Professional Documents

Culture Documents

Steel Connections Bolted Joint Design

Steel Connections Bolted Joint Design

Uploaded by

Shindiya Lal0 ratings0% found this document useful (0 votes)

3 views26 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views26 pagesSteel Connections Bolted Joint Design

Steel Connections Bolted Joint Design

Uploaded by

Shindiya LalCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 26

JS TRMCTARA. STEER

Conilecmioni¢ / THeoky ¢ DESUN |

PARTE | Boutey conmections

‘Coy alg go GNNE CTOs Confonersig

(eg. ppletis, bvsdbeds) aut

CONNECTRRS oe s Be belie mene)

The Come will oe ean

f Te Comic crees (welts fe

3.1.6_BOLTED CONNECTION GEOMETRY

‘Minimum Edge Distance

Minimum-edge distances from the centre of a bolt

hole to the edge of a plate or the flange of a rolled

section are specified in AS 4100 as fotlows—

1.75 d+ for sheared or hand flame cut edges

1.50 4; for machine flame cut, sawn or planed

edges

1.25 d; for rolled edges or rolled sections

— where d; is the nominal diameter of the

fastener.

Table 3.1.6.1 lists these minimum edge distances

for commonly used boit diameters.

‘Maximum Edge Distance

AS 4100 specifies the maximum edge distance

from the centre of a bolt to the nearest edge. This is

limited to 12t, or 150 mm, whichever is the lesser,

where t, is the thickness of the thinner outer ply.

Minimum Pitch of Bolts

Minimum pitch of bolts is specified in AS 4100 to

be 25 times the nominal diameter of the bolt

Howover, if it is intended to tension bolts with a

special tensioning tool, the minimum distance

between the centres of bolt holes shall be

appropriate to the type of tool used.

Maximum Pitch of Bolts

Maximum pitch of boits is stipulated in AS 4100 to

be the lesser of 15t, and 200 mm where t may be

taken as the thickness of the thinner outside ply.

However, in the following cases the maximum

distances shall be:

(@) For fasteners which are not required to carry

design actions in regions not liable to corrosion

the lesser of 32t, and 300 mm.

TABLE 3.1.6.1 :

MINIMUM EDGE DISTANCES

Nominal | Sheared | Rolled Plate;| Rolled

Diameter | orHand | Machine | Edge

of Flame | Flame Cut, | ofa

Fastener | CutEdge | Sawnor | Rolled

dy Planed Edge| Section

mm mm mm mm

12 24 18 15

16 28 24 20

20 35 30 25

24 42 36 30

30 53 4 |- 38

36 63 54 45

(b) For an outside line of fasteners in the direction

Of the design force the lesser of 41, + 100 mm,

‘and 200 mm.

Bolt Holes,

The diameter of bolt holes in bolted connections is

stipulated in AS 4100 to be larger than the bolt

diameter by either-

2mm_ for M24 bolts or smaller

3mm_ for bolts larger than M24

6mm for holes in base plates

In some applications, thé use of slotted or oversize

holes may be justified in order to ease erection

difficulties. The large oversize holes permitted in

base plates is to assist in column erection and is

related to the out-of-position of anchor bolts

permitted in AS 4100.

‘AS 4100 also makes provision for the use of short

and long slotted holes and oversize holes, and the

detailed provisions for such holes are summarised

in Table 3.1.6.2.

tt A veamelor

“a

AJAX SPURWAY FASTENERS

NEW ZEALAND

PO. BOX 30026 LOWER HUTT

‘Metric High Strength

\, Structural

Bolts & Nuts.

Metric High Strength Structural Bol & Nuts

General Grade. (ISO Property Class 88) ISO

Metric Coarse Pitch Series Threads. Class 69.

~ Relevant Australian Standard, 1252 i

1.DIMENSIONS £ -

4

All dimensioas in miimettes

Pich | Shank Head md

Nominal of Dia Across Flats ‘Thickness Thickness:

Diameter | Thread ds s k m

D a

mie [20 | 1870 11590 | 27 | ees6 | 1075 | 026 | 171 | 1600

mzo| 25 | 2ose | 1016 | a2 | 3.00 | 1390 | 12:10 | 213 | 2000

Maz [ 2s | 2286 | 2136 |_a6 [3500 | s40 | 1310 | 2330 | 22.00

m24_| 300 | 2404 | 2316 | 41 | 4000 1590 | 14:10 | 253 | 24.00 | Note, Thread lengths,

30 [35 | sose | eae | 50 | 49001 1975 | 1765 | 513 | 3000 | dimension b,

a6 | 40 | ara 13800 | 60 | saeo | pass | 145 | 376 | 9800 | refer over.

BREAKING AND PROOF LOADS. The following tables list tensile breaking and

See proof loads of Ajax Spurway bolts calculated

from tensile on proof load stress and ‘Stress

Area" of the thread, and nut proof loads, and

are based on:

BOLTS NUTS

‘Tnsile Strength “Proof Load” Stress Proof Load Stress = 1075 MPa (Nim)

1830 MPa (Nimm) min, 600 MPa (Némm') min, (on stress area of BLACK NUTS

420 Kipsfin' min. 87 Kipsfin’ min. corresponding bolt) = 1165 MPa (Nim)

536 tontfin’ min. 388 tonffin’ min. GALVANIZED NUTS

4 Kip = 1000 Ibt

Tensile BOUTS: NUTS

Nominal} Stress

Got | Arcsot | Breaking Load Procf Load rool Lose

Diameter) ‘Thread Minimum binisiaie Black Galvanised

D mm’ _|~kN 1 Kips [tont_[ eT Kins [tof iN KN

wie _|_167__| 190 | 292 | 1904 | 942 | on.2 [94s | 169 183

zo [pas | 203 | 456 | 2037 | 1470 | oa0 | 7475 | 263 285

zz {303 | 252 | 567 | 253 | 182 | 409 | teas |" 3257 3529

M24 353. 293 | 658 | 2040 | 2120 | 476 | 21.27 379. att

MSO. 561 466 |" 1047 | 46.76 | 3370 | 75.7 | 3382 603, B54

M36. BIT e7a_| 162.4 | 6804 | 4900 | 1101 | 49:17 78 952.

Continued over.

©

AJAX SPURWAY FASTENERS

NEW ZEALAND

PO. BOX 30026 LOWER HUTT

3, LENGTHS OF STRUCTURAL BOLTS.

rls

Nominal bor dametr D

Sopht eh we] a wee] Wa 1

Bay his and rp nis

‘ @[al4| «lela él 4

Tem ran. | ax [min [ax | mon | mex ran, [ma

0 s]*l-7-|-]- See

’ | ae | fs) — | — ee

© s[ iti fizs| = | = ot

55 Wy wr] to 175 | a] ar oy fg

60 wi] 2{io jive} i) 21 -|[- ~

65 a] ar pispae | 2] 2 ooo

m| ee fies| 2 | sal Se

% ai] ar [ars| a [ae] ar eet

0 as| @ [aos] oe | 7b oe aoe

rs | artars| a | 2 | 3 | 9 |

* a5] 52 [355 | ae | 27 | 36 8 | 30

ES | sr [ais | a | | a we | 2

+00 se] se ]ass| se | a7 | a6 xa | 30

0 & | 7 [ses |e | | se a

120 me |e leas| % | s7| oe a| 42

420 |e |1a2 | a | 09 | 705] 78 | ot | 70 a | 6

uw [ise |s42 | Go| 98 | aos] a | 7] a a | 5s

as [40 |s52 | 100 | x05 | 05] 98 | er | 90 | 66

veo fics jase | si | 300 & | 7

0 [ree five | 101 | 10 va | os hs

180 | 176 | 184 = pope] am | it fi a4 | 96 —~| 4s

soo [wee fies | — | > | = |X | tas | t20 4 | 108 |

zo fase fae | = | = | = |X | ass | 40 sos | 116

zo fae jee | — | — | — | = | tae | se tn | 128

20 [oe [as | — | = | = | = | 58 | 67 wa | 8

1. Body Length (¢s) 2. Grip Lengthi¢g). 3. Bolts with lengths above the

‘The distance from the bearing ‘This distance between the heavy line have thread lengths

surface of the bolt head to the last bearing face of the head and — shorter then the nominal

‘scratch of thread, or top of the: the nearest face of a nut with Jengths reierred to below.

extrusion angie, whichever is ‘io countersink, when serewed

coser fo the head. conto the bott as far as

practicable by hand.

{his represents the approximate

minimum thickness of materials

which can be clamped, excluding

the washer thickness.

4, NOMINAL THREAD LENGTHS 7

em bok | Basis for

iat” | onan | Nomina tng ches» REFER TO TECHNICAL DATA SHEETS —

Z D ints [a0 [iba [Mb TS 2/90 FOR METRIC HIGH STRENGTH

7 = ‘STRUCTURAL WASHERS.

laos easy tl Etentet sett] seit ge-Paot [ore tt ee 3190 FOR CORONET® LOAD INDICATING

3 200 z+2s | — |e | 7 | as [97 WASHERS.

4/90 FOR ASSEMBLY, TIGHTENING AND

Note. These thread lengths are not applicable to INSPECTION PROCEDURES.

bolt lengths above the heavy line in the above

Distributed by:

en

WELLINGTON SALES AUCKLAND SALES CHRISTCHURCH SALES PRUE

18.25 SEAVIEW ROAD 104 HUGO JOHNSTON DRIVE CNA COLOMBO & BEALEY AVENUE

LOWER HUTT PENROSE ‘CHRISTCHURCH

PHONE (04) 682 244 ‘AUCKLAND, PHONE (03) 652 902

FAX (04) 684634 PHONE (09) 526 1143, FAX (03) 652.040

FAX (08) 525 1148, *

Bete in stehe

‘

\'p < Py a ¢ nea poke AV

Crefec Teele ow e io, which pres dofin sons)

NITE! Beth shear chengtis have bee, o¢teblrchedl

air Ond ove velated to INAiAt eae

by tog

Tensile MoT yal chength,

SHERR AREA wy : :

aoe 3245

SS 3.2 (dt) @®

sreec ices ue!

diandle-efhole elongertes

For short end distances &e. plate tearout failure will ooo

before plate bearing failure

>

and inthe case_| V\= aete fe

That is when the edge distance is less than 3.2dgthe second Forel

equation for Vi, becomes cia ene

REFER Lecruge aires $2. fee

BoLTeD CONNECTION Geometgy————

Ceortinned

fem )

Fadkwe aAooss “Thesthy can ako oceuwy

refer (b) 4 ©) om chagrane below !—

Ne Powsk Ae e

PN =PAg &, , whichever is les.

where 1— I von 045 ~ Woo (Le eccost: icy)

Pq = Ares aren, > Paz nl avea,

45] =

o a @

+ G@ HE

@ @

ca

Figure 8.7 Bolted shear conn: vais andthe potential eves of flr ofits (a Plate fractures

) Bol ls) Crbing on melt el sank (d) Plate tearing failure;

(© Pa frre ober balan cred) Bok bk ie

ond Pte ete ade pac! —

N * < PN :

leads to slippage

Bolt Grades

There are two bolt grades generally available

© Grade4.6 (f, = 400MPa)

Gradeae (1, = e80NPs) ——pe Typical

Grade 4.6 can be used only in the snug tight mode and is generally used only for very lightly

loaded connections, and/or timber to steel connections, not being cost effective otherwise.

8.2.2 Bolt Modes ( Grade 8.8)

Grade 8.8 bolts are high capacity connectors, and are used for all major bolted connections.

‘These can be used in 3 different load carrying modes

+ Snugtight (8.888) ——> typed

‘+ Fully tensioned ~ bearing action ( 8.8/TB ) r

‘+ Fully tensioned - friction action ( 8.8/TF )

A grade 8.8/S (snug tight) mode bolt provides a high éapacity, easily installed, cost efficient

option in terms of cosUkN of force transfer. Bolts are tightened manually to bring all the

connection ply interfaces into full contact, but without the need for further tightening to achieve a

minimum installed bol tension, as load transfer is entirely by bolt shear from the plys bearing

i

against the bolt shank. 8.8/5 is normally used in simple construction, i.e. where the primary

~Ioad transfer mechanism is via boit shear, and any moment transfer is by means of the bolt

group eccentricity, e.g. a simple web side plate connection. Some slippage andior rotation of

the bolt group under load wil occur.

