Professional Documents

Culture Documents

Marine Electronics Communications Article

Uploaded by

Sơn TrầnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Marine Electronics Communications Article

Uploaded by

Sơn TrầnCopyright:

Available Formats

46 | CARGO CONTROL

Integrating tank monitoring,

control and automation

Scanjet’s ITAMA system is an integrated cargo tank monitoring and

automated control system for chemical, product and crude oil tankers

S

canjet developed the intelligent

tank management system,

ITAMA, with integrated cargo

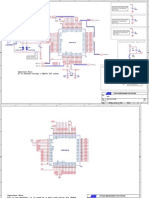

ITAMA is an integrated tank monitoring and control

tank monitoring and automated

controls, in 2017. It is intended for tankers

with complex cargo tank configurations.

A new addition, introduced this year, is a

wireless tank monitoring and alarm unit

that is certified to meet two EU directives

about explosive atmospheres (atmosphères Electropneumatic Tank pressure

explosibles, or ATEX) that crew can use to gauging Oil discharge monitoring Line pressure

and control system Pump pressure

keep track of tank levels and operations. Sensor with enclosure

Managing director Niklas Falkmer

explained to Marine Electronics &

Communications that ITAMA was

required because shipowners were

under greater pressures than before to

protect high-value cargoes and comply

with increasingly stringent safety and

environmental regulations.

Uninterruptible

He said ITAMA was scalable and could power supply

be adapted by shipyards for different

owner requirements, reducing newbuilding

costs. For tanker owners, he said “the

synergies among the related products are

key to achieving operating economies and

maintaining vessel compliance with new

regulations as they emerge.”

ITAMA incorporates automatic and real-

time tank monitoring alarm and control

and remote valve and pump controls.

These are linked to:

• Fixed and portable tank cleaners.

• Pressure valves.

• Gas-freeing equipment.

• Inert gas system. Temperature Microwave radar

Draft gauging Various tanks

• Oil-discharge monitor. compensated hydrostatic level gauging

pressure sensor

• Vapour emission control.

ITAMA has been designed as a modular

platform, said Mr Falkmer. This brings Electric pressure sensors

together “embedded proprietary software,

an operating system and hardware in

an integrated system.” It has flexibility

Marine Electronics & Communications | 2nd Quarter 2018 www.marinemec.com

CARGO CONTROL | 47

in input and output (I/O) connections for

different tanker configurations. ITAMA

can “accommodate virtually unlimited “ITAMA can accommodate virtually unlimited

numbers and types of instruments with

more than 3,000 I/O connections,” he said. numbers and types of instruments with

It can also communicate with non-Scanjet

equipment and can be “upgraded to meet

more than 3,000 I/O connections”

new standards, regulations and changing

requirements,” he added.

Scanjet has avoided multiplexing signals

to simplify installation, commissioning ITAMA has its own power supply, and battery-powered memory backup

and diagnostics. It incorporated multiple voltage, cabling and sensors. There is also ensures data preservation. “Critical

workstations with touchscreens that display redundancy as it can switch to alternate settings protection, local and remote

tank levels and a link to a tanker’s satellite power supplies and system settings are kept trouble-shooting and watchdog functions

communications network so managers can in multiple locations within the electronics. have been built into the system for

provide crew with remote support. There is no hard disc or moving parts absolute reliability,” said Mr Falkmer.

ITAMA tank level and liquid density

measurement technology is based on

high-frequency radar and temperature-

compensated absolute pressure sensors.

system that connects a whole ship‘s network “Proprietary mathematical algorithms filter

out instrument fluctuations and compensate

for the effects of tank liquid movement

arising from pitch and roll, additionally

Tank cleaning

avoiding false alarms,” said Mr Falkmer.

Inert gas system Portable tank Temperatures are measured at multiple

cleaning Gas freeing fan points, with readings used to recalculate

NEW

the specific gravity of a liquid automatically

as a function of the temperature. ITAMA

can also have an electro-pneumatic

system for tank level gauging and

submersed pressure sensors.

There is a system control panel with

Air driven a digital readout of each measuring point

and user-defined visual and audible

alarms. This can be connected to other

onboard monitoring and alarm systems

and the tanker’s loading computer through

serial line communications.

ITAMA continuously corrects level

readings to compensate for the vessel’s

trim and list. It automatically monitors oil

discharge and controls the overboard

and slop tank valves. It has a single- or

dual-point high-level and overfill alarm that

displays on the alarm panel and is linked

to external lights and siren.

Scanjet has also included a sensor pack

for measuring volatile organic compounds

Anti-pirate (VOCs), such as liquefied petroleum gases,

water cannon

and controlling pressure release valves.

“This ensures ullage space pressure does

Independent overfill alarms

not drop below the VOC valve’s opening

Vapour emission control SCANVENT P/V valves Temperature element pressure,” said Mr Falkmer.

“During loading, the main valve opens

to provide full capacity but during a voyage

it is only the thermal variations valve

that works,” he explained. This improves

VOC handling and optimises use of inert

gas plant. All this is integrated with tank

management and cleaning controls. MEC

www.marinemec.com Marine Electronics & Communications | 2nd Quarter 2018

You might also like

- Can CrusherDocument81 pagesCan CrusherJhon Don100% (1)

- Linde HeavyDutyMotors PDFDocument44 pagesLinde HeavyDutyMotors PDFAndre StorianNo ratings yet

- Guide To ResistorsDocument34 pagesGuide To ResistorsViet Anh NguyenNo ratings yet

- Design of Analog Filters ShauumanDocument7 pagesDesign of Analog Filters ShauumanReem El-Adawi50% (4)

- ASC SpecificationsDocument6 pagesASC SpecificationsChan Sek YeongNo ratings yet

- Micom P241 Motor Management RelayDocument12 pagesMicom P241 Motor Management Relaydave chaudhuryNo ratings yet

- Manual-V2Document44 pagesManual-V2Ray DavisNo ratings yet

- Ger 3658d Speedtronic Mark V Gas Turbine Control System PDFDocument19 pagesGer 3658d Speedtronic Mark V Gas Turbine Control System PDFyos100% (1)

- Spec Nalco Trasar 3DTfBoilerDocument16 pagesSpec Nalco Trasar 3DTfBoilercarlos caleroNo ratings yet

- Automatic Controls for Heating and Air Conditioning: Principles and ApplicationsFrom EverandAutomatic Controls for Heating and Air Conditioning: Principles and ApplicationsRating: 4 out of 5 stars4/5 (2)

- DL8000 Preset Controller - For Measuring The Loading of Liquid Hydrocarbons Into Transporting TankersDocument8 pagesDL8000 Preset Controller - For Measuring The Loading of Liquid Hydrocarbons Into Transporting Tankerssalem100% (1)

- MA408 Ultrasonic Water MeterDocument9 pagesMA408 Ultrasonic Water Meterjaja_asa50% (2)

- ABB Aquamaster 3Document40 pagesABB Aquamaster 3prasanthvvNo ratings yet

- Atmos Tightness Monitor: Statistical Tightness Monitoring System For Airport Hydrant SystemsDocument2 pagesAtmos Tightness Monitor: Statistical Tightness Monitoring System For Airport Hydrant SystemsBen Hamed KhaterNo ratings yet

- A Production Logging Tool With Simultaneous Measurements: February 1980 191Document8 pagesA Production Logging Tool With Simultaneous Measurements: February 1980 191Lulut Fitra FalaNo ratings yet

- Rex TI Sales 201019en Ed2 RevADocument16 pagesRex TI Sales 201019en Ed2 RevAwilfredoNo ratings yet

- Ap M09 02a 01e - 509 - ItmDocument8 pagesAp M09 02a 01e - 509 - Itmlaime_floresNo ratings yet

- Valve Actuation at The World's Largest Flow Metering: Calibration FacilityDocument5 pagesValve Actuation at The World's Largest Flow Metering: Calibration FacilityFelipe Gamboa GálvezNo ratings yet

- Ficha Técnica Medidor Gallus IV PSCDocument2 pagesFicha Técnica Medidor Gallus IV PSCAlejandro Olivo ZúñigaNo ratings yet

- Ficha Técnica Medidor Gallus IV PSCDocument2 pagesFicha Técnica Medidor Gallus IV PSCAlejandro Olivo ZúñigaNo ratings yet

- Instrument Ation, Control and Management of Batch Reactors Using Distributed ControlsDocument4 pagesInstrument Ation, Control and Management of Batch Reactors Using Distributed ControlsVytha MarmoetNo ratings yet

- Cpi031 T Ts-TankDocument4 pagesCpi031 T Ts-TankaltipatlarNo ratings yet

- PRO026 FloatTankGaugingDocument5 pagesPRO026 FloatTankGaugingNithin GNo ratings yet

- Tankcare: - . .Total NDT SolutionsDocument4 pagesTankcare: - . .Total NDT SolutionsEur-Ing Nicola GalluzziNo ratings yet

- Management of Available Power in Substation Transformers Based On ReliabilityDocument5 pagesManagement of Available Power in Substation Transformers Based On ReliabilityrajfabNo ratings yet

- Catalog GTS Product 2020.R5Document24 pagesCatalog GTS Product 2020.R5markotop90No ratings yet

