Professional Documents

Culture Documents

Question Paper Amu Petrochemical

Question Paper Amu Petrochemical

Uploaded by

Hatif Alam0 ratings0% found this document useful (0 votes)

4 views17 pagesOriginal Title

question paper amu petrochemical

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views17 pagesQuestion Paper Amu Petrochemical

Question Paper Amu Petrochemical

Uploaded by

Hatif AlamCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 17

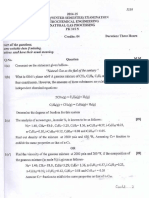

3618)

2018-19

B.TECH. (AUTUMN SEMESTER) EXAMINATION

BRANCH: PETROCHEMIEAL ENGG.

COURSE TITLE: Process Dynamies and Control

COURSE CODE: PK 411

Maximum Marks: 60 Credits: 04 Duration; Two Hours

Answer all the questions.

Assunte suitable date if missing,

Notations used have theiv usual meaning.

Q.No Question MM.

eh Discuss the characteristics of first order system for step forcing funetion in the input [5]

variable of the system. (col)

Se Develop the transfer function for an evaporator, Draw its block diagram and state all [5]

the assumptions made in the analysis, How the transfer Runetion will be modified for (CO)

tnultiple effect evaporator?

OR

place ina CSTR. The reactor hold up is [5]

1 (bY) The reaction A —* B (k=0.02/min} take

2000 lites, while the feed rate is 100 lites‘min. The inlet concentration of A shows

@ cyclic variation with 2 mean value of 0.01 molllitre and a fiequeney of I sad/min,

Obtain um expression for the exit concentration, if the amplitude of the input is 0.001

molllitre.

N(s)_ The Armhenius law gives the dependence of the seaetion rate constant k with the [3]

reaction temperate T and the energy of activation of the reaction FE, Obiain (COL)

Fincarised solution. Further use Taylor's series approximation ta. linearise a seeand

order reaction as:

rkVC,?

Discuss the effect of interaction on step response of two tank multicapacity control [5]

YQ

system. How the transportation lag parameter can be minimized in the petrochemical (CO2)

industry?

Daa

ease

‘A step change of magnitude 5 is introduced into the nity feedback control systern

‘The second order eomtrol system having the transfer function as-

1/(1.25 +2545) is being contgolled by means of proportional controller having the

vulue of gain (Ke =10}. Obtain damping factor and rise time:

OR

‘A mercury. filled manometer 3s to be used to meusure the pressure drop across an

ofifies meter, The meter will monitor the flow rate of air through a pipe

Specifications call for a decay ratio (not damping factor) of 0.3. ‘The maximum

pressure differential is such that « liguid column length of 75 em. should suffice

Derive the equations used, Find the diameter of suitable glass tubing for the

manometer, The specifie gravity of mercury is 15.6 and the viscosity is 1.6 C.P

‘Avinit step change in the etvor is introduced into a PID controller. IF Ke= 10,

Integral lime =I, and derivative time= 05, Plot the response of the eontsaller.

OR

34a") What are the types of plugs used in pneumatic valves? Discuss the fhetors that affect

the selection of the valve type (linear, square rool, equal percentage, and

hyperbolic)

3(b) Determine the range of values of k Rot the systems with the following characteristic

SY, ssuation to be stable,

St+KS?+S*sS+k=0.

vy Plot the root locus diagram for the following system andl also determine which

values of K make the system stable.

Gis)= K (s#2V# t5+3)

A) Draw the schematic diagram of cascade control of temperature in 2 jacketed CSTR,

where a highly exothermic reaction is taking place

Bale

to

(Fl

C02)

(10)

(C02)

15]

(C03)

(C03)

15]

B)

(C03)

[5]

(cosy

contd oe

‘Seg

Aw

Obiain Gy for the system as shown below: bl

(con

OR

4)

Fuel cells are used in space craft for generating power and heal, ‘The cell produces

electric power by the reaction between liquid oxygen and liquid hydrogen. [5]

2H24+02—® 2H20, (C04)

‘The flows of bydrogen and oxygen to produce 0.5 kg/hr of water. The eontrol

scheme should manipulate the flow of oxygen to maintain the required wanio. The

transmission signals are linear with respeet to the rates, Caleulate ‘the Tange for the

transmitters,

4(6) Describe briefly any vo the following: 5]

(Discrete Lime model ofa second order process (COMy

Gi) Samplers and hold elements

iii) Supervisory control

2018-19 (AUTUMN SEMESTER) Code: 3619

B.YECH, (VI SEM.) END-TERM EXAMINATION

PETROCHEMICAL ENGINEERING

PLANT DESIGN AND ECONOMICS

PK-d3i

Maximum Marks: 60 ‘Credits: hd Duration: 2 Hours

Attempt alt the four questions fimarks will be given for steps).

