G-7 HORIZONTAL 16-7 drainage - site development 25-5

Financial leverage G-7 introduction 16-3 Foundation types 19-5

Financial ratios G-7 SELF-SUPP 16-6 Foundations

Financial risk G-7 STORAGE 16-8 civil plant bulks 19-3

Financial statements G-7 THRM-OX LC 16-8 Fractionator. See Towers

Financial structure G-7 vapor control 16-8 Frame filters (F) 14-9

Finish float G-7 Flat roof tank (storage) Free float G-8

Finish-to-finish lag G-7 Vertical Tank (VT) 10-18 Free standing wall

Finish-to-start lag G-7 Flg. G-7 fencing - site development 25-9

Finishers. See Drum Dryers Float G-7 FREIGHT

(DD); Evaporators FLOAT-CELL Elevators, Lifts (EL) 13-9

(E); Reactors; Tubular Agitated Tanks (AT) 2-9 Freight

reactors; Wiped Film Evaporators FLOAT-HEAD code of accounts 35-12

(WFE) Heat Exchangers (HE) 5-3 Freight elevator

Finishing. See Mills (M) Floatation machine (AT) 2-9 Elevators, Lifts (EL) 13-9

Finishing activity G-7 Floating head heat exchanger 5-3 Fringe benefits

Finned double-pipe heat exchanger 5-11 Floating lien G-8 construction overhead 36-59

© ICARUS Corporation, 1998. G3

Index I-13

Fringe benefits (FB) G-8 GAS HOLDER Ground beam

Froude number Vertical Tanks (VT) 10-22 civil foundation types 19-7

Agitated Tanks (AT) 2-11 Gas turbine 4-7 Ground grid

FS-WALL Gasifiers. See Vessels electrical plant bulks 22-5

fencing - site development 25-9 GATES Grout

FU. See Furnaces, Process Heaters (FU) fencing - site development 25-9 CONCRETE - civil plant bulks 19-3

Fuel gas GC G-8. See also Gas Compressors Growth crystallizer

utility piping services 18-14 (GC) Crystallizers (CRY) 12-4

Full loan amortization G-8 GEAR Grubbing

FULL-FRAME Gear Pumps (GP) 7-10 earthwork - site development 25-6

Scales (S) 13-12 GEAR DRIVE GUNITE

Fume exhaust systems. See Dust Agitators (AG) 2-3 earthwork - site development 25-6

Collectors (DC) Gear Pumps (GP) Gunite

Funded debt G-8 CANNED RTR 7-10 lining materials 28-52

Funded debt to net working capital G-8 GEAR 7-10 Gunite slope protection

Funds forecast G-8 MECH-SEAL 7-10 earthwork - site development 25-6

Furnaces GEN-SERV Gunning mixes, linings 6-5

procurment lead times 36-11 Centrifugal Pumps (CP) 7-6 Gutter (and curb)

Furnaces, Process Heaters (FU). See also General conditions G-8 site development 25-11

Heating Units (HU) General earthwork GUYED

BOX 5-21 site development 25-6 Flares (FLR) 16-5

HEATER 5-21 General electrical GYRATORY

PYROLYSIS 5-22 electrical plant bulks 22-3 Crushers (CR) 11-3

REFORMER 5-22 General materials

VERTICAL 5-22 base indices 33-3 H

Furniture, buildings 26-4 General purpose

electrical class/division 22-15 Halogenerators. See Mixers (MX)

G General service pumps 7-3, 7-6 HAMMER-MED

Generators. See Electrical Generators Crushers (CR) 11-5

G & A G-8 (EG); Turbines (TUR) Hammermill. See Crushers (CR)

GALLERY Glass. See Foam glass Hammocks G-8

steel plant bulks 20-6 lined steel pipe 18-20 Hand activation

GALV-ANODE lining materials 28-53 sensor loop descriptions 21-17

electrical plant bulks 22-7 Globe Hand excavation

Galvanic anode control valves 21-20 earthwork - site development 25-7

electrical plant bulks 22-7 Fisher control valve information 21- HAND GT

Gantt (bar) chart G-8 19 Hoists (HO) 13-11

Garage 26-4 GMP G-8 Hand hoists

GARAGE, builidngs 26-4 Go Back G-8 Hoists (HO) 13-11

GAS GP. See Gear Pumps (GP) HAND NT

Turbines (TUR) 4-7 Grades Hoists (HO) 13-11

Gas conveyor section types 13-8 HAND PT

standard equations for piping diam- Grading, site development Hoists (HO) 13-11

eters 18-13 landscaping 25-10 HAND-EXCV

utility piping services 18-14 roads - slabs - paving 25-11 earthwork - site development 25-7

Gas absorbers Granulators. See Crushers (CR); Mills Hangers

demineralizer 15-7 (M) piping plant bulks 18-3

packed columns 8-7, 8-12 Graphite HARD ROCK

Packing (PAK) 6-7 default piping materials 18-15 civil soil types 19-9

Gas Compressors (GC). See also Air Grassroots G-8 HARDPAN

Compressors (AC); Fans, Blowers GRATE civil soil types 19-9

(FN) steel plant bulks 20-7 Hastelloy

axial 3-5 Grating default piping materials 18-15

CENTIFG-IG 3-6 GRATE, steel plant bulks 20-7 non-ferrous plate materials

CENTRIF 3-5 GRAVEL ASME 28-9

inline 3-5 civil soil types 19-9 BS 28-21

RECIP-GAS 3-7 Gravel DIN 28-45

RECIP-MOTR 3-7 packing materials 28-55 JIS 28-33

Gas constant 29-10 Gravitational constant 29-10 non-ferrous tube materials

Gas conveying systems. See Air Com- GRND BM ASME 28-14

pressors (AC); Conveyors civil foundation types 19-7 BS 28-26

(CO); Fans, Blowers (FN); Gas GRND-GRID DIN 28-50

Compressors (GC) electrical plant bulks 22-5 JIS 28-38

pipe materials 18-18

G3 © ICARUS Corporation, 1998.

I-14 ICARUS Reference

HAULING High alloy steel Hortonspheriod

earthwork - site development 25-7 default piping materials 18-15 spheroid vertical tanks 10-17

HD STOCK ferrous plate materials Host G-8

Piston, Other Positive Displacement ASME 28-7 HOT TAP

Pumps (P) 7-13 BS 28-19 piping plant bulks 18-9

HDPE-PIPE 18-11 JIS 28-31 How Questimate develops material

HE. See Heat Exchangers (HE) ferrous tube materials costs 36-9

Head design, towers/columns 8-6 ASME 28-13 HP G-8

Heat Exchangers (HE) BS 28-25 HT. See Horizontal Tanks (HT)

AIR COOLER 5-7 JIS 28-37 HU. See Heating Units (HU)

CROSS BORE 5-11 pipe materials 18-17 HUMMER

FIN TUBE 5-11 High density polyethylene pipe 18-11 Screens (VS) 14-16

FIXED-T-S 5-5 High density stock pump HVAC G-8

FLOAT-HEAD 5-3 Piston, Other Positive Displacement Hydraulic convey systems

HEATER-ELC 5-12 Pumps (P) 7-13 pneumatic - Conveyors (CO) 13-5

HEATER-STM 5-12 High energy level process interface units Hydrogenation reactors

JACKETED 5-13 instrumentation plant bulks 21-6 packed columns 8-7, 8-12

ONE SCREW 5-13 High nickel alloy Hydrotreaters

PLAT+FRAM 5-14 casting materials 28-54 CYLINDER 10-8

PRE-ENGR 5-10 High pressure gas/liquid storage Hypalon rubber

procurment lead times 36-11 Vertical Tanks (VT) 10-15 lined steel pipe 18-20

SHELL+TUBE 5-11 Histogram G-8

SPIRAL PLT 5-13 Historical average cost of capital G-8 I

SUC-HEATER 5-12 Historical cost estimating G-8

TEMA exchanger construction HL-PIU I-P (inch-pound)

nomenclature 5-23 instrumentation plant bulks 21-6 units of measure 29-3, 36-39

TEMA types 5-24 HO. See Hoists (HO) ICARUS 2000 G-8

TWO SCREW 5-13 HOIST ICARUS Process Evaluator (IPE) G-8

U-TUBE 5-8 Cranes (CE) 13-9 ICARUS Project Manager (IPM) G-8

WASTE HEAT 5-14 Hoists (HO) 13-11 ICARUS systems are based on craft

Heat recovery units. See Furnaces, Hoist labor 36-8

Process Heaters (FU); Heat construction equipment 32-9 Icon G-8

Exchangers (HE); Heating Units Hoist trolley ICUE G-8

(HU); Steam Boilers (STB) Cranes (CE) 13-9 Immersion heaters

Heat tracing Hoists (HO). See also Cranes (CE) HEATER-ELC (HE) 5-12

piping plant bulks 18-8 1 SPEED 13-11 Impactors. See Crushers (CR); Mills (M)

Heat transfer. See Furnaces, Process 5 SPEED 13-11 Impeller materials 2-14

Heaters (FU); Heat Exchangers HAND GT 13-11 Impeller type references 2-14

(HE); Reboilers (RB) HAND NT 13-11 Impeller types 2-12, 2-13

Heat treated steel HAND PT 13-11 Import G-8

ferrous plate materials HOIST 13-11 IN LINE

ASME 28-4 Holding tanks. See Tanks; Vessels Centrifugal Pumps (CP) 7-8

BS 28-16 Home office 36-56 In line pump. See Centrifugal Pumps

DIN 28-40 disciplines and wage rates (CP); Piston, Other Positive

JIS 28-28 JP 31-5 Displacement Pumps (P)