- Innovations Improve LNG: Terminal Efficiency and SafetyDocument3 pagesInnovations Improve LNG: Terminal Efficiency and SafetyL0NE DruidNo ratings yet

- Implementation of A Transformer Monitoring Solution Per IEEE C57.91-1995 Using An Automation ControllerDocument8 pagesImplementation of A Transformer Monitoring Solution Per IEEE C57.91-1995 Using An Automation Controllertsogbadrakh ArvanNo ratings yet

- Water Mist Fire Protection Systems For Rolling StockDocument3 pagesWater Mist Fire Protection Systems For Rolling StockAdvenser GroupNo ratings yet

- f0332002 Tapmotion TD Ism enDocument12 pagesf0332002 Tapmotion TD Ism enknsbNo ratings yet

- ABB Magnetik FlowmeterDocument36 pagesABB Magnetik FlowmeterPurwanto NugrohoNo ratings yet

- Cameron Flow Computer Solutions BrochureDocument12 pagesCameron Flow Computer Solutions BrochureMauro BolpatoNo ratings yet

- Labimpex Monitor Radiation 874-Data SheetDocument4 pagesLabimpex Monitor Radiation 874-Data SheetToomas PruudenNo ratings yet

- K-Gauge CLS IntegratedDocument4 pagesK-Gauge CLS IntegratedCem BozNo ratings yet

- Leaknet DigitalDocument4 pagesLeaknet DigitalRicNo ratings yet

- Taptrans enDocument2 pagesTaptrans enRanderson MoraisNo ratings yet

- 777 Series: Protection RelaysDocument3 pages777 Series: Protection RelaysUnique AllianceNo ratings yet

- Avoid Costly Measures: Remote Thickness TrackingDocument8 pagesAvoid Costly Measures: Remote Thickness TrackingJack PadiNo ratings yet

- Transmitter SpecsDocument40 pagesTransmitter SpecsJamesh BabuNo ratings yet

- Static Check Synchronisers: MeasurementsDocument6 pagesStatic Check Synchronisers: MeasurementssravankotlasNo ratings yet

- Epm9000 Gea12823cDocument8 pagesEpm9000 Gea12823cAulia RahmanNo ratings yet

- ISA InTech Journal - April 2021Document50 pagesISA InTech Journal - April 2021Ike EdmondNo ratings yet

- Residential Excellence, The New REX MeterDocument2 pagesResidential Excellence, The New REX MeterAlexanderGabrielQuicañoZapanaNo ratings yet

- Features Summary Applications Summary: Switchboard Case OptionDocument8 pagesFeatures Summary Applications Summary: Switchboard Case OptionjocemirferstNo ratings yet

- WT4401Document2 pagesWT4401SOUMEN PARUINo ratings yet

- Custody Transfer SystemDocument8 pagesCustody Transfer SystempriyoNo ratings yet

- Aqualog PQ ENGDocument4 pagesAqualog PQ ENGlaoudinimohamedNo ratings yet

- Top FlowDocument2 pagesTop FlowmontanovillarroelfabiolalourdeNo ratings yet

- Icountlasercm20: Fluid Condition MonitoringDocument7 pagesIcountlasercm20: Fluid Condition MonitoringMarcos VieroNo ratings yet

- VAI 2022 DEC Catalog (120 184)Document65 pagesVAI 2022 DEC Catalog (120 184)ihssanlabroujNo ratings yet

- Brochure Dresser Micro Corrector IMCW2 Brochure NGS - MI - .0007aDocument4 pagesBrochure Dresser Micro Corrector IMCW2 Brochure NGS - MI - .0007arahman ariwibowoNo ratings yet

- Atmos Pipe Product SheetDocument2 pagesAtmos Pipe Product SheethmhdecNo ratings yet

- 19SMzo-WP 2102795-EN B WEBDocument4 pages19SMzo-WP 2102795-EN B WEBariasdelarossaNo ratings yet

- Smart Density GaugeDocument4 pagesSmart Density Gaugekunal shahNo ratings yet

- Polysonics DCT6088Document2 pagesPolysonics DCT6088Fadjar TandabawanaNo ratings yet

- Aqualog Monitor ENGDocument4 pagesAqualog Monitor ENGlaoudinimohamedNo ratings yet

- Controller For EspDocument2 pagesController For EspJohn WatsonNo ratings yet

- Iris Power PDA-IV: Periodic On-Line Partial Discharge Monitoring Using A Portable Instrument For Hydro GeneratorsDocument4 pagesIris Power PDA-IV: Periodic On-Line Partial Discharge Monitoring Using A Portable Instrument For Hydro Generatorsle hoai NamNo ratings yet