Assume suitable dada if missing.

Use of basic ealeutatars is allowed.

Q.No. Question MM.

Monochlorobenzent is prosiuced by the reaction of benzene with ehlorine. The reaction (13)

Produces a mixture of monochlorobenzene and dichlorobenzene, with a sinall amount of

\richlorebenzene. Hydrogen Chloride is produced as a by-product, Benzene is fed to the reactor (O41,

inexeess to promote the production of manoghlorobenzene,

The reactor products are fed to a condenser Where the chlorobenzenes and unreacted

benzene are condcused, The condensate is separaed ftom the non-condensable gases tra

Separator. The non-condensuble gases, hydrogen chloride and unneacted chlorine, pass an

absorption column where the hydrogen chloride is absorbed in water, The ehlorine av ing tho

absorber is recycled to the reactar,

The Liquid phase from the separator, containing chlorobenzenes and unreacted benzene,

is fed to a distillation column, where the chlorobenzenes are separated {rom the unreacted

bearene, The benzene is reeyele ty the reactor

Using the date given below, caloulets the stream flows and draw up.a preliatinary low-

Sheet For the production of 1.0 tonne (metric ton) of monachlorobenzcne per day,

Data:

Reacior

Reactions; Cellg + Cl SHsCl+ HCI

Cols + 2Cha > Catla Cla + HCI

Mole ratio Cl> : Celie, at inlet to reactor = 0.9

Overall conversion af benzene = 35.3%

Yield of monochlorobenzene = 73.6%

Yield of dichlorabenzene = 27.3%

Production of other chlorinated! compounds can be neglected.

Separator

Assume 0.5% of the liquid stream is entrained with the vapor.

Absorber

Assume 99.99% absorption of Bydrogen cliloride, and that 98 per eemt of the chlorine ts

fecycled, the remainder being dissolved in the water. The water supply to the absorber ie set to

produce « 30% ww strength hycrochlosie acid

Disitlation coftmn

Take the recovery of benzene zo be 95 jer cent, and 99.99% recovery of the ghlorvbenzenes

‘Mote; Start the material balance at the resetor inlet (afier the recycle stzeums have been addled )

and assume 100 kmol/h of benzene at this point,

contd

2a)

2b)

2b")

ue)

2d)

3a)

-u-

Code: 3619

Suy, the purchased cast of a glass-lined jacketed reactor with volume of 1.5 min August 2017 [3] /

‘was 20,00,000, Estimate the purchased cost af a similat reactor with volume of 0.5 min July

2018, Make use of tables given at the end jp obtain relevant data.

Make a study estimate of the fixed capital investment for a process plant if the purchased — [4]

equipment cost is Rs, 80 lakh. The plant requires high degree of automatic controls, (02

OR

In few semtences describe the following: 4]

3, Breakeven point

ii, Time value of money COL

iii, Minimum acceptable rate of return

iv. The basic conditions in a banking transaction that makes it ‘Islamic?

Answer any one of the fallowing problems: (3)

G) A company has direet production costs equal to 50 percent of total annual sales, and fixed (7

charges, overhead, and general expenses equal to #1,50,00,000. Lf management proposes to

increase present annual sales of €6,00,00,000 by 25 percent with a [8 percent increase in fixed

charges, overhead, and general expenses, what annual sales amount is required to provide the

same gross carnings as the present plant operation? What would be the net profit if the

expanded plant were operated ut full capacity with an income tax on gross eamings of 30

percent? What would be the net profit for the enlarged plant if total annual sales remained at

'26,00,00,0007 What would be the net profit for the enlarged plant if the total annual seles

actually decreased to %5,00,00,0007

(ii) Suppose 2 manufacturing company purchases a machinery for %80,00,000 snd the useful

life of the machinery are 3 years and the restdual value of the machinery is $20,00,000.

Calculate the depreciation charges {or each year using Double cclining Balance (DDB)

methed.

(iii) In the design of a chemical plant, the following expenditures und revenues are estimated

afier the plant has achieved its desired production rate

Total capital investment = 275,00,00,000

Working capital 28.00,00,000.

‘Anmual sales £60,00,00,000/yr

‘Annual expenditures 17,00,00,000/yr

‘Assuming straightline depreciation over a {0-year project analysis period, determine: the

relurn an the investment aftcr taxes; and the payback peried

Acash flow consisting of %8,00.000/- per year is received in one diserete amount at the end of [3]

cach year for 10 yeass. Interest wil be at 8% per year compounded annually, Determine the 08

present worth at time zero and the dature worth at the end of LO years of this cash flow

Answer any one of the following: (3)

i. Draw and describe a typical characteristic curve of a centrifugal pump “03

Provide a basic guideline for preliminary sclection of pumps with help af'a Head vs.

Capacity plot

iii, Provide a busie guideline for preliminary selection of compressors with help ofa Head

vs. Capacity plot

iv. Discuss general guidelines in selection of separstion process for homogenous

mixtures.

combed +

Code: 3619

G@) Enlist the design considerstions for selection of reactors. Also, write some general rules [6+4]

of thumb of selecting appropriate reactor for a given reaction, C02

(ii) With help of a flowchart discuss the general methods for design of heat exchangers.

OR

A heat exchanger is required for cooling gasoline with a Now rate of $.0-Kg/s and a pressure [10]

of 4 MPa, Gasotine, with a heat eapacity of 2.22 kiikg-K, enters the exchanger at 65°C and ty

leaves at 35°C, Water, with a heat capacity of 4.2 kJ/ka-K, serves as the coolant and eatexs the

exchanger at 25°C with a flow rate of 2.5 kgs, Evaluate the alternative heat exchangers listed

ina Table attached herewith, and make a preliminary selection based an exchanger suitability

and economies.

What do you understand by the following in

i) objective fimetion; ii) decision variables;

ards to process optimization: B)coz

) dependent variables

A vinegar-making company has received an order for 500 litres of vinegar with the consteaints

thal the vinegar must contain > peicent acetic acid by volume, and it must be supplied

immediately. The company wishes to fill the order, but does not have 3 percent vinegar in

stock. {is decided to mix two vinegars now in stock to give the desired final product. One of

the vinegars in stock (vinegar A) contains 3.5 percent acetic acid by volume and is valued at

24010 per litre. The other vinegar in stock (vinegar B) contains 2.7 percent acetic acid by

volume and is valued at 2350 pertitre. Water can be added to the blend at no cost, What volume

combination of the wg vinegars in stock with water, ineluding at least $0 lites of vinegar A,

Will give the minimum ingredient cost for the 500 litres of 3 percent vinegar?

OR

A plant produces automotive diesel a the rate of, barrels per day. The variable costs per 15] Cag

barre! have been established to be $27.73 + 0.1 P!?. The total daily fixed charges are $1850,

and all other expenses are constant at $8325 per day, Ifthe sclling price of the diesel per barrel

is $208, determine:

a, The daily profit at a production schedule giving the minimum eost per barvel of diesel

b. The daily profit at a production schedule giving the maximum daily prolit

©. The production schedule at the breakeven point

(i Deseribe the following with respect to plantwide eomtal: outputieantrolled variables; B+? og,

manipulated variables; and disturbance variables Ry

(ii) Can all of the output variables af a process be controlled? Give reasons

(ii) Discuss on “Degrees of Freedom” and number of manipulated variables permissible.

OR

The figure appearing below shows a process for the isothermal production of C fiom A and B17] ge

(A+B — C). The owo reagents are fed to a CSTR, R-100, where complete conversion of B is

assumed. The reactor effluent stream consisting of C and unreucted A is separated in a

distillation column, T-100, where the more volatile A is withdrawn in the distillate and

recycled, and produet C is withdrawn in the bottoms stream, Your task is to devise a conceptvel

plantwide control system for the process

Hint: It may be helpful \o reposition the feed stream of A,

dootd -

sy Code: 3619

sy

a

o

8

Useful Expressions, Tables and Figures:

Alt)" =

= ACEO. P=Fa+i-

Total Product Cost = Manufacturing costs (Variable product costs + Fixed charges + Plant overhead

costs) + General expenses (Administative expenses + Distribution & Marketing expenses + R&D)

