Professional Documents

Culture Documents

Load Variability Management & System Reliability and Maintaianance

Load Variability Management & System Reliability and Maintaianance

Uploaded by

Muhammad TayyabCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Load Variability Management & System Reliability and Maintaianance

Load Variability Management & System Reliability and Maintaianance

Uploaded by

Muhammad TayyabCopyright:

Available Formats

1-Load Variability Management: Address the variability in cooling demands across

different storage areas due to fluctuations in inventory levels and seasonal variations in

ambient temperatures. Develop adaptive control strategies, thermal insulation techniques, and

capacity modulation mechanisms to optimize system operation and maintain energy

efficiency under varying load conditions.

The restaurant comprises four refrigeration units, each facing fluctuations due to varying inventory

levels and seasonal temperature changes. The strategies presented aim to optimize system operation

and maintain energy efficiency.

1. Adaptive Control Strategies

Objective: To dynamically adjust cooling based on real-time data to match demand fluctuations.

Real-Time Monitoring and Control

a. Item Required: IoT-enabled temperature and humidity sensors.

b. Purpose: These sensors will continuously monitor the internal conditions of each refrigeration

unit, providing data for real-time adjustments.

Zonal Cooling

c. Item Required: Zonal control systems for refrigeration units.

d. Purpose: Implement zonal controls to independently manage cooling in different sections

within each refrigeration unit, ensuring specific cooling needs are met without overcooling

other areas.

2. Thermal Insulation Techniques

Objective: To reduce heat gain and improve cooling efficiency by enhancing insulation.

Enhanced Insulation

a. Item Required: High-performance insulating panels and upgraded door seals

b. Purpose: These materials will reduce external heat transfer into the refrigeration units,

maintaining lower internal temperatures more efficiently.

Thermal Zoning

a. Item Required: Thermal barriers or curtains

b. Purpose: Install thermal barriers inside larger refrigeration units to create zones with varying

temperatures, catering to the specific cooling requirements of different inventory items.

3. Capacity Modulation Mechanisms

Objective: To adjust cooling capacity based on demand, improving energy efficiency.

Variable Speed Compressors

a. Item Required: Variable speed compressors for refrigeration units

b. Purpose: These compressors will adjust their cooling capacity in real-time according to the

actual demand, enhancing energy efficiency.

Modulating Fans and Blowers

c. Item Required: Variable speed fans and blowers

d. Purpose: These components will adjust airflow based on cooling requirements, ensuring

efficient operation.

4. Integrative Energy Management

Objective: To optimize energy use and incorporate renewable sources.

Renewable Energy Integration

a. Item Required: Solar panels and associated inverters.

b. Purpose: Integrate solar panels to supply supplementary power to the refrigeration units,

especially during peak demand periods.

Energy Recovery Systems

c. Item Required: Energy recovery ventilators (ERVs) or heat recovery systems.

d. Purpose: Reclaim and reuse waste heat from kitchen appliances or HVAC systems, using it to

pre-cool air entering the refrigeration units.

5. Continuous improvement and maintenance

Objective: To sustain long-term efficiency and reliability of refrigeration systems.

Preventive Maintenance

a. Item Required: Comprehensive preventive maintenance plan and schedule.

b. Purpose: Ensure all refrigeration units operate at peak efficiency and avoid unexpected

breakdowns through regular maintenance.

Employee Training

c. Item Required: Training programs for staff on refrigeration management.

d. Purpose: Train staff on best practices for managing refrigeration units, such as minimizing

door openings and correctly organizing inventory to maintain optimal cooling efficiency.

By optimizing adaptive control, enhancing insulation, and utilizing capacity modulation mechanisms,

the restaurant can maintain energy efficiency and ensure reliable operation under varying load

conditions. Regular maintenance and staff training further ensure the long-term success and

sustainability of these improvements.

2- System Reliability and Maintenance Design a reliable refrigeration system with built-in

redundancy, fault tolerance, and predictive maintenance capabilities to minimize downtime

and ensure continuous operation. Incorporate remote monitoring and diagnostic tools to

enable proactive maintenance scheduling and early detection of potential issues.

