Professional Documents

Culture Documents

Isd-C12-001f (09-2006)

Isd-C12-001f (09-2006)

Uploaded by

Gustavo Felipe0 ratings0% found this document useful (0 votes)

4 views12 pagesOriginal Title

ISD-C12-001F (09-2006)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views12 pagesIsd-C12-001f (09-2006)

Isd-C12-001f (09-2006)

Uploaded by

Gustavo FelipeCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 12

‘Non-Confidential

“Ts standard ay be

released the pulse

I Ss U 2 U ISUZU ENGINEERING STANDARD - STANDARD PARTS ISD-C12-001F

‘Quantity Geil

Set Parts

‘With Modified GM Weld nuts

Part Number

Shown Together Established on: Jan. 1962

Revised on: Sep. 25, 2006

1. SCOPE This standard covers weld nuts (hereinafter referred to as ‘nuts’) for general use in

automobiles.

2, TYPES AND APPLICATION The types and application of nuts are shown in Table 1

Table 1

Types | Shape Pilot Pilot ae

Hexagon Projection welding 1

Without

without 2

Projection welding

Without 3

With Spot welding 4

a

© Copyright Sep. 2006 ISUZU MOTORS LIMITED Al Rights Reserved

ops grlebeee ‘Sep. 25, 2006

2

ISUZU ENGINEERING STANDARD - STANDARD PARTS ISD-C12-001F

3. MECHANICAL PROPERTIES Nuts shall conform to the requirements specified in the following

Tables 2 and 3 per property class of ISA-M-004Y ‘Mechanical properties of threaded fastener.

3.1. Property Class

“Table 2 Property Class of Nuts

Types Property Class

A

Hexagon | —= SN/8N

C GN (M4 to M8)

Square 5N (M10 to M12)

o ON

ii 5N

3.2. Mechanical Properties

Table 3 Mechanical Properties of Nuts

Property class SN éN aN | __ON

Proof load stress MPa 500 600 soo | 900

HV

Hardness (maximum) ae

HRC. 30

Remark Maximum values of hardness of nuts shall be common in all property classes

in order to weld.

4. SHAPES AND DIMENSIONS ‘The shapes and dimensions of nuts are shown in Attached

Tables 1 through 4.

5. THREADS:

5.1 Threads shall conform to JIS B 0205-4:2001.

5.2 The accuracy of thread of a nut shall conform to 6H specified in JIS B 0209-2:2001

6. APPEARANCE

6.1 Surface defects of nuts shall conform to JIS B 1042:1998.

6.2 _ Nut overall surface roughness shall be 6.3 1 m Re specified in ISA-E-004Y. Threads shall be

finished smoothly.

6.3 Nuts shall be free from burrs, flash, rust and other defects harmful in use.

7. MATERIAL Material of nuts shall be carbon steel containing less than 0.2 % carbon which

meets the mechanical property requirements specified in Table 3.

8. FINISH No surface treatment is required.

9. MECHANICAL PROPERTIES TEST METHODS

9.1 Mechanical Properties Test Methods Nuts shall be tested for mechanical properties per

'SA-M-004Y. However, the projection of a weld, etc. shall be notified for proof load applying

direction for nuts as be shown in Figure 1

{© Copyight Sep. 2906 ISUZU MOTORS LIMITED At Rights Reserved

capt 22. canar See

Fomor cuss Seiten no becgce To purest covnen cnmrnaraesatac

3

ISUZU ENGINEERING STANDARD - STANDARD PARTS ISD-C12-001F

(@) Hexagon and square nuts () T-shaped nuts

SSS

Mandrel

Figure 1 Application of Proof Load Stress

10. PARTNUMBER Attached Tables 1 through 4 shall be referred to for part numbers.

10.1 The 10-digit isuzu part number of a nut shall consist of a [shown in Table 4,

followed by a size number (nominal size x length) and a change suffix number.

Table 6

Property class 8N, type A, hexagon

09110-524/5

09110-532/3 Property class 8N, type B. hexagon

#00 #2402131 al pepe cnes eae

S01i19916 [aaa S|

acet09 ema leet

Ami? st a ec

ee dicen

Remark : Functional numbers 90% * >- shall apply to d=M6 through M10,

and 992% % >k- to d=M4, 5, 12.

[Example of Isuzu part number)

11-4028

Functional number

Size number Type A: Nominal thread diameter + 40,

Type B: Nominal thread diameter + 20

Type C: Nominal thread diameter + 80

Type D: Nominal thread diameter + 60

Type T: Nominal thread diameter + 60

— Change suffix number

{© Copyright Sep, 2008 ISUZU MOTORS LIMITED Al Rights Reserved

pacts S212. ee, Sep.25, 2006

sEmattan, ear oe ere

4

ISUZU ENGINEERING STANDARD- STANDARD PARTS _ISD-C12-001F

10.2 The Isuzu standard ‘Administrative Procedures for Assignment of GM Part Number’ 27-U-11

shall be referred to for converting an 8-digit GM part number to a 10-digit Isuzu one. This 10-digit

Isuzu part number is referred to as “Modified GM part number’.

[Example of Modified GM part number]

$-24000128-

Control number (8: Prefix indicating Modified GM part number)

GM part number (8 digits)

— Change suffix number

10.3 Use of part numbers. tsuzu part numbers shown in Attached Tables shall be used in

engineering part lists other than the part lists which require modified GM part numbers (10 digits)

‘such as those for GM projects, etc. The modified GM part numbers (10 digits) in Attached

Tables are shown for reference as used only in the engineering part lists requiring modified GM

part numbers,

11. RESTRICTED AND REPORTABLE SUBSTANCES Restricted and reportable

chemical substances shall conform to ISC-A00-008Y.

12, NORMATIVE REFERENCES The standards shown below shall be construed as part

of this standard by making reference to them herein. For the standards, carrying their issue years,

the editions of the years alone shall be deemed as constituting part of this standard but the

revisions including amendments issued in the succeeding years shall not be deemed as so. For

the standards carrying no issue years, the latest edition (including amendments) alone shall be

construed as constituting part of this standard:

ISA-E-004Y Surface roughness

; ISA-M-004Y Mechanical properties of threaded fasteners

ISC-A00-008Y Restricted and reportable substances for parts

JIS B.0205-4;2001 1SO general purpose metric screw threads-Part4:Basic dimensions

JIS B 0209-2:2001 ISO general purpose metric screw threads-Tolerances-Part2:Limit of

sizes for general purpose external and internal screw threads-Medium

quality

: JIS B 1042 : 1998, Fasteners - Surface discontinuities - Part 2: Nuts

13, OTHERS

13.1. This standard shall become effective from Oct. 10, 2006 on.

13.2 The previous standard ISD-C12-001E ‘Weld nuts’ revised on June 2, 2003 shall be superseded

by this standard,

Related Standards

IsT-$013-002 Nut; Projection

27-U-11 Administrative Procedures for Assignment of GM Part Number

JIS B1196:2001 Weld Nuts

{© Copyright Sep. 2008 ISUZU MOTORS LIMITED A Rights Reserves

coger ee es ‘Sep. 25, 2006

5

ISUZU ENGINEERING STANDARD - STANDARD PARTS_ISD-C12-001F

Quantity Ceiling Functional Numbers

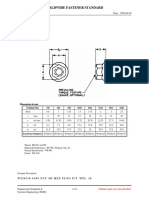

Set Parts Attached Table 1 90911-402/3

NUT; PROJECTION, types A and B 99911-402/3

With Modified GM Type A Type B 90911-404/5

td aes

Shown Together 8 tt 4, Application morcteaars

Upper rows: Isuzu standard part numbers,

Lower rows: Modified GM part numbers(shown in parentheses for reference)

Type A

5N

Part ape:

ae Type A

8N

Type B

MBR125 | WiO«1 25 | MIT OS

810.25 i ti 3 75 cia 9

sn) | TEM)

| Dimension 5 5 6 vo | -ee

Tolerance 2075, 402

r [OF BY

0

in fb 08 08 08 08 19 10

© ae 08 08 08 08 12 12

J approximate z Z = Ti 3 5

“01

Eas 7 7 8 " 13 15

ypsA] os 05 08 8 08.

gmx) bribes

QIN a [aati gues [eeacbeanfn05

4

eee ae oS O71 oa OT

G03 Type. i z i 13 15

wating [2°99 PRBS BT —5 n n if 3

bs Thickness | 08~20 | -08~20 05-26 | 73~52 [16-52

© Copyiht Sep. 2006 SUZU MOTORS UMITED Al Rights Reserved

aod SIF. ep. 75, 2008

Nan tng perc ana to 6 SSS

6

ISUZU ENGINEERING STANDARD- STANDARD PARTS _ISD-C12-001F

Remarks 1. Thread chamfering diameter for type A top surface and type B top / bottom

surfaces shall be sight larger than diameter ofthe thread root diameter

“Thread chamfering diameter for type A bottom surface shall be equal to or greater

than the extemal thread clameter +0.6 mm. The pilot bottom shall have a fat

surface,

Dee ee eee ee Ema

Height incluaing welding points: (HK) for type A and (Hh) for type B

3. The details ofthe projection are not specified here, but shall be ina shape and

dimension suitable for weld.

