Professional Documents

Culture Documents

PR-Inspection & Testing Procedure

PR-Inspection & Testing Procedure

Uploaded by

sfda.badrmedicalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PR-Inspection & Testing Procedure

PR-Inspection & Testing Procedure

Uploaded by

sfda.badrmedicalCopyright:

Available Formats

Mawj Alsama Medical Company

Procedure for Inspection & Testing

Doc No.: MAMC-MD-QMS-PR-15 Date: 06/02/2022

Mawj Alsama Medical Company

ISO 13485:2016

Medical Devices-Quality Management System

Address: AL NAHDA DISTRICT AL SAFA STREET, JEDDAH, 21493, KSA

PROCEDURE FOR INSPECTION AND TESTING

Authorized By Name Designation Date & Sign

Prepared By

Reviewed By

Approved By

Rev No.: 00 Page No. 1 of 8

Mawj Alsama Medical Company

Procedure for Inspection & Testing

Doc No.: MAMC-MD-QMS-PR-15 Date: 06/02/2022

Revision History and Approval

Rev. Nature of Changes Approval Date

Rev No.: 00 Page No. 2 of 8

Mawj Alsama Medical Company

Procedure for Inspection & Testing

Doc No.: MAMC-MD-QMS-PR-15 Date: 06/02/2022

Table of Contents

1. Purpose……………………………………………………………………………………………………………………..…………………………………….....4

2. Scope……………………………………………………………………………………………………….……………….…………………..…………………….4

3. Resposibilities…………………………………………………………………………..…………...……………................................................4

4. Definitions………………………………………………………………………………………………………….....…………….……………………….…....4

5. Procedure…………………………………………………...……………………………………….................................................................4

5.1 Competencies Resources of Inspection Program………………………………………………………............................…….........4

5.2 Inspection Program………………………………….............................................................................................................5

5.3 Random Inspection.....................….…………………………….…......................................................................................5

5.4 Annual Inspection Plan & Schedule ……………...…………………………………...................................................................5

5.5 Inspection Documentation.....................................................................................................................................6

5.6 Inspection Program Record Keeping & Updating of MD-QMS Inspection Checklist……………………………………..……6

5.7 Monitoring and Reviewing of Inspection Program………………………….…………………………….………………………………….6

5.8 Performing the MD-QMS Inspection………………………………………………………………………..………………………………….…..7

5.9 Inspection Program Reporting & Monitoring…………………………………………………………………………………….……………..7

5.10 Subcontractor Inspection and Test Plans………………………………………………………….……………………………………………8

5.11 Sector MD-QMS Inspections Categories………………………………………………………………………………………………………..8

6. Records Or Exhibits…………………………………………..……………………………………………………………..………………………..……...8

Rev No.: 00 Page No. 3 of 8

Mawj Alsama Medical Company

Procedure for Inspection & Testing

Doc No.: MAMC-MD-QMS-PR-15 Date: 06/02/2022

1. Purpose

The purpose of this procedure is to establish, implement and maintain a documented process for planning

and conducting the on-going workplace inspection, testing and monitoring activities in order to ensuring

the implementation of safe work practices in Mawj Alsama Medical Company.

2. Scope

This procedure is applicable to Mawj Alsama Medical Company activities in conformance to its Health &

Safety Management System based on the requirements of the guidelines of the Audit and Inspection and

Technical Guideline.

3. Responsibilities

The MD-QMS Officer is responsible for ensuring that appropriate workplace inspection, testing and

monitoring activities are carried out in Mawj Alsama Medical Company.

All supervisors and department heads are responsible for performing MD-QMS inspections of the

workplace in accordance with this procedure.

4. Definitions

Inspection – Refer to critical examination of work tasks, facilities and equipment during a physical walk –

through of an area to determine conformance to applicable requirements, standards and policies.

Non-Conformance – Is a non-fulfillment of a requirement. Specially, a nonconformance is any deviation

from work standards, parties, procedures, regulations, management system performance etc. that could

either directly or indirectly lead to injury or illness, property damage, or a combination of these.

Corrective Action - Steps that are taken to remove the causes of an existing non conformity or undesired

situation. The corrective action process is designed to prevent the recurrence of nonconformance or

undesired situation.

MR – “Management Representative”, a person appointed to manage and monitor the implementation of

the organization.