- SVC Flicker KompanzasyonDocument12 pagesSVC Flicker KompanzasyonLeonardoNo ratings yet

- Monitoring and Protection of Distribution Transformer Using GSM ModuleDocument5 pagesMonitoring and Protection of Distribution Transformer Using GSM Moduleatheb12345No ratings yet

- Activecomp System Catalogue Neptune DucatiDocument2 pagesActivecomp System Catalogue Neptune DucatiMauricio Oropeza CabreraNo ratings yet

- Manara: Production and Reservoir Management SystemDocument2 pagesManara: Production and Reservoir Management SystemabdouNo ratings yet

- Tank Control Systems Land Application Brochure2011Document12 pagesTank Control Systems Land Application Brochure2011_commandos_No ratings yet

- 16-QAM Digital ModulationDocument8 pages16-QAM Digital ModulationGowtham Sivakumar100% (1)

- 022 Lecture 22 360 Chapter 7 Single Phase Induction MotorDocument28 pages022 Lecture 22 360 Chapter 7 Single Phase Induction Motorrelavarasan_eee999No ratings yet

- EDC Lab Manual (Exp - 5)Document8 pagesEDC Lab Manual (Exp - 5)Osama AsgharNo ratings yet

- KK C55 User ManualDocument5 pagesKK C55 User ManualKeshav BhatNo ratings yet

- 01 1299134310 2255Document90 pages01 1299134310 2255Lee Kar HuoNo ratings yet

- A Method For Obtaining The Transfer Function of Inverting and Non Inverting Op Amp Circuits Based On Classical Feedback TheoryDocument9 pagesA Method For Obtaining The Transfer Function of Inverting and Non Inverting Op Amp Circuits Based On Classical Feedback TheoryFiroDjinsoNanoNo ratings yet

- Install Guide 9-0 AccXES 8825-30Document3 pagesInstall Guide 9-0 AccXES 8825-30devarajNo ratings yet

- All EPSON ResetterDocument12 pagesAll EPSON ResetterInty MejiaNo ratings yet

- Affinium Led String KitDocument2 pagesAffinium Led String KitDani Good VibeNo ratings yet

- E Com ProjectDocument8 pagesE Com ProjectAisha RashidNo ratings yet

- RKR XXGTSDocument5 pagesRKR XXGTSahmedhassankhanNo ratings yet

- Schematics Stk525Document5 pagesSchematics Stk525linuxlismNo ratings yet

- C6500/C6500P/ C5500 Main Body Main Body: Service ManualDocument142 pagesC6500/C6500P/ C5500 Main Body Main Body: Service ManualgrtrainsNo ratings yet

- ECE 305 Homework: Week 10: SolutionsDocument6 pagesECE 305 Homework: Week 10: SolutionsjiosNo ratings yet

- Microwave and Antennas ELC3510: Department of Electronics Engineering Aligarh Muslim University, AligarhDocument23 pagesMicrowave and Antennas ELC3510: Department of Electronics Engineering Aligarh Muslim University, AligarhAfzal MalikNo ratings yet

- Sercel Seal 428 SpecsDocument8 pagesSercel Seal 428 SpecstaufanwigunaNo ratings yet

- Electrical Engineering Hawassa UniversityDocument3 pagesElectrical Engineering Hawassa Universityኮኾብ ጽባሕNo ratings yet

- Chapter 26 Barcode ReaderDocument8 pagesChapter 26 Barcode Readersathish77sNo ratings yet

- DTC ChartDocument28 pagesDTC ChartMarcelo LealNo ratings yet

- 2011 Honda OdysseyDocument16 pages2011 Honda OdysseyFloridaHossNo ratings yet

- Voltage Detector RT9818-11Document14 pagesVoltage Detector RT9818-11Quỳnh ChồnNo ratings yet

- PA Networks Visio Index SheetDocument7 pagesPA Networks Visio Index SheetIsrael Aguilar BalcazarNo ratings yet

- PV-UE130MF5N PV-UE125MF5N PV-UE120MF5N PV-UE115MF5N: 130Wp 125Wp 120Wp 115WpDocument2 pagesPV-UE130MF5N PV-UE125MF5N PV-UE120MF5N PV-UE115MF5N: 130Wp 125Wp 120Wp 115WpEmmanuel Entzana HdzNo ratings yet

- How To Terminate LVDS ConnectionsDocument3 pagesHow To Terminate LVDS Connectionstian yuNo ratings yet

- 480W Single Output Industrial DIN RAIL With PFC Function: SeriesDocument2 pages480W Single Output Industrial DIN RAIL With PFC Function: Seriesmario_iv1No ratings yet