4. In case of using a nut of a size for which no part number is assigned in Attached

table 1, quantity ceiling set parts standard of "NUT;PROJECTION’(IST-S013-002Y)

shall be referred to. Application for using a new number shall be submitted in

accordance with “The rules for quantity ceiling set pa ration” (270-R-01).

© Copyright Sep. 2006 ISUZU MOTORS LIMITED All Rights Reserved

6.0f 12, Sep. 25, 2006

‘Bolas rh Sh wigstna ita TBAT EE) -COWN OUNTAGTHESRACO

ii

ISUZU ENGINEERING STANDARD - STANDARD PARTS |SD-C12-001F

‘Quantity Ceil With Modified GM Functional Number

Set Parts Part Number Attached Table 2 90911-408/9

Shown Together | NUT; PROJECTION, type C 99911-408/9

Application

(Before welding)

Upper rows: Isuzu standard part numbers,

Lower rows: Modified GM part numbers(shown in parentheses for reference)

Part umpere | B14 ]BBETTADH=D ] 9097050 | BOOTTAOGED RTT AO] BOSTTADEST

Done | oan a) | gousan | ous | gout

Honda} ist [ ioeog nto [aera [ wiostae-[-Wine ta

Ss; 4 3

8 eo oe] ah] tt ch] us eh] m0 2] v0 ah

¢ 30 | 20 | ao [us 2 | as ole 2

i a2 gy | a gh | 2 ah | os | es gdh feo a

Cie) — as — ar gl] Soa | oo eR

Cant) —s08-| 78 07a] coo | |

7 03~15 03~10 03~10 03~15. 03~15 05~20

7

ho Si me 10 10 10 ‘0 2

fi ca o 3 aa ma a

& 0.28 038 038 0.49 055 0.59

Tasha pa Tah

eRe 6 3 7 3 a 3

76-32 _|

Re

jemarks 1: Variation in height (Hh) including welding points in a single nut : Within 0.15 mm.

2. Thread chamfered diameter shall be the thread external diameter(d) + 1.5 40. 5mm.

3. Welding points are acceptable if they do not protrude from the side.

4. The details of the projection are not specified here, but shall be in a shape and

dimension suitable for welding

5. Flash in the projection end shall be neglected in considering the tolerance for

projection height ‘ty’

6. In case of using a nut of a size for which no part number is assigned in Attached

table 2, quantity ceiling set parts standard of ‘NUT;PROJECTION"(IST-S013-002Y)

shall be referred to. Application for using a new number shall be submitted in

‘accordance with “The rules for quantity ceiling set parts operation” (270-R-01).

re os~20_ | 08~20 | os~26 | 08~26 | 42~a2.

© Copyright Sep 2008 ISUZU MOTORS LIMITED Al Rights Reserved

era TQ Base ene

ean et os

8

ISUZU ENGINEERING STANDARD - STANDARD PARTS _ISD-C12-001F

Quantity Ceiling |{ With Modified GM eiiiciionsl Number

Set Parts. Part Number Attached Table 3 90911-406/7

Shown Together _| NUT; PROJECTION, type D 99911-406/7

A Application

(Before welding)

R R

BS oo

aaa a

g

Upper rows: Isuzu standard part numbers,

Lower rows: Modified GM part numbers(shown in parentheses for reference)

Part numbers sor aoneoe ap

Ce EE

uo gh | #0 gp [m0 yo

wo [me 2 | oa 2

4 75 eto een [ieee

Ci (Ref) 05 160 782 aS

C2 (Ref) 405 150 165 195,

f 05=20 05~20 05~20

h eo 10 10 13

04 04 04

049 056 08

Mang pan (oh

ey iw ° 11 8

Thickness O8~56 08-36 08=36

Remarks | Variation in height Fh) including welding points ina single nut: Within 0.15 mm.