5. Procedure

5.1 Competencies Resources of Inspection Program

• Planning for MD-QMS Inspection, Testing & Monitoring

Inspection program planning and implementation processes, including:

i. Criteria

ii. Frequency and schedules

iii. Methods of collecting and verifying information

iv. Reporting inspection results

v. Non-conformance and corrective action process

Rev No.: 00 Page No. 4 of 8

Mawj Alsama Medical Company

Procedure for Inspection & Testing

Doc No.: MAMC-MD-QMS-PR-15 Date: 06/02/2022

vi. Inspection program record keeping

• MD-QMS Inspection Team

The MD-QMS Management Representative and/or MD-QMS Officer shall form and maintain an MD-QMS

Inspection Team who will be responsible for conducting inspection, testing and monitoring for the purpose

of establishing and maintaining safe working conditions and discovering unsafe practices in the workplace.

It shall be the responsibility of the MD-QMS Officer to train all members of the MD-QMS Inspection Team

in matters related to health & safety workplace inspection.

The MD-QMS Inspection Team shall be composed of first-line supervisors and department heads, who shall

conduct 2 different types of inspections:

i. Supervisory Inspection

MD-QMS inspections in supervisory level shall be conducted on a monthly basis by first line supervisors

and to be facilitated by the MD-QMS Officer.

ii. Management Inspection

MD-QMS inspections in management level shall be conducted on a quarterly basis by department

heads, and shall be facilitated by the MD-QMS Management Representative and/or MD-QMS Officer.

5.2 Inspection Program

The Inspection program should cover all the activities that the Mawj Alsama Medical Company undertakes

and should be developed on a risk-based approach.

When developing an inspection program, the FIES should review the output of their MD-QMS to determine

which areas of their business require more frequent inspection than others.

It is good practice to ensure that all areas of the business are inspected as minimum twice (2) per year.

However, for more medium to high-risk activities/ process the FIES should consider monthly inspections.

The inspection program should be communicated to all relevant stakeholders within the FIES so they are

aware of the requirements.

5.3 Random Inspection

Although the program should detail what the planned inspection requirements are, the FIES should also

consider undertaking random inspections when the need arises.

Random inspections should be used to compliment the planned inspections and also to verify their results.

Further the frequency of random inspections should be based upon the outputs of the MD-QMS and where

poor compliance is seen, it may be that the MD-QMS Manager decides to undertake more frequent

random inspections.

5.4 Annual Inspection Plan & Schedule

MD-QMS Officer shall prepare “Annual Inspection Plan” of MD-QMS inspections every start of the year and

shall be approved and signed by the MD-QMS Management Representative.

The approved Annual Inspection Plan shall be posted in MD-QMS related bulletin board and shall serve

Rev No.: 00 Page No. 5 of 8

Mawj Alsama Medical Company

Procedure for Inspection & Testing

Doc No.: MAMC-MD-QMS-PR-15 Date: 06/02/2022

as a monitoring sheet for the actual performance of inspection.

MD-QMS Officer shall be responsible to monitor the actual performance of inspection and shall update the

“Annual Inspection Plan” on a regular basis.

The MD-QMS Officer shall prepare the “Detailed inspection Plan” which will include the following

information:

• Objectives of the inspection;

• inspection Scope;

• Assigned inspector;

• Date & Time of inspection;

• Itinerary.

Internal inspection shall be based on the activities related to MD-QMS, which include the work instructions,

compliances to health & safety legal requirements, and other requirements from interested parties (e.g.,

Competent Authority, Sector Regulatory Authority, etc.).

The inspection plan shall be based on the MD-QMS Monitoring Program as provided in

Doc #: MAMC-MD-QMS-PR-13 Monitoring and Reporting procedure which includes but not limited to:

• Fire Fighting Equipment Inspection (Fire Extinguisher, Fire Pump, Fire Alarms etc.)

• Machinery safety inspection

• Fork Lift Inspection

• Personnel Protective Inspection

• General Amenities Inspection

• Ladders Inspection

• Hygiene Inspection

• First Aid Equipment Inspection

5.5 Inspection Documentation

The MD-QMS Manager/ MD-QMS Officer shall develop checklist that can be used to standardize the

inspections being undertaken. Inspection’s checklist should be developed as basic checklist that can verify

work practices and equipment is being maintained in line with the FIES.