= Trout Tes Tein

a

=F

‘eaut — Tein

2=P[(R+1)—- (+ a)

2 4, Lisch tect 8 Oe a gee

Ea Waa Yin (gp) Dm = PUR 41) + (R$ I,

Oe

crak bmae +e

‘eogi07 sealer se ero enced connate eto

ails tae ater Sa) DK era ees reed a el

trend rend ses ng cacnay Bben Cam ip JOe6 E72)

font -

og5

Code: 3619

encier,dauble cone ovary, carina sleet (€8.1

Blower, cennifupal

slid bole,

iver, vacuum bateh, 5.

Carmperssor reciprcaling. ait-caoled, Weo-slage,

108F-KPa discharge

Compressor: nary. single

HNBS-RPi lischarge

Dayer. drum, single vaewuns

Dryer, dim, single atrmaspesie

Van, centstngat

Heat exchanger, shell-ana-tale, uatings head,

Lent exchaiiger shell-si-tabe, fixed sheat, 6

Ket, castenon, packete

wd. jacketed

Motor, squintel eage. induetioa. 440-V, explosion ;woot

Mor. squtercl cage, induction, 440-V, explasiaa proof

Purp, rssisrocating, horizontal eas-inon (includes motor)

Pump. censifugal, beriaostal ens steel fineledes moter)

Reaciur. plansotined, jackets (wuvhowt drive)

Reacans, staintess sil, 2070-4Pa

Separstor, cemeifugal ©.

Tank, flac head. ¢

Tower. 05.

‘Tray, bubble cap. es,

i

sighs,

17.1 mn (3H 280405)

85417 cvs 10108 sniny

25-75 OW (TE hyd dive

15-200 m3} (500-Ta00 te)

0.005-0.19 1x" (Lo-noD seeing

01.05-0.5 sn '¥.¢10" 108 Fa)

1m? (10-10)

10 m2 (WOLF HF)

1-160 n? (10716 £2)

"Ys (1020 Sain)

aoe (2a 17-2 OF Sy

140 m2 (160-100 803

10-40 m? (100-400 $5

128m} (250-K0 pot)

0.8-3 ww (200-800 exh

41S R(S-20 hp)

15-150 EW 120-200 hp)

Tx 10 6.010°! mts 2-160.gpm

4-40 nfs kPa (10°—10° gpempsip

0.2-2.2 m¢st600 gar)

OAK i? COPANF gay

LS Ta (50-250 10)

0.410 m¢Lo—10" gay

04-40 1 (10%10? gal

310710" kg {20"-2 10°10)

1-3 m (3-104) diameter

19 mi -10 69 diame

Table Typical percentages of fixed-capital investment values for

direct and indirect cost segments for muttipurpose plants

co largo additions ta existing taedtition,

cl equepment

Puccluused-equipinent insealtation

Iagnumentation aid santzals (installed)

Piping (installed

Blecivieal syscems (stated)

Buildings (including ser

‘yard impravements

rie

Legal eapenses

Camiracten's fee

Cort

ee

15000

i

zn

elt

210

079

76

naa

asd

aad

it

0.060

usd

oat

031

0.69

099

034

033

os

036

nay

ost

i)

092

120

086

Code: 3619

rg Dung ono

2pm SRAM 1D PEE CHS RO “Ld MOE RIO OO 29/182 era "EAE LAT RUE

soaouecy pe weer meron 2310249

lg paral wtp ON FOYAN,

‘Wisap parnscpars| ‘onzanves ap aa ap oan

“uouse(SF 29 26) 25 JOANN ose, uO DIRE peony

sop Huor ‘adit Kop oscovdn Woe 2-0

_E ines ys rend sauuin 008 —0L0-

wep "stuajoapeade 98007 PHEW — GOD qoove-or —VMMos—ore- GEE

sou vopnnsuns (0

ayaa avo} ‘=iqutapy Pre O57 1 ost os qm minds

“Pry bopoansun

eae ‘025 JO] Pape ocean cocesdn z ares FES

sano

ring wesnieg dy wose- 1 oors e sree Pepa

wsoo Fars years

‘vopnsuso poy nse SLL- t= stro amd yee

suiasksuon sagas 04 to

rayysistin som 0 Sues spe o-z cone ody toe iesepalens,

sath

eeur “2ygedepe an +09 = 00e— of acer puEIPAS

ero =e aa,

(uae) 0 adW-apnect

Se Pod,

sents sump

7edh soGueyae jeay meudardde sip Jo UaRDe/os Krmywyaad off 20) BBLS ae)

peliey

Table Approximate design vakios of overall hnaLiranster eeotficients

Puc fetoninr valuesef ove bccrtanafercenfiet tic are based primarily on raul wbsacT in andinoy

fusinecring pracies, The values ane spprutuate Beraase variilon bn fhild ilotien sonun)

pancondewinhte pate, vinvosiien elrantinenr cf Wateranierwafaten ype tp halen vgerodarer sear

nel sill icons con love w sleuifcaae effect ox the averotf Reattrvsfercogffusonts The values one

‘sehfor pret aary desig essen ox for nnugh checks on hea-inoferaleubutann

Pe agp range rf veal coagiciens given for cowders wy abi be used for condensers, while she

epee anys af everatt eects piven for heater a2) lem be 4sed for crupwreane

icin Taw

Wace 3

Mathanol water 2

Ammonis Water 2

Acs weer 1250-2500, 2

Lighcorsiics Water 375-750 6

>ediomargancs? Water 250 900 6

dMeavy ones Water 2-475 5

Ges ‘water 10-256 5

Brine $00 1040, 6

‘organics ane 200 a0 5

Heners

Stes Water 1000 ~ 3800 zeiet

Metbanat 10g —35n9 Beto

‘Acoma 1009 = 350, Be

‘Agaeous seta

#26 10%Pes nu -3500

we2x Pos S00 3509

Steam Ligh organist 001000

Steen Medium osganisst 50 S00

Stes Heavy organs? 30-300

Steam Green 25-250

Usility tit fez. Dewitermy —Casea 20-200

ity uid Ce. Downer) Heavy engnicat 30-300

Exchangers (0 phoee cbange)

wt oer teca— 2550

‘Aqacous solutions Aqueoussolutions ——1400— 2850.

Lightorganics! Light ogganica*

Medium organics ‘Mecinm oganlest

Hexvy oiganies! Heavy organic!

‘cary organics!

Heavy erganiont

[Tipdewratons thoueCa,gasclin, ght hols kecoocicsqa 283 ¥ 15> Poa

[Absisber flat gn ol. tase, and Uphteradea:O8 ie 10" © Ae 28 x 10- "Rs

est wi ol al ole gino, heany sf need eta: 28 0 pe 1D Pe

Cartel a

Cade: 3619

ones we

Chan ning eoriest mesa tenperause-aiereuse diving force for an

/

i

i

i

‘Ectanger wih one theless andlien er roe

1 bre imerchangeabsel Coswctron fact Fc based On th Tag ey oe COME

Pow. FF fees tan 7 operation of heexchaager tay tt be pracical

omen fa

cores tsi F

led

aa

Thwart?

w

Figure

“Ternpereture driving fone covreetion facts for crussflow heat exchas-

(one shell puss, one cr enore parallel sows of tubess opewu shell

passes, nwo rows OF Lbs (for more Chan Gwe passes, uEe F = 1): (6) ame

shell pass, book (uids umuixed. (Pan are inirchangeable)

Cade: 3619

cantd veel

—~4-

sees?

Pitire

-Puschsed cost of ipl pips hea exchangers

Figure

Purchased cost af U-tubeheatexchungerswithO.0254-m (In) ODeabes 0284-41.)

apr pc ae hey (6-40) hurls opcrting st [036 KPa (180 pls)

Code; 3619

020)

2018-19

B, TECH, (AUTUMN SEMESTER) EXAMINATION

PETROCHEMICAL ENGINEERING

ROCHEMICAL TECHNOLOGY IL

PR-A32

Maximum Marks: 60) ‘Cremice: O4 Durution: Two Hours

Auasiver al questions

Assunte steteible deat if missing.

Notations and spmbots used huve their sesiol miwevring.

Question co MM,

-muulsification is done in the eumene oxidation seaetor during phenol «CO1) [ony

turing process?

Nb) Phenol isa white __(erystalline/amorphaus) solid material at (C01) on)

soon temperature

Ve) What are the main applications of phthalic anhydride? won 02)

Aa) Why is vacuum distillation required for maleic anhydride refining? Explain (C01) (06)

with the help of a pracess Now sheet, how maleic anhyuride is

manufactured?

