Professional Documents

Culture Documents

SHC 68L CO2 Cylinder 1

SHC 68L CO2 Cylinder 1

Uploaded by

Châu Nhật Minh0 ratings0% found this document useful (0 votes)

2 views2 pagesOriginal Title

SHC-68L-CO2-cylinder-1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views2 pagesSHC 68L CO2 Cylinder 1

SHC 68L CO2 Cylinder 1

Uploaded by

Châu Nhật MinhCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

CO2 .

gas fire extinguishing system

Technical documentation of system components

DT-SHC86L Version 2.1

68L / 45kg . type fire extinguisher Effective from: 09/2021

Item code SHC-68L

CHARACTERISTICS • Standard cast steel tank: ISO9809 / TPED, • Tank capacity and intake air volume 68L/ 45kg

DESCRIPTION SHC-68L gas cylinder made of cast steel, 68L

capacity used in CO2 fire extinguishing system, containing 45kg

CO2 extinguishing gas. The gas tank is installed with the top

valve, on the top valve there is a safety pressure relief valve.

OPERATION

SHC-68L gas cylinders are activated to discharge by the manual/air-

activated valve included on the top valve, when there is trigger

pressure from the trigger cabinet (Item model number: STV-P1L).

INSTALLATION The air tank is mounted vertically with the top

valve facing up. The gas cylinder is connected to the gas cylinder

manifold or the air discharge pipe through the exhaust hose with

a check valve.

The gas cylinder is secured by two sets of tank holders (Item

number STV-CC8X), the tank holders need to be fixed to the wall

or structure.

ORDERING INFORMATION

Order code for CO2 fire extinguisher SHC-68L type

Dirty, debris, unsealed materials and other foreign materials may

68L/45kg with accessories as in the table below:

cause the system to fail or operate inefficiently when discharging

PLU Describe extinguishant.

SHC-68L CO2 fire extinguisher type 68L / 45kg with

valve head. Air ANNUAL CHECKLIST

SHC-FC20 release hose with one-way valve connecting

the tank to the At least once a year, or more often as required by the authorities,

the entire system must be checked and operationally tested by

STV-CC8X manifold Air tank holder (02 sets for each tank)

personnel trained by the manufacturer.

STV-P1L 1L trigger cabinet (including solenoid valve

trigger tank, exhaust pressure switch) Containers

Containers shall be periodically inspected as required from the

INSPECTION AND

relevant national standard. Conduit

MAINTENANCE According to ISO/TCVN standard, the following

All system

inspection and/or maintenance procedure implementation plan

should be implemented as below and implemented when an piping should be inspected annually for damage. If visual inspection

unusual event occurs that may affect to system security. reveals any defects, the conduit must be replaced.

6 MONTHS / 1 TIME

1. Check the amount of gas in the tank by reweighing to check the

Area using gas fire extinguishing system At least

amount of gas in the tank.

once every 12 months, the room using the gas fire extinguishing

2. Inspect all components, including bracket, and tighten, repair or

system must be inspected and evaluated, to determine if there are

replace if necessary.

structural changes that may affect the loss of extinguishant. fire or

3. Replace any component if the component's ability to function affect the effectiveness of fire fighting. If visual assessment is not

properly is in doubt. possible, a room tightness test should be performed as specified.

4. . Inspect all hoses, fittings and exhaust nozzles for loose, dusty

or other damage.

All outlet pipes must be clean and free of dust

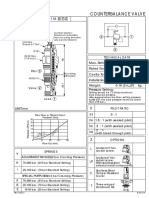

SPECIFICATIONS

PLU SHC-68L

CO2 charge amount 45kg

Height 1500mm (±20mm)

Diameter 267mm ±1%

Inner volume 68L

Weight of empty tank 75kg (±5%)

Material of the jar Steel 37Mn

Paint color Powder coating red RAL3000

Maximum filling pressure of the tank 150 bar

Shell test pressure 250 bar

Technical standards for tank shells ISO 9809-1

You might also like

- Volvo d12 Workshop Manual Less Specifications Abby PDFDocument709 pagesVolvo d12 Workshop Manual Less Specifications Abby PDFkoaa8592% (39)

- B - ZF - Transmission - 4 WG-98 TSDocument114 pagesB - ZF - Transmission - 4 WG-98 TSCesarSuarezNo ratings yet

- Configuracion 854k 428Document9 pagesConfiguracion 854k 428dj danielilloNo ratings yet

- Mechanical Practice ExamDocument20 pagesMechanical Practice ExamRazif Rasheed78% (9)

- Sampling ProbeDocument5 pagesSampling Probetriminhdang_phar6701No ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Boiler Safety Program Boiler ProgramDocument8 pagesBoiler Safety Program Boiler Programsalman akbarNo ratings yet