2. Thread chamfered diameter shall be the thread external diameter(d) + 1.5 0.5mm,

3, Welding points are acceptable if they do not protrude from the side.

4. The details of the projection are not specified here, but shall be in a shape and

dimension suitable for welding

5. Flash in the projection end shall be neglected in considering the tolerance for

projection height ‘h’

6. In case of using a nut of a size for which no part number is assigned in Attached

table 3, quantity ceiling set parts standard of NUT;PROJECTION*(IST-S013-002Y)

shall be referred to. Application for using a new number shall be submitted in

accordance with "The rules for quantity ceiling set parts operation” (270-R-01).

{© Cooyright Sep, 2006 ISUZU MOTORS LIMITED Al Rights Reserved

eee BOF I ne Sep. 25, 2006

9

ISUZU ENGINEERING STANDARD - STANDARD PARTS 1SD-C12-001F

Quantity Celing

Set Parts Attached Table 4, Functional Number

NUT; WELD, type T 90911-42

With Modified GM eee

Part Number

‘Shown Together sige Application

renee! asics

A

‘Approx. 120°

D

LAS

‘Approx. 120°

?

i

Upper rows: Isuzu standard part numbers,

Lower rows: Modified GM part numbers(shown in parentheses for reference)

Part numbers | 9991142650 9091142060 | 9091142680 | 9091142700

(6240091590) | (@940091600) | (8040081610) | (8040091620)

msx08 | Mexto | Mex1.25 | Mi0x125

24x07 [261.0 | 28e10 | 3281.2

B 1220.25 1480.3 1940.4

[Dimension [6.5 70 85 40

Tolerance |__ +04 205 206

> Ppimension | 62 78 95 12.5

+03 *

Tolerance a we

42802 1,640.25; 2403

D, ae | i 9 fm 13

Hy Po 08 08 08 12

ti 0.42, 0.45 0.49) 056

mating [do “3° 7 9 " a3

art (ef) | Thickness | 0.8~2.0 08~26 12~32

Remarks 1. The number of complete thread ridges shall be 4 pitchs or more.

2. Thread chamfering diameter shall be slightly larger than the thread

root diameter.

3. In case of using a nut of a size for which no part number

is assigned in Attached table 4, quantity ceiling set parts standard

of *NUT;PROJECTION’(IST-S013-002Y)shall be referred to.

Application for using a new number shall be submitted in

‘accordance with "The rules for quantity ceiling set parts operation”

{© Copyright Sep. 2006 ISUZU MOTORS LIMITED Al Rights Reserved

cog ta SOF Ne ne, maple cee

10

ISUZU ENGINEERING STANDARD- STANDARD PARTS _ISD-C12-001F

Annex A (For Reference) Welding of nuts

1, Recommended distance ‘L’ from plate to nut is shown in the following Reference Table 1.

Reference Table 1

Nominal | Hex, Square | T Shape

Tess

M5; 200

M6 z

we $200

M10 $250

Loz

2. Welding Conditions Nut adhesion.

strength and accuracy in threads after

welding depend on the following conditions:

(1) Shape and volume of welding points

(2) Thickness, shape and surface conditions of mating steel sheets

(3) Capacity of welding machine, welding current, applied pressure and welding time

Welding conditions for each nominal thread diameter and steel sheet thickness are shown in

Reference Table 4 in determining optimum welding conditions.

Sheet

Wielding machine

3, Push/Torque Separation Strength (excerpt from JIS B 1196:2001 Reference)

Remark This strength shows values (for reference) of strength needed in order to tighten parts of the

external thread and can be value of higher strength where nuts should be welded on the

most suitable condition.

3.1 Push separation strength and the test method

(1) Push separation strength Push separation strength when a nut is tested using the

method specified in the next subclause 3.1 (2) is given in Reference Table 2. The welded

assembly is deemed satisfactory even if the welded part is deformed in the push separation

test when the load at the test is no less than the relevant value given in Reference Table 2.

