0% found this document useful (0 votes)

31 views4 pagesHazard Management for Fire Damper Installation

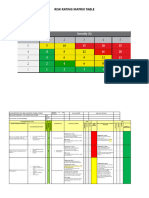

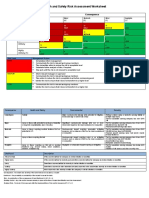

The document discusses the hazards and risk management process for installing a fire damper and motorized damper. It identifies hazards such as falling from heights during scaffolding erection, chemical spills, and working at heights. It provides controls to mitigate these risks, such as using proper scaffolding, PPE, chemical storage, and fall protection. It also describes the emergency response procedure.

Uploaded by

sheik.rasith.anvarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

31 views4 pagesHazard Management for Fire Damper Installation

The document discusses the hazards and risk management process for installing a fire damper and motorized damper. It identifies hazards such as falling from heights during scaffolding erection, chemical spills, and working at heights. It provides controls to mitigate these risks, such as using proper scaffolding, PPE, chemical storage, and fall protection. It also describes the emergency response procedure.

Uploaded by

sheik.rasith.anvarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd