Professional Documents

Culture Documents

B5B15301

Uploaded by

quality.rudrapurCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B5B15301

Uploaded by

quality.rudrapurCopyright:

Available Formats

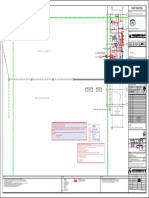

ASHOK FIRST ANGLE PROJECTION -D

IN

ALTERATIONS

IX

E

ER TE

AD

FF

D A

GR

SU

MED NOTE UPDATED #.1

841.4

840.4

LEYLAND GYK/VVS

140 (REF)

PLM ERROR RECTIFIED #.2

4 RIVETS

GYK/VVS

= =

CHILD PART DRG F4N32914 #.3

UPDATED.

MED NOTE ADDED.

GYK/VVS

#.3

PLM ERROR RECTIFIED #.4

-2

60

GYK/VVS

CHANGES FOR 2523 VEHICLE:

= = (IN F8H05714 / F8H05814 GUSSETS) ER-DIN- A

8-HOLES 13.5, 1-HOLE 25.5 AND 0014154

1-HOLE 40 ADDED

205 (REF) K.BALA / JOSEPH

= =

292 (REF) 5

FILLET WELD BOTTOM PLATE

UNIFORMLY ALL AROUND CHANNLE WEB

AND BOTTOM FLANGE

1

M

44.45

C O

51 (TYP)

D .

A N

Y L

L E

K . 3 1

H O 1 2

.

AS 3-08

35

@ 01

L A - 2

G -0 6

I N 0

: 2

FILLET WELD

Z3 OUTER CHANNEL R .S

111 INNER CHANNEL A 2 7

AND BOTTOM PLATE

U M .1

K 13 . 5

A

J I V 0 .

A 1

R

2 3

1.0 A

FRONT OF FRAME

ASHOK LEYLAND LTD.

TECHNICAL CENTRE, VELLIVOYALCHAVADI

#.1 NOTE:

#.3

FINISH PART TO MEET CLASS C OF ALS 268.03

ALL FILLET WELDS ARE OF 5MM SIZE AL PLM VAULT

USE ELECTRODE TO AWS E6012/E6013 OR EQUIVALENT REVISION : A DATE : 1/3/2013 STATUS : RELEASE

STAGE : III ER-DIN NO : ER-DIN-0014154 DATE : 1/3/2013

6 F3536110 RIVET SEE DRG 12 ALTERED BY : Balasubramanian.K5 CHECKED BY : sasikumar.r

5 FC151114 BOTTOM PLATE SEE DRG 1 MED APPROVAL : sunilraj.s APPROVED BY : ajs.alvvc

4 F4N32914 RE-INFORCING CHANNEL SEE DRG 1

#.3 DIGITALLY SIGNED . PHYSICAL SIGNATURE NOT REQUIRED

3 F8H05814 END GUSSET - RH SEE DRG 1 DRAWN/ CHECKED/ MED APPROVAL/ APPROVED/ STDS APP/

DATE DATE DATE DATE DATE

2 F8H05714 END GUSSET - LH SEE DRG 1 GYK vvs ________ SD

______

1 F4N32714 CHANNEL SEE DRG 1 19.07.10 19.07.10 19.07.10

S.NO PART NUMBER DESCRIPTION MATERIAL QTY MATERIAL

________

HEAT TREATMENT

________

+ - IMPORTANT C - CRITICAL S - SAFETY. THIS DRG. CONTAINS - SAFETY CHARACTERISTIC SL.No. PART NO. DESCRIPTION MATERIAL QTY.

SPECIAL INSTRUCTIONS/NOTE:

REMARKS

UNLESS OTHERWISE SPECIFIED BILL OF MATERIALS

FOR 3123 AND 2523

APPEARANCE ITEM ER-DIN DATE

ASHOK TOLERANCES REFER IS:2102 : MEDIUM FOR MACHINING AND COARSE FOR FABRICATION DESCRIPTION

YES NO ER-DIN-5064 17.07.2010

FABRICATED COMPONENTS TO BE DEGREASED, DESCALED. APPLY ZINC PHOSPHATE, APPLY EPOXY PRIMER

SECOND CROSS MEMBER

SURFACE AND APPLY BLACK ENAMEL TO MEET 300 HRS OF SALT SPRAY LIFE WHEN TESTED AS PER ASTM B117 FINISHED WEIGHT(APPROX) REF. PT. No. B1086402

PROTECTION (UNDER PELLICULAR CORROSION <= 2mm. NO BLISTERING IS ALLOWED.)

31 Kgs ________ PART

MACHINED SURFACE TO BE APPLIED WITH RUST PREVENTIVE OIL TO IS:1154

METRIC SCREW THREADS SHALL CONFORM TO THE LIMITS

S/A PT No.