This report outlines strategies for designing a reliable refrigeration system for a restaurant with four

refrigeration units. The goal is to incorporate built-in redundancy, fault tolerance, and predictive

maintenance capabilities to minimize downtime and ensure continuous operation. Additionally,

remote monitoring and diagnostic tools will be included to enable proactive maintenance scheduling

and early detection of potential issues.

1. Redundancy and Fault Tolerance

Objective: Ensure continuous operation by incorporating backup components and fault-tolerant design

features.

Redundant Refrigeration Units

a. Item Required: Backup refrigeration units.

b. Purpose: Install an additional refrigeration unit for each primary unit. This backup will take

over in case of a primary unit failure, ensuring that cooling continues without interruption.

Fault-Tolerant Control Systems

c. Item Required: Fault-tolerant Programmable Logic Controllers (PLCs)

d. Purpose: Use PLCs with fault tolerance to manage refrigeration units. These systems will

continue to operate even if part of the control system fails, maintaining system functionality.

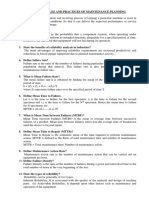

2. Predictive Maintenance Capabilities

Objective: Minimize downtime by predicting and addressing potential issues before they lead to

system failures.

Vibration and Temperature Sensors

a. Item Required: Vibration and temperature sensors for critical components

b. Purpose: Install sensors to monitor compressors, fans, and other critical parts. These sensors

detect early signs of wear or malfunction, enabling timely maintenance.

Oil Analysis Kits

c. Item Required: Oil analysis kits

d. Purpose: Regularly analyze the oil in refrigeration units to detect contaminants and

degradation, which can indicate mechanical issues. This proactive measure helps in

scheduling maintenance before significant problems arise.

3. Remote Monitoring and Diagnostic Tools

Objective: Enable proactive maintenance and early detection of potential issues through continuous

monitoring and diagnostics.

Remote Alarm Systems

a. Item Required: Remote alarm and notification systems

b. Purpose: Install systems that send alerts and notifications to maintenance personnel when

issues are detected, ensuring immediate attention and reducing response time.

4. Proactive Maintenance Scheduling

Objective: Schedule maintenance activities proactively to reduce unexpected failures and extend

equipment lifespan.

Maintenance Management Software

a. Item Required: Computerized Maintenance Management System (CMMS)

b. Purpose: Implement a CMMS to track maintenance schedules, work orders, and equipment

history. This helps organize and prioritize maintenance tasks efficiently.

Historical Data Analysis

c. Item Required: Data analytics software for historical performance analysis

d. Purpose: Analyze historical data to identify patterns and trends in equipment performance,

helping refine maintenance schedules and improving reliability.

5. Training and Documentation

Objective: Ensure staff are well-trained and informed about system operations and maintenance

procedures.

Training Programs for Staff

a. Item Required: Comprehensive training programs

b. Purpose: Provide regular training to staff on the operation and maintenance of refrigeration

units, including troubleshooting and emergency response procedures.

c. Maintenance Manuals and Documentation

d. Item Required: Detailed maintenance manuals and documentation.

e. Purpose: Ensure up-to-date maintenance manuals and documentation are available for

reference, helping staff perform maintenance tasks accurately.

By implementing these strategies with the specified items, the restaurant can design a reliable

refrigeration system with built-in redundancy, fault tolerance, and predictive maintenance capabilities.

Remote monitoring and diagnostic tools will enable proactive maintenance scheduling and early

detection of potential issues, minimizing downtime and ensuring continuous operation. Regular

training and comprehensive documentation further support the long-term reliability and efficiency of

the refrigeration systems.

You might also like

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- Best Practice Guide RefrigerationDocument36 pagesBest Practice Guide Refrigerationbarelihb100% (1)

- MaintenanceDocument18 pagesMaintenancemohammad baniissaNo ratings yet

- Maintenance of Equipment: Philippine Society of Mechanical Engineers Professional Development CourseDocument23 pagesMaintenance of Equipment: Philippine Society of Mechanical Engineers Professional Development CourseAngel Silva VicenteNo ratings yet

- Maintenance ManagementDocument22 pagesMaintenance ManagementMohan Gupta0% (1)

- Maintance PlanningDocument0 pagesMaintance PlanningSHIVAJI CHOUDHURY100% (1)

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Hydraulic Roller Press - HRP PDFDocument12 pagesHydraulic Roller Press - HRP PDFGyanaranjan20110% (1)

