Professional Documents

Culture Documents

Piper Classic Airplanes Inspection Checklist

Piper Classic Airplanes Inspection Checklist

Uploaded by

Florian Sterchi0 ratings0% found this document useful (0 votes)

9 views5 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views5 pagesPiper Classic Airplanes Inspection Checklist

Piper Classic Airplanes Inspection Checklist

Uploaded by

Florian SterchiCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

NAST ER

PIPER

CLASSIC AIRPLANES

INSPECTION REPORT

J-2 SERIES CUB

J-3, NE-1, L-4 SERIES CUB

o-4 SERIES COUPE

d-5, J-5C, L-14, AE-1, HE-1 SERIES CUB CRUISER

PA-I1 CUB SPECIAL

PA-12 SUPER CRUISER

PA-14 FAMILY CRUISER

PA-15 AND PA-17 VAGABOND

PA-16 CLIPPER

NOTE

This inspection report provides recommendations for an inspection

program per requirements of FAR Part 43 and Advisory Circular 91-60

(The Continued Airworthiness ol older Airplanes}.

his is a comprehensive inspection report designed to encompass

more than one model airplane. it will be neccessary to determine

which inspection item is applicable to the partioular airplane

being inspected.

PIPER AIRCRAFT CORPORATION

(PART NUMBER 230 3000) 850601

PE ARERAFY CORPORATION

INSPECTION REPORT

ns ones nn 1

z sia EL [ rat Raa

Nake CLASSIC MRPLANES: ‘AE. HE, PALIT, 12.14.15, 16.17 | No No,

" ; 7

Give Te epi eestor amt cert exc ot :

oT SB Ts” iat |.Nalate| |] ctrinenns a micetyeceee | lelalal

DESCRIPTION ee) DESCRIPTION 2

#PnoPatsh GRour PSone Sores Q

op espera selene ate Geet aero 33. Inspect throttle, carburetor heat, and mixture

ae Sere sisisis controls for travel and operating condition o}o}o|

tee eee eee ‘gaskets (Replace exhaust gaskets es required}... | 0} 0} 0] 0

a taunt _ ‘9 2]0/0} I as. inspect muller neat exchanaer and battles giale

inspect propeller mounting bolts and ste 36. Inspect exhaust stacx braces

+, Seema teh | I ee slele

8. ENGINE GROUP 38. Check cylinder compression (Ref. AC43.13-1A) 0}0|o

CAUTION: Grounet Magnata Primary Circuit 40. Ingpest orankeace for cracks, leaks and °

BE emg ale of ojojo 41. Inspect wiring to engine and accessories.

4 RETR ig sessed cs

fission ans lees ores esters eigie Inspect terminals for security and cleanliness:

sins for freon paris. See Nate lof a pac ete eerarienancaeearseee ane

foreign particles) ofojo ‘spec fbr eng 9 ololo

ota secieey dojo secunty ojolo

crack See Note 7 0]0]0] 26. inspect condition and tension af generator or |

damage # spplcable 2]9)2) I] a7, Inspect condition of generator or aiternator|

08 aparece |o]31818) fae teammates giele

fa ooacenee) ©10]0) |] 38. Compiete averhaut of engine or tepiace wih

12 ron opr ss in oe ier alle 7

iercmeceeeee | | | |. [lan emnmneee olold

+s utc resis ih @. can onove

ep cay ool

cesataars delete nae .| |o}0)0| || totum sand san slele

ig Routttopear festa gishe| I), Seeaeesth ta sce alele

ig hipet cee meson | |8[8[9) |] 2 inp onnenaes or gigs

Spe Sane ea 4 eae ce

vg Beri ig 5) [81818] |g freer neonate ncaa 3iei3

38 Sree Sloe gee $e a

Relate cerere 10/0) Ww fiir ain sans” | [O1°]9

x siatinwse | |810]2) Io awe ole

Sepa) Yololo| fz zeros nc amatmarmns. | [888

eceircnmesnyeapc [ole] |. seamncrmnswranamests | (°°

2» eee ’ ofofo| I) \* arose mer ofolo

Be ea re es fol) Ug tapers ine sess an =” | |°/°)°

el Pesasnt rere caer meaatutisasreatemase\”.| lololo

Feces inainasonna’’””| [°|°|°| |] taaetstate dunt sencrson

*Papnieable . oj}o apoiieatie (See Note 9) jojolo

a

Continued on reverse aide

aes TE] Pestorm inspection or operation at each ofthe =

50 on cao To09 awmwt | fel e|g] gif tection ervats av iniieated by circle CD. | lata g|

wnt _tale]a) 218 7 a/2|2|2 |:

DESCRIPTION z DESCRIPTION é

CABIN GROUT (coe etl ond du 7. tspec wing alchment ols fr setty ofofo

ee ete B. Inspect lift and jury struts for security (Refer

Fe see el cece oye {nest rvoroy ol Poe See Blain

Inspec onation| o Notete sra'187 ncure ‘Se

20, Inspect operstion and sandiion a parking brake 9. am co damage leo ojojo

it applicable = latest revision of Piper Service Bulletin 187)

D. FUSELAGE AND EMPENNAGE GROUP tisute AD 80:20-15 fr napection and epace E

1. Remove inspection plates and panels... 0010] |} 10, inspect ateren tap appicabie ane wing

2. Inopect ter and tna fo rae ander Structure for damage and ovosion

Siaten tf Gondtion of abr doubt, ret 1. Inept sietonatachments and bracket (or

TOPAR AG 31314 to teat fabric use tghinese and damage °

Seipestetiod enn 0] ]) 12, inipectaioron nnge pine and biacks for

uane coing applcable ° Socks as equred) olo}o

4, Choos that ue fonk a marked fr apaciy 13. inspect flap attachments and Bracket or

*appbeable oo tightness: corrosion and damage apoicste .. | [0 |0 [0

5. Inspect tet tari and ines for damage isi 14, tape lap ttierank, contol 04 pins and

stotorandsessterdeteraaion andeaptrvent-| | | | Hons for excess west and erosion

6. Inept ful header or secure ink 15, Cebneate a conc where appieabe 8/8 ]8

tnd condion Wsppleabe ofolo] |f 18: Remsian nspecion sates panes and avings | JO|0[0

7, inapeetbatey, bok an cables inspact at

Toast every 30 ye, Flush bow as required and

fitoater) #appleable ojo F. LANDING GEAR GROUP

«8. Inspactelecrame stains ior sary

‘foppieable ©] |]. nemave tarings and shock cord covers

9. Inspect anterind munis on ict wing 4 Sppteable o|ofo

{or damaged inulaion and security 2, Inspect fabri iis fe rack and

‘appteate : ofojo deterioration \

10. Inspett ELT stallion nd conden of 3. Inepest gear, catane and shecsv bois

{iitry and antanna appease fee Piper Sdn for saety o

Service Letter No. 820) =| ]o]o]o] |}. Hostarplane inspect gor. eddane and shock

11. Inagest rude elevator ad sibiizer rm Sit ots and bushings for excess wear and

cables, turnbuckles, guides and pulleys for corrosion (Replace bolts and/or bushings as

Salety, damage. corrosion and operation olo equwed) Jo}olo

ofojo \Cedtness andi aplable, shoo stu or

13. inspettWeiage frame tubing fer coraion Weakness (Replace orgs anor shock sis

tGumage and deterioration ololo Ss necessany) o|o}o

14, Inspect rade, stair ad vad | 6 inspec gat wil aignment i Toe i/o 8/6

Srocres fe damage: 0]0/0} |) 5. inspect tres for ute, uneven or excessive olole

conoge 0} 0/0] |} 2, Remove wnass: clean, inspec ond vepack

16, nape ude hinge sos ond bushings for Cnnge ololo

treees woo an Caronion place pre and/ 8, pect wheeis er cracks, cvrsion and

Sr busings ae required) of oo broken bots ojolo

17, Inapeet stables yoke and serew fr 6d pay 10, Chest main wheel ire presbure (B00 x 4-24

fn ecunty i appieaoe ofolo $Ri%or'tapphebte S00 8-26 Yn ofojolo

18, inspec statier tachmanis and atachment 11, inpect bre ing and rum for excessive

tube fr sie pay appucable ololo went (Replace brake inong a8 accessor) ololo

19, Inspect stabiizer brave wares for cvrsion. 12, Inspect brake ines for chafing, corosion

‘ghness and safe . ofojo tnd security ololo

20, Inapet elevator attachments and horn Yor ingest wigs brake tube assy freaks

(domage i ofo]o| |] 1% snPSeienorauon teplece es required on

21, Inepee igvaic hinge pine and busings tor Haves inattowon o]ofo

tcess wear and covosion Replace pine ane” 14, Inepet brake eyinders, and paring vaves far

Gr bushing a requires) ojojo {operat and eaks (Chock Wid level a6

22, Cobweate ai conto where sppicabia 9]o]o ‘que olololo

58, Reinaal inspection plates and sancls 0[0]0] I] 5. mses aiaaisarhironic ov iganens

