Professional Documents

Culture Documents

Calculating Lube Requirements Graco

Calculating Lube Requirements Graco

Uploaded by

A0 ratings0% found this document useful (0 votes)

5 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views2 pagesCalculating Lube Requirements Graco

Calculating Lube Requirements Graco

Uploaded by

ACopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Calculating Lube Requirements

VOLUME REQUIRED Gears - Calculate Each Gear in Train

V = A x T x Service Factor A = π P.D. x W

A = Equivalent Area π = 3.14

T = Film Thickness P.D. = Pitch Diameter of Gear

W = Width of Gear

SERVICE FACTORS AFFECTING VOLUME Large Bull Gears

Service Conditions Service Factor Severity

A = 2 π P.D. x W

π = 3.14

Standard in Plant 1.0

P.D. = Pitch Diameter of Pinion

Shock Loading 1.3 — 3.0

W = Width of Pinion Gear

Extreme Heat 1.3 — 3.0

High Speed 1.0 — 0.5

Dirt & Water Environment 1.3 — 8.0 Worm Gears

Process Contamination .75 — .25 A = π (P.D.1 + P.D.2) W

π = 3.14

P.D. = Pitch Diameter of Worm

FILM THICKNESS, REPLACEMENT P.D.2 = Pitch Diameter of Worm Gear

Manual System — Terminating W = Width of Worm Gear

• Grease – 0.002 Film Thickness per Application (8 hours)

Automatic System — Terminating Labyrinth Seals

• Oil – 0.001 Film Thickness every 1 hour period A = πDLx3

π = 3.14

• Grease – 0.001 Film Thickness every 4 hour period

D = Shaft Diameter

Automatic System — Circulating L = Total Length of Sealing Surfaces

• Oil – 0.001 Film Thickness every 1 minute period

Ball Screw

EQUIVALENT AREA A = π P.D. x (Rows + Length of Travel)

Rolling Element Bearings π = 3.14

A = D2R P.D. = Pitch Diameter of Ball Race

D = Shaft Diameter Rows = No. of Rows in Engagement with Shaft

R = Number of Rows (Consider each row 1”)

(Consider needle & long roller types as two rows)

Chain

Plain Bearings A = 3DW + .1LW

D = Sprocket Diameter

A = π DL

W = Chain Width

π = 3.14

L = Chain Length

D = Shaft Diameter

L = Length of Bearing

Linear Guide Bearings

A = D2 x 3

Slides, Gibs, and/or Ways

D = Shaft Diameter

A = LxW

Notes:

L = Length of Surface

1. All units are in inches

W = Width of Surface

2. These general guidelines for calculating lubricant replacement volumes will

(Area of Largest Contact Surface) normally provide adequate levels of lubrication. However, since every operating

condition on each different type of equipment is beyond the scope of a single set

of guidelines, it is the equipment builder’s and/or equipment user’s responsibility

to insure that the lube points on his, or her equipment receive adequate

lubrication under the actual operating conditions encountered.

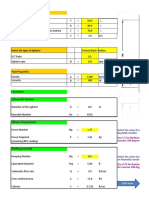

Lube Design Chart

Customer: ________________________________________________ Type of System: Manual Automatic Date: ________________

Machine or Equipment: _______________________________________ Lubricant : _____________ Operating Tem. (F): _____________ Page ____ of ____

Ref. Bearing Volume Lube Volume Divider

Location or Name of Bearing Notes

No. Size Type Calculation (CU.IN./HR) Grouping

All written and visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

Contact us today!

To receive product information or talk with a Graco representative,

call 800-533-9655 or visit us online at www.graco.com.

©2006-2009 Graco Inc. Form No. L20115 Rev. B 3/09 Printed in U.S.A. All other brand names or marks are used for identification purposes and are trademarks of their respective owners. All written and

visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

You might also like

- LTM 1200-5.1 - (069553) - 200624 - 110036Document1,648 pagesLTM 1200-5.1 - (069553) - 200624 - 110036노란깔깔이100% (3)

- 220C Ultra C Bell Feller BuncherDocument265 pages220C Ultra C Bell Feller BuncherFernando Emmanuel PradoNo ratings yet

- 722.6 AtraDocument10 pages722.6 AtraTransmisiones Guero100% (7)

- Chevrolet Indo 2018Document802 pagesChevrolet Indo 2018jeffryNo ratings yet

- ChaptersDocument11 pagesChaptersshriramnimbalkar99No ratings yet

- METHODOLOGYDocument14 pagesMETHODOLOGYKipkirui YegoNo ratings yet

- LSG007 - Automated System DesignDocument6 pagesLSG007 - Automated System DesignwilmerNo ratings yet

- ACCROPODEII Design GuidelinesDocument41 pagesACCROPODEII Design Guidelinesborsacidayi06No ratings yet

- Du BushDocument39 pagesDu BushDevang RathodNo ratings yet

- Milling 23Document25 pagesMilling 23KhabirIslamNo ratings yet

- Du Dub PDFDocument55 pagesDu Dub PDFSURESH100% (1)

- Delta PTDocument6 pagesDelta PTWK SinnNo ratings yet

- Design of Agitator 8 Batch Volume PDFDocument3 pagesDesign of Agitator 8 Batch Volume PDFakash kumarNo ratings yet

- Руководство По Эксплуатации На Термопласт Un-230epiiiDocument69 pagesРуководство По Эксплуатации На Термопласт Un-230epiiiДмитрий ТарасенкоNo ratings yet

- Test Data API 610Document4 pagesTest Data API 610Anton PaneNo ratings yet

- Design Process of Rotating Electrical MachinesDocument28 pagesDesign Process of Rotating Electrical MachinesAli HashemiNo ratings yet

- Bearing Design Method BDocument38 pagesBearing Design Method BTeguh FahrezaNo ratings yet

- Bearing Design MethodDocument38 pagesBearing Design MethodTeguh FahrezaNo ratings yet

- Strip CladdingDocument8 pagesStrip CladdingRenny DevassyNo ratings yet

- A Design Approach For Automatic Tyre Inflation SystemDocument3 pagesA Design Approach For Automatic Tyre Inflation Systemseid negashNo ratings yet

- Manhole ScheduleDocument7 pagesManhole SchedulejibinNo ratings yet

- Winche Lantec Spec SheetDocument4 pagesWinche Lantec Spec SheetisraelitajudaNo ratings yet

- FLOW - CASE STUDIES and SELECTIONDocument32 pagesFLOW - CASE STUDIES and SELECTIONshiva100% (1)

- Angle of Nip PDFDocument11 pagesAngle of Nip PDFanasabdullah100% (1)

- Basics of GrindingDocument18 pagesBasics of GrindingmaulikgadaraNo ratings yet

- GGB DU BearingsDocument52 pagesGGB DU BearingsMSc Kostic MilosNo ratings yet

- What Is Blade Loading and How Is It Specified - by ADT - MediumDocument1 pageWhat Is Blade Loading and How Is It Specified - by ADT - MediumZain KhanNo ratings yet

- Flexibond Agitator ModificationDocument26 pagesFlexibond Agitator ModificationGLENDA CASINONo ratings yet

- FlywheelsDocument2 pagesFlywheelstisha revillaNo ratings yet

- Agitator Power Requirement and Mixing Intensity CalculationDocument26 pagesAgitator Power Requirement and Mixing Intensity CalculationNitin KurupNo ratings yet

- Design of Two-Way SlabDocument48 pagesDesign of Two-Way SlabAboobackar SidheeqNo ratings yet

- Bearing Design Method ADocument6 pagesBearing Design Method ALartit LIANTHAVYVANHNo ratings yet