Table 8.2.2 : Grade 8.8 Bolt Capacities, for 8.8/S and 8.8/TB

| Shear Capacity (Single shear)

Bolt Size | Axial Tension | Threads Included in| Threads Excluded from

Capacty | Shear Plane (6.8NIS) | Shear Plane (8.8X/S)

Oy (KN) OV (KN) OV, (KN)

Lute 14 |g 827

a) 163 92.6 129

M24 234 133 186

M30 373 214 291

ws | 541] at 419

Note :

1. For ultimate limit state combined shear and tension see Clause 9.3.2.3.

2, The no-siip friction mode 8 8ITF is a serviceability limit state condition

Further information on bolts and bolt design is provided in the HERA Design Guides [10] in

sections 1.5, 10.2.3, & 103.

3.1.3 AS 4100 DESIGN REQUIREMENTS — STRENGTH LIMIT STATE

3.1.3.1 General

The strength limit state design provisions which apply for static load applications are found in Clause 9.3.2 of AS

4100. These provisions are summarised in Table 3.1.3.1. The design provisions follow directly from the strength of

bolts discussed in Section 5.13 and References 2 and 36,

TABLE 3.1.3.1

AS 4100 CLAUSE 9.3.2 PROVISIONS

STRENGTH LIMIT STATE—STATIC LOADS

Limit

State

‘AS 4100

Clause

“Design Requirement

Bolt in

Shear

93.21

ow

jesign shear force

.ominal capacity in shear

B2hyk A,

apacity factor = 0.8

minimum tensile strength of bolt (Table 3.1.1)

100 MPa Grade 4.6 to AS 1111

330 MPa Grade 88 to AS 1252

reduction factor for bolted lap splice connections

(Gection 3.1.3.2). For all other connections, k, = "1.0

available bolt shear area (Section 3.1.3.3),

Fora single bolt with single shear plane, threads

included, A, = A, core area.

For a single bolt with single shear plane, threads

excluded, A, = Ap shank area.

Bolt in

Tension

93.22

lig SO Ny

fesign tension force

Ny = nominal capacity in tension

Bolt in

Shear

and

Tension

93.23

Plyin

Bearing

93.24

Ve

design bearing force on a ply

nominal capacity of ply in bearing

32 dit; typ (local failure)

sty hp (tearout failure)

capacity factor = 0.9

bolt diameter

thickness of the ply

minimum distance from the edge of a hole to the edge

of a ply in the direction of the component of force plus

half the bolt diameter

fy = tensile strength of the ply

AISC: DESIGN OF STRUCTURAL CONNECTIONS DsC/o4—1994

exefu * 4

TAH the connection inclicaled Se

ly lott shea stew / cale he

Matimum ULS ( encdabte) Jensile arenglh

PN 5 heat can be cusghained,

LJ

Take kK =10, Milnes bet

Co result debited yale

we “tke er Cohen 4).

x ref ug 4} Covuttons

Both we Geshe shee bat one Shear

we wreobn dos Leb Theeds, te Aha

ont has The beth shosk

Ie -4 ocafif A+ Ae

—> f= oF Hes)

{. = 8%o wR

fro = BI mel

Ke = 225 mak ©

-(spVp = 222 ku —e = BN, (Ho),

Corpeoe “Palle B24

M20 —2 PV = Jue

a 2400

2 aarlks = PACH).

Vx

Exams #2

4) for The Connection Crag 4, Cox fen

he ney. (or Stherwnse) oe On

rene (fone tenet a) od

ovker ( [edunc Zmm thik C2),

Tho blk of focalad cockrully Trend Te

Pies wh an end chstarce(ae) “ Orn,

Mucincum henslle the cometioy

4 = 440 Me, on Minin

Ne

xy <— N*® 222k

: —

De <——

b) ae to 1 and Con tack cespectvely,

TRE 1.3) be vere cdlagne

Cot tiermse DQ end-Asvhence ae)= a?

[Aoke 413) ble nates |

@

te #2! Seuctins

STR O

Ontos, hy Henssle Seathure, J yseha

(mer PLY (Geckice) Bonn Wy (fehwe)

Pir FORALL, | yheecpoar tf,

= 0 frote feea)

a “dN 2 as ae

a Ny = 31Sky —p =

Inn Ry (pola) Foun Poy (gold

ios | tons

* OF toy 142 3x0

= PN Baek —p

7 = Bape

dys BL | cyoks +

STER@ ; Check Ply bears hres Palace

[Dem Py beeen.