E. wiNG GROUP v6, Meet th wheelie Tovanass oa" | 1° ]°1°

1. Remove inspection plates, panes, and tavings | |0]0]0 brecket olo}o

2 Inapoct tre and ish for erecks and doer 17, apee al whee ior cuts and uneven 6

oraten if condion of fabri ie doubt, Feler loeecetsasse ololo

Sirip test method) ololo enenenie | Jolojo

3 Inspect fl tars ad ines fo dana 19. Inspect tall wie! fos craks, corrosion and

leaks and water, sels for deterioration and fees ae ololo

caps for proper venting if apelcable gala} 20 insect tt wie ie ressre i appicate

4, Shot ut el arad or apa S]o}o (aOrsh olofolo

: Shoot fc ton] marked for nena octane eae cients ease

tating f ° for rocks, corrosion and security. o|ofo

6. Inspel sist and i applicable fap cabs, 22, Uereste al vot pointe wnere apicabic |". Jo]0[0 [0

turnbuetee guides ant pulleys for att, 23 Install faving and snack cord covers o}o}o

damage, covrsion and operation ofolo

Circle Type of Inspection (See Ne) Bf tortor specie or operation a each he A

0 too aanat | lele|g] gif tmtecon moral ae nated bya ctrcte Oh | la] gl]

48 |8)8/2| 3 }}-— ; 3/8/83 )2 16

DESCRIPTION : DESCRIPTION 2

«. FLOAT GROUP (t Apples) 1 OPERATIONALINSPECTION

1 tngpeet finat attachment fittings ofo}o Lee o aa 2 a 7 8

2. Inspect floats for damage ojeie 3. Check oil pressure and temperature alolojo

3. Inspect pulleys and cables o}ojo 4A. Check generator output if applicable o}0/o/o

2 Meat natant on stg damave aes eer gigisis

Conon aid secur appcole ofofo] |] § Sree ee ie gigigig

2: Gneck vacuum gauge spteatie

AGRICULTURAL GROUP (lt Applicable} 3, ERE fers etne ks Sad neugheoss syerele

sopiesBie e}ojoje

1, Check i aval ste gear box o}ololo| |] ». cheer cava hater aseraton 8{0|0|9

4 Sapee unas ve fs 8/010 )0| |} 10. enece monte seh oeroson 8}9}9/9

4: Ibe braves ard conte 8/0/8\0) |f 3s. cnc magneto RP. tances 8}e/o)o

4 Inspect grease cop. srve ion 815/810) |} 32: Enea tonic ond more operation i

&: Citirndper Sree 8}3\8/9 ce ololala

&: Inspect popper ok do 8/8 ]010| 1, eheck rosaiar smcatmess ty

5, inspect baton Pope ant wal 8}5/6|0) 12: Gree etcrorc soupmeneperaion i

€ Remove metal bel slate ppzable and oleate 9)o]o}o

o Scag s elo]aio| |) rs. Sacer ii and PH slolle

neoct str aroun asari 18: heck propater governor seo apes

10. Check operation of dump vaive. o}olo}o eee cr cigisla

11 heck aptator operation “}8}9]9 {5

Ty (geet Brtepser ane stsanésezar’=---.|0] 0/00] | s. cenenan

15 leapt spray boom attachments 8[8/99

1 Chan apy ous 8151910) | + aver contons 0 FAA Soeiiatins. olololo

1 ropes at ain eek 8]0}9/9) |} 2 AneaA Rtacorniness Dvectves camped

4. lebecSray pune moun sien 8{0]0/8 aie ofololo

3, Asse Sass Loto and

Gulls comptog wi 9|0}0]0

4, Gheckiocpoper Fight Wana Seetow v7. [8/0 |8/0

5. Rrerat paper oer oe 3jalolo

NOTES; 1

u

Taler to the lst card alte Piper Parte Price List - Aerofiche for @ check Wat of current

Fevision dates to Piper Inspection Reports and Manuals.

[Alinspections or ope‘ations are requted at each othe inspection intervals as marked by 8

{0} Ban the ennuel and 100 hour inspections are complete inspections ofthe ail

tdentieal in scope, eve both the 500 and 1000 hour inspections are extensions of he

“andoverhaut or replacement of some major components Inspections mustbe accomplished

by pereons authorized by the FAA.

Ploer Service Bulletins ae of special importance and Piper considers compliance mandetor.

Piper Service Later are product improsements and sevice hints pertaining toserviing the

iplene and should be given careful attention

Bvemout os teconditon, (Per Ieest Mariza Service Lever 01, oF pu: MuCauley Service

Bulleun 1376) the recommend fight ine betwoon reconditioning for Sensenich fixed

Ditch mata peopellers Ts 1000 hours. provides. the propelor has not received poe

Samage requiring. immediate attention. Reconcitioning accomplishes the removel of

faxgued Serface metal anc accumulated small nleks and cuts 100 numerous to rep

Individually, Contact Sansenven factory approved repair station

FR Lycoming Inervale between ol changes can be Mereased as much 8s 100% On ena

Ines eauipped wath full flow cariraje type ‘ol Titers, provided the element ©

Feplaced each 60 how's of operation and the specified octane fuel is used

Shoutd fuel ether thon the specie’ octane rating for the power plant be used

feler to Lycoming "Service Latter No. 185A. for additional information and

8 Comment Every 100 sours remove ol sump, clean suction tube screen, replace oi

sump and safety

Replace flexible oi lines at Engine T.B.0. per latest Lycoming Service Bulletin No, 240,

of every five yoars in sevice.