- Reactor Geometry: MM MM MMDocument26 pagesReactor Geometry: MM MM MMDaniel Agudelo RinconNo ratings yet

- Ventury Ejector CalculatedDocument26 pagesVentury Ejector Calculatedbudi utomoNo ratings yet

- S-Ind-e-03-Eng-Eng-12-001 Rev001 Measurement Sheet of Electrical Maintenance Checking ReportDocument1 pageS-Ind-e-03-Eng-Eng-12-001 Rev001 Measurement Sheet of Electrical Maintenance Checking ReportDeepakNo ratings yet

- 15 SlabDocument3 pages15 SlabNiranjan ShresthaNo ratings yet

- Staircase Design FinalDocument18 pagesStaircase Design FinalSiddiqui RanaNo ratings yet

- PC300LC-6 (A80001 - )Document3 pagesPC300LC-6 (A80001 - )julianoNo ratings yet

- Agitator Power Requirement & Mixing Intensity CalculationDocument26 pagesAgitator Power Requirement & Mixing Intensity CalculationYusuf DabhiyaNo ratings yet

- King Buchas DUDocument53 pagesKing Buchas DUAilson CarnierNo ratings yet

- Base Plate Design Is 800-2007Document6 pagesBase Plate Design Is 800-2007soumyaNo ratings yet

- Manual d3 Engine 30 08 08Document102 pagesManual d3 Engine 30 08 08Anil kumarNo ratings yet

- MPM 312 03 08Document3 pagesMPM 312 03 08Mousa PetrolNo ratings yet

- Two Way SlabDocument47 pagesTwo Way SlabSuson DhitalNo ratings yet

- Agitator Power Requirement and Mixing CalculationDocument26 pagesAgitator Power Requirement and Mixing CalculationNeeraj BhallaNo ratings yet

- IEC Hydro Noise Mass 4C R1bDocument16 pagesIEC Hydro Noise Mass 4C R1bJeromeNo ratings yet

- Agitator Power Requirement and Mixing Intensity CalculationDocument26 pagesAgitator Power Requirement and Mixing Intensity CalculationSIL PROJECTSNo ratings yet

- Agitator Power Requirement and Mixing Intensity CalculationDocument26 pagesAgitator Power Requirement and Mixing Intensity CalculationVaibhav KaleNo ratings yet

- Chapter 2 MotionDocument49 pagesChapter 2 Motionaman muleNo ratings yet

- Flexican: "Design Calculation of Bellows Subjected To Vacuum Condition" As Per CODE EJMA Clause No: 4.15Document2 pagesFlexican: "Design Calculation of Bellows Subjected To Vacuum Condition" As Per CODE EJMA Clause No: 4.15Raji SuriNo ratings yet

- Strainer Pre. Drop and Sizing CalcDocument6 pagesStrainer Pre. Drop and Sizing CalcChandrakant SalunkheNo ratings yet

- Angrenaj MelcatDocument4 pagesAngrenaj MelcatDiana Maria CozmaNo ratings yet

- Machine Operation CalculationsDocument9 pagesMachine Operation CalculationsGangadhar NavnageNo ratings yet

- Details Centrifugal FanDocument6 pagesDetails Centrifugal FanNguyễn Đình TháiNo ratings yet

- Padeye CALCULATIONDocument9 pagesPadeye CALCULATIONramana_96392699No ratings yet

- CRT InquiryDocument2 pagesCRT Inquirysalman buttNo ratings yet

- Agitator Power Requirement and Mixing Intensity CalculationDocument26 pagesAgitator Power Requirement and Mixing Intensity CalculationNitin KurupNo ratings yet

- DP4 UsDocument46 pagesDP4 UsRaja Sekaran SajjaNo ratings yet

- Gear Calculation Worksheet: and A - Follow The Steps BelowDocument1 pageGear Calculation Worksheet: and A - Follow The Steps Belowتاج نيسهاNo ratings yet