- Position Summary:: Winnipeg, MBDocument10 pagesPosition Summary:: Winnipeg, MBZaman Bhuiyan100% (1)

- Temp MappingDocument13 pagesTemp MappingJoshua JumaNo ratings yet

- Cooling Tower Handbook - FINAL PDFDocument33 pagesCooling Tower Handbook - FINAL PDFOscarJimenez19870% (1)

- Maintenance Management QA CHPDocument7 pagesMaintenance Management QA CHPjasminezaidNo ratings yet

- Minimum Learing Material - MaintenanceDocument144 pagesMinimum Learing Material - MaintenanceSaravanan Ak100% (1)

- Coker UnitDocument15 pagesCoker UnitAhmed YousryNo ratings yet

- Subject: Production and Operations Management Unit 5: Maintenance and Waste ManagementDocument19 pagesSubject: Production and Operations Management Unit 5: Maintenance and Waste ManagementAnonymous yL88Jj100% (1)

- Maintenance and Maintenance Engineering ObjectivesDocument26 pagesMaintenance and Maintenance Engineering ObjectivesPedro Ramírez Toala100% (1)

- Green Building ConceptDocument3 pagesGreen Building ConceptNaik Himanshu A.67% (6)

- Din - 18599-6Document91 pagesDin - 18599-6Melinda GyorfiNo ratings yet

- ME 2037 Maintenance Engineering Unit 2 FAQDocument9 pagesME 2037 Maintenance Engineering Unit 2 FAQVaradha YamunanNo ratings yet

- Egypt Environmental IssuesDocument7 pagesEgypt Environmental IssuesAbdelrahman NoureldinNo ratings yet

- Solar Panel Sustainability Project ProposalDocument14 pagesSolar Panel Sustainability Project ProposalSayed Abu SufyanNo ratings yet

- Maintenance ManagementDocument21 pagesMaintenance ManagementRahul WaghmareNo ratings yet

- Plant Maintenance Manual 2007Document23 pagesPlant Maintenance Manual 2007api-26042912100% (6)

- Topic 1 - Maintenance System LatestDocument77 pagesTopic 1 - Maintenance System LatestAfhnan TemiziNo ratings yet

- HVAC System Sizing Comparison SelectionDocument7 pagesHVAC System Sizing Comparison Selectionbabadapbadap100% (1)

- Maintenance of A Coal Fired Power PlantDocument11 pagesMaintenance of A Coal Fired Power PlantRuel Agon Jr.100% (1)

- Maintenance NaimurDocument26 pagesMaintenance Naimurnaimur.7566No ratings yet

- Ueeneee110A Develop and Implement Energy Sector Maintenance Programs Assessment1 Maintenance Program DevelopmentDocument3 pagesUeeneee110A Develop and Implement Energy Sector Maintenance Programs Assessment1 Maintenance Program Developmentamrit palasaurNo ratings yet

- Digital Realty 1705 Maintenance and Operations Standards v5.6Document17 pagesDigital Realty 1705 Maintenance and Operations Standards v5.6mancangkulNo ratings yet

- Document 7Document4 pagesDocument 7bernardNo ratings yet

- Energy Set PointsDocument5 pagesEnergy Set PointsSachin BadheNo ratings yet

- Appendix A: Additional Opportunity Assessment QuestionsDocument6 pagesAppendix A: Additional Opportunity Assessment Questionshelloworld1368No ratings yet

- ASHRAE TC0909 Data Center Cooling Resiliency Brief 1.0Document3 pagesASHRAE TC0909 Data Center Cooling Resiliency Brief 1.0Dimitris KolettisNo ratings yet

- Best Energy Management: For HVACDocument10 pagesBest Energy Management: For HVACMarc Emil CasilaoNo ratings yet

- Name: Jesca Edward Mikina Subject: Human Resource Management NIM: 12010121419097Document6 pagesName: Jesca Edward Mikina Subject: Human Resource Management NIM: 12010121419097Jessica EdwardNo ratings yet

- Define Maintenance MergedDocument73 pagesDefine Maintenance MergedBipul Verma100% (1)

- Job Description: Designation: Executive - Electrical Reporting ToDocument3 pagesJob Description: Designation: Executive - Electrical Reporting Tovishal9patel-63No ratings yet