OR

1(a") Elaborate how styrene is produced from ethylbenzene? Also drawa neat — (Caml [05

and clean flow shee! far the process.

Ife) What are the basie feedstocks of 2 petrochemical industry? Briefly explain (CO!) [03]

atleast Iwo processes by which they can he produced

2a) Match the following: (C02) [e3)

LTPA p. Esterification

IL DMT 4g. Orthopedics

HL MMA, 1, MOBIL process

Ab) What are the various routes of manufacturing terephuhaiie acid? Briefly i851

explain each of them

OR

240) With the help ofa neat and clean process Now sheet, explain AMOCO (COB) tos}

process

Condel ov-2

240)

3a)

stb)

ey

Sud)

3)

4a)

ib)

ae)

Aud)

Mention some important uses of:

i) Dimethyt terephthalate

ii) Methy! methsers

Weite a short note om the catalysts used jn olefin polymerization.

Differentiate between:

i) Polyethylene and Polypropylene

i PP-homopalymer and PP-copolymer

Note down the applications of ANY TWO of une fallow

iy pve

i HDPE

iii) LLDPE

With the help of a neat agcbeteaa process flow sheet explain the Unipal

process of manufacturing paly propylene

OR

Explain how the presence of pheny! group(-Cols) is key to the properties

of polystyrene"! Draw a process flow sheet for the manufacturing prices

of PVC.

What ure elastomers? How ancl why vulcanization 4Fnatural rubber is

done?

Differentials between the following (ANY TWO}:

i) ABS and styrene

Epoay resins and unsaturated polyester resins

iii) Natural Rubber and Synthetic Rubber

Draw the chemical structure of the follewing:

i) Aerytonitrite

ify Nvton 6

Write Short noles on ANY TWO of the folknwing

i) Natural Rubber

iSDR

Nylon @

«co2y

(com

COR}

(cosy

(cosy

(cosy

(coy,

(coy

(cosy

3620

jaa

[02]

{o4)

fo]

(os)

[ost

[03]

(04)

[02]

106]

Hat)

2018-19

ECH, (AUTUMN SEMESTER) EXAMINATION

PETROCHEMICAL ENGINEERING

POLYMER SCIENCE AND TECHNOLOGY

PK-433,

Maximum Marks: 60 Credits: 04 Duration: Two Hours,

Answer all questions.

Asstine suitable data if missing,

Notations and symbols tsed have their usval meaning.

QNo. Question co MM.

1(a) Explain the mono functional atid trifinetional reactions af phenol. (con (0s)

1(b) Write the kinetic expressions for self-eatalysed and estemally catalysed (CON [05]

polyesterification reaction and state which type of reaction is faster with

Justificatian,

16) Show the ¢feet of temperature, pressure, plasticizer content and molecular vcight on (COL) — [05]

viseomettic plot of polymer with the help of'a graph (1115. 7)

2a) Differentiate between the Free Radical Chain Polymerization and Paly- (CO2) [05]

Addition reaction of styrene monomer with the help af reactions involve in

both types of polymerize

or

2a") What do you mean by average kinetig chain length? Drive the expression for (C02) [05]

it

2¢b) Caleulate the feed mio (1) of Adipic acid (AAJ and Hexamethylene diamine (CO2) [05]

(HMD) that should be used ta get polyamide 6,6 of molecular weight 15000 at

p= 99.5 and 100% conversion,

oR

. eantel

2b")

Xe)

2e)

Bay

aa")

3b)

3th)

30)

in a DSC experiment it was found that the area under the melting peak

corespands to heat of fusion (Af4p) 125.0 Jig. W the pereentage erystallinity

(96 Xe) of sample is 50.0%, calculate the heat of fusion oF [00% crystalline

polymer 7).

What do you mean by photo-depradation of polymer? Name and explain the

role ofa photo-stabilizer with the help of photo-stabilization reaction

OR

Derive the following relationship for step polymerization reaetion:

Ry = K.Ks1CGOH|-(HAL OH]

Also explain the assumptions for above relation,

Drive the Maxwell's equation for viscoelastic materials, Also explain the

practical significance of relaxation time (2).

OR

Write down the cquation for “Shear Stress Profile” and “Velocity Profite” for

flow of polymer melt in a circular capillary alang with the description of

nomenelsnure.