________ No. B 5 B 1 5 3 0 1 A

SURFACE FINISH AS PER

SHARP EDGES TO BE REMOVED SCALE SUPERSEDES

AND TOLERANCES SPECIFIED IN THE CURRENT IS:4218 DIMENSIONS ARE IN MM

LEYLAND IS:3073 (CLA VALUE) CLASS 6g EXTERNAL OR 5H INTERNAL. DO NOT SCALE DRAWING 1:3 SPEC NO. ALF513 1 1

SHEET NO..................OF........... A1

You might also like

- Wiring Diagram (FS-527)Document1 pageWiring Diagram (FS-527)Emerson Fonte Dos Santos Freire0% (1)

- Citation VII: Ap Off Yd Off CMPRTR Warn HYD Temp LOW Flap O SPD Ap Off Yd Off CMPRTR Warn HYD Temp LOW Flap O SPDDocument2 pagesCitation VII: Ap Off Yd Off CMPRTR Warn HYD Temp LOW Flap O SPD Ap Off Yd Off CMPRTR Warn HYD Temp LOW Flap O SPDFernando GalindezNo ratings yet

- Williams Space Mission Pinball SchematicDocument1 pageWilliams Space Mission Pinball SchematicsnackadmiralNo ratings yet

- Broota K D - Experimental Design in Behavioural Research - 3eDocument26 pagesBroota K D - Experimental Design in Behavioural Research - 3eRANJAN ROY67% (3)

- Drawings 1 PDFDocument20 pagesDrawings 1 PDFjoegieNo ratings yet

- Itr Fob PDFDocument1 pageItr Fob PDFAlok Kumar100% (1)

- A Feasibility Study of Using Two-Component Polyurethane Adhesive in PDFDocument6 pagesA Feasibility Study of Using Two-Component Polyurethane Adhesive in PDFALINo ratings yet

- Bistos BT-550 - CatalogoDocument3 pagesBistos BT-550 - CatalogoRobinsson Tafur FloridaNo ratings yet

- B5A18205Document1 pageB5A18205quality.rudrapurNo ratings yet

- Right: SCALE 1:2Document1 pageRight: SCALE 1:2Sekar NaikNo ratings yet

- Ashok: First Angle ProjectionDocument1 pageAshok: First Angle ProjectionNitesh JangirNo ratings yet

- Balachaur 4MLD STP Layout RevisedDocument1 pageBalachaur 4MLD STP Layout RevisedManinder Preet SinghNo ratings yet

- D.Co MDocument2 pagesD.Co MNirmal BairwaNo ratings yet

- FTML - Unit-1 - Plant LayoutDocument1 pageFTML - Unit-1 - Plant Layoutdr.afroza1875No ratings yet

- Mapas Hidrogeologica RJDocument1 pageMapas Hidrogeologica RJChen Kuang HsiaoNo ratings yet

- Proposed Pumping Station LocationDocument1 pageProposed Pumping Station LocationApollo BarcelonaNo ratings yet

- Ifugao Poverty MapDocument2 pagesIfugao Poverty Mapart83360911554No ratings yet

- 018409-Jingold M&e Bole Me FC SH 01 08Document1 page018409-Jingold M&e Bole Me FC SH 01 08Getahun AbebeNo ratings yet

- d1 Ph3a1 Inf 000 Inc Ae7 DWG Rtu Se Ab 004a (Location 01)Document1 paged1 Ph3a1 Inf 000 Inc Ae7 DWG Rtu Se Ab 004a (Location 01)Ali HaiderNo ratings yet

- Updated Stair Det. 4TH 7TH Flr. 8TH 9TH Flr. 12 06 21 A3Document1 pageUpdated Stair Det. 4TH 7TH Flr. 8TH 9TH Flr. 12 06 21 A3Edward Jr. ChoiNo ratings yet

- Plano Primer Piso - JackDocument1 pagePlano Primer Piso - Jackalexpato71104652No ratings yet

- Mux 1.3 MMCDocument1 pageMux 1.3 MMCuaftab543No ratings yet

- Shop Drawing: Key PlanDocument1 pageShop Drawing: Key Planlibin513No ratings yet

- Modular Construction - ToiletDocument1 pageModular Construction - ToiletstutiNo ratings yet

- OT3073-20 L3 LAB Condenseur R3Document1 pageOT3073-20 L3 LAB Condenseur R3becemNo ratings yet

- Spare Part List 5587258891Document2 pagesSpare Part List 5587258891Ndikumasabo EtienneNo ratings yet

- f03 - Executivo Arquitetonico - Andre e RafaelDocument1 pagef03 - Executivo Arquitetonico - Andre e RafaelBrunoNo ratings yet