Reference Table 2 Unit: kN

Nominal thread ra 5 6 8 | 40 12

diameter (mm)

Push separation |

ear 3.24 3.24 3.24 373 | 603 | 603

Remarks 1. Push separation strength ‘F’ is obtained from the following formula:

F=Sxnx o

‘where S: cross sectional area at the root of one welding point

1: number of welding points in a single nut

(For S and n, median values of the standards for type A hexagon weld nuts are

used in calculating the strength.)

o : tensile strength of welded part (0 =294 Nimm*)

(2) Push separation strength test method _ JIS B 1196:2001 ‘Weld Nuts’ Reference shall be

referred to.

3.2 Torque separation strength and the test method

(1) Torque separation strength Torque separation strength when a nut is tested using the

method specified in the next paragraph 3.2 (2) is given in Reference Table 3. The welded

assembly is deemed satisfactory even if the welded part is deformed in the torque separation

© Copyrignt Sep, 2006 ISUZU MOTORS UMITED All Rights Reserved

Sok 109842 oer Sep. 25, 2006

W

ISUZU ENGINEERING STANDARD - STANDARD PARTS _ISD-C12-001F

test when the load at the test is no less than the relevant value given in Reference Table 3.

Reference Table 3 Unit: Nm

Nominal thread

diameter (mm) a | 2 uo iB

4 | 5

Torque separation

Sen ah 127 127 155 | 20.5 373 422

Notes 1. Torque separation strength Tis obtained from the following formula:

T=Sxnx ¢ xb

where S: cross sectional area at the root of one welding point

1n: number of welding points in a single nut

LL: distance from thread center to welding point

(For S, n and L, median values of the standards for type A hexagon weld nuts are

used in calculating the strength.)

+: shear strength of welded part (

‘x0.7=294x0.7=206 N/mm?)

(2) Torque separation strength test method JIS B 1196:2001 ‘Weld Nuts’ Reference shall

be referred to.

© Copyright Sep_ 2006 ISUZU MOTORS LIMITED All Rights Reserved.

11,08, 12 Sep. 25, 2006

ee we Ser Gite becanen roar cov aurngrasinnce

12

ISUZU ENGINEERING STANDARD -STANDARD PARTS _ISD-C12-001F

Reference Table 4 Welding Conditions for Nominal Thread Diameter x Steel Sheet Thickness.

(Excerpt from JIS B 1196 : 1982

iding conditions:

Types | thickness | — Current Pressure Weld time

mm A EN Ki Hz

We] 08 710,000 5

Botts | ms | 08~1.0 | 13,000~14,000 |245~3.42 {250~350) | 7~18

ms _| 1.0 41,600 2.06 {210} 40

MB | 1.0 15,000 Tie~t77__{120~180} | __8

Ms | 10 11,000 2.06 10) 6

ms | 10 41,000 2.06 10) 6

m6 | __4.0__| 14,000~14,200 | __ 2.16 20) 40

a lat 16 48,000 2.75 30=40

2 168 45,000 2.94~3.53, 10

= 18 14,000 3.92 40

5 18 44,000 3.92 40

8 16 43,000 147 19

5 18 | 15,300~15,400 |_2.35 1

iz 18,000 5 I 30

Mio] 23 | 15,000~16,000 | 2.94~3.54 (300~360)| 10

mio] 23 46,000 4a (450) 19

Mio] 23 16,000 4ai {450} 40

mio| 23 | 16,100~16,300 | __3.63 370) 40

ME 7.0 | 10,000~12,000 | 1.16~208 _{120~270} | 6~

MB] 10 111,000 2.08 210) 8

Ms | 1.0 191800 221 225) 8

Mp | 10 196 t200} &

Mp | 1.0 196 200} 40

MBS} 10 2.94 300} 4~5

M5 | 10 216 1220) 3

Ms | 10 2165 1270} io

ms | +0 1.96 200} 8

MB | 10 | 10,000~12,000 | 1.16~208 {120~210} |_6~10

Me | 10 11,000 2.08 (210) 8

Me | 10 13,800 2.94 300} 6

Ms | 40 41,000 284 300) 5-6

Ms | 10 11,000 2.06 f210) 8

Me} 190 44/500 314 320) 4

Ms | 10 13,000 294 300) 5

Ms | 10 14'500 216 (220) 5

me | 10 13,100 275 280) io

Me | 10 14,000 245 250) 5

2 | Me] 10 14,000 2.45 250) 8

2 |e] 10 40,000 1196 {200} 14

S Le] 10 | 14,300~14,400 | 2:16 220) 49,

§ [MB] 10] 44,300~14,400 16 0} 1

3 | me] 10 10,000 2.94 300} 10

& | we} 10 15,000 314 320) 4

Mp | 10 14,000 324 1330) 8

Me | 1.0 46,000 2.26 230) 7

MB} 10 44/800 363 370) 19

me | 1.0 44,000 2.45 250) 5

MB | 10~20 | 13,000~16,000 | 204~353 _{300~360} |__8~10

Mp | 16 | 14,300~14,400 | |" 2.16 (220), 10

Ms | 216 | 14/000~18/000 | 3.14~412 {920~420)| 7~10

Me | 16 9,000 2.70 (275) 18

MB | 03~23 14,500 2.94 {300} ri

MIO, fT T4000~ 14 3.43 (350), g

Mio| 216 | 16,000~20,000 | 3.63~4.90 {390~S00)| 9~13

mio} “1.6 21,000 3.78. {385} 2

[MI0-|-20~25 | 13,000~17,000 | 294~412 —{a00~420} | ~10

Mio | © 20 15,500 444 (450) 10

Mio| 20 13,000 47 1480) 6

Mio| 20 15,500 444 1450) 40

MIZ | T2=25-| TS O00 18 000 | 33412 —{o60~400} | TOF

Miz| 23 19,000 5.88 (600 14

mi2|__23 19,000 5.88 1600) 44

(© Copyright Sep. 2005 ISUZU MOTORS LIMITED All Rights Reserved

212 we,

Sep. 25, 2006

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hes D 2003-05Document15 pagesHes D 2003-05Gustavo FelipeNo ratings yet

- 90202-GHR - 6400 (11-2003)Document1 page90202-GHR - 6400 (11-2003)Gustavo FelipeNo ratings yet

- NM 87 (05-1997)Document20 pagesNM 87 (05-1997)Gustavo FelipeNo ratings yet

- We 500 - M8 (11-2005)Document1 pageWe 500 - M8 (11-2005)Gustavo FelipeNo ratings yet

- WX100 - S451Document1 pageWX100 - S451Gustavo FelipeNo ratings yet

- Ford Worldwide Fastener StandardDocument1 pageFord Worldwide Fastener StandardGustavo FelipeNo ratings yet

- Is 2830-2012Document9 pagesIs 2830-2012Gustavo FelipeNo ratings yet

- Embrittlement Avoidance WSS-M99A3-A 1. Scope: Engineering Material SpecificationDocument5 pagesEmbrittlement Avoidance WSS-M99A3-A 1. Scope: Engineering Material SpecificationGustavo FelipeNo ratings yet

- STD 121-0003Document9 pagesSTD 121-0003Gustavo FelipeNo ratings yet

- Din 2819-2018Document27 pagesDin 2819-2018Gustavo FelipeNo ratings yet

- Flange Lock Nuts: ReleasedDocument2 pagesFlange Lock Nuts: ReleasedGustavo FelipeNo ratings yet

- W 703173 (11-1996)Document1 pageW 703173 (11-1996)Gustavo FelipeNo ratings yet

- W 703193 (11-1996)Document1 pageW 703193 (11-1996)Gustavo FelipeNo ratings yet

- Iso 6157 2 1995Document9 pagesIso 6157 2 1995Gustavo FelipeNo ratings yet

- 9.10187 (02-2004)Document7 pages9.10187 (02-2004)Gustavo Felipe100% (1)

- Parte 4: Condições Técnicas de Fornecimento de Aços para Beneficiamento Versão Alemã EN 10263-4:2001Document18 pagesParte 4: Condições Técnicas de Fornecimento de Aços para Beneficiamento Versão Alemã EN 10263-4:2001Gustavo FelipeNo ratings yet

- Parte 2: Condições Técnicas de Fornecimento de Aços Não Previstos para Um Tratamento Térmico Após o Processamento A Frio Edição Alemã EN 10263-2:2001Document8 pagesParte 2: Condições Técnicas de Fornecimento de Aços Não Previstos para Um Tratamento Térmico Após o Processamento A Frio Edição Alemã EN 10263-2:2001Gustavo FelipeNo ratings yet

- Standard: Flänssvetsmuttrar Flange Weld NutsDocument3 pagesStandard: Flänssvetsmuttrar Flange Weld NutsGustavo FelipeNo ratings yet

- Din 898-6 (02-1996)Document11 pagesDin 898-6 (02-1996)Gustavo FelipeNo ratings yet