- Business Portal Online Print 05-09-2018Document164 pagesBusiness Portal Online Print 05-09-2018rafael100% (1)

- Proposal Document For HVAC Equipment Design, Installation and Maintenance Services For Offshore Oil & Gas FacilitiesDocument35 pagesProposal Document For HVAC Equipment Design, Installation and Maintenance Services For Offshore Oil & Gas FacilitiesIB Ismady100% (1)

- Fire Protection Overview2008Document66 pagesFire Protection Overview2008undertaker55100% (1)

- FM200 System MaintenanceDocument3 pagesFM200 System MaintenanceJohn CarloNo ratings yet

- Controlling Fired HeatersDocument20 pagesControlling Fired HeatersArjun Shantaram ZopeNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Procedure For Governing Oil SystemDocument29 pagesProcedure For Governing Oil SystemLakshmi NarayanNo ratings yet

- 45Kg Cylinder & Valve Assembly PN.81-100067-002Document4 pages45Kg Cylinder & Valve Assembly PN.81-100067-002max_powerNo ratings yet

- Pressure Test ProcedureDocument11 pagesPressure Test ProcedureRolando Nicanor0% (1)

- Controlling Fired Heaters: INTRODUCTION. The Purpose of A FiredDocument24 pagesControlling Fired Heaters: INTRODUCTION. The Purpose of A FiredAntonio MezzopreteNo ratings yet

- Medical Gas SytemDocument22 pagesMedical Gas SytemMamdouh AwadNo ratings yet

- Trace CO and CO in Hydrogen and Light Gaseous Hydrocarbons by GCDocument6 pagesTrace CO and CO in Hydrogen and Light Gaseous Hydrocarbons by GCgoodcharacter1No ratings yet

- EMD 645 Parts Catalog 302 Part 1Document164 pagesEMD 645 Parts Catalog 302 Part 1KarlaFernanda Roque Rodriguez0% (1)

- Kidde Fire Systems Nitrogen Fire Protection System System DescriptionDocument6 pagesKidde Fire Systems Nitrogen Fire Protection System System DescriptionAbdel KoddousNo ratings yet

- Stack Monitoring KitDocument53 pagesStack Monitoring KitknbiolabsNo ratings yet

- Kidde Nitrogen Fire Protection Systems K-79-001 Print AADocument6 pagesKidde Nitrogen Fire Protection Systems K-79-001 Print AADaddy YantulaNo ratings yet

- Ansul R-102Document4 pagesAnsul R-102heliopintoNo ratings yet

- DGSEngineering Circular 1 of 2022Document12 pagesDGSEngineering Circular 1 of 2022Audumbar BhoiNo ratings yet

- Gas Train Requirements For Gas or Dual Fired Steam Boiler PDFDocument2 pagesGas Train Requirements For Gas or Dual Fired Steam Boiler PDFringo limNo ratings yet

- General Circuit BreakerDocument3 pagesGeneral Circuit BreakerYuliandiHidayat Gacodi DalimuntheNo ratings yet

- Process Gas ChromatographRaphyDocument8 pagesProcess Gas ChromatographRaphyoviemeNo ratings yet

- Co2 Requirement and Maintenance SystemDocument4 pagesCo2 Requirement and Maintenance SystemSupriya DasNo ratings yet

- PAC Vol III-B1-1 Turbine & Auxiliaries - TS-08!05!17Document8 pagesPAC Vol III-B1-1 Turbine & Auxiliaries - TS-08!05!17Hoang Le DangNo ratings yet

- MTR 144Document1 pageMTR 144Wissam JarmakNo ratings yet

- Ansul R-102Document4 pagesAnsul R-102Phamngoc SonNo ratings yet

- AQABA NEW PORT PROJECT - Package 3 - Infrastructure, Yards, Buildings & Sheds CO2 Automatic Supression SystemDocument4 pagesAQABA NEW PORT PROJECT - Package 3 - Infrastructure, Yards, Buildings & Sheds CO2 Automatic Supression Systemghostz0rNo ratings yet

- FPS - MS9001Document3 pagesFPS - MS9001shravani mangalpalliNo ratings yet

- Pneumatic TestDocument6 pagesPneumatic TestShrichand G. BathvNo ratings yet

- E4651042 Technical Specification 1450504930Document12 pagesE4651042 Technical Specification 1450504930RJ MechNo ratings yet

- Technology Bulletin: SUBJECT: New API Recommended Practices For Coiled Tubing Well-Control Equipment AnnouncedDocument4 pagesTechnology Bulletin: SUBJECT: New API Recommended Practices For Coiled Tubing Well-Control Equipment AnnouncedJose Leonardo Materano PerozoNo ratings yet

- Development Testing of A New Bi Propellant Propulsion Subsystem For The GMP T SpacecraftDocument9 pagesDevelopment Testing of A New Bi Propellant Propulsion Subsystem For The GMP T Spacecraftபொன்னியின் செல்வன்No ratings yet

- TB43 0151Document10 pagesTB43 0151Glenn SussNo ratings yet

- ZZ - 1207652196 - Fast Loop Sampling System Specification-R2 PDFDocument4 pagesZZ - 1207652196 - Fast Loop Sampling System Specification-R2 PDFJohn PaulNo ratings yet

- Jenbacher: 1. Gas FilterDocument1 pageJenbacher: 1. Gas FilterArîfNo ratings yet

- 60 MW GE Frame 7B+ Gas Turbine Generator Package PG 7801BDocument5 pages60 MW GE Frame 7B+ Gas Turbine Generator Package PG 7801BvcharlesNo ratings yet

- Key ComponentsDocument17 pagesKey ComponentsRussel John Morillo QuerubinNo ratings yet

- TFP330 10 2013Document4 pagesTFP330 10 2013Mihai CatalinNo ratings yet

- Capital Controls® Series Nxt3000: Modular Design Gas Feed System With Self Contained Automatic Switchover CapabilityDocument8 pagesCapital Controls® Series Nxt3000: Modular Design Gas Feed System With Self Contained Automatic Switchover CapabilityLoan NguyênNo ratings yet

- Turn Key Steam Boilers System Section 1 1.00 - GENERAL 1.01 Related DocumentsDocument18 pagesTurn Key Steam Boilers System Section 1 1.00 - GENERAL 1.01 Related DocumentsKarim Galal IsmailNo ratings yet

- Induction Furnace - 50 KG Capacity: Tender Document OFDocument17 pagesInduction Furnace - 50 KG Capacity: Tender Document OFChayon MondalNo ratings yet

- Type ACE95jr Tank Blanketing ValveDocument8 pagesType ACE95jr Tank Blanketing Valvearomero888No ratings yet

- 2002002Document2 pages2002002waselcoNo ratings yet

- D2882Document6 pagesD2882rimi7alNo ratings yet

- Emergency Reserve Manifold - Technical DatasheetDocument4 pagesEmergency Reserve Manifold - Technical DatasheetRaydoon SadeqNo ratings yet

- Tescom-Topworx Flow MeasurementDocument18 pagesTescom-Topworx Flow MeasurementGrupoMecatrónicaNo ratings yet

- Model 3011 / 3041: Industrial ProductsDocument4 pagesModel 3011 / 3041: Industrial ProductsccglobalincNo ratings yet

- Gek 28138Document20 pagesGek 28138Mauricio GuanellaNo ratings yet

- TCCC 1 SD 439 0001 R0Document11 pagesTCCC 1 SD 439 0001 R0Luis Angel PatiñoNo ratings yet

- Tech Spec Guvnl-NffesDocument9 pagesTech Spec Guvnl-NffesShantanu DasNo ratings yet

- Fisher 67cfrDocument8 pagesFisher 67cfrTuấn Anh NguyễnNo ratings yet

- Safe Handling of Compressed GasesDocument48 pagesSafe Handling of Compressed GasesChandan SahooNo ratings yet

- Use of The (Nline Gas Chromatograph For Gas Sales From An Offshor PlatformDocument22 pagesUse of The (Nline Gas Chromatograph For Gas Sales From An Offshor PlatformAlcimar MonteiroNo ratings yet

- Villa Gas System Specifications 28.05.2018Document11 pagesVilla Gas System Specifications 28.05.2018NAHEEMA KPNo ratings yet

- Altecnic Expansion Vessel GuideDocument13 pagesAltecnic Expansion Vessel GuidePedro Quintal100% (1)

- CJK5 - Equipment Specification (En 2011)Document12 pagesCJK5 - Equipment Specification (En 2011)Christian ThompsonNo ratings yet

- 1290 RegulatorsDocument3 pages1290 RegulatorsPitichai PakornrersiriNo ratings yet

- Dokumen - Tips Miniblock Maintenance Field Guide v247Document15 pagesDokumen - Tips Miniblock Maintenance Field Guide v247tatifurusawaNo ratings yet

- 02 PDFDocument11 pages02 PDFSerban LucianNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Data Sheet: Individual Relays For TERMSERIES - Electromechanical Relays - Different Contact MaterialsDocument5 pagesData Sheet: Individual Relays For TERMSERIES - Electromechanical Relays - Different Contact MaterialsChâu Nhật MinhNo ratings yet

- Miniature Power Relay: Specifications How To Order Coil DataDocument1 pageMiniature Power Relay: Specifications How To Order Coil DataChâu Nhật MinhNo ratings yet

- Bcsoft: Operating InstructionsDocument31 pagesBcsoft: Operating InstructionsChâu Nhật MinhNo ratings yet

- 8408IBT-4!60!04 Burner Local Panel BCU R1Document10 pages8408IBT-4!60!04 Burner Local Panel BCU R1Châu Nhật MinhNo ratings yet

- Ah112 Hmi RtoDocument59 pagesAh112 Hmi RtoChâu Nhật MinhNo ratings yet

- (Translationifk - Com) 20 Nichi de Goukaku N3Document213 pages(Translationifk - Com) 20 Nichi de Goukaku N3Châu Nhật MinhNo ratings yet

- Ozen Kompresor Ozen-Gm - Com Katalog 2018 INGDocument48 pagesOzen Kompresor Ozen-Gm - Com Katalog 2018 INGBoško Vasić100% (2)

- 390D L Excavator WAP00001-UP (MACHINE) POWERED BY C18 Engine (SEBP5236 - 43) - Sistemas y ComponentesDocument3 pages390D L Excavator WAP00001-UP (MACHINE) POWERED BY C18 Engine (SEBP5236 - 43) - Sistemas y ComponentesJuan Pablo Virreyra TriguerosNo ratings yet

- Design and Function: System Description EMS2Document1 pageDesign and Function: System Description EMS2user1No ratings yet

- D.A. Cylinder (Bush and Drilled Rear End)Document1 pageD.A. Cylinder (Bush and Drilled Rear End)Tadas PNo ratings yet

- 2005 Seadoo Rotax 1503 4 Tech Shop Manual - 26 50Document25 pages2005 Seadoo Rotax 1503 4 Tech Shop Manual - 26 50Oscar Eduardo GomezNo ratings yet

- Spare Parts List: Hydraulic BreakerDocument28 pagesSpare Parts List: Hydraulic BreakerTeknik MakinaNo ratings yet

- SC 1281Document11 pagesSC 1281bartosz_marcini7505No ratings yet

- Generator Set Data Sheet HTW 1030 t5 Soundproof EnglishDocument7 pagesGenerator Set Data Sheet HTW 1030 t5 Soundproof EnglishChhoan NhunNo ratings yet

- Gorvening and Protection System For TurbineDocument54 pagesGorvening and Protection System For TurbineMorassa ChonaNo ratings yet

- BeltDocument2 pagesBeltVănPhùngLươngNo ratings yet

- Cool Bear Maintenance ManualDocument606 pagesCool Bear Maintenance Manualeurotaller Calderon calderonNo ratings yet

- TyreDocument3 pagesTyreHussain AnsariNo ratings yet

- Ather450X SpecificationsSheetDocument4 pagesAther450X SpecificationsSheetNitin DevnaniNo ratings yet

- List of ConsumablesDocument2 pagesList of ConsumablesJosephino CastilloNo ratings yet

- Power Take-Off EG6R DDXXBDocument3 pagesPower Take-Off EG6R DDXXBPatricio G. ArrienNo ratings yet

- B 121 101 (Cb-11a-33 (3a) (3C) (3Q) )Document1 pageB 121 101 (Cb-11a-33 (3a) (3C) (3Q) )sasidharreddyNo ratings yet

- ROV Magnum 120Document2 pagesROV Magnum 120Robert FlateråsNo ratings yet

- Havells Fans Price List 20 02 2021Document6 pagesHavells Fans Price List 20 02 2021Ramu MylaramNo ratings yet

- Base Line: Air. Anytime. AnywhereDocument4 pagesBase Line: Air. Anytime. Anywheremogwai71No ratings yet

- ECO-Turbo Product Launch CPMS Internal 202106 For Channel PartnerDocument18 pagesECO-Turbo Product Launch CPMS Internal 202106 For Channel PartnerjesparzamNo ratings yet

- 1st MPS (Methods Processes & Systems) Call May 2019Document43 pages1st MPS (Methods Processes & Systems) Call May 2019Wilfredy Medina M.No ratings yet

- PL FY&XYG&MULIA April 2022 - UmumDocument19 pagesPL FY&XYG&MULIA April 2022 - UmumHendra GunawanNo ratings yet

- 2023 Hyundai Staria Premium - SolaireDocument3 pages2023 Hyundai Staria Premium - SolaireLucy BarbaronaNo ratings yet

- Lead Acid Battery CareDocument35 pagesLead Acid Battery CareRohit ChaubalNo ratings yet