Depending on the size and complexity of the entity, it may be decided to develop several checklists to cover

the undertakings. These can be split by function or even by hazard.

It shall be the responsibility of the MD-QMS Officer to update an inspection checklist using the “Workplace

Inspection Checklist”.

5.6 Inspection Program Record Keeping & Updating of MD-QMS Inspection Checklist

Inspection results should record leaving the area to discuss findings and recommendations. Report even

minor items which the supervisor can immediately correct. Record this in the report as corrected. This

keeps the report up-to-date and serves as a reminder to check the condition during the next inspection. All

Inspection records must be kept at least for 5 years at least.

5.7 Monitoring and Reviewing of Inspection Program

Rev No.: 00 Page No. 6 of 8

Mawj Alsama Medical Company

Procedure for Inspection & Testing

Doc No.: MAMC-MD-QMS-PR-15 Date: 06/02/2022

The implementation of the inspection program should be monitored to ensure it is meeting the

objectives and also to identify any areas for improvement. When undertaking the review FIES should

consider:

• Feedback for auditee's, inspectors and other relevant stakeholders;

• Adherence to the inspection schedule program; and

• Outputs from the inspections.

The review process should feed into the overall management review program as defined in management

review procedure.

The MD-QMS Manager in consultation with Managing Partner shall monitor and review the progress of the

recommendations and follow-up shall be carried out to ensure corrective actions have been implemented

and are effective.

5.8 Performing the MD-QMS Inspection

The MD-QMS Inspection Team, headed by the MD-QMS Manager, shall conduct workplace inspection using

Doc #: MAMC-MD-QMS-PR-15-F-01 “Workplace Inspection Checklist”.

Areas to inspect shall be as follows:

Process - Walk through the inspection area and examine the work processes taking place. Does the

workplace layout limit awkward body positioning? Is the need for repetitive motion and forceful exertion

limited?

People - Observe workers performing their jobs. Pay particular attention to worker interaction with

materials, equipment and co-workers. Are safe work procedures being followed? Are tools, equipment and

PPE being used appropriately? Are workers aware of the hazards of their jobs? Are people using safe

working postures?

Equipment - Inspect the condition of the equipment. Look for signs of wear (rust, cracks, and leaks).

Ensure that guards and safety devices are in place and that the equipment has been regularly maintained.

Consider ergonomic issues arising out of the design and use of the equipment.

Materials - Consider the hazards of the materials such as toxicity, flammability, etc. Are materials labelled

and stored properly? Are MSDS available and up-to-date? Have workers been trained is safe use and

emergency procedures?

5.9 Inspection Program Reporting & Monitoring

The MD-QMS Inspection Team shall prepare the “MD-QMS Inspection Summary Report”.

The inspection report shall include the completed checklist, a description and location of all identified

hazards, and recommendations for eliminating or controlling the hazards.

The implementation of the inspection program should be monitored to ensure it is meeting the objectives

and also to identify any areas for improvement. When undertaken the review the entity

should consider:

• Feedback for Auditee’s, inspection and other relevant stakeholders;

Rev No.: 00 Page No. 7 of 8

Mawj Alsama Medical Company

Procedure for Inspection & Testing

Doc No.: MAMC-MD-QMS-PR-15 Date: 06/02/2022

• Adherence to the inspection schedule program; and

• Outputs from the inspection

The report shall be communicated to all appropriate people who have the authority to implement

the recommendation. This may include the plant Manager, MD-QMS Management Representative, and

relevant Department Heads. Once the appropriate people are involved, the report should name the

persons responsible for corrective actions, and the expected completion dates.

The MD-QMS Committee shall monitor and review the progress of the recommendations and follow-up

shall be carried out to ensure corrective actions have been implemented and are effective.

5.10 Subcontractor Inspection and Test Plans

Where elements of the work are to be performed by Suppliers / Subcontractors in the FIES, the following

steps shall apply.

• The MD-QMS Committee shall ensure that the appropriate Quality requirements are specified in the

procurement documents.

• The MD-QMS Management Representative shall ensure that supplier / subcontractor ITP’s including any

necessary Hold or Witness Points.

5.11 Sector MD-QMS Inspections Categories

MD-QMS Planned Inspections - are inspections to be conducted on regular basis and intervals; planned

inspections are inspections scheduled in advance to take place at a certain time and date. These

inspections are generally done in accordance with the hazards associated with the FIES’s operations and its

potential for serious MD-QMS incidents and threats.

MD-QMS Random Inspections - FIES shall conduct random/ surprise MD-QMS Inspections of operations to

ensure the effectiveness and efficiency of MD-QMS. FIES shall not be informed of the Schedule of Random

Inspections prior to inspections.

6. Records or Exhibits

Inspection Check List MAMC-MD-QMS-PR-15-F-01

Certificate, License Tracking Register MAMC-MD-QMS-PR-15-F-02

MD-QMS Equipment Inspection MAMC-MD-QMS-PR-15-F-03

Rev No.: 00 Page No. 8 of 8

You might also like

- Qualification of Equipment - A Risk-Based ApproachDocument6 pagesQualification of Equipment - A Risk-Based ApproachJorge Humberto Herrera100% (9)

- Seafastening ExcelDocument13 pagesSeafastening ExcelRiyan EsapermanaNo ratings yet

- Presentation Model Lesson Plan TemplateDocument7 pagesPresentation Model Lesson Plan Templateapi-352433525No ratings yet

- Human Walking RoseDocument248 pagesHuman Walking RosePablo CruzNo ratings yet

- MDSAP AU P0002.004 Audit Model PDFDocument81 pagesMDSAP AU P0002.004 Audit Model PDFCarolina MolfinoNo ratings yet

- OBJECT 187 QOP-82-03 (01) In-Process Inspections A 1Document4 pagesOBJECT 187 QOP-82-03 (01) In-Process Inspections A 1Andy RojasNo ratings yet

- CAPA ExampleDocument5 pagesCAPA Examplechemist_tmaNo ratings yet

- PR-Monitoring & Reporting ProcedureDocument7 pagesPR-Monitoring & Reporting Proceduresfda.badrmedicalNo ratings yet

- PR-Control of Non ConformanceDocument6 pagesPR-Control of Non Conformancesfda.badrmedicalNo ratings yet

- Management ResponsibilityDocument8 pagesManagement Responsibilitysfda.badrmedicalNo ratings yet

- PR-Statistical TechniquesDocument5 pagesPR-Statistical Techniquessfda.badrmedicalNo ratings yet

- PR-Product Identification & TraceabilityDocument5 pagesPR-Product Identification & Traceabilitysfda.badrmedicalNo ratings yet

- SSI - RBI by TN HJ Mohamad B Jamil (DOSH)Document31 pagesSSI - RBI by TN HJ Mohamad B Jamil (DOSH)antidote_de100% (1)

- Q and A-MedicalDeviceSingleAuditProgram-2022 08 22Document35 pagesQ and A-MedicalDeviceSingleAuditProgram-2022 08 22sm9449hwz8No ratings yet

- QMR-Q-M-PR-24 Procedure For Management of Documented InformationDocument7 pagesQMR-Q-M-PR-24 Procedure For Management of Documented InformationMohammedNo ratings yet

- FDA Medical Device Quality Systems Manual - Quality Systems AuditsDocument5 pagesFDA Medical Device Quality Systems Manual - Quality Systems AuditsucbdmoNo ratings yet

- Q A Medical Device Single Audit Program August 8 2017Document35 pagesQ A Medical Device Single Audit Program August 8 2017Ganesh M - QA and Regulatory Affairs ManagerNo ratings yet

- PR-Management Review ProcedureDocument5 pagesPR-Management Review Proceduresfda.badrmedicalNo ratings yet

- Complete Maco Quality Manual Vol. 1Document172 pagesComplete Maco Quality Manual Vol. 1Syed Imran100% (3)

- Pi 037 1 Recommendation On Risk Based Inspection Planning Copy1Document17 pagesPi 037 1 Recommendation On Risk Based Inspection Planning Copy1jljimenez1969No ratings yet

- 1 - QS RegDocument4 pages1 - QS RegNathan GoodpastureNo ratings yet

- MDSAP Certification White Paper EMERGODocument8 pagesMDSAP Certification White Paper EMERGOTomasz WojteraNo ratings yet

- BRC FSMA VoluntaryDocument19 pagesBRC FSMA VoluntaryMauricio Martinez VeraNo ratings yet

