Professional Documents

Culture Documents

958174D01 - en - O.1 - 958174D01 - en - O.1 Codes de Pannes KCE Complète

958174D01 - en - O.1 - 958174D01 - en - O.1 Codes de Pannes KCE Complète

Uploaded by

Pape SeckOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

958174D01 - en - O.1 - 958174D01 - en - O.1 Codes de Pannes KCE Complète

958174D01 - en - O.1 - 958174D01 - en - O.1 Codes de Pannes KCE Complète

Uploaded by

Pape SeckCopyright:

Available Formats

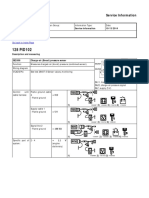

KCE FAULT CODES R14.2 958174D01 en.N.

Fault Priority FaultName FaultReason FaultAction

Code

1000 1 Serial communication Communication to both 1) Check TTS cables and

broken on board (both channels of the node is broken connectors (7.5.4)

TTS channels) a) Board is broken 2) Replace board which is

b) Cable is broken or missing (Data1) (7.7.9)

disconnected

Data1 (missing board):

1 = KCEDZS A

2 = KCEDZS B

16 = KCECCG-1

64 = Motion control

128 = Logic CPU

1001 1 Board added after setup Board is not part of the 1) Check that correct TTS

configuration recorded at setup boards are connected

(new board has been added to (7.5.1)

the system) 2) Check DIP switch

settings on KCEMSC

Data1 (extra board): (7.13.1)

1 = KCEDZS A 3) Check KCEDZS cable

2 = KCEDZS B and connectors (7.12.4)

4 = KCEDZS-C 4) Perform shaft setup (9)

8 = KCEDZS-D

16 = KCECCG-1

32 = KCECCG-2

64 = Motion control

128 = Logic CPU

1002 1 Serial communication Communication to channel-1 of 1) Check TTS-1 cable

broken on board (TTS-1) the board is broken and connectors (Data1)

a) Board is broken (7.5.5)

b) Cable is broken or 2) Replace board which is

disconnected missing (Data1) (7.7.9)

Data1 (missing board):

1 = KCEDZS A

2 = KCEDZS B

16 = KCECCG-1

64 = Motion control

128 = Logic CPU

Copyright © 2018 KONE Corporation 1/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1003 1 Serial communication Communication to channel-2 of 1) Check TTS-2 cable

broken on board (TTS-2) the board is broken and connectors (Data1)

a) Board is broken (7.5.6)

b) Cable is broken or 2) Replace board which is

disconnected missing (Data1) (7.7.9)

Data1 (missing board):

1 = KCEDZS A

2 = KCEDZS B

16 = KCECCG-1

64 = Motion control

128 = Logic CPU

1004 1 TTS serial Communication to all boards in 1) Check TTS-1 and/or

communication broken. other TTS channel is broken TTS-2 cables and

One channel a) Cable is broken or connectors between

disconnected on KCEMSC KCEMSC and KCECPU

b) KCEMSC is broken (7.5.8)

2) Check other TTS-1

Data1: and/or TTS-2 cables

1 = TTS-1 inoperative (7.5.7)

2 = TTS-2 inoperative 3) Replace KCEMSC

board (14.26)

1005 1 TTS serial Communication to all boards in 1) Check TTS-1 and/or

communication broken. both TTS channels is broken TTS-2 cables and

Both channels a) KCEMSC is broken connectors between

b) Cable is broken or KCEMSC and KCECPU

disconnected on KCEMSC (7.5.8)

2) Check TTS cables and

connectors (7.5.4)

3) Replace KCEMSC

board (14.26)

1006 1 TTS line failure a) Cable is broken 1) Make manual reset

b) TTS network termination with RESET button on

resistor is missing KMI (11.2)

c) KCEMSC is broken 2) Check TTS cables and

connectors (7.5.4)

Data1: 3) Replace KCEMSC

0 = Channel indication not board (14.26)

supported

1 = TTS-1 inoperative

2 = TTS-2 inoperative

3 = Both channels inoperative

Copyright © 2018 KONE Corporation 2/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1007 1 Safety circuit: Final limit a) Final limit switch is active 1) Move elevator from

(C1) (C1) final limit (7.14.43)

b) Cable to final limit switch is 2) Check cable connected

disconnected to XS1 on KCECCG

c) Wire jumper missing in (safety input C1) (7.3.1)

unused input 3) Check that there is

wire jumper in XS1 on

Data 1: KCECCG if no devices

1 = at bottom final limit are connected (7.3.4)

2 = at top final limit

3 = direction unknown

Data 2:

Lift speed, unit 0.1 m/s

1008 1 Safety circuit: Safety a) Safety gear is active 1) Remove elevator from

gear (C2) b) Cable is broken safety gear (7.14.3)

c) Connector is disconnected 2) Check safety gear

d) Wire jumper missing in contact and mechanical

unused input function (7.14.40)

3) Check cable connected

Data 1: to XS2 on KCECCG

Lift speed, unit 0.1 m/s (safety input C2) (7.3.1)

4) Check that there is

wire jumper in XS2 on

KCECCG if no devices

are connected (7.3.4)

1009 1 Safety circuit: a) Trap door is open 1) Check cable connected

Emergency exit (C3) b) Cable is broken to XS3 on KCECCG

c) Connector is disconnected (safety input C3) (7.3.1)

d) Wire jumper missing in 2) Check that there is

unused input wire jumper in XS3 on

KCECCG if no devices

are connected (7.3.4)

1010 1 Safety circuit: blocking a) Broken switch 1) Check cable connected

device (C4) b) Loose connector to XS4 on KCECCG

c) Broken connector (safety input C4) (7.3.1)

d) Broken wire 2) Check that there is

e) PCB broken wire jumper in XS4 on

KCECCG if no devices

are connected (7.3.4)

Copyright © 2018 KONE Corporation 3/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1011 1 Car door contact opened a) Car door contact is open 1) Check door operator

during drive (C5) b) Cable is broken cables and power supply

c) Connector is disconnected (7.8.13)

d) Wire jumper missing in 2) Check that door

unused input operator is functioning

properly (7.8.14)

3) Check that there is

wire jumper in XS5 on

KCECCG if no devices

are connected (7.3.4)

1012 1 Rear car door contact a) Car door contact is open 1) Check door operator

opened during drive (C6) b) Cable is broken cables and power supply

c) Connector is disconnected (7.8.13)

d) Wire jumper missing in 2) Check that door

unused input operator is functioning

properly (7.8.14)

3) Check that there is

wire jumper in XS6 on

KCECCG if no devices

are connected (7.3.4)

1013 1 Safety circuit: car top a) Balustrade is not down while 1) Check car top

balustrade not down on normal mode balustrade position

while on normal mode b) Cable is broken (7.14.23)

(C7) c) Connector is disconnected 2) Check that supervision

d) Wire jumper missing in switches are working

unused input properly (7.3.2)

3) Check cable connected

to XS7 on KCECCG

(safety input C7) (7.3.1)

4) Check that there is

wire jumper in XS7 on

KCECCG if no devices

are connected (7.3.4)

1015 1 Safety circuit: car top a) Balustrade is not up while on 1) Check car top

balustrade not up while top of car inspection mode balustrade position

on inspection mode (C8) b) Cable is broken (7.14.23)

c) Connector is disconnected 2) Check that supervision

d) Wire jumper missing in switches are working

unused input properly (7.3.2)

e) Balustrade is not up in RDF 3) Check cable connected

or Pit inspection mode with SSA to XS8 on KCECCG

RTE feature enabled and person (safety input C8) (7.3.1)

on car roof detected 4) Check that there is

wire jumper in XS8 on

KCECCG if no devices

are connected (7.3.4)

Copyright © 2018 KONE Corporation 4/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1016 1 Safety circuit: Fireman a) Fireman stop switch is active 1) Check fireman stop

stop switch b) Cable is broken or switch status (7.3.15)

disconnected 2) Check fireman stop

switch cable and cable

connection (7.3.14)

1017 1 Safety circuit: in-car stop a) In-car stop switch is active 1) Check in-car stop

switch b) Cable is broken or switch mode (7.14.32)

disconnected 2) Check in-car stop

switch cable and cable

connection (7.14.31)

1018 1 Deceleration failure Drive did not decelerate when 1) Check drive

requested. deceleration parameters

(A2)

1019 3 Inspection run Overspeed (0.63 m/s) during 1) Check inspection

overspeed inspection mode speed parameters from

Overspeed (0.35m/s) during drive (A10)

RDF or Pit inspection mode 2) Check rope slip

Data 1: Floor (7.14.13)

Data 2: Direction 3) Check elevator speed

0 = unknown, 1 = down, 2 = up during inspection (12.3)

1020 3 Overspeed during ADO Overspeed (0.75 m/s) during 1) Check elevator speed

ADO during ADO (12.2)

Data 1: Floor

Data 2: Direction

0 = unknown, 1 = down, 2 = up

1021 3 Overspeed during Overspeed (0.20 m/s) during 1) Check relevelling

relevelling doors open relevelling while doors open speed parameters from

drive (A16)

Data 1: Floor 2) Check elevator speed

Data 2: Direction during relevelling (12.4)

0 = unknown, 1 = down, 2 = up

1022 3 Speed information a) Speed measurement failure 1) Check motor encoder,

missing during on drive wiring and connectors

inspection mode b) Internal fault on KCEDZS (7.14.12)

2) Check KCEDZS and

magnet alignment

(7.12.1)

3) Check drive

parameters (A1)

1023 1 Car door bypass switch Car door bypass switch active 1) Check car door bypass

active switch status on KMI

(7.1.7)

Copyright © 2018 KONE Corporation 5/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1024 1 Hoistway door bypass Hoistway door bypass switch 1) Check hoistway bypass

switch active active switch status on KMI

(7.1.1)

1025 2 Inner door zone Car has moved out of inner door 1) Check brakes

protection zone (+/-75 mm) with doors (7.14.16)

open 2) Check rope slip

(7.14.13)

Data 1: Floor 3) Check deceleration

magnet positions

(7.11.10)

4) Check drive

parameters (A1)

5) Check gear

1027 1 Landing door Swing door contact (safety input Check landing door type

configuration failure H4) has been seen closed when configuration

it has not been configured to be

used.

