Professional Documents

Culture Documents

HDPE Bracketry: 4. Underground Installation of HDPE

Uploaded by

Bora0 ratings0% found this document useful (0 votes)

1 views1 pageHDPE Soil

Original Title

23

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHDPE Soil

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1 views1 pageHDPE Bracketry: 4. Underground Installation of HDPE

Uploaded by

BoraHDPE Soil

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

HDPE Bracketry

4. Underground installation of HDPE Embedding of the pipe

(consolidation) – zone 2

Please see markings of pipes and fittings to indicate the permitted application area(s) for which they are intended: The fill for the pipe system embedding

B: application area code for components intended for use above ground inside the building, or for components outside buildings must consist of stone-free sand or

fixed onto the wall; similar material: the fill must ensure

optimal compacting of the ground. The

D: application code for the area under and within 1m from the building where the pipes and fittings are buried in ground and are embedding is, to a large extent, a decisive

connected to the underground drainage and sewerage system; factor in distributing the soil pressure

BD: application area code for components intended for use for both code B and code D application areas and load, as well as providing lateral soil

pressure on the pipe with the resulting

Installation guidelines before Soil and traffic loads It is assumed that the increased pressure unburdening effect.

installing HDPE underground The load capacity of underground plastic resulting from traffic loads caused by

pipes is based on changes in the pipe road or rail traffic are surface loads evenly

Due to specific properties such as flexibility

distributed over the pipe sectional plane. The height of zone 2 must extend to at least 150 mm above the pipe. This must also be

and resistance to cold temperature and movement of the ground. The

at least 100mm above any pipe fittings.

(freezing), HDPE pipe systems are ideal for soil load causes the top of the pipe to Groundwater

use in underground pipe lines. Buried pipes deflect downward. The sides of pipe are Underground pipes can be subject to

are exposed to various loads. It is, in effect, correspondingly pressed outward against the external overpressure, especially in areas with

the stability of HDPE in withstanding these surrounding soil. The reaction pressure, the high groundwater levels. In addition, a pipe Filling of trench (protective layer)

pressures that makes it possible to lay the lateral force exercised on the pipe, prevents enclosed in concrete is exposed to external

a larger cross-sectional deformation (support – zone 3

pipes at substantial depth. The suitability pressure, though just for a short period.

depends on such factors as depth, function). The construction of the trench, The trench is backfilled in layers and

groundwater level, density of the soil and the type of bedding used and the backfilling Underground compacted. Types of soil and materials

traffic load. of the trench are, to a large extent, decisive Pipe systems subject to additional external that can cause dents may not be used to

factors determining the load capacity of an pressure must be tested for the ability to backfill the trench (e.g. ash, waste, stones).

underground plastic pipe. The load needs withstand dinting. The effective load due The use of heavy compacting equipment

to be evenly distributed over the entire pipe to external pressure will agree with the to compact the soil is not permissible for

line. For this reason, the trench must be related hydrostatic pressure on the pipe soil layers <1,0 m. The required thickness

created in such a manner that bends in a axis. For special circumstances, request of zone 3 depends on trench form and

longitudinal direction and loads at specific assistance from our Technical Services pipe-wall thickness. Our Technical Support

points are avoided. department by calling 01622 852695. department can advise you in this regard.

Due to the risk of the waste water freezing, the pipes must be laid at a frost-free depth.