- X17AUDITDocument10 pagesX17AUDITtrungthanhnguyen_83No ratings yet

- The Saudi Quality Management System Requirements For Medical DevicesDocument8 pagesThe Saudi Quality Management System Requirements For Medical DevicesAyman AliNo ratings yet

- 2022 01 14 MCQ Specifications.V0.6Document28 pages2022 01 14 MCQ Specifications.V0.6Lucas Leite CoelhoNo ratings yet

- GP 4161 FSSC FSMS AnnexDocument4 pagesGP 4161 FSSC FSMS AnnexRagesh PawarNo ratings yet

- brc072 Brcgs Audits Impacted by Covid 19 v4 14052020Document7 pagesbrc072 Brcgs Audits Impacted by Covid 19 v4 14052020Alifah MauludinahNo ratings yet

- Guideline-Conditional Approval For Covid-19 RTK Self-Test - 120821 - V6Document14 pagesGuideline-Conditional Approval For Covid-19 RTK Self-Test - 120821 - V6James Ching-Hoong LiewNo ratings yet

- BRC Covid RequirementsDocument7 pagesBRC Covid RequirementsGeorge MargaritopoulosNo ratings yet

- Internal audit ProcedureDocument2 pagesInternal audit Proceduresuryakant.frenchcertNo ratings yet

- GCI0056 Imexpharm C2 Rev 04 17012013Document12 pagesGCI0056 Imexpharm C2 Rev 04 17012013Tuan NguyenNo ratings yet

- Control of Non-ConformanceDocument5 pagesControl of Non-ConformanceLawzy Elsadig SeddigNo ratings yet

- Integrated Management System: Quality Assurance ProcdeureDocument6 pagesIntegrated Management System: Quality Assurance ProcdeureLawzy Elsadig SeddigNo ratings yet

- Qa Qc Audit ChecklistDocument20 pagesQa Qc Audit Checklistvisvasmech999No ratings yet

- The Quality System Regulation: Flexibility of The GMPDocument6 pagesThe Quality System Regulation: Flexibility of The GMPtrungthanhnguyen_83No ratings yet

- Good Manufacturing Practice (GMP) Audit Procedure: MARCH 2016Document26 pagesGood Manufacturing Practice (GMP) Audit Procedure: MARCH 2016stankoNo ratings yet

- Warning Letter-1Document11 pagesWarning Letter-1Hema KrishnaNo ratings yet

- Who QRMDocument24 pagesWho QRMHellautomobileNo ratings yet

- MDSAP PresentationDocument31 pagesMDSAP PresentationAditya C KNo ratings yet

- Guidanc CTspectionDocument17 pagesGuidanc CTspectionVinod PandeyNo ratings yet

- Audit KecuranganDocument16 pagesAudit KecuranganBintiwNo ratings yet

- Kementerian Kesihatan Malaysia: Malaysian Certification Scheme (MCS) For Hazard Analysis andDocument29 pagesKementerian Kesihatan Malaysia: Malaysian Certification Scheme (MCS) For Hazard Analysis andCheahNo ratings yet

- Audit Planning Conducting and ReportingDocument49 pagesAudit Planning Conducting and ReportingjackhanNo ratings yet

- Handling of Pharmaceutical Deviations A Detailed CDocument10 pagesHandling of Pharmaceutical Deviations A Detailed Csherif sherifNo ratings yet

- Ed Sce Management and VerificationDocument30 pagesEd Sce Management and Verificationliamo88880No ratings yet

- Preventive ActionDocument9 pagesPreventive ActionATHMANATHAN SNo ratings yet

- Criteria For Performing Calibration and Intermediate Checks On Equipment Used in Accredited FacilitiesDocument6 pagesCriteria For Performing Calibration and Intermediate Checks On Equipment Used in Accredited FacilitiesJeji HirboraNo ratings yet

- Pharmaceutical Validation: Presented By: Bharatlal Sain 1 M.Pharm PharmaceuticsDocument32 pagesPharmaceutical Validation: Presented By: Bharatlal Sain 1 M.Pharm PharmaceuticsRaman KumarNo ratings yet

- Audit Cover Summary PageDocument12 pagesAudit Cover Summary PageJoe EleanNo ratings yet