1028 3 ETSL supervision ETSL supervision on KCEMSC 1) Check ETSL safety

activated has tripped parameters

Data 1: Lift speed, unit 0.1 m/s

Data 2: Lift direction, 0 =

unknown, 1 = down, 2 = up

1029 1 Safety circuit: Pit safety a) Pit stop switch active 1) Check pit stop switch

contact open (H1) b) OSG-rope tension weight (7.3.25)

switch active 2) Check OSG rope

c) Pit ladder switch active tension weight (7.14.36)

d) Shaft emergency door open 3) Check pit ladder switch

e) Pit access door open 4) Check shaft

emergency door contact

(7.3.28)

5) Check pit access door

contact (7.3.24)

1030 1 Safety circuit: buffer a) Overspeed governor safety 1) Check OSG contact

contact or OSG contact contact has opened (7.14.35)

(H2) b) Buffer switch is active 2) Check buffer contact

(7.14.27)

Data 1:

Lift speed, unit 0.1 m/s

Copyright © 2018 KONE Corporation 6/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1031 1 Safety circuit: Landing Landing door contact opened 1) Check coupler and

door opened during drive during drive door rollers (7.8.24)

2) Adjust landing door

Dat 1: Actual position lock contact (7.8.22)

Data 2: Direction 3) Check car sliding

0 = unknown shoes (7.14.4)

1 = down 4) Check DBG (7.14.2)

2 = up

1032 1 Safety circuit: swing Swing door contact opened 1) Check door contacts

door opened during drive during drive (7.8.3)

2) Check that swing door

Dat 1: Actual position is working properly

Data 2: Direction (7.8.20)

0 = unknown 3) Check that car retiring

1 = down ramp working properly

2 = up (7.3.5)

1033 1 Safety circuit: Buffers Buffer is not up while in 1) Check buffer position

supervision. Up input inspection mode (7.14.28)

failure 2) Check that supervision

switches are working

properly (7.3.2)

1034 1 Safety circuit: Buffers Buffer is not down while in 1) Check buffer position

supervision. Down input normal (or setup) mode (7.14.28)

failure 2) Check that supervision

switches are working

properly (7.3.2)

1035 1 Unintended movement Car has moved out of door zone 1) Check brakes

with doors open (7.14.16)

2) Check rope slip

Data 1: Floor (7.14.13)

Data 2: Direction 3) Check deceleration

0 = unknown, 1 = down, 2 = up magnet positions

(7.11.10)

4) Check drive

parameters (A1)

1036 3 Inner door zone Car has moved out of inner door 1) Check brakes

supervision zone (+/- 75 mm) with doors (7.14.16)

open 2) Check rope slip

(7.14.13)

Data 1: Floor 3) Check deceleration

Data 2: Direction magnet positions

0 = unknown, 1 = down, 2 = up (7.11.10)

4) Check drive

parameters (A1)

Copyright © 2018 KONE Corporation 7/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1037 1 Faulty door contact a) Car door contact stuck closed 1) Check that there is no

b) Landing door contact stuck over connection on door

closed circuit (7.3.10)

c) Door open end limit stuck 2) Check car door

closed (door fully open) contacts (7.8.1)

3) Check landing door

Data1: contacts (7.8.2)

Bit coded door stuck 4) Check door operator

information(one bit/door) open end limit signal

1 = A-side car door (7.8.10)

2 = B-side car door 5) Check that door

4 = C-side car door operator is functioning

8 = D-side car door properly (7.8.14)

16 = Landing door 6) Check coupler and

door rollers (7.8.24)

7) Check car door contact

cable

1038 1 Car door contact and car Either car door contact or car 1) Check car door

door close end signal door close end signal is failed or contacts (7.8.1)

does not match cable is broken 2) Check car door close

end signal and wires

Data 1: (7.8.8)

1 = Front

2 = Rear

Data 2:

1 = CCG1

2 = CCG2

1039 1 Person in shaft detected Person in shaft detected 1) Check that nobody is

on car top or in the pit ()

Data1: 2) Check landing door

1 = pit entered lock L1 and L2 circuits

2 = top of car entered (7.3.19)

3 = both pit and top of car 3) Check landing door

entered contacts (7.8.2)

4) Check car top

inspection drive unit

(7.14.5)

5) Check pit inspection

drive unit (7.14.37)

6) Reset DOM with key

switch (7.3.39)

7) If reset is not

successful activate safety

device and then back to

normal position (Data2)

(7.3.38)

Copyright © 2018 KONE Corporation 8/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1040 1 Drive time supervision Car movement not detected with 1) Make manual reset

magnets while motor is running with RESET button on

KMI (11.2)

2) Check that elevator

moves normally to avoid

any mechanical problem

(7.14.15)

3) Check KCEDZS and

magnet alignment

(7.12.1)

1041 3 Person in shaft reset Person in shaft reset switch has 1) Check Person in shaft

switch stuck been active over 30s reset switch (7.3.22)

2) Check wiring of Person

in shaft reset input (L3)

(7.3.23)

1042 3 Additional limit switch Additional limit switch C9 or C10 1) Check operation of

failure required with SSA has failed. additional limit switch(es)

(C9/C10) (7.11.18)

2) Check wiring of

additional limit switch(es)

(7.3.35)

3) Check that connectors

on CCG are ok (7.6.19)

1043 1 Start permit fault a) Contacts in start permit circuit 1) Check start permit

are not closed while lift is circuit and connections

standing (7.2.1)

b) Contacts in start permit circuit 2) Check that main

are not opened when lift is contactors open and

driving close correctly (7.14.22)

3) Check brake circuit

Data1: (7.14.1)

0 = Input permanently OFF

1 = Input permanently ON

1044 1 Drive not OK Drive system is failed. Motion 1) Check that

Control has reported a fault to communication with drive

KCEMSC. Refer to Motion is working properly

Control fault codes for more (7.10.1)

information. 2) Check cables between

controller and drive unit

(7.6.10)

3) Check drive fault codes

(7.10.2)

Copyright © 2018 KONE Corporation 9/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1045 3 Pit inspection buttons Pit inspection direction button is 1) Check pit inspection

stuck on ON when mode is activated drive unit (7.14.37)

Both pit inspection direction

buttons are on at the same time

Direction button stays ON after

lift has stopped

1046 1 Brake feedback fault Emergency Brake failed to pick. 1) Check brake switch

adjustment (7.14.26)

2) Check emergency

brake switch wiring and

connections (7.3.12)

1047 2 Car top inspection Car top inspection direction or 1) Check car top

buttons on stuck run button is on continueously. inspection drive unit

(7.14.5)

Data1: 2) Replace inspection

1 = Down button stuck drive unit (14.15)

2 = Up button stuck

(3 = Both direction buttons

active at the same time)

4 = Enable button stuck

8 = Enable low button stuck

(12 = Both enable buttons active

at the same time)

1048 2 KMI inspection buttons KMI inspection direction or run 1) Switch RDF to NORM

on stuck button is stuck on. and back to RDF on KMI

Data1: (7.1.4)

1 = Down button stuck 2) Replace KCEFUI

2 = Up button stuck board (14.25)

4 = Run button stuck

1049 2 HAC landing switch HAS board inspection direction 1) Check HAC landing

stuck inputs are on continueously. switch (7.8.33)

2) Replace HAC landing

Data1: switch (7.8.34)

1 = Down direction switch stuck

2 = Up direction switch stuck

1050 1 KCEMSC board failure - Internal supervision has 1) Make manual reset

Sw version cross check detected fault with RESET button on

KMI (11.2)

2) Replace KCEMSC

board (14.26)

Copyright © 2018 KONE Corporation 10/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1051 1 KCEMSC board failure - Internal supervision has 1) Make manual reset

Safety input common detected fault with RESET button on

test KMI (11.2)

2) Replace KCEMSC

board (14.26)

1052 1 KCEMSC board failure - Internal supervision has 1) Make manual reset

Safety input test detected fault with RESET button on

KMI (11.2)

2) Replace KCEMSC

board (14.26)

1053 1 KCEMSC board failure - Internal supervision has 1) Make manual reset

Safety input cross check detected fault with RESET button on

KMI (11.2)

2) Replace KCEMSC

board (14.26)

1054 1 Safety circuit: ground Ground fault on 100 V safety 1) Disconnect all safety

fault chain chain cables from

KCEMSC (7.3.37)

Data1: 2) Check safety chain

Voltage level, unit 1V cables one by one

(7.3.27)

3) Make full power break

with battery disconnected

(14.6)

4) Replace KCEMSC

board (14.26)

1055 1 Safety circuit: power a) Problem with 24V power 1) Check 24V power

supply voltage out of 10 supply or cables supply and cables (13.2)

% range b) Problem with main supply 2) Check main power

c) Problem with KCEMSC safety supply (13.4)

chain cables 3) Check safety chain

cables from KCEMSC

(7.3.26)

4) Make full power break

with battery disconnected

(14.6)

5) Replace KCEMSC

board (14.26)

Copyright © 2018 KONE Corporation 11/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1056 1 Safety circuit: power a) Problem with 24V power 1) Check 24V power

supply voltage out of 15 supply or cables supply and cables (13.2)

% range b) Problem with main supply 2) Check main power

c) Problem with KCEMSC safety supply (13.4)

chain cables 3) Check safety chain

cables from KCEMSC

(7.3.26)

4) Make full power break

with battery disconnected

(14.6)

5) Replace KCEMSC

board (14.26)

1057 1 Safety circuit: power a) Problem with 24V power 1) Check 24V power

supply voltage out of 20 supply or cables supply and cables (13.2)

% range b) Problem with main supply 2) Check main power

c) Problem with KCEMSC safety supply (13.4)

chain cables 3) Check safety chain

cables from KCEMSC

(7.3.26)

4) Make full power break

with battery disconnected

(14.6)

5) Replace KCEMSC

board (14.26)

1058 3 Speed comparison Too large difference in speed 1) Check motor encoder,

warning measurement from motion wiring and connectors

control and door zone sensor. (7.14.12)

2) Check drive

Data 1: parameters (A1)

0...1 = KCEDZS A vs. Motion 3) Check KCEDZS and

control magnet alignment

2...3 = KCEDZS B vs. Motion (7.12.1)

control 4) If KCEDZS internal

4 = KCEDZS A internal supervision fails, replace

supervision corresponding KCEDZS

5 = KCEDZS B internal (7.12.6)

supervision

6...9 = KCEDZS A vs. KCEDZS

B

Data 2: speed difference (unit

0.1 m/s)

1059 1 KCEMSC board failure - Internal supervision has 1) Make manual reset

ROM test detected fault with RESET button on

KMI (11.2)

2) Replace KCEMSC

board (14.26)

Copyright © 2018 KONE Corporation 12/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1060 1 KCEMSC board failure - Internal supervision has 1) Make manual reset

RAM test detected fault with RESET button on

KMI (11.2)

2) Replace KCEMSC

board (14.26)

1061 1 KCEMSC board failure - Internal supervision has 1) Make manual reset

Internal data comparison detected fault with RESET button on

KMI (11.2)

2) Replace KCEMSC

board (14.26)

1062 1 KCEMSC board failure - Internal supervision has 1) Make manual reset

No reciprocal detected fault with RESET button on

communication KMI (11.2)

2) Replace KCEMSC

board (14.26)

1063 1 KCEMSC board failure - Internal supervision has 1) Make manual reset

Relay K51 feedback detected fault with RESET button on

KMI (11.2)

2) Replace KCEMSC

board (14.26)

1064 1 KCEMSC board failure - Internal supervision has 1) Make manual reset

Relay K52 feedback detected fault with RESET button on

KMI (11.2)

2) Replace KCEMSC

board (14.26)

1065 3 SSA safety device check Pit or car roof safety device is in 1) Check operation of car

failed an undetermined state. roof (C7/C8) or pit

(H6/H5) safety device

(7.3.21)

2) Check wiring of car

roof or pit safety device

(7.3.36)

1066 1 24 V power supply Problem with 24v power cables 1) Check 24V power

voltage out of +- 10 % or connectors supply and cables (13.2)

range 2) Check main power

supply (13.4)

3) Check 24V circuits for

ground faults (13.3)

Copyright © 2018 KONE Corporation 13/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1068 1 24V power supply a) Machine room stop button 1) Check machine room

voltage out of +- 20 % used stop button (7.3.6)

range b) Cable to XM1 broken or 2) Check connector XM1

connector loose on KCEMSC (7.6.17)

3) Check 24V power

Data1: supply and cables (13.2)

Voltage level on this channel

decreased by 10V, unit 0.1V

Data 2:

Voltage level on other channel

decreased by 10V, unit 0.1V

1069 1 KCEMSC board failure - Internal supervision has 1) Check 24V power

3.3 V power supply detected fault supply and cables (13.2)

2) Check main power

supply (13.4)

3) Make full power break

with battery disconnected

(14.6)

4) Replace KCEMSC

board (14.26)

1070 1 KCEMSC board failure - Internal supervision has 1) Check 24V power

Processor core power detected fault supply and cables (13.2)

supply 2) Check main power

supply (13.4)

3) Make full power break

with battery disconnected

(14.6)

4) Replace KCEMSC

board (14.26)

1071 3 Energy saving warning Energy saving requested when Actions to be defined

lift is running

1072 2 Energy saving failure Energy saving mode selection Energy saving SW fix

failure required

Data 1:

R&D only

1073 1 Person in shaft detection Person in shaft detection input is 1) Make manual reset

input failure stuck at ON state. Person in pit with RESET button on

detection is not possible. KMI (11.2)

2) Replace KCEFUI

board (14.25)

Copyright © 2018 KONE Corporation 14/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1074 3 TTS communication a) Board is broken 1) Check TTS cables and

disturbance b) TTS cable connector is loose connectors (7.5.4)

2) Check earthings (7.6.7)

Data 1:

0 = unknown

1 = KCEDZS-A

2 = KCEDZS-B

3 = KCEDZS-C

4 = KCEDZS-D

5 = KCECCG-1

6 = KCECCG-2

7 = Motion control

8 = Logic CPU

9 = KCEPVSC

10 = Absolute position sensor

1075 1 KCEFUI board Connection between KCEMSC 1) Check connection

disconnected and KCEFUI loose or broken between KCEFUI and

KCEMSC (7.1.6)

2) Replace KCEFUI

board (14.25)

3) Replace KCEMSC

board (14.26)

1076 1 KCEMSC board failure - Internal supervision has 1) Make manual reset

Shift registers detected fault with RESET button on

KMI (11.2)

2) Replace KCEMSC

board (14.26)

1077 1 KCEMSC board failure - Internal supervision has 1) Make manual reset

Relay K41 feedback detected fault with RESET button on

KMI (11.2)

2) Replace KCEMSC

board (14.26)

1078 1 KCEMSC board failure - Internal supervision has 1) Make manual reset

Relay K42 feedback detected fault with RESET button on

KMI (11.2)

2) Replace KCEMSC

board (14.26)

1079 1 KCEMSC board failure - Internal supervision has 1) Make manual reset

100V power supply detected fault with RESET button on

KMI (11.2)

2) Replace KCEMSC

board (14.26)

Copyright © 2018 KONE Corporation 15/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1080 1 KCEMSC DIP switch DIP switches on KCEMSC at 1) Remove KCEFUI

mismatch different position on S4 and S5 board to get access to

DIP switches (7.13.4)

Data 1: 2) Check DIP switch

Status of dips on channel 1 settings on KCEMSC

(7.13.1)

Data 2: 3) Make manual reset

Status of dips on channel 2 with RESET button on

KMI (11.2)

The data value on both channels 4) Replace KCEMSC

must be the same board (14.26)

1081 1 KCEMSC board failure - Internal supervision has 1) Make manual reset

Input comparison detected fault with RESET button on

KMI (11.2)

2) Replace KCEMSC

board (14.26)

1082 1 KCEMSC board failure - Internal supervision has 1) Make manual reset

Comparison of KCEFUI detected fault with RESET button on

inputs 1 = Up button KMI (11.2)

2 = Down button 2) Replace KCEFUI

3 = Run button board (14.25)

4 = Reset button 3) Replace KCEMSC

5 = Test switch middle position board (14.26)

6 = Boost button

7 = Setup button

8 = Version selection

9 = Car door bypass switch

10 = SB-1

11 = SB-2

12 = SB-3

13 = SB-4

14 = Stop switch

15 = Inspection switch

16 = Landing door bypass

switch

17 = OSG button

18 = Pendant up input

19 = Pendant down input

20 = Test switch

21 = Terminal stop bypass

button

22 = Unintended movement test

switch

23 = Speed test switch

24 = Pendant run input

25 = Person on car roof

detection

26 = Person in pit detection

27 = Person in shaft reset input

Copyright © 2018 KONE Corporation 16/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1083 1 KCEDZS A data Internal supervision has 1) Make manual reset

comparison failure detected fault with RESET button on

KMI (11.2)

2) Disconnect and

reconnect KCEDZS cable

from KCECCG (7.12.5)

3) Make manual reset

with RESET button on

KMI (11.2)

4) Replace KCEDZS-A

unit (14.21)

5) Replace KCEMSC

board (14.26)

1084 1 KCEDZS B data Internal supervision has 1) Make manual reset

comparison failure detected fault with RESET button on

KMI (11.2)

2) Disconnect and

reconnect KCEDZS cable

from KCECCG (7.12.5)

3) Make manual reset

with RESET button on

KMI (11.2)

4) Replace KCEDZS-B

unit (14.22)

5) Replace KCEMSC

board (14.26)

1085 1 KCEDZS C data Data1: 1) Make manual reset

comparison failure R&D use only with RESET button on

KMI (11.2)

2) Disconnect and

reconnect KCEDZS cable

from KCECCG (7.12.5)

3) Make manual reset

with RESET button on

KMI (11.2)

4) Replace KCEDZS-C

unit (14.23)

5) Replace KCEMSC

board (14.26)

Copyright © 2018 KONE Corporation 17/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1086 1 KCEDZS D data Data1: 1) Make manual reset

comparison failure R&D use only with RESET button on

KMI (11.2)

2) Disconnect and

reconnect KCEDZS cable

from KCECCG (7.12.5)

3) Make manual reset

with RESET button on

KMI (11.2)

4) Replace KCEDZS-D

unit (14.24)

5) Replace KCEMSC

board (14.26)

1087 1 KCEABS data Data1: 1) Make manual reset

comparison failure R&D use only with RESET button on

KMI (11.2)

2) Disconnect and

reconnect KCEDZS cable

from KCECCG (7.12.5)

3) Make manual reset

with RESET button on

KMI (11.2)

4) Replace KCEDZS unit

(14.20)

5) Replace KCEMSC

board (14.26)

1088 1 KCECCG-1 data Internal supervision has 1) Make manual reset

comparison failure detected fault with RESET button on

KMI (11.2)

Data 1: 2) Make full power break

4 = Safety input C1 (fnal limit) with battery disconnected

16 = Inspection up and after that make

17 = Inspection down manual reset with RESET

18 = Inspection run button on KMI

19 = Inspection run low speed 3) Replace KCECCG

20 = Car door close end limit board (14.16)

front door 4) Replace KCEMSC

21 = Car door open end limit board (14.26)

front door

22 = Car door close end limit

rear door

23 = Car door open end limit

rear door

24 = Car door nearly closed

front door

25 = Car door nearly closed rear

door

Copyright © 2018 KONE Corporation 18/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1089 1 KCECCG-2 data Data 1: 1) Make manual reset

comparison failure 4 = Safety input C1 (fnal limit) with RESET button on

16 = Inspection up KMI (11.2)

17 = Inspection down 2) Disconnect and

18 = Inspection run reconnect xx connector

19 = Inspection run low speed on KCECCG-2 board ()

20 = Car door close end limit 3) Make manual reset

front door with RESET button on

21 = Car door open end limit KMI (11.2)

front door 4) Replace KCECCG-2

22 = Car door close end limit board (14.17)

rear door 5) Replace KCEMSC

23 = Car door open end limit board (14.26)

rear door

24 = Car door nearly closed

front door

25 = Car door nearly closed rear

door

1090 1 KCECPU data Data1: 1) Make manual reset

comparison failure R&D use only with RESET button on

KMI (11.2)

2) Disconnect and

reconnect xx connector

on KCECPU board ()

3) Make manual reset

with RESET button on

KMI (11.2)

4) Replace KCECPU

board (14.18)

5) Replace KCEMSC

board (14.26)

1091 1 Lift on final limit magnet Final limit magnet has been read 1) Move elevator from

by KCEDZS final limit (7.14.43)

2) Check KCEDZS and

Data 1: magnet alignment

1 = at bottom final limit (7.12.1)

2 = at top final limit

3 = direction unknown

Data 2:

Lift speed, unit 0.1 m/s

Copyright © 2018 KONE Corporation 19/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1092 1 KCEMSC OSG test KCEMSC is not able to control 1) Disconnect OSG test

signal failure OSG test output cable from KCEMSC

XOSGT1/XOSGT2. connector XOSGT1 or

XOSGT2. If fault

Data 1: removed, then check that

1 = OSG test signal on no short circuit or external

connector XOSGT1/XOSGT2 is voltages are connected to

active without making OSG test the OSG test cable.

with KMI 2) Make power break

2 = OSG test signal on (main switch) (11.1)

connector XOSGT1/XOSGT2 is 3) Make manual reset

not active when OSG test with with RESET button on

KMI is made KMI (11.2)

4) Replace KCEMSC

board (14.26)

1093 3 Too much resistance on Measured resistance in landing 1) Check landing door

landing door contact door locked (H3) or landing door contacts (7.8.2)

closed (H4) input is higher than

2kohms. If resistance is over

10kohms landing door is seen

open even if physically closed

Data 1:

Safety input H3 resistance

(kohm)

Data 2:

Safety input H4 resistance

(kohm)

1094 4 Induced noise in landing Voltage seen in analog safety 1) Check for possible

door contact input when it is open or voltage sources for the induced

goes to the noise detection are noise (7.14.29)

when input is closed due to 2) Check the resistance

excessive resistance in the of the H3 and H4 circuits

circuit. (7.3.32)

In latter case lift cannot run

because safety input is open.

Copyright © 2018 KONE Corporation 20/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1095 1 DOM resistor failure a) Pit access floor resistor at 1) Check DOM resistors

wrong floor (7.3.11)

b) Normal floor resistor at the pit 2) Check DIP switch

access floor settings on KCEMSC

c) Resistors with wrong values (7.13.1)

in the circuitry

d) Internal failure on KCEMSC

board (either on resistance

measurement circuitry or ADC)

Data1:

1 = Pit access floor resistor at

wrong floor

2 = Normal floor resistor at the

pit access floor

3 = Resistors with wrong values

in the circuitry OR internal failure

on KCEMSC board

1096 2 KCEFUI board failure - Button on KMI is on 1) Switch TEST switch on

Button stuck continueously. KMI to OFF position and

then to 263 position

Data1: (7.1.3)

1 = Setup button stuck 2) Make full power break

2 = Boost button stuck with battery disconnected

4 = OSG button stuck (14.6)

8 = Select button stuck 3) Replace KCEFUI

16 = Reset button stuck board (14.25)

1097 1 Device picked fault a) There is failure on the device 1) Reset fault by

picked circuitry outside the switching elevator to RDF

KCEMSC board (7.1.13)

b) KCEMSC board has failed 2) Check device picked

wiring and contacts

Data1: (7.3.9)

0 = Input permanently OFF 3) Check devices

1 = Input permanently ON connected to device

picked input (7.3.8)

4) Check DIP switch

settings on KCEMSC

(7.13.1)

5) Replace KCEMSC

board (14.26)

Copyright © 2018 KONE Corporation 21/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1098 1 Motion control data Internal supervision has 1) Make manual reset

comparison failure detected fault with RESET button on

KMI (11.2)

2) Disconnect Motion

control board from TTS

networks and reconnect it

(7.10.4)

3) Make manual reset

with RESET button on

KMI (11.2)

4) Replace Motion control

unit (7.10.5)

5) Replace KCEMSC

board (14.26)

1099 1 Main stop circuit open a) Safety device connected to 1) Check the status of all

KCEMSC/XM1 is activated (e.g. safety devices connected

machine room stop button, RBO to KCEMSC/XM1

switch, slack rope switch contact 2) Check KCEMSC/XM1

open) connection and wiring

b) Cable to KCEMSC/XM1 3) Check that there is

broken or connector loose wire jumper in XM1 on

c) KCEMSC/XM1 wire jumper KCEMSC if no devices

plug not connected are connected

1101 1 Door zone information Internal supervision has 1) Make manual reset

mismatch detected fault with RESET button on

KMI (11.2)

Data1: 2) Disconnect and

0 = KCEDZS-A reconnect KCEDZS cable

1 = KCEDZS-B from KCECCG (7.12.5)

2 = KCEDZS-C 3) Make manual reset

3 = KCEDZS-D with RESET button on

KMI (11.2)

4) Replace KCEDZS unit

(14.20)

5) Replace KCEMSC

board (14.26)

Copyright © 2018 KONE Corporation 22/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1102 1 Speed comparison fault Too large difference in speed 1) Check motor encoder,

measurement from motion wiring and connectors

control and door zone sensor. (7.14.12)

2) Check drive

Data 1: parameters (A1)

0...1 = KCEDZS A vs. Motion 3) Check KCEDZS and

control magnet alignment

2...3 = KCEDZS B vs. Motion (7.12.1)

control 4) If KCEDZS internal

4 = KCEDZS A internal supervision fails, replace

supervision corresponding KCEDZS

5 = KCEDZS B internal (7.12.6)

supervision

6...9 = KCEDZS A vs. KCEDZS

B

Data 2: speed difference (unit

0.1 m/s)

1103 1 KCEMSC board failure - Program flash is corrupted 1) Make manual reset

ROM test with RESET button on

KMI (11.2)

2) Replace KCEMSC

board (14.26)

1104 1 KCEMSC board failure - a) I/O controller inside the uC is 1) Make manual reset

IO controller not working with RESET button on

KMI (11.2)

2) Replace KCEMSC

board (14.26)

1105 1 Boards in TTS network Some board in TTS network is 1) Replace board which

are not compatible wrong version has wrong version (see

Data1) (14.9)

Data1:

1 = KCEDZS-A

2 = KCEDZS-B

4 = KCEDZS-C

8 = KCEDZS-D

16 = KCECCG-1

32 = KCECCG-2

64 = Motion control

128 = Logic CPU

Data2:

1 = KCEPVSC

2 = Absolute position sensor

4 = KCEMSC (other channel)

Copyright © 2018 KONE Corporation 23/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1106 1 Setup failed Data 1: 1) Check floor magnets

0 = Reason unknown (7.11.2)

1 = Motion control phase 1 2) Check final limit

expected magnets (7.11.6)

2 = Motion control phase 2 3) Check KCEDZS and

expected magnet alignment

3 = Motion control phase 3 (7.12.1)

expected 4) Check bottom and top

4 = Node missing floor magnets and their

5 = Node did not clear signature types (7.11.12)

6 = Node did not set setup 5) Check drive speed

required parameters (A11)

7 = Node did not go to setup 6) Check possible other

mode fault codes for additional

8 = Node exited setup mode too information (7.14.38)

early 7) Check deceleration

9 = Node did not clear setup magnet positions

required 8) Perform shaft setup (9)

10 = Node did not get setup

mode completed

11 = Node did not form new

signature

12 = Battery power detected

13 = Bypass jumper or switch

activated while in setup mode

14 = Lift stopped above bottom

and below top floor after phase

1

15 = Safety chain opened while

lift was moving

16 = Test switch not in test

position

17 = Overspeed detected during

Copyright © 2018 KONE Corporation 24/117

KCE FAULT CODES R14.2 958174D01 en.N.1

20 = Run time calculation failed

21 = Lift did not start withing

required time after movement

was allowed

22 = Hydraulic final limit magnet

found in rope lift

23 = Rope final limit magnet

found in hydraulic lift

24 = Lift type from Motion

Control changed during setup

25 = Setup interrupted by higher

priority mode

26 = The other channel did not

go to setup mode

27 = Node self test failure

28 = Motor speed missing

29 = Speed command missing

30 = Terminal floor deceleration

failure

31 = Floor Magnet Upside Down

32 = Speed information cross

check

33 = Severe fault detected

34 = Roll call active when new

setup initiated

35 = Device picked/Secondary

permit failure

36 = Start permit fault

37 = Setup writing to EEPROM

be added to setup completion

conditions

38 = Motion control cancelled

phase 3

Copyright © 2018 KONE Corporation 25/117

KCE FAULT CODES R14.2 958174D01 en.N.1

41 = Other channel did not

complete setup step in time

42 = Direction selection failed

Data 2 when Data 1 = 1-3:

The setup phase of MCU not

expected by MSC

0 = No setup

1 = Setup phase 1

2 = Setup phase 2

3 = Setup phase 3

Data 2 when Data 1 = 4-11 or

39:

Number of the node

1 = KCEDZS A

2 = KCEDZS B

3 = KCEDZS C

4 = KCEDZS D

5 = KCECCG-1

6 = KCECCG-2

7 = Motion control

8 = Logic CPU

9 = KCEPVSC

10 = KCEABS

Data 2 when Data 1 = 13:

Active bypass switch/jumper

1 = SB1

2 = SB2

3 = SB3

4 = SB4

Copyright © 2018 KONE Corporation 26/117

KCE FAULT CODES R14.2 958174D01 en.N.1

5 = Car door bypass switch

6 = Hoistway door bypass switch

Data 2 when Data 1 = 17:

Phase of setup when overspeed

detected

1 = Setup phase 1

2 = Setup phase 2

Data 2 when Data 1 = 18:

The channel that wanted to

interrupt setup first

1 = Channel 1

2 = Channel 2

Data 2 when Data 1 = 19:

Unknown final limit

0 = Final limit unknown

1 = Final limit different between

channels

Data 2 when Data 1 = 21:

Time limit

30 = first start time limit 30s

10 = further starts time limit 10s

Data 2 when Data 1 = 22-23:

Final limit

1 = bottom final limit

2 = top final limit

Data 2 when Data 1 = 24:

Lift type

0 = rope lift

1 = hydraulic lift

Data 2 when Data 1 = 25:

Higher priority mode that

interrupted setup

1 = Pendant

2 = Service drive/Top of car

inspection

3 = Hoistway access

4 = RDF/Emergency electrical

operation

5 = Machine room inspection

9 = Pit inspection mode

Data 2 when Data 1 = 26:

Channel that did not go to setup

mode

1 = Channel 1

2 = Channel 2

Copyright © 2018 KONE Corporation 27/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1108 3 Door open end reached Doors are adjusted to open too 1) Check door open end

before lift stops fast limit signal (7.8.9)

2) Check door operator

settings (7.8.18)

3) Decrease door speed

(7.8.31)

1109 1 Landing door not opened a) Service technician switches 1) Check that there is no

after inspection mode the top of car inspection mode over connection on door

switched OFF OFF before opening the landing circuit (7.3.10)

door 2) Reset Pit inspection

mode (7.3.40)

b) Landing door contact is

overconnected

c) Service technician switches

the pit inspection mode OFF

before opening the landing door

d) Service technician does not

reset Pit inspection mode after

switching the Pit inspection

mode OFF

1110 3 Additional 24V Too large difference between 1) Check KCEMSC/XM1

measurement failure incoming 24V measured through connection and wiring

DAC with comparator and 2) Check the status of all

analog input. safety devices connected

to KCEMSC/XM1

The additional voltage 3) Make full power break

measurement to detect if full with battery disconnected

power exist when Main stop is and after that make

switched OFF does not work. manual reset with RESET

button on KMI

4) Replace KCEMSC

board (14.26)

1111 1 KCEFUI SPI failure KCEFUI shift register SPI is not 1) Make manual reset

working or hard coded inputs with RESET button on

are in wrong state KMI (11.2)

2) Replace KCEFUI

board (14.25)

Copyright © 2018 KONE Corporation 28/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1112 1 KCEFUI board failure - Internal supervision has 1) Make manual reset

Safety input test detected fault with RESET button on

KMI (11.2)

2) Replace KCEFUI

board (14.25)

3) Make manual reset

with RESET button on

KMI (11.2)

4) Replace KCEMSC

board (14.26)

1113 1 TTS communication TTS node is sending continuosly 1) Make full power break

stuck the same (old) message with battery disconnected

(14.6)

Data1: 2) Replace board whose

1 = KCEDZS-A communication is stuck

2 = KCEDZS-B (see Data1) (14.1)

4 = KCEDZS-C

8 = KCEDZS-D

16 = KCECCG-1

32 = KCECCG-2

64 = MCU

128 = KCECPU

Data2:

1 = KCEPVSC

2 = KCEABS

4 = KCEMSC (other channel)

1114 2 Pit inspection mode input Pit inspection mode input is a) Check that Pit

failure active but Pit stop input (H1) inspection station is

does not open. connected to lon

b) Check buttons of Pit

a) Pit inspection Run and inspection station

Direction button are stuck c) Check wiring of Pit

inspection station

b) Pit inspection Mode switch

wiring problem

c) Pit inspection lon node is

missing

1115 1 KCEMSC board failure - Internal supervision has 1) Make manual reset

Safety input power detected fault with RESET button on

supply KMI (11.2)

2) Replace KCEMSC

board (14.26)

Copyright © 2018 KONE Corporation 29/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1116 1 KMI safety chain bypass Bypass jumper is active during 1) Remove bypass

jumper at place Pit inspection mode, normal jumper on KMI (7.1.12)

mode, setup mode or no setup 2) Make manual reset

mode with RESET button on

KMI (11.2)

Bypass jumper is active during 3) Replace KCEFUI

TOC mode when SSA is in use board (14.25)

4) Replace KCEMSC

Data1: board (14.26)

1 = SB-1 bypass jumper placed

2 = SB-2 bypass jumper placed

3 = SB-3 bypass jumper placed

4 = SB-4 bypass jumper placed

1117 1 KMI stop switch active The stop switch on KCEFUI 1) Release KMI stop

board is active switch (7.1.10)

2) Make manual reset

with RESET button on

KMI (11.2)

3) Replace KCEFUI

board (14.25)

4) Replace KCEMSC

board (14.26)

1118 1 KCECCG-2:Safety circuit a) Final limit switch is active 1) Move elevator from

Final limit b) Cable to final limit switch is final limit (7.14.43)

disconnected 2) Check final limit cable

c) Final limit tag has been read connections (7.3.13)

by KCEDZS

Data 1:

0 = direction unknown

1 = at bottom final limit

2 = at top final limit

Data 2:

Lift speed, unit 0.1 m/s

1119 1 KCECCG-2 Safety a) Safety gear is active 1) Remove elevator from

circuit: Safety gear b) Cable is broken safety gear (7.14.3)

c) Connector is disconnected 2) Check safety gear

contact and mechanical

Data 1: function (7.14.40)

Lift speed, unit 0.1 m/s 3) Check elevator speed

(12.1)

1120 1 KCECCG-2 Safety a) Trap door is open 1) Check trap door

circuit: KCECCG-2 b) Cable is broken contact (7.3.33)

emergency exit c) Connector is disconnected

Copyright © 2018 KONE Corporation 30/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1121 1 KCECCG-2 Safety - Broken switch 1) Check blocking device

circuit: KCECCG-2 - Loose connector (7.14.25)

blocking device - Broken connector

- Broken wire

- PCB broken

1122 1 KCECCG-2 Car door a) Car door contact is open 1) Check door operator

contact opened during b) Cable is broken cables and power supply

drive c) Connector is disconnected (7.8.13)

2) Check that door

operator is functioning

properly (7.8.14)

1123 1 KCECCG-2 Rear car a) Car door contact is open 1) Check door operator

door contact opened b) Cable is broken cables and power supply

during drive c) Connector is disconnected (7.8.13)

2) Check that door

operator is functioning

properly (7.8.14)

1124 1 KCECCG-2 Safety a) Balustrade is not down while 1) Check car top

circuit: car top balustrade on normal mode balustrade position

not down while on b) Cable is broken (7.14.23)

normal mode c) Connector is disconnected 2) Check that supervision

switches are working

properly (7.3.2)

1125 1 KCECCG-2 Safety a) Hoistway access enable 1) Check hoistway access

circuit: Hoist way access activated while driving switch status (7.3.18)

enable activated while b) Cable is broken 2) Check hoistway access

driving c) Connector is disconnected switch cable (7.3.16)

3) Check hoistway access

switch connectors

(7.3.17)

1126 2 KCECCG-2 Safety a) Balustrade is not up while on 1) Check car top

circuit: car top balustrade top of car inspection mode balustrade position

not down while on b) Cable is broken (7.14.23)

normal mode c) Connector is disconnected 2) Check that supervision

switches are working

properly (7.3.2)

1127 1 KCECCG-2 Safety a) Fireman stop switch is active 1) Check fireman stop

circuit: Fireman stop b) Cable is broken or switch status (7.3.15)

switch disconnected 2) Check fireman stop

switch cable and cable

connection (7.3.14)

Copyright © 2018 KONE Corporation 31/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1128 1 KCECCG-2 Safety a) In-car stop switch is active 1) Check in-car stop

circuit: in-car stop switch b) Cable is broken or switch mode (7.14.32)

disconnected 2) Check in-car stop

switch cable and cable

connection (7.14.31)

1129 1 Inspection drive unit stop a) Top of car stop button is 1) Check car top stop

button active active button, cable and cable

b) Cable is broken or connections (7.14.24)

disconnected 2) Reset KCECCG

(7.7.12)

3) Replace inspection

drive unit (14.15)

4) Replace KCECCG

board (14.16)

1130 4 SSA input supervision a) Other channel has set SSA Indication only. Normal

reservation warning input supervision reservation ON operation is allowed.

when lift is moving

b) Other channel has kept SSA

input supervision reservation ON

for more than 60 seconds

1131 1 SSA input supervision Other channel has kept SSA 1) Make manual reset

reservation failure input supervision reservation ON with RESET button on

for more than 24 hours KMI (11.2)

1132 4 Pit inspection mode a) Pit inspection reset input is 1) Switch pit inspection

reset input active too stuck ON reset input to OFF state

long

1133 3 Terminal floor Terminal deceleration magnet 1) Reset KCECPU

deceleration failure position wrong of setup (7.7.13)

corrupted. 2) Drive elevator to both

Data 1: terminal floors (no RDF)

1 = deceleration to bottom floor (7.14.42)

failed 3) Check terminal floor

2 = deceleration to top floor deceleration magnets

failed (7.11.5)

Data 2: Door side 4) Perform shaft setup (9)

1 = A-side

2 = B-side

4 = C-side

8 = D-side

1134 1 Deck configuration KCECCG-2, KCEDZS-C or 1) Check DIP switch

mismatch KCEDZS-D board exists when settings on KCEMSC

according to KCEMSC DIP (7.13.1)

switch only one KCECCG board

should exist

Copyright © 2018 KONE Corporation 32/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1135 1 Safety output control Relay control signal feedback is 1) Make manual reset

signal failure (Relay A, seen in different state than with RESET button on

K51) intended. KMI (11.2)

2) Replace KCEMSC

board (14.26)

1136 1 Safety output control Relay control signal feedback is 1) Make manual reset

signal failure (Relay B, seen in different state than with RESET button on

K52) intended. KMI (11.2)

2) Replace KCEMSC

board (14.26)

1137 1 Safety output control Relay control signal feedback is 1) Make manual reset

signal failure (Relay A, seen in different state than with RESET button on

K41) intended. KMI (11.2)

2) Replace KCEMSC

board (14.26)

1138 1 Safety output control Relay control signal feedback is 1) Make manual reset

signal failure (Relay B, seen in different state than with RESET button on

K42) intended. KMI (11.2)

2) Replace KCEMSC

board (14.26)

1139 1 KCEMSC - KCEFUI KCEFUI board is incompatible 1) Make manual reset

boards mismatch (wrong with KCEMSC with RESET button on

version) KMI (11.2)

2) Check KCEMSC and

KCEFUI board versions

and replace incorrect one

(7.7.3)

1140 1 Safety circuit: Inspection a) Inspection up limit is active 1) Check inspection up

up limit b) Cable is broken or limit switch, cable and

disconnected cable connection

(7.14.34)

1141 1 Safety circuit: Inspection a) Inspection down limit is active 1) Check inspection down

down limit b) Cable is broken or limit switch, cable and

disconnected cable connection

(7.14.33)

1142 1 KCECCG-2 Safety a) Inspection up limit is active 1) Check inspection up

circuit: Inspection up limit b) Cable is broken or limit switch, cable and

disconnected cable connection

(7.14.34)

1143 1 KCECCG-2 Safety a) Inspection down limit is active 1) Check inspection down

circuit: Inspection down b) Cable is broken or limit switch, cable and

limit disconnected cable connection

(7.14.33)

Copyright © 2018 KONE Corporation 33/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1145 1 KCECCG-1 safety a) Outside resistance of an 1) Check wiring of the

contact input cross KCECCG safety input has risen reported safety input on

check failure to the level of cut of point of the KCECCG-1

safety input 2) Check the resistance

b) KCECCG board failure of the reported safety

input circuit on KCECCG-

1

3) Clean the contacts in

the circuit of the reported

safety input

4) Replace contacts in the

circuit of the of the

reported safety input

5) Replace KCECCG-1

board

1146 1 KCECCG-2 safety a) Outside resistance of an 1) Check wiring of the

contact input cross KCECCG safety input has risen reported safety input on

check failure to the level of cut of point of the KCECCG-2

safety input 2) Check the resistance

b) KCECCG board failure of the reported safety

input circuit on KCECCG-

2

3) Clean the contacts in

the circuit of the reported

safety input

4) Replace contacts in the

circuit of the of the

reported safety input

5) Replace KCECCG-2

board

1147 1 Safety contact input a) Too much resistance in the 1) Check wiring of the

cross check warning safety contact or its wiring reported safety input on

b) Internal KCEMSC failure in KCEMSC

the safety contact input 2) Check the resistance

of the reported safety

input circuit on KCEMSC

3) Clean the contacts in

the circuit of the reported

safety input

4) Replace contacts in the

circuit of the of the

reported safety input

5) Make manual reset

6) Replace KCEMSC

board

Copyright © 2018 KONE Corporation 34/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1148 1 KCECCG board failure - KCECCG failure 1) Make manual reset

Self check failed with RESET button on

Data 1: KMI (11.2)

1 = KCECCG-1 failed 2) Replace KCECCG

2 = KCECCG-2 failed board (14.16)

1149 1 KCECCG board failure - Fatal failure on KCECCG board 1) Make manual reset

Manual reset needed with RESET button on

Data 1: KMI (11.2)

1 = KCECCG-1 failed 2) Replace KCECCG

2 = KCECCG-2 failed board (14.16)

1150 1 Final limit missing a) Final limit magnet missing 1) Install final limit magnet

b) Final limit switch not if it is missing (7.11.17)

connected to XS1 connector on 2) Check KCEDZS and

KCECCG magnet alignment

b) Ramp missing or switch does (7.12.1)

not hit the ramp 3) Check final limit wiring

if final limit switch is used

Data 1: (7.3.7)

0 = direction unknown 4) Perform shaft setup (9)

1 = at bottom final limit

2 = at top final limit

1151 1 KCEMSC DIP switch Person in shaft detection 1) Check DIP switch

failure (DIP 5) enabled with G01, G03 or G04 settings on KCEMSC

version of KCEMSC (7.13.1)

2) Make manual reset

with RESET button on

KMI (11.2)

3) Replace KCEMSC

board (14.26)

1152 1 KCECCG internal failure Internal supervision has 1) Make full power break

detected fault with battery disconnected

(14.6)

2) Replace KCECCG

board (14.16)

1153 1 KCEMSC board failure - a) Production test input is active 1) Make manual reset

Production test input b) KCEMSC board failure with RESET button on

KMI (11.2)

2) Replace KCEMSC

board (14.26)

Copyright © 2018 KONE Corporation 35/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1154 1 KCECCG-2: Safety a) Wire jumper missing from S1 1) Check bypass jumper

circuit S1 on KCECCG-2 on KCECCG-2 XS1

b) KCEINSP connected to connector (7.7.1)

KCECCG-2 and stop button is

active

c) Failure on KCECCG-2 board

1155 1 KCECCG-2: Safety a) Wire jumper missing from S1 1) Check bypass jumper

circuit S2 on KCECCG-2 on KCECCG-2 XS2

b) KCEINSP connected to connector (7.7.2)

KCECCG-2 and inspection

mode activated

c) Failure on KCECCG-2 board

1156 2 Pendant input on stuck Pendant direction or run button 1) Check car top

is stuck on. inspection drive unit

Data1: (7.14.5)

0x01 = Down input stuck 2) Replace inspection

0x02 = Up input stuck drive unit (14.15)

0x04 = Run input stuck

1157 1 KCEMSC board failure - Internal supervision has 1) Make manual reset

Assembly variant input detected fault with RESET button on

KMI (11.2)

2) Replace KCEMSC

board (14.26)

1158 1 KCEMSC board failure - Internal supervision has 1) Make manual reset

Assembly variant detected fault with RESET button on

detection KMI (11.2)

2) Replace KCEMSC

board (14.26)

1159 4 KCEMSC board failure - Internal supervision has 1) Make manual reset

Nameplate detected fault with RESET button on

KMI (11.2)

2) Replace KCEMSC

board (14.26)

1160 3 KCEFUI board failure - Failure on KCEFUI board 1) Check test switch

Test switch position on KMI (7.1.8)

2) Switch TEST switch on

KMI to OFF position and

then to 263 position

(7.1.3)

3) Replace KCEFUI

board (14.25)

Copyright © 2018 KONE Corporation 36/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1161 1 KCEDZS board failure - KCEDZS failure 1) Make manual reset

Self check failed with RESET button on

Data 1: KMI (11.2)

1 = KCEDZS-A failed 2) Disconnect and

2 = KCEDZS-B failed reconnect KCEDZS cable

3 = KCEDZS-C failed from KCECCG (7.12.5)

4 = KCEDZS-D failed 3) Make manual reset

with RESET button on

KMI (11.2)

4) Replace KCEDZS unit

(14.20)

1162 1 KCEDZS board failure - Fatal KCEDZS failure 1) Make manual reset

Manual reset needed with RESET button on

Data 1: KMI (11.2)

1 = KCEDZS-A failed 2) Disconnect and

2 = KCEDZS-B failed reconnect KCEDZS cable

3 = KCEDZS-C failed from KCECCG (7.12.5)

4 = KCEDZS-D failed 3) Replace KCEDZS unit

(14.20)

1164 1 DIP switch error - Configuration DIP switch not 1) Check DIP switch

Unsupported DIP switch supported by SW has been set settings on KCEMSC

ON ON (7.13.1)

2) Make manual reset

Data 1: with RESET button on

Bit coded data, which indicates KMI (11.2)

changed DIPs 3) Perform shaft setup (9)

2 = DIP2, 4) Replace KCEMSC

16 = DIP 5, board (14.26)

18 = DIP2 and DIP5

1165 1 KCEMSC configuration a) Both KCEDZS-A and 1) Check DIP switch

failure - DIP 6 KCEDZS-B board exists when settings on KCEMSC

through type car is not (7.13.1)

configured with DIP switch 2) Make manual reset

b) Both KCEDZS-C and with RESET button on

KCEDZS-D board exists when KMI (11.2)

through type car is not 3) Check that all required

configured with DIP switch boards and cables in TTS

network are connected

(7.5.2)

4) Perform shaft setup (9)

5) Replace KCEMSC

board (14.26)

Copyright © 2018 KONE Corporation 37/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1166 1 KCEMSC configuration Position of DIP switch 6 has 1) Check DIP switch

failure - DIP 6 position been changed after shaft setup settings on KCEMSC

changed (7.13.1)

2) Make manual reset

with RESET button on

KMI (11.2)

3) Check that all required

boards and cables in TTS

network are connected

(7.5.2)

4) Perform shaft setup (9)

5) Replace KCEMSC

board (14.26)

1167 1 Board changed after New board has been installed to 1) Check that correct TTS

setup TTS network boards are connected

(7.5.1)

Data1: 2) Perform shaft setup (9)

1 = KCEDZS-A

2 = KCEDZS-B

4 = KCEDZS-C

8 = KCEDZS-D

16 = KCECCG-1

32 = KCECCG-2

64 = MCU

128 = KCECPU

Data2:

1 = KCEPVSC

2 = KCEABS

1168 2 Linear position failure a) Reading error on KCEDZS 1) Make manual reset

while standing b) KCEDZS alignment to with RESET button on

magnets not correct KMI (11.2)

c) KCEDZS board broken 2) Disconnect and

reconnect KCEDZS cable

Data 1: from KCECCG (7.12.5)

Car position 3) Make manual reset

Data 2: Door side with RESET button on

1 = A-side KMI (11.2)

2 = B-side 4) Check floor magnets

4 = C-side (7.11.2)

8 = D-side 5) Check KCEDZS and

magnet alignment

(7.12.1)

6) Replace KCEDZS unit

(14.20)

Copyright © 2018 KONE Corporation 38/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1169 1 Linear position failure a) Reading error on KCEDZS 1) Make manual reset

when moving b) KCEDZS alignment to with RESET button on

magnets not correct KMI (11.2)

c) KCEDZS board broken 2) Disconnect and

reconnect KCEDZS cable

Data 1: from KCECCG (7.12.5)

Car position 3) Make manual reset

Data 2: Door side with RESET button on

1 = A-side KMI (11.2)

2 = B-side 4) Check floor magnets

4 = C-side (7.11.2)

8 = D-side 5) Check KCEDZS and

magnet alignment

(7.12.1)

6) Replace KCEDZS unit

(14.20)

1170 2 Overspeed start between Lift is driving too high speed 1) Check correction drive

floors after starting out of door zone speed parameters (A9)

1171 1 KCEMSC setup data Setup data on KCEMSC board 1) Make manual reset

corrupted has corrupted with RESET button on

KMI (11.2)

2) Perform shaft setup (9)

1172 1 KCEMSC internal failure Internal supervision has 1) Make manual reset

detected fault with RESET button on

KMI (11.2)

2) Replace KCEMSC

board (14.26)

1173 1 Final limit detection Final limit is active but the 1) Move elevator from

failure during setup direction cannot be detected final limit (7.14.43)

(Bottom / Top final limit) 2) Perform shaft setup (9)

1174 1 KCEMSC board failure - Internal supervision has 1) Make manual reset

Safety input test register detected fault with RESET button on

KMI (11.2)

2) Replace KCEMSC

board (14.26)

Copyright © 2018 KONE Corporation 39/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1175 1 Safety system in Safe KCEMSC is in Safe Mode 1) Make full power break

mode with battery disconnected

(14.6)

2) Make manual reset

with RESET button on

KMI (11.2)

3) Replace KCEMSC

board (14.26)

1176 4 EMC disturbance EMC disturbance on KCEMSC 1) Check that there are

warning board no cables or components

which could disturb

KCEMSC board (7.7.7)

1177 1 EMC disturbance EMC disturbance on KCEMSC 1) Check that there are

warning board no cables or components

which could disturb

KCEMSC board (7.7.7)

2) Make manual reset

with RESET button on

KMI (11.2)

3) Replace KCEMSC

board (14.26)

1178 1 KCEMSC board failure Internal supervision has 1) Make manual reset

detected fault with RESET button on

KMI (11.2)

2) Replace KCEMSC

board (14.26)

1179 1 KCEMSC DIP switch DIP switch 1, 2 or 5 active at the 1) Check DIP switch

compatibility failure same time with DIP 7 in ON settings on KCEMSC

position with G02 (7.13.1)

2) Make manual reset

with RESET button on

KMI (11.2)

3) Replace KCEMSC

board (14.26)

1180 3 Speed information a) Speed measurement on 1) Check KCEDZS and

missing (ADO or ACL KCEDZS does not work magnet alignment

mode) b) KCEDZS internal supervision (7.12.1)

2) Replace KCEDZS unit

(14.20)

1181 1 Door bypass switch Car and hoistway door bypass 1) Switch OFF at least

misuse switches active simultaneously one of the bypass

switches on KMI (7.1.2)

Copyright © 2018 KONE Corporation 40/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1182 1 KCEMSC configuration Position of DIP switch has been 1) Perform shaft setup (9)

failure - DIP position changed 2) Check DIP switch

changed settings on KCEMSC

(7.13.1)

3) Make manual reset

with RESET button on

KMI (11.2)

4) Replace KCEMSC

board (14.26)

1183 1 KCEMSC board failure - Internal supervision has 1) Make manual reset

short circuit on feedback detected fault. with RESET button on

inputs KMI (11.2)

2) Replace KCEMSC

board (14.26)

1184 2 KCEMSC board failure - Internal supervision has 1) Make manual reset

Relay K51 feedback detected fault. with RESET button on

KMI (11.2)

2) Replace KCEMSC

board (14.26)

1185 2 KCEMSC board failure - Internal supervision has 1) Make manual reset

Relay K52 feedback detected fault. with RESET button on

KMI (11.2)

2) Replace KCEMSC

board (14.26)

1186 2 KCEMSC board failure Internal supervision has 1) Make manual reset

warning - Relay K41 detected fault. with RESET button on

feedback KMI (11.2)

2) Replace KCEMSC

board (14.26)

1187 2 KCEMSC board failure Internal supervision has 1) Make manual reset

warning - Relay K42 detected fault. with RESET button on

feedback KMI (11.2)

2) Replace KCEMSC

board (14.26)

1188 1 Safety circuit: Buffers up Pit safety device not active while 1) Check position of pit

input (H7) in inspection mode. safety device (7.3.3)

2) Check wiring and

switches on pit safety

device (7.3.34)

1189 4 KCEMSC board internal KCEMSC has detected a failure 1) Make manual reset

failure in the board internal with RESET button on

supervisions KMI (11.2)

2) Replace KCEMSC

board (14.26)

Copyright © 2018 KONE Corporation 41/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1190 1 Device picked input Device picked input has dropped 1) Check devices

dropped while lift running while lift is running. This can connected to device

happen due to a short power cut picked input (7.3.8)

or a problem in devices

connected to device picked

input.