Construction and installation of

underground pipe systems

Zone 3

Trench base (bedding) – zone 1

The state and form of the trench base must

match the mechanical properties of the

Zone 2 Underground

thermoplastic pipe. The existing or newly Zone 1

constructed support layer must consist

Marley offers a wide range

of stone-free sand that has been slightly of Underground systems:

compressed using a suitable piece of The height of zone 1 depends on the soil conditions and the nominal pipe width, and is

equipment. The pipe must be laid in such calculated using the following equation. • Solid wall system

a way that a stable surface with at least a • Quantum Sewer

90° arc of enclosure is created in order to DN

Hso = Hm + • Quantum Highway

prevent sagging or intermittent loads. 10

The trench in which the pipe is laid must

• Large diameter Quantum Highway

Hso = height of the soil in zone 1 (mm)

be sufficiently narrow in order to keep the

Hm = minimum initial thickness normal soil conditions: 100mm rocky or thick soil: 150 mm

final soil pressure as low as possible. The For more information,

space between pipe and trench wall must DN = nominal pipe width (mm)

be at least 100mm.

visit marleypd.co.uk

44 | MARLEY HDPE MARLEY HDPE | 45

You might also like

- SSC Je Previous Year Question and Solution (2007-2018) PDFDocument336 pagesSSC Je Previous Year Question and Solution (2007-2018) PDFv sai charanNo ratings yet

- Module-2: 3.1.1. Design Criteria of Earthen DamDocument9 pagesModule-2: 3.1.1. Design Criteria of Earthen DamsakshiNo ratings yet

- Concrete Slab MoistureDocument2 pagesConcrete Slab MoistureaaNo ratings yet

- Tunneling On Soft SoilsDocument12 pagesTunneling On Soft Soilsdsananda50% (2)

- Studies On Soil Disturbance Caused by Grouting in Treating Marine ClayDocument9 pagesStudies On Soil Disturbance Caused by Grouting in Treating Marine Clayhutuguo100% (1)

- HDPE Handbook - Chapter 7 Underground InstallationDocument44 pagesHDPE Handbook - Chapter 7 Underground InstallationAlfonso PatuktokNo ratings yet

- Api 650Document16 pagesApi 650cfpc10459No ratings yet

- BSS502 Construction Technology 1Document63 pagesBSS502 Construction Technology 1PATCADS STRUCTURAL SOLUTIONSNo ratings yet

- Dreno Tex PDFDocument10 pagesDreno Tex PDFvranceanu.ovidiu-1No ratings yet

- Modelling of Prefabricated Vertical Drains in Soft Clay and Evaluation of Their Effectiveness in PracticeDocument11 pagesModelling of Prefabricated Vertical Drains in Soft Clay and Evaluation of Their Effectiveness in PracticeHUGINo ratings yet

- 62 Determination Load Sharing Effects Sprayed Concrete Tunnel LiningsDocument8 pages62 Determination Load Sharing Effects Sprayed Concrete Tunnel Liningsp_ignatiusNo ratings yet

- Mecanismos Pop UpDocument44 pagesMecanismos Pop UpJose Agustin Legarreta Rodriguez100% (29)

- Method Statement For Drainage Work at VBC KG Titi Besi (CH 232457.551)Document7 pagesMethod Statement For Drainage Work at VBC KG Titi Besi (CH 232457.551)MAYMODERN STEELNo ratings yet

- Upgrading Substation Grounding SystemDocument30 pagesUpgrading Substation Grounding SystemWonbae ChoiNo ratings yet

- W38B New Bolts For Charge Air CoolerDocument3 pagesW38B New Bolts For Charge Air CoolerD.PoljachihinNo ratings yet

- Tunneling On Soft Soils PDFDocument12 pagesTunneling On Soft Soils PDFGourab MandalNo ratings yet

- DocumentDocument9 pagesDocumentea_she3415No ratings yet

- Design of A NATM Tunnel For Mission Valley Light Rail - East ExtensionDocument12 pagesDesign of A NATM Tunnel For Mission Valley Light Rail - East ExtensionconcretetechgroupNo ratings yet

- 3-Potsdamer Platz Raft Slab Project Journal Paper - Application of Steel Fibre Concrete For Underwater Concrete SlabsDocument9 pages3-Potsdamer Platz Raft Slab Project Journal Paper - Application of Steel Fibre Concrete For Underwater Concrete SlabsTian NgNo ratings yet