AL $32} (dp-t,)

F O42 EUO * Zoxe17

ABU j= Bo kes ab

®

bly

Qa nm Wy (ew)

PM> Pea fie(g-4)

BoE xre _ Sofi as

we

S

Ak Pry “fearoct“ fube,

Vane Puy

pl, Pato fy

ea 0-4xe(Gbxi2) x teeo

Dl = 237 ka — >

*

U5 cra Ne = ltl kw

Conpere te leagt vafue

Go Hepsi 2,3

“ Mivcpatin de fe-dabte

a ee

ae Wh kes -

Bou Ry

p4- pact fy

= OF xCox20)x “YO

~p\y- 396 ka —>

us foce =I 222 kw

dite

\

Mic nicer

Copenty = 39h kn

= NE hark

Co

Confirven Fopse RF,

Cafe eomong could probally bay reduce al

@ e

«se Rot

foretnes§

9.1.3(b) Design Capacities of Commonly Used Bolts — Strength Limit State

HIGH STRENGTH STRUCTURAL BOLTS Perey

8.8/S, 88/18, 8.8/TF BOLTING CATEGORIES :

TABLE 9.1.3(b): Design Capacities

(fut = 830 MPa)

[ Single Shear Plate Tearout in kN Bearing in kN

ial | Threads | Threads Mp for fh & aot: $¥etor

Bolt | Axial included jexcluded’ (forte *

in Shear

Pian | shear h=6 | h=8 | h=10| =12 6 | 8B | 10

| Plane 2

oN OVin_ | OV I Ni

kN kN KN '35|40|45|35|40/45/35|40/45(35|40| 45.

mis | tod | 593 | 827 190] ¢ 122 | 162 | 203

M20 | 163 | 926 129 | g3/95|to7/111/137\14alra9ltsali7aies| [rad 152 | 208 | 253

M24 234 | 183 186 h"_ 182 | 243 | 304

mao | 373 | 214. | 201 | 228 | 304 | 380

was | 541 [313 | 419) a> Aomin = 1.5 Ob __| 274 | 355 | 456 |

o= o= 09

$= 08) sens | 8.8XiS fi = 440 MPa fuy = 440 MPa

Note:The above table lists the design capacity of d ply in bearing for Grado 900 (f= 440 MPa) steel only. For stings and guidance on

design capacities ir ply faiure in other grades of steel refer to Section 2.14.

‘thread excluded from shear plane

—— —— — thread included in shear plane

|

300

TNO ALE

0 50 100 150 200. 250 300 350 400

TENSION, Nf (kN) (le)

Figure 9,1.3(b): Shear - Tension Interaction Diagram

ocro2nvs-ts4- AISC:.DESIGN CAPACITY TABLES FOR STRUCTURAL STEEL 9-5

ANALYSK fe BELT Zhoule

es

0) GANECrioNs Lenten “sy Roane”

(D Cormections Leroen * Out-or_Rawe!

© AN-Rme cennlecn

Fn thes, cate, The lead sc pts only

ow tek ne The betts

bet ex: res by Capderction

ae c ce creme in sng

=p

re

mod

STEAD

—

perenne a st" de dvect actiore

ont oo Dro cc ba

at

©) " |

tes ic © +)

hee MET a

fee pol

Fav the Ey pas, <

ws ‘io pia ee ac

[ER mom Pom Lett vets,

oe

ae Jo ku

oh ME 2 42 knee.

a

Se

CaleLati belt ghea deah Deer Aces.

fe | The shear shes uc bk

r oF ane t) end dish

fee +)m* & ene Shreve Mechanics i

foo | we . Mir c

To 2.3

lot om shes -h Lone.

“Vy = Mie zt Me

3 & Ser

~~ adic ethane eo walwates, -

2r= a4) :

1

oom

Mg ME Ve ie |

2(eep) Sen)

eongat ree ~)

eed) [oe fs

O BOR) = FE Sw

ae « o Lesed ov Ne reo

hip crewed More — tis will be Be ene

al opectet wy value,

X= ISP FS

Y= ISO me

A Muoge 4ax ese 2 Ble

#4, 509

Vesey = fe On 2 fobs >

AF So

Skt @

Commie atl four shear Components

dee The ck CrNteme elk,

his

Vee 2s Vem) = Bupha.