- Course - Operations Management Answer-1 Plant Layout: Plant Layout Is A Plan of Optimal Arrangement of Facilities EquipmentDocument10 pagesCourse - Operations Management Answer-1 Plant Layout: Plant Layout Is A Plan of Optimal Arrangement of Facilities Equipmentashish.itbhuNo ratings yet

- Introduction To Mee 506Document9 pagesIntroduction To Mee 506Akunwa GideonNo ratings yet

- HTM 119 Act. No. 3Document8 pagesHTM 119 Act. No. 3Shairen MacraNo ratings yet

- SLA TashomeDocument7 pagesSLA TashomeMulugeta AbebeNo ratings yet

- MSE - Unit-4Document33 pagesMSE - Unit-4Joel ChittiproluNo ratings yet

- Maintenance UNIT - 1Document25 pagesMaintenance UNIT - 1rajeshkannahNo ratings yet

- Isom Unit SpecDocument5 pagesIsom Unit SpecMarlow Touch RugbyNo ratings yet

- How To Get Energy Audit of My BuildingDocument2 pagesHow To Get Energy Audit of My BuildingRavi RajNo ratings yet

- STP 221 Lecture 1Document7 pagesSTP 221 Lecture 1oluwafolukemiakinseye2001No ratings yet

- FLUKE - PDM OverviewDocument5 pagesFLUKE - PDM OverviewofedulloNo ratings yet

- GCP Sect9 EngineeringMaintenanceDocument9 pagesGCP Sect9 EngineeringMaintenancelevanvui161No ratings yet

- Info Sheet - 2 Maintanace ManagementDocument16 pagesInfo Sheet - 2 Maintanace ManagementAbenetherNo ratings yet

- Report Energy Management Systems WebinarDocument4 pagesReport Energy Management Systems WebinarAlfi Al FahreizyNo ratings yet

- Common Maintenance and Troubleshooting Issues For Reefer ContainersDocument9 pagesCommon Maintenance and Troubleshooting Issues For Reefer Containerswilly wilantaraNo ratings yet

- ASMA BuildingDocument5 pagesASMA BuildingmicrefeeNo ratings yet

- Untitled DocumentDocument18 pagesUntitled Documenthomerjudesatuito568No ratings yet

- Chapter 1 Mini Ice Plant Training Module FinalDocument3 pagesChapter 1 Mini Ice Plant Training Module FinalChristian DianoNo ratings yet

- Quiz 2Document4 pagesQuiz 2Izzat AzmanNo ratings yet

- Design Maintainability Report Group 2 Final Na Final NaDocument40 pagesDesign Maintainability Report Group 2 Final Na Final NaEren Kruger100% (1)

- Cat 22Document1 pageCat 22Japheth NgugiNo ratings yet

- Inventory and Stock MGMT SysDocument4 pagesInventory and Stock MGMT SyswabiinafNo ratings yet

- Appendix ADocument15 pagesAppendix AAdem Ebrahim ButtaNo ratings yet

- Maintanance Engg MaterialDocument58 pagesMaintanance Engg MaterialSiva KrishnanNo ratings yet

- Work Based Career Episodes Ajith JohnsnDocument5 pagesWork Based Career Episodes Ajith JohnsnAjith JohnsonNo ratings yet

- Diagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceFrom EverandDiagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceNo ratings yet

- CAD Semester Project Report 3d PrinterDocument43 pagesCAD Semester Project Report 3d PrinterMuhammad TayyabNo ratings yet

- 35 Muhammad TayyabDocument30 pages35 Muhammad TayyabMuhammad TayyabNo ratings yet

- MatlabDocument25 pagesMatlabMuhammad TayyabNo ratings yet

- MVDocument14 pagesMVMuhammad TayyabNo ratings yet

- Imageprocessingusing MatlabDocument4 pagesImageprocessingusing MatlabMuhammad TayyabNo ratings yet

- Experiment 2-Double Pipe Heat Exchanger 2Document22 pagesExperiment 2-Double Pipe Heat Exchanger 2Muhammad TayyabNo ratings yet

- Mathematical ModellingDocument1 pageMathematical ModellingMuhammad TayyabNo ratings yet