- CB Requirements in Relation To Novel Coronavirus (COVID-19) - Version 2Document5 pagesCB Requirements in Relation To Novel Coronavirus (COVID-19) - Version 2Gabriel MateoNo ratings yet

- 2.10 Risk-Based Qualification For The 21st CenturyDocument7 pages2.10 Risk-Based Qualification For The 21st CenturyJorge Humberto HerreraNo ratings yet

- Guidance On Non Conformity Grading and Time Frame To Close Ncs Version PDFDocument2 pagesGuidance On Non Conformity Grading and Time Frame To Close Ncs Version PDFhoanam2009100% (1)

- Medical Device Single Audit Program - Frequently Asked QuestionsDocument29 pagesMedical Device Single Audit Program - Frequently Asked QuestionsloboufrjNo ratings yet

- Corrective Action ReportDocument6 pagesCorrective Action ReportErick Vega GarciaNo ratings yet

- GMP / QS RegulationDocument7 pagesGMP / QS RegulationPapa ChickenNo ratings yet

- VMP GuideDocument6 pagesVMP GuidedsevolveNo ratings yet

- Audit Risk Alert: Government Auditing Standards and Single Audit Developments: Strengthening Audit Integrity 2018/19From EverandAudit Risk Alert: Government Auditing Standards and Single Audit Developments: Strengthening Audit Integrity 2018/19No ratings yet

- Pharmaceutical Quality Management System (QMS) Questions and AnswersFrom EverandPharmaceutical Quality Management System (QMS) Questions and AnswersNo ratings yet

- Guidelines for Asset Integrity ManagementFrom EverandGuidelines for Asset Integrity ManagementRating: 5 out of 5 stars5/5 (1)

- (MDS-G21)enDocument13 pages(MDS-G21)ensfda.badrmedicalNo ratings yet

- ID NumbersDocument1 pageID Numberssfda.badrmedicalNo ratings yet

- (MDS-G22)enDocument16 pages(MDS-G22)ensfda.badrmedicalNo ratings yet

- Attestation Accompanying Application For Marketing AuthorizationDocument1 pageAttestation Accompanying Application For Marketing Authorizationsfda.badrmedicalNo ratings yet

- F-Audit SummaryDocument1 pageF-Audit Summarysfda.badrmedicalNo ratings yet

- Model NumbersDocument1 pageModel Numberssfda.badrmedicalNo ratings yet

- Environmental FactorsDocument1 pageEnvironmental Factorssfda.badrmedicalNo ratings yet

- PolicyDocument1 pagePolicysfda.badrmedicalNo ratings yet

- F-Supplier Performance ReportDocument1 pageF-Supplier Performance Reportsfda.badrmedicalNo ratings yet

- PR-Management Review ProcedureDocument5 pagesPR-Management Review Proceduresfda.badrmedicalNo ratings yet

- Work Instructions For ForcepsDocument1 pageWork Instructions For Forcepssfda.badrmedicalNo ratings yet

- MD-QMS ObjectivesDocument1 pageMD-QMS Objectivessfda.badrmedicalNo ratings yet

- Work Instructions For MarkingDocument1 pageWork Instructions For Markingsfda.badrmedicalNo ratings yet

- Work Instructions For ChimtiDocument1 pageWork Instructions For Chimtisfda.badrmedicalNo ratings yet

- Work Instructions For StoreDocument1 pageWork Instructions For Storesfda.badrmedicalNo ratings yet

- Work Instructions For Ultrasonic CleaningDocument1 pageWork Instructions For Ultrasonic Cleaningsfda.badrmedicalNo ratings yet

- MILADY Data SheetDocument8 pagesMILADY Data Sheetsfda.badrmedicalNo ratings yet

- Zero Max - Refell - Liqued - BoxDocument1 pageZero Max - Refell - Liqued - Boxsfda.badrmedicalNo ratings yet

- 12 - Eye Irritation Study On RabbitsDocument23 pages12 - Eye Irritation Study On Rabbitssfda.badrmedicalNo ratings yet

- Transfluthrin MSDS Zero MaxDocument8 pagesTransfluthrin MSDS Zero Maxsfda.badrmedicalNo ratings yet

- 13 - Leaflet-XDocument2 pages13 - Leaflet-Xsfda.badrmedicalNo ratings yet

- 5 - Certificate of Orgin Zero MaxDocument2 pages5 - Certificate of Orgin Zero Maxsfda.badrmedicalNo ratings yet