- Agitator Power Requirement and Mixing Intensity CalculationDocument26 pagesAgitator Power Requirement and Mixing Intensity CalculationChemical Engineering100% (2)

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Document8 pagesUsing The ASME VIII-1 Nozzle F Factor (UG-37)Liu YangtzeNo ratings yet

- Kohler Generator g2166Document4 pagesKohler Generator g2166philipNo ratings yet

- Agitator Power Requirementand Mixing Intensity CalculationDocument26 pagesAgitator Power Requirementand Mixing Intensity Calculationkkaranag100% (1)

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- OilTestCardDocument1 pageOilTestCardANo ratings yet

- SKF F4BC 25M-CPSS-DFHSquare Flanged Ball Bearing Unit With Set Screw Locking and Narrow Inner Ring, Composite Housing, SKF Food Line SpecificationDocument5 pagesSKF F4BC 25M-CPSS-DFHSquare Flanged Ball Bearing Unit With Set Screw Locking and Narrow Inner Ring, Composite Housing, SKF Food Line SpecificationANo ratings yet

- A carbon-efficient way toDocument2 pagesA carbon-efficient way toANo ratings yet

- Lanxess Anderol® 5150 PLUS - en - USDocument4 pagesLanxess Anderol® 5150 PLUS - en - USANo ratings yet

- Systematic Lubrication FBS de enDocument4 pagesSystematic Lubrication FBS de enANo ratings yet

- TMBH 5Document4 pagesTMBH 5ANo ratings yet

- FAG Arcanol Multi 3Document1 pageFAG Arcanol Multi 3ANo ratings yet

- SKF Introduction Guide To Vibration MonitoringDocument33 pagesSKF Introduction Guide To Vibration MonitoringANo ratings yet

- Lincoln Spray Systems, Chain Lubrication and Specialty Systems 2005Document24 pagesLincoln Spray Systems, Chain Lubrication and Specialty Systems 2005ANo ratings yet

- MOLYKOTE Food Machinery Oil Spray TdsDocument1 pageMOLYKOTE Food Machinery Oil Spray TdsANo ratings yet

- MOLYKOTE Longterm 00 Fluid Grease 2019Document2 pagesMOLYKOTE Longterm 00 Fluid Grease 2019ANo ratings yet

- UNI Oeler UNI Feeder OilersDocument1 pageUNI Oeler UNI Feeder OilersANo ratings yet

- Greases 2022Document8 pagesGreases 2022ANo ratings yet

- FUCHS Wind Industry BrochureDocument28 pagesFUCHS Wind Industry BrochureANo ratings yet

- FLEX Perma 2017Document2 pagesFLEX Perma 2017ANo ratings yet

- TLGB 1262 2022Document1 pageTLGB 1262 2022ANo ratings yet

- Shims 2014Document2 pagesShims 2014ANo ratings yet

- Dropsa Automatic Mist Lubrication 2004Document6 pagesDropsa Automatic Mist Lubrication 2004ANo ratings yet

- 16 5T3 FSI G HiwinCorporation 2DSalesDrawing 04 26 2023Document1 page16 5T3 FSI G HiwinCorporation 2DSalesDrawing 04 26 2023ANo ratings yet

- Compact Oil Supply Unit: DescriptionDocument1 pageCompact Oil Supply Unit: DescriptionANo ratings yet

- M, MFDocument16 pagesM, MFANo ratings yet

- Product Recommendation New Holland TX TX 34 (1987-1994)Document3 pagesProduct Recommendation New Holland TX TX 34 (1987-1994)ANo ratings yet

- Technical Datasheet - ENDocument1 pageTechnical Datasheet - ENANo ratings yet

- Single-Line Automatic Lubrication Systems: Product Catalogue 2023Document208 pagesSingle-Line Automatic Lubrication Systems: Product Catalogue 2023ANo ratings yet