- Ahmed, Mostafa, Therese (2020) Bruied Pipes Using GeogridDocument19 pagesAhmed, Mostafa, Therese (2020) Bruied Pipes Using GeogridCarlos Arturo Gomez JimenezNo ratings yet

- Excavation Backfill For UtilitiesDocument13 pagesExcavation Backfill For UtilitiesGHL AdaroNo ratings yet

- Buried GRPDocument14 pagesBuried GRPlfpachecoNo ratings yet

- NHBC Standards 2020 5 PDFDocument202 pagesNHBC Standards 2020 5 PDFalberto5791No ratings yet

- Information Sheet I Ch2 Braced Cut FinalDocument17 pagesInformation Sheet I Ch2 Braced Cut Finalhelen haileselassieNo ratings yet

- Functions of Bedding and Filling Materials: Sewer ConstructionDocument9 pagesFunctions of Bedding and Filling Materials: Sewer ConstructionJenny Vi EstoneloNo ratings yet

- Grounding Systems: EM 1110-2-3006 30 Jun 94Document4 pagesGrounding Systems: EM 1110-2-3006 30 Jun 94Rizwan RaoNo ratings yet

- International Society For Soil Mechanics and Geotechnical EngineeringDocument7 pagesInternational Society For Soil Mechanics and Geotechnical EngineeringAnonymous zpNy2bltNo ratings yet

- Numerical Behaviour of Buried Flexible Pipes in Geogrid - 2020 - Computers andDocument17 pagesNumerical Behaviour of Buried Flexible Pipes in Geogrid - 2020 - Computers andarifyunandoNo ratings yet

- A Field Case Study On Construction of Underground Passageway 2014Document6 pagesA Field Case Study On Construction of Underground Passageway 2014Ivan MojicaNo ratings yet

- Outlet ProtectionDocument6 pagesOutlet ProtectionalikoleiniNo ratings yet

- Earth Pressure Cells: 3500, 4800 SeriesDocument4 pagesEarth Pressure Cells: 3500, 4800 Seriesapi-3706095No ratings yet

- Plumbing and Drainage 2870 2011 NotesDocument4 pagesPlumbing and Drainage 2870 2011 NotesSimon KhamalaNo ratings yet

- Numerical Simulation of A Deep Excavation Near A Shield TunnelDocument9 pagesNumerical Simulation of A Deep Excavation Near A Shield TunnelEfi GusfianaNo ratings yet

- TBM Full Face DrivingDocument13 pagesTBM Full Face DrivingBob MoncrieffNo ratings yet

- InstructionDocument10 pagesInstructiongreenday3No ratings yet

- Diaphragm Walls Construction and DesignDocument18 pagesDiaphragm Walls Construction and DesignShirley Munoz100% (1)

- Vertical Drains: Consolidation PhenomenonDocument4 pagesVertical Drains: Consolidation Phenomenonfandhiejavanov2009No ratings yet

- Engineering DrawingDocument15 pagesEngineering DrawingroyjameswangNo ratings yet

- Design Concept For An Anchored DiaphragmDocument9 pagesDesign Concept For An Anchored Diaphragmnirgun sherchanNo ratings yet

- CLSM With Fine AggregatesDocument5 pagesCLSM With Fine AggregatesBuild StreetNo ratings yet

- Compliance Sheet - Roof Waterproofing MFGCDocument3 pagesCompliance Sheet - Roof Waterproofing MFGCumn_mlkNo ratings yet

- Ground Improvement Techniques UNIT-1Document23 pagesGround Improvement Techniques UNIT-1Raghuram Vadiboyena VNo ratings yet

- Concrete Construction Article PDF - Floor Construction by Vacuum DewateringDocument4 pagesConcrete Construction Article PDF - Floor Construction by Vacuum DewateringYuri De SantisNo ratings yet