1191 1 Drive interface type Drive interface type parameter 1) Check that drive

changed after setup has been changed after setup interface type parameter

is correctly set (A6)

2) Perform shaft setup (9)

1192 1 Wrong type final limit Final limit magnet has been 1) Check final limit

magnet changed after setup. magnets (7.11.6)

2) Replace faulty magnet

(7.11.14)

3) Perform shaft setup (9)

1193 1 KCEMSC board failure - Internal supervision has 1) Make manual reset

EEPROM detected fault. with RESET button on

KMI (11.2)

2) Replace KCEMSC

board (14.26)

1194 2 Unintended movement Lift moves out of door zone with 1) Check brakes

warning doors open (7.14.16)

Data 1: Floor 2) Check drive

Data 2: Direction parameters (A1)

1 = down 3) Check rope slip

2 = up (7.14.13)

1195 1 KCEMSC board failure - Setup data corrupted on 1) Perform shaft setup (9)

setup data KCEMSC. 2) Replace KCEMSC

board (14.26)

1196 1 KCEMSC board failure - Internal supervision has 1) Make manual reset

EEPROM on other detected fault. with RESET button on

channel KMI (11.2)

2) Replace KCEMSC

board (14.26)

1197 1 KCEMSC main relay Internal supervision has 1) Check KCEMSC/XD1

failure detected fault. connection and wiring

(7.6.8)

2) Make manual reset

with RESET button on

KMI (11.2)

3) Replace KCEMSC

board (14.26)

Copyright © 2018 KONE Corporation 42/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1198 1 KCEMSC secondary Internal supervision has 1) Check KCEMSC/XD2

relay failure detected fault. connection and wiring

(7.6.9)

2) Make manual reset

with RESET button on

KMI (11.2)

3) Replace KCEMSC

board (14.26)

1199 4 Operation mode not Data 1: 1) Remove at least one of

allowed 1 = Pendant mode is not allowed the bypass jumpers on

when SSA is enabled with DIP 7 KMI (7.1.11)

or 8

1200 1 KCECCG board failure Internal supervision has 1) Make manual reset

detected fault with RESET button on

KMI (11.2)

2) Replace KCECCG

board (14.16)

1201 1 KCECCG board failure Internal supervision has 1) Make manual reset

detected fault with RESET button on

KMI (11.2)

2) Replace KCECCG

board (14.16)

1202 1 KCECCG board failure - Internal supervision has 1) Make manual reset

Safety input cross check detected fault with RESET button on

KMI (11.2)

2) Replace KCECCG

board (14.16)

1203 1 KCECCG board failure Internal supervision has 1) Make manual reset

detected fault with RESET button on

KMI (11.2)

2) Replace KCECCG

board (14.16)

1204 1 KCECCG 24V power KCECCG has detected too low 1) Check that all required

supply failure or too high supply voltage 24VDC powers are

installed (13.5)

2) Check 24V power

supply and cables (13.2)

3) Replace KCECCG

board (14.16)

Copyright © 2018 KONE Corporation 43/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1205 1 KCECCG board failure - Internal supervision has 1) Make manual reset

3.3 V power supply detected fault with RESET button on

KMI (11.2)

Data1: 2) Make full power break

0 = over voltage with battery disconnected

1 = under voltage (14.6)

3) Make manual reset

with RESET button on

KMI (11.2)

4) Replace KCECCG

board (14.16)

1206 1 KCECCG board failure - Internal supervision has 1) Make manual reset

Software version cross- detected fault with RESET button on

check KMI (11.2)

2) Make full power break

with battery disconnected

(14.6)

3) Make manual reset

with RESET button on

KMI (11.2)

4) Replace KCECCG

board (14.16)

1207 3 Serial communication a) Loose TTS cable connection, 1) Check TTS cables and

lost on KCECCG plug not fully plugged in to the connectors (7.5.4)

connector 2) Replace faulty board

b) Damaged TTS cabling on TTS (may be any

c) TTS cables run through board connected to TTS)

potential EMC noise sources (14.14)

d) Damaged board (could be

any board connected to TTS

network)

1208 1 KCECCG board failure - Internal supervision has 1) Make manual reset

No internal detected fault with RESET button on

communication KMI (11.2)

2) Make full power break

with battery disconnected

(14.6)

3) Make manual reset

with RESET button on

KMI (11.2)

4) Replace KCECCG

board (14.16)

Copyright © 2018 KONE Corporation 44/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1209 1 KCECCG board failure - Internal supervision has 1) Make manual reset

Data comparison detected fault with RESET button on

KMI (11.2)

2) Make full power break

with battery disconnected

(14.6)

3) Make manual reset

with RESET button on

KMI (11.2)

4) Replace KCECCG

board (14.16)

1212 1 KCECCG board failure - a) 24 V power supply failure 1) Check 24V power

24V power supply b) 24 V input on KCECCG does supply and cables (13.2)

not work 2) Make full power break

with battery disconnected

(14.6)

3) Make manual reset

with RESET button on

KMI (11.2)

4) Replace KCECCG

board (14.16)

1213 1 Serial communication KCEMSC is sending continuosly 1) Check TTS cables and

stuck failure the same (old) message connectors (7.5.4)

2) Make manual reset

with RESET button on

KMI (11.2)

3) Make full power break

with battery disconnected

(14.6)

4) Replace KCEMSC

board (14.26)

1214 1 Jumper failure on a) Wire jumper on KCEAPS 1) Check wire jumper on

KCECCG KCEAPS connector has been placed or KCEAPS connector

connector removed after making setup. (XB16 on KCECCG)

b) KCECCG board broken (7.7.8)

2) Perform shaft setup (9)

3) Make full power break

with battery disconnected

(14.6)

4) Replace KCECCG

board (14.16)

1215 1 CCG Production Test 1) Internal supervision has 1) Make manual reset

Input Failure in TTS detected fault with RESET button on

FUI

2) If fault remains, replace

KCECCG

Copyright © 2018 KONE Corporation 45/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1216 4 KCECCG TTS Internal supervision has 1) Make manual reset

Nameplate Failure detected fault. with RESET button on

KMI

Data1: 2) If fault comes again,

1 = Electronic nameplate change KCECCG board

missing

2 = Electronic nameplate

corrupted

3 = Electronic nameplate SW

CRC mismatch

4 = Electronic nameplate SW

variant mismatch

5 = Electronic nameplate SW

version mismatch

1300 3 KDEDZS reader unit Internal supervision has 1) Make full power break

broken detected fault with battery disconnected

(14.6)

2) Replace KCEDZS unit

(14.20)

1301 3 Magnet failure - RFID a) Magnet is installed upside 1) Check KCEDZS and

tag missing from magnet down magnet alignment

b) Magnet is broken (7.12.1)

c) Severe external 2) Check position

electromagnetic inteference magnets (7.11.3)

d) Door zone sensor broken 3) Replace faulty magnet

(7.11.14)

Note: It is possible that strong 4) Perform shaft setup (9)

external magnetic field or 5) Check possible

magnetized object in the vicinity sources for interference

of KCEDZS reader may cause (7.14.39)

this fault. This fault may also 6) Make full power break

result if magnet is installed in a with battery disconnected

metallic surface extending (14.6)

outside magnet physical limits at 7) Replace KCEDZS unit

magnet ends (14.20)

8) Perform shaft setup (9)

Copyright © 2018 KONE Corporation 46/117

KCE FAULT CODES R14.2 958174D01 en.N.1

1302 3 Magnet failure - Tag type a) Door Zone Sensor installation 1) Check KCEDZS and

error failure magnet alignment

b) Magnet failure (7.12.1)

c) EMC disturbance 2) Check position

d) Door Zone Sensor broken magnets (7.11.3)

3) Replace faulty magnet

(7.11.14)

4) Perform shaft setup (9)

5) Make full power break

with battery disconnected

(14.6)

6) Replace KCEDZS unit

(14.20)

7) Perform shaft setup (9)

1303 1 Magnet not found in a) New magnet added or 1) Check KCEDZS and