Taha Gate bet are a SWsGee SHERE |

Asgume Leth chads ae inckudod wi the

cheer (one ( ‘@ &F N/s)

for vag Paka —dte Mac /ees betks

> Telke Vi ab (pie) + AVp, = GWulky

kn

We @N° Macleans bets aia (ee

@

A) Ou-v¢ Pinte Bours ‘ecm

fade a typeral odd} Iptene,

Pane ae as 3 3

S Aetiow

Say N® 120 kes. uu

al .

* ke,

a M's ISo £8.

Be V¥ = bo ka. g c

beets og, batt gan (datn > ep hb)

Phe [2m (e+ amex] rlaenas)]

GN

-TWe tySa~ (rows E ap beti- rom)

2 Ban Cheln ff bear),

Tt beam acl n®

rer oe en

Nt Se kes s *

Ms = Son vurfe Oy Kes se .

CNet Hemost nm Connection = ISo— wy

pees reece

STEP ®

Caledate belt seer,

VF = bok.

VE 2% = Pore ees — >

GD

SRD

Cahedde QureX edt tegen

oe eens

Nie Be» debe poche

StS)

Clea bet Rano® dreds Memes

fin Chad steer sha

Wehatensship col be

wed to Asta;

NE Wel BeAb Ato

(aux TA) +(2nxTid,) = 0

wee Ap USY-I% — Ge / a3SRen

atk dj, x 358— Fo = haw

CD

aq, 03st) 4 aT, (osx) = eG

“A oO MET, a oSPT = 1406 —e

ak TT = ie

—pP.

358 ASE

Ee Te toe T

Subrbttin,

DHe (urgsTe)t OSH Tr > M046

one Th = leorka-

Ts RR RSS

RR ©

For cocheat (lye) bells

ae 125 bes Par bk

ste?

Force, Liter Aches (pec belt)

& Ne 12 +20 = ERK (Teron)

EVE = Joka (sword)

He

es)

—>

i Akon Poeun '

(ae) “(Gey < lo

ey Nae | es bats ;—

a —

AVp = WE ko

ae 163 a |

&) +(“2). 6

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- KL 1, MD 1Document2 pagesKL 1, MD 1Shindiya LalNo ratings yet

- Double Stringer Staircase Loads, Moment and ShearDocument2 pagesDouble Stringer Staircase Loads, Moment and ShearShindiya LalNo ratings yet

- Gantt ChartDocument5 pagesGantt ChartShindiya LalNo ratings yet

- ULS (KL 1, MD 0.9)Document9 pagesULS (KL 1, MD 0.9)Shindiya LalNo ratings yet

- Updated Gantt ChartDocument5 pagesUpdated Gantt ChartShindiya LalNo ratings yet

- Initial Project NetworkDocument2 pagesInitial Project NetworkShindiya LalNo ratings yet

- Shipping Container Connections Catalogue 01 09 19Document13 pagesShipping Container Connections Catalogue 01 09 19Shindiya LalNo ratings yet

- 1Document2 pages1Shindiya LalNo ratings yet

- Chapter 31 - Special Construction, California Building Code 2022 (Vol 1 & 2) - UpCodesDocument4 pagesChapter 31 - Special Construction, California Building Code 2022 (Vol 1 & 2) - UpCodesShindiya LalNo ratings yet

- LID PlacementDocument1 pageLID PlacementShindiya LalNo ratings yet

- Engineering Structures: Yi-Fan Lyu, Guo-Qiang Li, Ke Cao, Si-Yuan Zhai, Heng Li, Chen Chen, Yuan-Zuo WangDocument17 pagesEngineering Structures: Yi-Fan Lyu, Guo-Qiang Li, Ke Cao, Si-Yuan Zhai, Heng Li, Chen Chen, Yuan-Zuo WangShindiya LalNo ratings yet

- LID RepresentationDocument1 pageLID RepresentationShindiya LalNo ratings yet

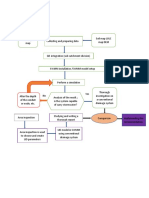

- Flow Chart of MethodologyDocument1 pageFlow Chart of MethodologyShindiya LalNo ratings yet

- Petrol PotentialDocument17 pagesPetrol PotentialShindiya LalNo ratings yet

- DCP Fill SheetDocument1 pageDCP Fill SheetShindiya LalNo ratings yet