- Chapter 07Document39 pagesChapter 07kevinmathew27No ratings yet

- C320 - Tunnelling Under The Thames: September 2003Document5 pagesC320 - Tunnelling Under The Thames: September 2003Jorge Baños LloredoNo ratings yet

- ACPPA TechSeries 12 JackingCPP FinalDocument6 pagesACPPA TechSeries 12 JackingCPP FinalWilliamray PabloNo ratings yet

- Notes On Pipe Subsoil Drain Construction SpecificationDocument14 pagesNotes On Pipe Subsoil Drain Construction SpecificationSitche ZisoNo ratings yet

- We 6 RFP 050Document3 pagesWe 6 RFP 050saturasatuNo ratings yet

- Geocomposite Edge Drain System Design - Transportation Research RecordDocument5 pagesGeocomposite Edge Drain System Design - Transportation Research RecordAnonymous CQ4rbzLVENo ratings yet

- Key Plan:: Date Rev No. DescriptionDocument4 pagesKey Plan:: Date Rev No. DescriptionING. ERNESTO AVALOS GARCIANo ratings yet

- 2006 - Preloading and Prefabricated Vertical Drains-Wick Drain (PVD)Document23 pages2006 - Preloading and Prefabricated Vertical Drains-Wick Drain (PVD)hajro hodzicNo ratings yet

- Project SpecificationsDocument23 pagesProject SpecificationsMydeen ThangalNo ratings yet

- Installing Factory-Made Corrugated Aluminum Culverts and Storm Sewer PipeDocument6 pagesInstalling Factory-Made Corrugated Aluminum Culverts and Storm Sewer PipeROHITNo ratings yet

- 7-7. Embankment Reinforcement: EM 1110-2-2300 30 Jul 04Document6 pages7-7. Embankment Reinforcement: EM 1110-2-2300 30 Jul 04eka nur fitriyanaNo ratings yet

- International Society For Soil Mechanics and Geotechnical EngineeringDocument5 pagesInternational Society For Soil Mechanics and Geotechnical EngineeringBelaniza GasparNo ratings yet

- Mansori Salmasi Horizontaldrain 2013 JCEUDocument9 pagesMansori Salmasi Horizontaldrain 2013 JCEUomed muhammadNo ratings yet

- Geo PipesDocument19 pagesGeo PipesJohn Francis PedrosoNo ratings yet

- Unit-3 Transport of Water and Waste WaterDocument20 pagesUnit-3 Transport of Water and Waste WaterAmanpreet100% (1)

- Tunnel Induced Settlement Soft GroundDocument24 pagesTunnel Induced Settlement Soft GroundKAI CHUAN CHUNo ratings yet

- ApplicationsDocument15 pagesApplicationspios.helectorNo ratings yet

- Introduction To Floplast Soil & Waste SystemsDocument1 pageIntroduction To Floplast Soil & Waste SystemsBoraNo ratings yet

- Soil & Waste Systems: 110mm Ring Seal SoilDocument1 pageSoil & Waste Systems: 110mm Ring Seal SoilBoraNo ratings yet

- Design: WC Manifold System Combined Branch Waste Waste TrapsDocument1 pageDesign: WC Manifold System Combined Branch Waste Waste TrapsBoraNo ratings yet

- Active Drainage Ventilation: HDPE BracketryDocument1 pageActive Drainage Ventilation: HDPE BracketryBoraNo ratings yet

- Underground: Marleypd - Co.ukDocument1 pageUnderground: Marleypd - Co.ukBoraNo ratings yet

- Marley Co UkDocument1 pageMarley Co UkBoraNo ratings yet

- Installation Data: Jointing Techniques Marley Pipe Support SystemDocument1 pageInstallation Data: Jointing Techniques Marley Pipe Support SystemBoraNo ratings yet

- HDPE Bracketry: Length de Ection Leg at Operating Temperature 25°C-100°CDocument1 pageHDPE Bracketry: Length de Ection Leg at Operating Temperature 25°C-100°CBoraNo ratings yet

- Sanitary Pipework DesignDocument1 pageSanitary Pipework DesignBoraNo ratings yet

- The Technical Experts in Plumbing & Drainage: HDPE Handling and StorageDocument1 pageThe Technical Experts in Plumbing & Drainage: HDPE Handling and StorageBoraNo ratings yet

- Soil & Waste Systems: AccreditationDocument1 pageSoil & Waste Systems: AccreditationBoraNo ratings yet

- Product Specifications: Additional Sizes Are AvailableDocument1 pageProduct Specifications: Additional Sizes Are AvailableBoraNo ratings yet

- Appendix: Used SymbolsDocument1 pageAppendix: Used SymbolsBoraNo ratings yet

- HDPE Bracketry: Choice of Pipe Installation MethodsDocument1 pageHDPE Bracketry: Choice of Pipe Installation MethodsBoraNo ratings yet

- HDPE Jointing Methods: Evaluating The Butt-WeldDocument1 pageHDPE Jointing Methods: Evaluating The Butt-WeldBoraNo ratings yet

- HDPE Jointing Methods: ElectrofusionDocument1 pageHDPE Jointing Methods: ElectrofusionBoraNo ratings yet

- Transitions To Other Materials: SanitaryDocument1 pageTransitions To Other Materials: SanitaryBoraNo ratings yet

- Installation HDPE Jointing MethodsDocument1 pageInstallation HDPE Jointing MethodsBoraNo ratings yet

- HDPE Jointing Methods: Butt-Weld ProcessDocument1 pageHDPE Jointing Methods: Butt-Weld ProcessBoraNo ratings yet

- Trapped Floor GullyDocument1 pageTrapped Floor GullyBoraNo ratings yet

- Material Properties: HDPE Properties Technical SpecificationsDocument1 pageMaterial Properties: HDPE Properties Technical SpecificationsBoraNo ratings yet

- Product Specifications: Pipe Length 5MDocument1 pageProduct Specifications: Pipe Length 5MBoraNo ratings yet

- WC Manifold System: Manifold Branch SM41W With SM42W A B Cut Line Projection DropDocument1 pageWC Manifold System: Manifold Branch SM41W With SM42W A B Cut Line Projection DropBoraNo ratings yet

- Marley Fire Protection Range Fire SleevesDocument1 pageMarley Fire Protection Range Fire SleevesBoraNo ratings yet

- Trapped Floor GullyDocument1 pageTrapped Floor GullyBoraNo ratings yet

- Eccentric Reducer: Soil and Vent ComponentsDocument1 pageEccentric Reducer: Soil and Vent ComponentsBoraNo ratings yet

- Two Piece Pipe Bracket Angle CleatDocument1 pageTwo Piece Pipe Bracket Angle CleatBoraNo ratings yet

- Tubular 'P' Trap Slimline Pedestal Trap: Universal Compression Joint TrapsDocument1 pageTubular 'P' Trap Slimline Pedestal Trap: Universal Compression Joint TrapsBoraNo ratings yet

- Access Cap & Pressure Plug: Soil and Vent ComponentsDocument1 pageAccess Cap & Pressure Plug: Soil and Vent ComponentsBoraNo ratings yet

- The Marley Soil & Waste Installation GuideDocument1 pageThe Marley Soil & Waste Installation GuideBoraNo ratings yet

- Openvswitch enDocument27 pagesOpenvswitch enLoris StrozziniNo ratings yet

- Manvi Final BriefDocument6 pagesManvi Final BriefManvi AgarwalNo ratings yet

- Table 7 Minimum Requirements For Fire Fighting InstallationsDocument11 pagesTable 7 Minimum Requirements For Fire Fighting Installationsjeet sharmaNo ratings yet

- Briggs Plume Rise Equations PDFDocument2 pagesBriggs Plume Rise Equations PDFWellfroNo ratings yet

- CV of Vele Rabelani FreddyDocument2 pagesCV of Vele Rabelani Freddylevy2011No ratings yet

- CHAPTER 11 Aircraft Instrument SystemsDocument48 pagesCHAPTER 11 Aircraft Instrument Systemsখালিদহাসান100% (1)

- Brother Da I-B712 DB I-B760: Instruction ManualDocument16 pagesBrother Da I-B712 DB I-B760: Instruction Manualbrikki4450% (2)

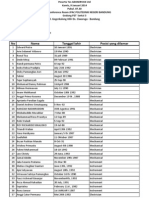

- Peserta Assessment PolbanDocument2 pagesPeserta Assessment PolbanJulianCPratamaNo ratings yet

- Exp 4 Buckling AnalysisDocument10 pagesExp 4 Buckling Analysissmg26thmayNo ratings yet

- Final C#Document45 pagesFinal C#Nguyễn Ngọc PhướcNo ratings yet

- Rainfall Map Preparation Arc GISDocument3 pagesRainfall Map Preparation Arc GISprasanththejusNo ratings yet

- Dept For Education EFA - Acoustic Standards For PSBP June 2013 v1.7Document35 pagesDept For Education EFA - Acoustic Standards For PSBP June 2013 v1.7mikelotingaNo ratings yet

- Saic Q 1017Document1 pageSaic Q 1017Hussain Nasser Al- Nowiesser100% (2)

- RT1-01 Rocket PrincipleDocument11 pagesRT1-01 Rocket Principlegarans68No ratings yet

- Energy Losses in Bends Lab ReportDocument14 pagesEnergy Losses in Bends Lab ReportJemuel FloresNo ratings yet

- 1 What Is A GmoDocument22 pages1 What Is A GmoPinaring BreederNo ratings yet

- Industrial Fault Indication System With Over Voltage Over TemperatureDocument46 pagesIndustrial Fault Indication System With Over Voltage Over Temperaturedivanshu16decNo ratings yet

- Lecture 02: The Waterfall Model: Course Leader(s) : Ms - Sahana.P.ShankarDocument11 pagesLecture 02: The Waterfall Model: Course Leader(s) : Ms - Sahana.P.ShankarPritam DasNo ratings yet

- Raghunath AnDocument68 pagesRaghunath AnRagunathan NarayananNo ratings yet

- Aryabhatta International School, Barnala: Time: 2 Hours Class: 5thDocument2 pagesAryabhatta International School, Barnala: Time: 2 Hours Class: 5tharunNo ratings yet

- Agile Curriculum SkillsoftDocument2 pagesAgile Curriculum Skillsoftanonymous_034aNo ratings yet

- Ground Floor PlanDocument1 pageGround Floor PlanNORTSEN ALBERTNo ratings yet

- WindowsOS SA 4.2Document6 pagesWindowsOS SA 4.2Madalina Croitoru-HeuserNo ratings yet

- Breaking Bad Chemistry Calculations: Step 1: Ephedrine + Hydroiodic Acid Iodoephedrine (+ Water)Document2 pagesBreaking Bad Chemistry Calculations: Step 1: Ephedrine + Hydroiodic Acid Iodoephedrine (+ Water)SanikNo ratings yet

- INS-4 2-01 Instruction For Management Systems Certification Bodies - InglésDocument11 pagesINS-4 2-01 Instruction For Management Systems Certification Bodies - InglésDiego TobrNo ratings yet

- Scheduling User Guide - PowerSchool 8.xDocument113 pagesScheduling User Guide - PowerSchool 8.xMuskegon ISD PowerSchool Support ConsortiumNo ratings yet

- Renewable Energy System: Simulation of Fuel Cell ForDocument30 pagesRenewable Energy System: Simulation of Fuel Cell ForVinayak KhandareNo ratings yet