HEATER UK 31-4 Incoloy

Furnaces, Process Heaters (FU) 5-21 US 31-3 tube materials

HEATER-ELC expenses and indirects 31-6 ASME 28-14

Heat Exchangers (HE) 5-12 Home office construction services 36-53 BS 28-26

HEATER-STM Homogenizers. See Mixers (MX) DIN 28-50

Heat Exchangers (HE) 5-12 Honeywell Inc. 37-6 JIS 28-38

Heating, buildings 26-4 Honeywell TDC 2000/3000 process Income bonds G-9

Heating Units (HU). See also Furnaces, control system 21-4 Income statement G-9

Process Heaters (FU) Hoppers. See Receivers; Tanks; Vessels

CYLINDER 15-5 HORIZ-DRUM

dowtherm unit 15-5 Horizontal Tanks (HT) 10-5

Hedging approach G-8 HORIZONTAL

Heights/levels, buildings 26-5 Flares (FLR) 16-7

Help G-8 Horizontal plate filters 14-9

Helper, crew mix 36-42 Horizontal Tanks (HT)

Hemispherical towers 8-5 HORIZ-DRUM 10-5

Hemispheriod JACKETED 10-7

speheroid vertical tanks 10-17 MULTI WALL 10-3

© ICARUS Corporation, 1998. G3

Index I-15

Inconel overview of report details 21-21 IPM. See ICARUS Project Manager

casting materials 28-54 panel 21-3 Iron

clad plate materials panel action descriptions 21-18 casting materials 28-54

ASME 28-10 panel option descriptions 21-19 IRR. See Internal rate of return (IRR)

JIS 28-34 plant bulks 21-3 ISO G-9

default piping materials 18-15 pneumatic multi-tube bundle runs 21- Isomerization reactors. See Distillation

pipe materials 18-18 3 systems

tube materials report details for analog/electrical 21- Isometric drawing. See ISO

ASME 28-14 22 Isostrippers. See Distillation systems

BS 28-26 sensor loop descriptions 21-7 Issued stock G-9

DIN 28-50 signal wire 21-3 Item G-9

JIS 28-38 thermocouple wire 21-3 Item run G-9

Incremental average cost of capital G-9 transmitter type 21-20 Item symbols

Indenture G-9 INSUL-AREA process equipment 1-3

Indices. See Base indices insulation plant bulks 23-3

INDIRECT INSUL-PIPE J

Rotary Dryers (RD) 12-11 insulation plant bulks 23-3

Indirect costs G-9 Insulation J-HAMMER

Indirects 36-53 code of accounts 34-13 earthwork - site development 25-7

code of accounts 34-5, 35-12 cold schedule 23-9, 23-10, 23- JAC-VACUUM

construction 36-64 14, 23-15 Rotary Dryers (RD) 12-11

construction overhead 36-59 existing piping 23-3 JACKETED

engineering 31-6 existing surface area 23-3 Heat Exchangers (HE) 5-13

INDIRECTS relation 35-12 fireproofing 23-3 Horizontal Tanks (HT) 10-7

Induction motors. See Electrical Motors hot - heavy schedule 23-8, 23-13 reactors. See Towers

(MOT) hot - light schedule 23-6, 23-11 Vertical Tanks (VT) 10-13

Industrial gate hot - medium schedule 23-7, 23-12 Jacketed rotary vacuum dryer

fencing - site development 25-9 materials 23-5 Rotary Dryers (RD) 12-11

Industry forecast G-9 piping (existing) 23-3 Jackhammer

Industry ratios G-9 plant bulks 23-3 earthwork - site development 25-7

Inert gas structural steel (existing) 23-3 JAW

utility piping services 18-14 Insulation and fireproofing Crushers (CR) 11-4

Inertial wet collectors plant bulks 23-3 Jet vacuum equipment. See Ejectors

Dust Collectors (DC) 14-6 Intalox saddles (E); Refrigeration Units (RU)

Inflation G-9 packing materials 28-55 JIS G-9

Info G-9 Intensifiers. See Blenders JIS design code

Inline (BL); Kneaders (K); Mixers (MX) clad plate materials 28-34

Gas Compressors (GC) 3-5 Intercoolers. See Air Dryers (AD); Heat ferrous plate materials

Inpregnators. See Vessels Exchangers (HE) carbon steel 28-27

Input-output model G-9 Interliners. See Linings heat treated steel 28-28

INST-PANEL Intermediate alloy steel high alloy steel 28-31

instrumentation plant bulks 21-3 pipe materials 18-17 low alloy steel 28-29, 28-30

INST-TRAY Intermediate term loan G-9 ferrous tube materials

instrumentation plant bulks 21-3 Internal rate of return (IRR) G-9 carbon steel 28-35

INST-WIRE International Electrical Code (IEC) 22- high alloy steel 28-37

instrumentation plant bulks 21-3 16 low alloy steel 28-36

Installation bulks G-9 Intrinsic value G-9 non-ferrous plate materials 28-32

Instrument Inventory holding costs G-9 non-ferrous tube materials 28-38

air. See Air Compressors (AC) Inventory reorder costs G-9 plate materials 28-27

Instrument air Inventory shortage costs G-9 tube materials 28-35

utility piping services 18-14 Inventory turnover G-9 John Zink Company 37-7

Instrumentation INVERTING JP country base 36-38

cable tray 21-3 Centrifuges (CT) 14-5 base indices 33-3

code of accounts 34-11 Inverting filter centrifuge craft wage rates 30-5

control valve options 21-20 Centrifuges (CT) 14-5 engineering wage rates 31-5

data-highway cable 21-6 Ion exchangers. See Packed expenses 31-6

fiber optic cables 21-6 columns; Water Treatment Systems indirects 31-6

Honeywell TDC 2000/3000 process (WTS) units of measure 36-39

control system 21-4 demineralizer 15-7 wire sizes 22-14

Honeywell TDC3000 21-6 Ion-exchange resins. See JUNC-BOX

junction boxes 21-4 Demineralizers; Packed columns instrumentation plant bulks 21-4

multifunction controllers 21-4 Packing, Linings (PAK, LIN) 6-7 Junction boxes

operator center 21-6 IPE. See ICARUS Process Evaluator instrumentation plant bulks 21-4

G3 © ICARUS Corporation, 1998.

I-16 ICARUS Reference

Jury of executive opinion method for Leading indicator G-10 introduction 6-5, 6-6

forecasting G-9 LEAF-DRY lead 6-6

Fitlers (F) 14-9 metallic 28-53

K LEAF-WET monolithic 28-52

Filters (F) 14-9 organic 6-7

K. See Kneaders (K) Lease G-10 procurment lead times 36-11

See Kneaders (K) Lease capitalization G-10 refractory brick 6-6

Karbate Lease capitalization rate G-10 replaceable 28-52

default piping materials 18-15 Length resin 6-6

KETTLE units of measure 29-5, 29-11, 29-12 rubber 6-6

Reboilers (RB) 5-15 Level zinc 6-6

TEMA exchanger construction sensor loop descriptions 21-11 Link G-10

nomenclature 5-23 Levels, buildings 26-5 Liquid

TEMA Types 5-24 Leverage G-10 standard equations for pipe diam-

Kettle reboiler Leverage ratios G-10 eters 18-13

Reboilers (RB) 5-15 LG BLOCK Liquidation value G-10

Kilns. See Reboilers (RB) civil foundation types 19-6 Liquidity G-10

Kneaders (K). See also Agitators Libraries Liquidity ratios G-10

(AG); Blenders (BL); Mixers (MX) equipment model 27-3 Live bottom

STATIONARY 2-16 unit cost 27-3 Vertical Tanks (VT) 10-24

TILTING 2-16 Library G-10 LIVE BTM

VAC-TILTING 2-16 Lien G-10 Vertical Tanks (VT) 10-24

Knock-out drums. See Tanks; Vessels LIFT Live loads

Horizontal Tanks (HT) 10-3 Vertical Tanks (VT) 10-18 civil structure 19-9

Vertical Tanks (VT) 10-8 Lifter roof tank (storage) LJ G-10

KV G-10 Vertical Tanks (VT) 10-18 LL-PIU

KVA G-10 Lifts. See Elevators, Lifts (EL) instrumentation plant bulks 21-6

KW G-10 Lighting Loaded labor rate G-10

KY (thousand YEN) 30-5 (area) electrical plant bulks 22-6 Loaders. See Conveyors (CO); Elevators,

Kynar Lighting, buildings 26-4 Lifts (EL); Feeders (FE); Hoists

lined steel pipe 18-20 Limestone (HO)

Kynar sheet lining 28-53 packing materials 28-55 Loads, live typical structure 19-9