- Experiment 3Document15 pagesExperiment 3Muhammad TayyabNo ratings yet

- Exp 9Document18 pagesExp 9Muhammad TayyabNo ratings yet

- Assignment 2 Viscous DampingDocument4 pagesAssignment 2 Viscous DampingMuhammad TayyabNo ratings yet

- Cooling TowerDocument13 pagesCooling TowerMuhammad TayyabNo ratings yet

- Assignment 4 Magnification FactorDocument5 pagesAssignment 4 Magnification FactorMuhammad TayyabNo ratings yet

- Building America Best Practices Mixed Humid ClimatesDocument139 pagesBuilding America Best Practices Mixed Humid Climatesbcap-oceanNo ratings yet

- IEA 2013 Annual ReportDocument28 pagesIEA 2013 Annual ReportEdwonkZapravoNo ratings yet

- Sustainable Production and ConsumptionDocument2 pagesSustainable Production and ConsumptionPraharsh ShahNo ratings yet

- CHP Units For Heat and PowerDocument20 pagesCHP Units For Heat and Poweranon_411130333No ratings yet

- Technical Report On Global WarmingDocument49 pagesTechnical Report On Global WarmingShivam AgarwalITF43No ratings yet

- A Comprehensive Review On Evaporative Cooling SystemsDocument14 pagesA Comprehensive Review On Evaporative Cooling Systemsamanliyu814No ratings yet

- IRENA Sector Coupling in Cities 2021Document80 pagesIRENA Sector Coupling in Cities 2021amsukdNo ratings yet

- (IJCST-V6I5P12) :Karthikeyan.R.A, Saran Sriram.K, Piyush.DDocument3 pages(IJCST-V6I5P12) :Karthikeyan.R.A, Saran Sriram.K, Piyush.DEighthSenseGroupNo ratings yet

- Boilers and Thermic Fluid HeatersDocument53 pagesBoilers and Thermic Fluid HeatersAmmar HalasaNo ratings yet

- ISO 50001 2018 Energy Management System Implementation GuideDocument34 pagesISO 50001 2018 Energy Management System Implementation Guidesaichand aeroNo ratings yet

- TopTherm Wall-Mounted Cooling Unit Blue eDocument5 pagesTopTherm Wall-Mounted Cooling Unit Blue eChung LêNo ratings yet

- Catalog Sisteme Panasonic VRF 2013Document164 pagesCatalog Sisteme Panasonic VRF 2013UPOTERMNo ratings yet

- Pumps and Automation Data PDFDocument76 pagesPumps and Automation Data PDFAbeth SabethNo ratings yet

- Energy Efficiency Policy & Program: IndonesiaDocument13 pagesEnergy Efficiency Policy & Program: IndonesiaMohits952No ratings yet

- The Energy Transition Conference 2023 - Delegates BrochureDocument17 pagesThe Energy Transition Conference 2023 - Delegates BrochureJunidi DoronsoiNo ratings yet

- 1 s2.0 S0973082622000710 MainDocument18 pages1 s2.0 S0973082622000710 MainAlexia Parra SanchezNo ratings yet

- Sustainability Report of Zaber and ZubairDocument29 pagesSustainability Report of Zaber and Zubairsupremejen019No ratings yet

- Communication SkillsDocument15 pagesCommunication SkillsZafar ShaikhNo ratings yet

- Mitsubishi Split SystemsDocument17 pagesMitsubishi Split Systemspatel_kiranNo ratings yet

- Business and Environment Ethics RoleplayDocument6 pagesBusiness and Environment Ethics Roleplaydivasingh311204No ratings yet

- Wienerberger AR 11 EngDocument172 pagesWienerberger AR 11 Eng0730118008No ratings yet

- Green Mark NRB 2015 Criteria (Last Update 01082018)Document114 pagesGreen Mark NRB 2015 Criteria (Last Update 01082018)yona nadiaNo ratings yet

- Accelerating Energy EfficiencyDocument81 pagesAccelerating Energy EfficiencyAlex TolozaNo ratings yet

- Green Hydrogen RussiaDocument22 pagesGreen Hydrogen RussiaPRIDE MAKANYISANo ratings yet

- Battic Door New Attic Access Building CodesDocument24 pagesBattic Door New Attic Access Building CodesRungtawan TyrolNo ratings yet

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-1-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)