- 2021 01 BMI Jolly Plus 002 CS ENG LOWDocument7 pages2021 01 BMI Jolly Plus 002 CS ENG LOWsfda.badrmedicalNo ratings yet

- Lack of Self-ConfidenceDocument29 pagesLack of Self-ConfidenceCaloña Piañar JinelynNo ratings yet

- Brochure BOP PODDocument4 pagesBrochure BOP PODtkthird siaminterNo ratings yet

- M2 Hazards in Confined SpaceDocument39 pagesM2 Hazards in Confined SpaceNasron MubinNo ratings yet

- Introduction To Community Psychology PDF TobaDocument22 pagesIntroduction To Community Psychology PDF TobaRishika SinghNo ratings yet

- La ConsolacionDocument2 pagesLa ConsolacionRex RegioNo ratings yet

- Ncp1 317rle Ronquillo BryanDocument2 pagesNcp1 317rle Ronquillo BryanPaul AnteNo ratings yet

- Intro To Public HealthDocument41 pagesIntro To Public HealthHai MendozaNo ratings yet

- InfloranDocument19 pagesInfloranMuhammed AskarNo ratings yet

- Opening Toward Life Experiences of Basic Body Awareness Therapy in Persons With Major DepressionDocument14 pagesOpening Toward Life Experiences of Basic Body Awareness Therapy in Persons With Major DepressionALEJANDRA NOGUERA PEÑANo ratings yet

- Superficial ParotidectomyDocument7 pagesSuperficial ParotidectomySajid Hussain ShahNo ratings yet

- Breathing Pattern DisordersDocument12 pagesBreathing Pattern DisordersAnastasia CaracașNo ratings yet

- Complaint For Declaratory and Injunctive ReliefDocument46 pagesComplaint For Declaratory and Injunctive ReliefLaw&CrimeNo ratings yet

- DocumentDocument5 pagesDocumentLUNA GamingNo ratings yet

- 猩际满分模板合集 20221220Document17 pages猩际满分模板合集 20221220weishun zhouNo ratings yet

- Week 24 Day 2: Learning CheckpointsDocument4 pagesWeek 24 Day 2: Learning CheckpointsAira Castillano CuevasNo ratings yet

- Curriculum Planning PBBSC Second Year Mental Health NursingDocument8 pagesCurriculum Planning PBBSC Second Year Mental Health NursingSAGAR ADHAONo ratings yet

- Newton Dee Application FormDocument7 pagesNewton Dee Application FormjohnyNo ratings yet

- Nuclear Medicine Training AccredditationDocument15 pagesNuclear Medicine Training Accredditationpriya selvarajNo ratings yet

- AnimalDocument78 pagesAnimalGaurav ModgilNo ratings yet

- Jurnal Binet AbdullahiDocument62 pagesJurnal Binet Abdullahimade marselusNo ratings yet

- Nano-Biomedical Engineering 2009 - Takami Yamaguchi (ICP, 2009) PDFDocument482 pagesNano-Biomedical Engineering 2009 - Takami Yamaguchi (ICP, 2009) PDFMedSparkNo ratings yet

- Pe 10 Week 1 and 2Document30 pagesPe 10 Week 1 and 2dave ZapsNo ratings yet

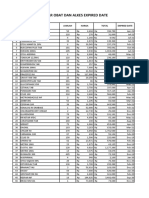

- DAFTAR OBAT ALKES ED RSJHMK UpdateDocument5 pagesDAFTAR OBAT ALKES ED RSJHMK UpdateINSTALASI FARMASI RSJHMKNo ratings yet

- Shatavari FDocument22 pagesShatavari FAPNEET100% (1)

- Athena Fall Risk AssesmentDocument2 pagesAthena Fall Risk AssesmentstaffdevNo ratings yet

- Autism and Adhd Handouts - Avendano PDFDocument69 pagesAutism and Adhd Handouts - Avendano PDFjlpabalan.tasiNo ratings yet

- Psychotic Symptoms and Population Risk For Suicide Attempt A Prospective Cohort StudyDocument9 pagesPsychotic Symptoms and Population Risk For Suicide Attempt A Prospective Cohort StudyGiselle Andrea Naranjo VillateNo ratings yet