LIN. See Packing, Linings (PAK, LIN) Loan amortization G-10

L Line of credit G-10 Local control network (LCN) 36-18

LAB, buildings 26-4 Line siding crossing Lock-box system G-10

Labor burden G-10 railroads - site development 25-13 Log G-10

Labor cost G-10 Lined steel pipe 18-20 LONG TUBE

Laboratory 26-4 Lined vessels Evaporators (E) 12-5

LADDER default piping materials 18-15 Long tube rising film

steel plant bulks 20-7 Lining materials Evaporators (E) 12-5

Ladders 20-7 abrasion resistant 28-52 Long tube vertical

caged 20-3, 20-7 brick 28-51 Evaporators (E) 12-6

Lag G-10 firebrick 28-51 LONG-VERT

Lagging indicator G-10 fireclay 28-51 Evaporators (E) 12-5

LANDSCAPE glass 28-53 Loop descriptions - instrumentation. See

landscaping - site development 25-10 gunite 28-52 Sensor loop descriptions

Landscaping metalic 28-53 Loss-in-weight

site development 25-10 monolithic 28-52 Feeders (FE) 13-10

Late finish G-10 organic 28-53 Low alloy steel

Late start G-10 over membrane-lined carbon steel 28- casting materials 28-54

LAUNDER-RD 51 default piping materials 18-15

piping plant bulks 18-9 replaceable 28-52 pipe materials 18-17

LAUNDER-SQ Linings. See Packing, Linings (PAK, plate materials

piping plant bulks 18-9 LIN) ASME 28-5, 28-6

Launders abrasion resistant 28-52 BS 28-17, 28-18

piping 18-9 acid brick 6-5, 6-7 DIN 28-41

LD STOCK brick 6-6, 6-7 JIS 28-29, 28-30

Screens (VS) 14-17 castable refractories 6-5, 6-7 tube materials

Lead difficulty adjustments 6-8 ASME 28-12

linings 6-6 firebrick 6-7, 28-51 BS 28-24

Lead times fluorocarbon 6-5 DIN 28-48

process equipment procurement 36- glass 6-7, 28-53 JIS 28-36

11 gunning mixes 6-5, 6-7

© ICARUS Corporation, 1998. G3

Index I-17

Low consistency bow screen Mastocators. See Agitators MIKRO-PULV

Screens (VS) 14-17 (AG); Blenders (BL); Mixers (MX) Mills (M) 11-7

Low consistency stock pump Material costs (Questimate) 36-9 Milestones G-11

Centrifugal Pumps (CP) 7-9 Material selections. See ASME design Mill building

Low energy level process interface units code; BS design code; Casting steel plant bulks 20-5

instrumentation plant bulks 21-6 materials; DIN design code; JIS MILL-BLDG

Lump sum quotation design code; Lining steel plant bulks 20-5

site development materials; Packing materials Mills (M). See also Crushers (CR)

demolition 25-4 Materials. See ASME design code; BS ATTRITION 11-7

drainage 25-5 design code; DIN design code; JIS attrition mill 11-7

earthwork 25-6 design code AUTOGENOUS 11-7

fencing 25-9 insulation 23-3, 23-5 autogenous mill 11-7

landscaping 25-10 Materials of construction BALL MILL 11-7

piling 25-12 towers 8-6 ball mill 11-7

railroads 25-13 Maturity value of a bond G-11 micro-pulverizer 11-7

roads / slabs / paving 25-11 MCC G-11 MIKRO-PULV 11-7

electrical plant bulks 22-10 procurment lead times 36-11

M MCC equipped space G-11 rod charger 11-7

MECH-BOOST ROD MILL 11-7

M. See Mills (M) Vacuum Pumps (VP) 9-7 rod mill 11-7

MACH-PULP MECH-SEAL ROD-CHARGR 11-7

Agitated Tanks (AT) 2-9 Agitators (AG) 2-3 ROLLER 11-7

Machine excavation Gear Pumps (GP) 7-10 roller mill 11-7

earthwork - site development 25-8 MECHANICAL Mineral wool

MAG DRIVE Crystallizers (CRY) 12-3 insulation materials 23-5

Centrifugal Pumps (CP) 7-9 Refigeration Units (RU) 15-5 Minimum market value G-11

Main Vacuum Pumps (VP) 9-7 MISC-STEEL

fractionators. See Distillation systems Mechanical steel plant bulks 20-7

line piping. See Yard pipe collectors. See Dust Collectors (DC) Miscellaneous

towers. See Towers crystallizers. See Crystallizers (CRY) construction overhead 36-59

Main substation G-10 seal agitators, MECH-SEAL (AG) 2- Miscellaneous equipment

power distribution 36-31 3 construciton equipment 32-9

Maintenance lease G-10 Mechanical bar screens procurment lead times 36-11

Make-up Screens (VS) 14-17 Miscellaneous expenses 36-53

air units. See Compressors; Fans, Mechanical booster 9-7 Miscellaneous indirect costs G-11