What do yout mean by the “Glass Transition Temperature (Tey" of polymer?

Briefly mention various structure factors affecting glass wansition

lemperature of polymers.

OR

Ina shealogical experiment the following data was obtained for a fuid;

Strain rate (7 0 100 a0 10000

[Scar Stress (MPa) «| IS4ATS4 | 15488.166 | 1.02 x10 | 6.76% 105 |

(. Caleulaie the power law index (i) aid viscosity (1)

Gi), Deseribe the type of fluid,

Name the viscoelastic model represented by the series combination of dasipgt

teen)

(coz

(02)

«cor,

(C03)

«o03)

(c03)

(03)

(05)

(5)

f03])

[051

105)

95]

(reeyy

as shown in figure below. Also calculate the rela;

and spi i time (2) for

lis mode.

OR

Me") What do you mean by crystallization of polymers? Does it change or rematn (CO3) [03]

a5 itis during polymer processing?

Atal What do you mean by process

i OF polymer? Write the name of any six (COA) [M5]

polymer processing technique with the examples of products that can be

produced by those techniques,

4h) Drave & neat and clean diagram of plastisizing screw and briefly explain the (CO4) [05]

‘erms helis angle, fight, compression rate, channel depth and pitch.

Me) Draw a neat and clean diagram of Blown Film Exarusion Line and explata the (CO4) fos}

funstions of followings

i, Breaker Plate and Sereen Pack

ii, Corona discharge treatitent

You might also like

- Unit 2Document1 pageUnit 2Hatif AlamNo ratings yet

- Oe 2023Document2 pagesOe 2023Hatif AlamNo ratings yet

- Fluid Statics1 Notes3Document21 pagesFluid Statics1 Notes3Hatif AlamNo ratings yet

- Project ManagementDocument2 pagesProject ManagementHatif AlamNo ratings yet

- Project ManagementDocument2 pagesProject ManagementHatif AlamNo ratings yet

- Ambdwats1Document15 pagesAmbdwats1Hatif AlamNo ratings yet

- Multi Component DisitillationDocument90 pagesMulti Component DisitillationHatif AlamNo ratings yet

- B.Tech. Petrochemical VI Semester 2014-2015Document12 pagesB.Tech. Petrochemical VI Semester 2014-2015Hatif AlamNo ratings yet

- Question Paper Amu PetrochemicalDocument15 pagesQuestion Paper Amu PetrochemicalHatif AlamNo ratings yet

- B.Tech. Petrochemical VI Semester 2018-2019Document22 pagesB.Tech. Petrochemical VI Semester 2018-2019Hatif AlamNo ratings yet

- Project ManagementDocument2 pagesProject ManagementHatif AlamNo ratings yet

- B.Tech. Petrochemical VI Semester 2012-2013Document17 pagesB.Tech. Petrochemical VI Semester 2012-2013Hatif AlamNo ratings yet

- B.Tech. Petrochemical VI Semester 2015-2016Document24 pagesB.Tech. Petrochemical VI Semester 2015-2016Hatif AlamNo ratings yet

- B.Tech. Petrochemical VI Semester 2016-2017Document15 pagesB.Tech. Petrochemical VI Semester 2016-2017Hatif AlamNo ratings yet

- Unit 2Document8 pagesUnit 2Hatif AlamNo ratings yet

- B.Tech. Petrochemical VI Semester 2013-2014Document27 pagesB.Tech. Petrochemical VI Semester 2013-2014Hatif AlamNo ratings yet

- Analytic Functions and Line Integrals (Examples 19-20)Document12 pagesAnalytic Functions and Line Integrals (Examples 19-20)Hatif AlamNo ratings yet

- Chandrika PrasadDocument235 pagesChandrika PrasadHatif AlamNo ratings yet

- MarketingDocument10 pagesMarketingHatif AlamNo ratings yet

- Unit 2 Chandrika MathsDocument8 pagesUnit 2 Chandrika MathsHatif AlamNo ratings yet

- LeadershipDocument11 pagesLeadershipHatif AlamNo ratings yet

- MotivationDocument8 pagesMotivationHatif AlamNo ratings yet

- Management 2Document16 pagesManagement 2Hatif AlamNo ratings yet

- Nominal & Effective Interest RatesDocument6 pagesNominal & Effective Interest RatesHatif AlamNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)