Replace or overhaul as required or at engine overhaul

No L0tw

B. Continental - For engine overhaul eter tothe latest revision of Continental Service

Bulletin 74-20.

Inspect rubber mount for severe cracking, signs of high temperature of burning. separation of

rubber rom motal surfaces, excessive "sag" or permanent deflection cesulting in internal

eitmang wits spacer, engine ane cow Interference a unvaval vibration. The rubber

mounts must be replaced no late shan angine 7.8.0.

Fer to latest revisions of Piper Service Bulletin No, 354 and Service Leter No. 984

{ica uel selector valve. valvanas 500 hours or more toa ime inservice, within next

100 hours of operation and every 500 hour thareafter Use Dow Corning Molyeoat No FS:

3481 or FS-2462, Per Part No, 781-281

he models 22, JANET Cot J 4, 0-9, JBC, L14, AE, MET andl PACT svc were

licensed under Pan-04 of Civil A Regulations and therefore do not require fight manuals

However, do require an “Operations Limitations Cerificate This certificate was obtained

from your local FAA. Regional Office.

snow

wvaivam

su.0N

awvaiwen?

enon

EVE NOLLWOTEENT

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Morane Saulnier 406 Le Fana 381 - 2001 08Document10 pagesMorane Saulnier 406 Le Fana 381 - 2001 08Florian SterchiNo ratings yet

- Manuel Elixir Aircraft FRDocument166 pagesManuel Elixir Aircraft FRFlorian SterchiNo ratings yet

- Morane 181 CMVDocument8 pagesMorane 181 CMVFlorian SterchiNo ratings yet

- Morane 230Document5 pagesMorane 230Florian SterchiNo ratings yet

- Squadronsignal 1198 Fieseler Storchpdf PDF FreeDocument52 pagesSquadronsignal 1198 Fieseler Storchpdf PDF FreeFlorian SterchiNo ratings yet

- Flying The Fiesler Storch Howard Cook 22Document7 pagesFlying The Fiesler Storch Howard Cook 22Florian SterchiNo ratings yet

- Beech 5Document18 pagesBeech 5Florian SterchiNo ratings yet

- Other Plane - Aug-Sept - 2008Document5 pagesOther Plane - Aug-Sept - 2008Florian SterchiNo ratings yet

- Mouss ChabertDocument4 pagesMouss ChabertFlorian SterchiNo ratings yet

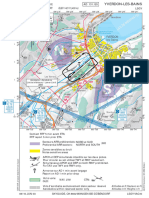

- Carte VAC LSGNDocument1 pageCarte VAC LSGNFlorian SterchiNo ratings yet

- Procédure PlasmaDocument1 pageProcédure PlasmaFlorian SterchiNo ratings yet

- Bulletin Fafl Novembre 44Document28 pagesBulletin Fafl Novembre 44Florian SterchiNo ratings yet

- Testing of Non-Standard FabricsDocument3 pagesTesting of Non-Standard FabricsFlorian SterchiNo ratings yet

- FDN D112 A D V D127Document5 pagesFDN D112 A D V D127Florian SterchiNo ratings yet

- Flight TestDocument11 pagesFlight TestFlorian SterchiNo ratings yet

- FA Airplane Mechanics TO&EDocument2 pagesFA Airplane Mechanics TO&EFlorian SterchiNo ratings yet

- Ls Adinfo 0000 Lsgy VacDocument1 pageLs Adinfo 0000 Lsgy VacFlorian SterchiNo ratings yet

- 72 028Document5 pages72 028Florian SterchiNo ratings yet

- LSPL VacDocument1 pageLSPL VacFlorian SterchiNo ratings yet

- En Vol, Aux Commandes Du North American T-6G: Jean-Pierre LAFILLEDocument5 pagesEn Vol, Aux Commandes Du North American T-6G: Jean-Pierre LAFILLEFlorian SterchiNo ratings yet

- An01 70ac 2 Emi PT 13D N2S 5Document148 pagesAn01 70ac 2 Emi PT 13D N2S 5Florian SterchiNo ratings yet

- BleriotDocument20 pagesBleriotFlorian SterchiNo ratings yet

- Bleriot 11Document3 pagesBleriot 11Florian SterchiNo ratings yet