Blowers (FN) Mechanical engineering G-11 Miscellaneous useful constants 29-10

compressors. See Compressors Mechanical oil-sealed vacuum pump 9-7 MIXER

Making a market G-10 mechanical scraped-surface crystallizer Agitated Tanks (AT) 2-5, 2-6

Man-hours Crystallizers (CRY) 12-3 Mixer-cookers. See Drum Dryers

adjustments 36-54 Mechanical/non-mechanical wage (DD); Dryers (D); Mixers

engineering adjustements 36-56 rates 30-6 (MX); Tray Drying Systems (TDS)

Manholes MED-ROCK Mixers (MX)

civil foundation types 19-8 civil soil types 19-9 EXTRUDER 2-17

drainage - site development 25-5 MESH FIXED PROP 2-17

towers 8-5 fencing - site development 25-9 MULLER EXT 2-17

Manual activation Metalic chests PAN 2-18

sensor loop descriptions 21-17 Vertical Tanks (VT) 10-28 PORT-PROP 2-17

Marginal average cost of capital G-11 Metallic procurment lead times 36-11

Marginal cost of capital G-11 lining materials 28-53 SIGMA 2-17

Mark text G-11 Metering pumps. See Gear Pumps SPIRAL RIB 2-17

Mark-up G-11 (GP); Piston, Other Positive STATIC 2-18

Market extension merger G-11 Displacement Pumps (P) TWO-ROLL 2-18

Market value G-11 Methanators. See Mobilization

Mass Columns; Reactors; Towers; Vessels construction overhead 36-59

units of measure 29-6, 29-14 METRIC Mobilization/Demobilization G-11

Mass per length units of measure 29-3, 36-39 Molecular sieve

units of measure 29-6 Micro-pulverizer packing materials 28-56

Mass per volume Mills (M) 11-7

units of measure 29-6 Micro-scheduling G-11

Mass pours Micronizers. See Crushers (CR); Mills

civil foundation types 19-5 (M)

MASSPOUR Microprocessor

civil foundation types 19-5 transmitter type 21-20

G3 © ICARUS Corporation, 1998.

I-18 ICARUS Reference

Monel Neoprene rubber ONE DECK

casting materials 28-54 lined steel pipe 18-20 Screens (VS) 14-16

clad plate materials Neoprene sheet lining 28-53 ONE SCREW

ASME 28-10 NEPNE. See Neoprene sheet lining Heat Exchangers (HE) 5-13

JIS 28-34 Net cash flows G-11 OPEN

default piping materials 18-15 Net present value (NPV) G-11 Electrical Motors (MOT) 4-3

pipe materials 18-18 Net working capital (NWC) G-11 OPEN BELT

tube materials Net working capital turnover G-11 Conveyors (CO) 13-3

ASME 28-14 Net worth G-11 Open excavations

BS 28-26 Net worth turnover G-12 drainage - site development 25-5

DIN 28-50 Network G-12 Open structure

JIS 28-38 Network analysis G-12 steel plant bulks 20-3

MONOLITHIC Network diagram G-12 OPEN TOP

Packing, Linings (PAK, LIN) 6-7 Neutralizers. See Mixers Agitated Tanks (AT) 2-8

Monolithic (MX); Reactors; Vessels Open top tank (storage)

lining materials 28-52 NEWCOA relation 35-8 Vertical Tanks (VT) 10-18

Mortgage bond G-11 Nickel Open-end mortgage bond G-12

MOT. See Electrical Motors (MOT) casting materials 28-54 Operating costs

Motion: axial, radial, vibration clad plate materials engineering adjustements 36-56

sensor loop descriptions 21-14 ASME 28-10 Operating lease G-12

Motor control center JIS 28-34 Operating leverage G-12

electrical plant bulks 22-10 default piping materials 18-15 Operational unit area G-12

Motor sizes (standard) pipe materials 18-18 Operator center

Electrical Motors (MOT) 4-6 plate materials instrumentation plant bulks 21-6

Motor speeds BS 28-21 Operator centers 36-14, 36-15, 36-17

synchronous 4-6 DIN 28-45 defining 36-21, 36-22

Motors. See Electrical Motors (MOT) JIS 28-33 major cost items 36-17, 36-18

procurment lead times 36-11 tube materials OPN-STL-ST

Mouse G-11 ASME 28-14 steel plant bulks 20-3

Moving averages G-11 BS 28-26 Opportunity cost G-12

MPS G-11 DIN 28-50 Option menu G-12

MULCH JIS 28-38 Order of magnitude: -30 to +50 percent

landscaping - site development 25-10 Nitrile rubber estimate G-12

MULLER EXT lined steel pipe 18-20 Organic

Mixers (MX) 2-17 NON-COND lining materials 28-53

MULT-CYCLO Turbines (TUR) 4-7 Organizational goal G-12

Dust Collectors (DC) 14-8 Non-condensing turbine 4-7 Organized exchange G-12

MULTI WALL Non-reversible hammermill Origin G-12

Horizontal Tanks (HT) 10-3 Crushers (CR) 11-5 OSHA G-12

Vertical Tanks (VT) 10-11 Nozzles OSLO

MULTI-CONT towers 8-5 Crystallizers (CRY) 12-4

instrumentation plant bulks 21-4 NPV. See Net present value (NPV) OT G-12

Multi-project analysis G-11 NWC. See Net working capital (NWC) OTHER

Multi-stage pumps. See Centrifugal Packing, Linings (PAK, LIN) 6-7

Pumps (CP); Piston, Other Positive O Other

Displacement Pumps (P) units of measure 29-10

Multifunction controllers OCT+PROJ Other positive displacement pumps. See

instrumentation plant bulks 21-4 civil foundation types 19-5 Piston, Other Positive Displacement

Multiple cyclone OCTAGONL Pumps (P)

Dust Collectors (DC) 14-8 civil foundation types 19-5 Other project costs

Multiple workforces 36-40 OFF-MACH code of accounts 34-5, 35-12

MWOOL. See Mineral wool Agitated Tanks (AT) 2-9, 2-10 Overhead G-12

Office building 26-4 Overhead transmission line

N OFFICE, buildings 26-4 electrical plant bulks 22-9

Offsites G-12 Overview of instrumentation report

National Electrical Code 22-15 OH G-12 details 21-21

Near-atmospheric gas storage Oil circuit breakers Overview of system input specifications

Vertical Tanks (VT) 10-21 electrical plant bulks 22-9 for power 36-27

Near-atmospheric liquid storage OIL-C-BRKR Oxidizers. See Agitated Tanks

Vertical Tanks (VT) 10-18 electrical plant bulks 22-9 (AT); Double Diameter Towers

Negative float G-11 OIL-WATER (DDT); Horizontal Tanks

Negatively correlated projects G-11 Separation Equipment (SE) 14-13 (HT); Single Diameter Towers

NEMA G-11 OK G-12 (TW); Vertical Tanks (VT)

© ICARUS Corporation, 1998. G3

Index I-19

P Pall rings. See Raschig rings Pipe envelope

introduction 6-3 area specifications 36-6

P. See Piston, Other Positive Displace- packing materials 8-5, 28-55 Pipe rack

ment Pumps (P) PAN steel plant bulks 20-3, 20-4

P&ID G-12 Dryers (D) 12-9 Pipe runs

Package refrigeration Mixers (MX) 2-18 piping plant bulks 18-3

procurment lead times 36-11 Panel Pipe schedule 18-12

Package transformer with panel instrumentation plant bulks 21-3 PIPE-RACK

PKG-TRANSF 22-11 solar, electrical plant bulks 22-8 steel plant bulks 20-3, 20-4

PACKAGED Panel action descriptions PIPE-SUPPT

Cooling Towers (CTW) 15-3 instrumentation 21-18 steel plant bulks 20-5

Packaged system Panel option descriptions PIPE-TRACE

Wiped Film Evaporators (WFE) 12-7 instrumentation 21-19 electrical plant bulks 22-4

PACKED Par value G-12 piping plant bulks 18-8

Double Diameter Towers (DDT) 8-7 Parallel activities G-12 Pipeline reactors. See Heat Exchangers

Single Diameter Towers (TW) 8-12 Particles, combustible (HE); Reactors; Tubular reactors

PACKING electrical class/division 22-15 jackedted pipe heat exchanger

Packing, Linings (PAK, LIN) 6-7 PASSENGER (HE) 5-13

Packing Elevators, Lifts (EL) 13-9 Piping

activated aluminas 6-4 Path G-12 above-grade 18-3

activated carbon 6-5 PAVING API pipe, ferrous materials 18-16

berl saddle 6-4 civil foundation types 19-5 buried 18-3

Packing, Linings (PAK, LIN). See also site development 25-11 buried concrete 18-6

Linings Paving coat and wrap 18-9

ACID BRICK 6-7 site development 25-11 code of accounts 34-8

activated aluminas 6-4 Payback method (PM) G-12 construction equipment 32-8, 32-10

activated carbon 6-5 Payroll burdens 36-53 control valve size 18-4

adjustments by difficulty 6-8 PC G-12 default materials 18-15

Berl saddle 6-4 Percent-of-sales method for diameters 18-12

Intalox saddle 6-4 forecasting G-13 drainage - site development 25-5

introduction to lining 6-5 Permits ductwork 18-6

introduction to packing 6-3 code of accounts 35-12 elbows 18-12

MONOLITHIC 6-7 Perpetual bond G-13 ferrous materials 18-16

OTHER 6-7 Perpetual warrants G-13 fluid heat tracing 18-8

PACKING 6-7 PERT. See Program evaluation and hig allow steel, ferrous materials 18-

Pall ring 6-3 review technique (PERT) 17

Raschig rings 6-3, 6-4 PF. See Power function hot tap 18-9

ring type packing 6-3 PF-CORRECT insulation for existing 23-3

Saddle type 6-3 Power factor connection capaci- launders 18-9

Packing materials 28-55, 28-56 tor 22-12 line steel 18-20

Packings PFD G-13 materials 18-16

procurment lead times 36-11 Phase 0 G-13 non-ferrous materials 18-18

tower internals 8-4 Phase I G-13 non-standard 18-12

PAC's G-12 Phase II G-13 paint 24-3

Paid-in capital G-12 PIER paint existing piping 24-3

Paid-in surplus G-12 civil foundation types 19-8 plant bulks 18-3

Paint Pile caps process ductwork 18-6

code of accounts 34-13 civil foundation types 19-6 remote & field shop for various

existing piping 24-3 PILECAP materials 18-23

existing structural steel 24-3 civil foundation types 19-6 remote shop procedures 18-24

existing surface 24-3 Piles, site development small bore procedures 18-25

grades 24-3 piling 25-12 spool type chart 18-20

introduction 24-3 PILING standard equations for pipe diam-

plant bulks 24-3 piling - site development 25-12 eter 18-13

process equipment 24-4 Piling tracing existing piping run 22-4

PAINT-AREA construction equipment 32-7 transfer lines 18-3

paint plant bulks 24-3 site development 25-12 UTIL-PIPE 18-5

PAINT-PIPE PIPE utility headers 18-5, 18-14

paint plant bulks 24-3 piling - site development 25-12 utility service lines 18-5

PAINT-SSTL Pipe utility services 18-14

paint plant bulks 24-3 rack, steel plant bulks 20-3 Victaulic Company of America 37-8

PAK. See Packing, Linings (PAK, LIN) supports, steel plant bulks 20-5 well head 18-10

yard pipe runs 18-3

G3 © ICARUS Corporation, 1998.

I-20 ICARUS Reference

Piston, Other Positive Displacement ferrous - low alloy steel 28- Potable water

Pumps (P) 29, 28-30 utility piping services 18-14

DIAPHRAGM 7-11 non-ferrous 28-32 Potential measurement test station

DUPLEX 7-11 PLATE+FRAM electrical plant bulks 22-8

HD STOCK 7-13 Filters (F) 14-9 Pounds Sterling

RECIP-MOTR 7-12 PLATFORM currency base 36-37, 36-38

ROTARY 7-12 steel plant bulks 20-6 POURED

SIMPLEX 7-11 PLC G-13, 36-25 piling - site development 25-12

SLURRY 7-12 PLC control centers 36-25, 36-26 Pours (mass)

TRIPLEX 7-11 Plot plan G-13 civil foundation types 19-5

PKG-TRANSF Plumbing, buildings 26-4 Power

electrical plant bulks 22-11 Plunger pump, reciprocating recovery turbines. See Electrical

Plant air Piston, Other Positive Displacment Generators (EG); Turbines (TUR)

Air Compressors (AC) 3-3 Pumps (P) 7-12 units of measure 29-9, 29-18

utility piping services 18-14 PM/PE G-13 Power distribution

Plant air dryers. See Air Dryers (AD) PN. See Power number components 36-29, 36-30

Plant bulk G-13 PNEUMATIC country base location differences 36-

Plant bulks. See Conveyors (CO) 13-5 29

Civil; Electrical; Fireproofing; Instrumentation; Insulation; Paint; Piping; Steel Pneumatic conveying system default 36-35

introduction 17-3 Conveyors (CO) 13-5 input specifications 36-27, 36-28

list of 17-3 Pneumatic portable tool introduction 36-29

PLANTING construction equipment 32-9 main substation 36-31

landscaping - site development 25-10 PNU-TUBING primary feeders 36-31

PLAST TANK instrumentation plant bulks 21-3 redundancy 36-32, 36-33

Vertical Tanks (VT) 10-21 PO G-13 reporting 36-36

Plastic storage tank POLE-LINE supply and distribution 36-29

Vertical Tanks (VT) 10-21 electrical plant bulks 17-5, 22-9, 22- transmission lines 36-31

Plastic-lined carbon steel valves 11, 22-12 unit substations 36-31

DOW Plastic-Lined Piping Prod- Polymerizers. See Reactors; Tubular unreferenced area requiring

ucts 37-4 reactors power 36-35