- 0901d19680203809 PDF Preview MediumDocument4 pages0901d19680203809 PDF Preview MediumANo ratings yet

- 350 Series Operations Manual: For Parts and Service (877) 227-8811Document70 pages350 Series Operations Manual: For Parts and Service (877) 227-8811José JuárezNo ratings yet

- Parts Manual RT-740B 05092014Document408 pagesParts Manual RT-740B 05092014Macline India100% (2)

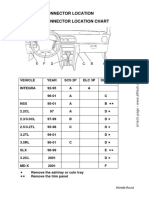

- Odb II LocationsDocument2 pagesOdb II Locationsjdcpe17No ratings yet

- Salient Features:: Pipe LayerDocument4 pagesSalient Features:: Pipe LayerJackson Phinni100% (1)

- NE 32-003 Rev RDocument34 pagesNE 32-003 Rev RedsonNo ratings yet

- Eta Checklist For Equipment InspectionDocument43 pagesEta Checklist For Equipment InspectionMumin DemirbasNo ratings yet

- Pasadores y Buijes CilindroDocument3 pagesPasadores y Buijes CilindrotallerNo ratings yet

- CAMA HILLROOM Service ManualDocument355 pagesCAMA HILLROOM Service ManualOrlando Contreras Muñoz100% (1)

- Mali Akong NasendDocument19 pagesMali Akong NasendMilesNo ratings yet

- AERO Q406 Article4Document10 pagesAERO Q406 Article4Vahid MOHAMMADİNo ratings yet

- Poornachandran - Procurement Profile (3+years)Document2 pagesPoornachandran - Procurement Profile (3+years)chandranNo ratings yet

- Turbine ProcedureDocument77 pagesTurbine Procedureenzobv100% (1)

- Brochure Alarm Prestige APS787Z - QSDocument2 pagesBrochure Alarm Prestige APS787Z - QSRogerNo ratings yet

- Electromechanical Fuel Shutoff Valves M25 - M50Document4 pagesElectromechanical Fuel Shutoff Valves M25 - M50AlejandroMuñozNo ratings yet

- Material Control Gates - BrochureDocument4 pagesMaterial Control Gates - BrochureAnonymous Cxriyx9HIXNo ratings yet

- Abs VSC PDFDocument1 pageAbs VSC PDFbengkel QNo ratings yet

- More Mounting Options - Less Maintenance: Small SeriesDocument2 pagesMore Mounting Options - Less Maintenance: Small SeriesNacho CorroNo ratings yet

- Billboards Come Into The Digital AgeDocument2 pagesBillboards Come Into The Digital AgeAchim BragancaNo ratings yet

- SUPRA 950U / 950U Mt° Spare Parts ManualDocument79 pagesSUPRA 950U / 950U Mt° Spare Parts ManualNizarChouchene100% (1)

- 10T en-GB MIDI PB 1 LRDocument16 pages10T en-GB MIDI PB 1 LRHidrokop PuteviNo ratings yet

- Bedford Middleweight Truck (1954) BrochureDocument20 pagesBedford Middleweight Truck (1954) BrochureNickiedeposieNo ratings yet

- Maintenance Hino Medium Bus FB / DutroDocument24 pagesMaintenance Hino Medium Bus FB / DutroDimas Dhita PrabowoNo ratings yet

- Buku Hed Ygp 1 Aug 2021Document383 pagesBuku Hed Ygp 1 Aug 2021Lilik HandzNo ratings yet

- Pneumatic Working Elements and ApplicationsDocument13 pagesPneumatic Working Elements and ApplicationsWilliam BatalunaNo ratings yet

- FB2022 Rules V1 - April 28 2021 1Document125 pagesFB2022 Rules V1 - April 28 2021 1Alap KCMNo ratings yet

- Malla Electrosoldada (US) PDFDocument2 pagesMalla Electrosoldada (US) PDFCarlos Eduardo RodriguezNo ratings yet