- Glo LT1Document1 pageGlo LT1Andre DoloksaribuNo ratings yet

- Vinicius Sitio Picapau Amarelo N11Document1 pageVinicius Sitio Picapau Amarelo N11Sobrevivência na Caatinga NORDESTENo ratings yet

- Samarinda - Usulan Perkerasan Jalan Mobil O2-ModelDocument1 pageSamarinda - Usulan Perkerasan Jalan Mobil O2-ModelAditya Rachman AlvaredzNo ratings yet

- Outdoor Earthing SystemDocument5 pagesOutdoor Earthing SystemSebastián LagosNo ratings yet

- Site Plan 02 Puerto Baru Rev.04Document1 pageSite Plan 02 Puerto Baru Rev.04TaihimyNo ratings yet

- Wiring Diagram For Main Body - A3Document4 pagesWiring Diagram For Main Body - A3Emerson Fonte Dos Santos FreireNo ratings yet

- Gal ModelDocument1 pageGal ModelJuan ZegarraNo ratings yet

- Sector Delineation Plan - Zone LDocument1 pageSector Delineation Plan - Zone LGirija UmathNo ratings yet

- Thumb 107 Haridwar-Master-PlanDocument1 pageThumb 107 Haridwar-Master-PlanJaideep BhardwajNo ratings yet

- Augusta County District and Precinct MapDocument1 pageAugusta County District and Precinct MapGabe CavallaroNo ratings yet

- Siddharth AdminDocument1 pageSiddharth AdminFan FollowingNo ratings yet

- Second Floor Plan PDFDocument1 pageSecond Floor Plan PDFRhapz Diaz CastilloNo ratings yet

- Old PlumbingDocument8 pagesOld PlumbingfaizanNo ratings yet

- BALLLAAAAAG1Document1 pageBALLLAAAAAG1CDFNo ratings yet

- 986123on Street Parking Zones - July 2011 PDFDocument1 page986123on Street Parking Zones - July 2011 PDFGuillermo MondeNo ratings yet

- SÑ 02 PDFDocument1 pageSÑ 02 PDFC.O. INGENIERIA Y CONSTRUCCIONNo ratings yet

- Typical 4Document1 pageTypical 4Mohamed MagdyNo ratings yet

- Beam & Girder ScheduleDocument1 pageBeam & Girder ScheduleCristinaB.DanglaCruzNo ratings yet

- LWD-01a Phase 1 Road LvlsDocument1 pageLWD-01a Phase 1 Road LvlsSahil SharmaNo ratings yet

- Tora Terbaru September Blok Dan JalanDocument1 pageTora Terbaru September Blok Dan JalanBobi Dwi DarmawanNo ratings yet

- Au1GeU PDFDocument1 pageAu1GeU PDFYOOOOOOONo ratings yet

- Road AvenueDocument1 pageRoad AvenueFirdaus FadzilNo ratings yet

- p168 NI Main Control Panel PartsDocument1 pagep168 NI Main Control Panel PartsFRANCISCO JAVIER RUEDA LOPEZNo ratings yet

- A6F04800 - Installation Drawing With Clutch Switch Setting DetailsDocument3 pagesA6F04800 - Installation Drawing With Clutch Switch Setting DetailsSridharan Venkat100% (1)

- Bizhub: Overall Wiring DiagramDocument56 pagesBizhub: Overall Wiring DiagramHugo Luis Escalante100% (1)

- C.plano de UbicacionDocument1 pageC.plano de UbicacionEdinson F. RomeroNo ratings yet

- Central London Bus MapDocument1 pageCentral London Bus MapTarek SakrNo ratings yet

- Cuadro de BM (Niveles de Control) : Municipalidad Distrital de El AltoDocument1 pageCuadro de BM (Niveles de Control) : Municipalidad Distrital de El AltoGustavo IpanaqueNo ratings yet

- DIV34Document1 pageDIV34Dilmer Javier Puel CruzNo ratings yet

- DIV34Document1 pageDIV34Dilmer Javier Puel CruzNo ratings yet

- Irrigacion Majes-1Document1 pageIrrigacion Majes-1Michelle Cabello AstorgaNo ratings yet

- Basement Plan - Fire Services: Construction DrawingDocument1 pageBasement Plan - Fire Services: Construction DrawingrajavelNo ratings yet

- Plano de Acabados 1Document1 pagePlano de Acabados 1Yered García MenaNo ratings yet

- MSW Series - Disconnect Switches: Compact Switching SolutionsDocument2 pagesMSW Series - Disconnect Switches: Compact Switching SolutionsRODRIGO_RALONo ratings yet

- Module M-07: EquipmentDocument1 pageModule M-07: EquipmentRobles DreschNo ratings yet

- B5a18205 TPHDocument1 pageB5a18205 TPHquality.rudrapurNo ratings yet

- B5a18205 PC 16.11.13Document1 pageB5a18205 PC 16.11.13quality.rudrapurNo ratings yet

- Apqp B5a18205Document4 pagesApqp B5a18205quality.rudrapurNo ratings yet

- Material RequirementDocument1 pageMaterial Requirementquality.rudrapurNo ratings yet

- B5B15102 - PC Finalized 30.08.13Document2 pagesB5B15102 - PC Finalized 30.08.13quality.rudrapurNo ratings yet

- FC151114 CATDrawingDocument1 pageFC151114 CATDrawingquality.rudrapurNo ratings yet

- Kema Three Core Power Cables - 1Document38 pagesKema Three Core Power Cables - 1Thinh Tien NguyenNo ratings yet

- Lexicology Unit 8Document24 pagesLexicology Unit 8Business EnglishNo ratings yet

- Results - Based Performance Management System (RPMS) For DepedDocument85 pagesResults - Based Performance Management System (RPMS) For DepedDizamar AbocNo ratings yet

- Conclusion HDFCDocument2 pagesConclusion HDFCSudeep MallNo ratings yet

- Composite Deck Technical Manual: 3WH-36 Hi FormDocument33 pagesComposite Deck Technical Manual: 3WH-36 Hi FormVinod Kumar ReddyNo ratings yet

- Uganda The National Slum Upgrading Strategy and Action Plan 2008Document62 pagesUganda The National Slum Upgrading Strategy and Action Plan 2008Maiga Ayub HusseinNo ratings yet

- The Cement Industry in EthiopiaDocument7 pagesThe Cement Industry in EthiopiaTesfaye Azanie1No ratings yet

- FS2 Le18Document1 pageFS2 Le18Jorebell W. QuiminoNo ratings yet

- 1625330538330Document3 pages1625330538330kossi abaloNo ratings yet

- The United Nations in A NutshellDocument8 pagesThe United Nations in A Nutshellfatimkbrova5No ratings yet

- National and International IssuesDocument5 pagesNational and International IssuesHaroon Karim BalochNo ratings yet

- FTIR 7800: SpectrophotometerDocument8 pagesFTIR 7800: SpectrophotometerAfzal SarfarazNo ratings yet

- U9C Mounting InstructionsDocument152 pagesU9C Mounting InstructionsGMAR ComercializadoraNo ratings yet

- Comparison of MPPT Algorithms For PV Systems Based DC-DC ConverterDocument11 pagesComparison of MPPT Algorithms For PV Systems Based DC-DC ConverterLeandro SouzaNo ratings yet

- What Is Consciousness?Document3 pagesWhat Is Consciousness?Lucia BeatrizNo ratings yet

- Educ 103Document2 pagesEduc 103Nina RkiveNo ratings yet

- Experimental Investigation On Fly Ash Bricks Using Industrial WasteDocument7 pagesExperimental Investigation On Fly Ash Bricks Using Industrial WasteIJRASETPublicationsNo ratings yet

- Office of The Mayor: Republic of The Philippines Province of La Union Municipality of Caba Tel. # (072) 607-03-12Document3 pagesOffice of The Mayor: Republic of The Philippines Province of La Union Municipality of Caba Tel. # (072) 607-03-12Sunshine MaglayaNo ratings yet

- CHCL 102-PM-LP-Unit 2-Topic 1Document15 pagesCHCL 102-PM-LP-Unit 2-Topic 1Mary Rose NaboaNo ratings yet

- This Is The New TitleDocument7 pagesThis Is The New TitleMUSÑGI MICAELA LEIGH SUZONNo ratings yet

- Hill Criterion and Von MisesDocument10 pagesHill Criterion and Von MisesSiva PrasadNo ratings yet

- Brandix Apparel BD LTD: Hazard Identification and Risk Assesment (HIRA) of Compressor RoomDocument4 pagesBrandix Apparel BD LTD: Hazard Identification and Risk Assesment (HIRA) of Compressor RoomShoaibNo ratings yet

- Chapter 9-Hydroelectric Plant PDFDocument118 pagesChapter 9-Hydroelectric Plant PDFsindyNo ratings yet

- Cambridge IGCSE (9-1) : Physics 0972/12Document20 pagesCambridge IGCSE (9-1) : Physics 0972/12Tristan GrahamNo ratings yet

- East Asian ArtDocument4 pagesEast Asian ArtMenchie PaynorNo ratings yet

- DP Cheat Sheet 2017Document5 pagesDP Cheat Sheet 2017HollyNo ratings yet

- Crowdsourcing Template: Description of Toxic School CultureDocument2 pagesCrowdsourcing Template: Description of Toxic School CultureMark Augustine VillegasNo ratings yet