Professional Documents

Culture Documents

Epson 6axis Robots

Epson 6axis Robots

Uploaded by

boukhil.gaith01Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Epson 6axis Robots

Epson 6axis Robots

Uploaded by

boukhil.gaith01Copyright:

Available Formats

EPSON PROSIX 6-AXIS ROBOTS

OUR 6-AXIS ROBOTS ARE

FREE TO MOVE

INCREASED FLEXIBILITY FOR COMPLEX HANDLING

Epson_6Achsroboter_210x297_EN.indd 1 30.05.11 13:17

ABOUT EPSON EPSON ROBOT 3

6-AXIS ROBOT

SYSTEMS — TO SPEED UP

About Epson 2 Epson, a subsidiary of Seiko Cor-

poration, launched the first robots

YOUR PRODUCTION RUN

Epson 6-axis robots 4 in the 1980ies. Those were used for

precise and fast assembly of Seiko

Epson 6-axis robots overview 5 watches. Soon Epson industrial

Typical applications 6 robots and controllers started to Our robots palletise, saw, mill, drill, grind, mount, move and assemble. They work

Epson 6-axis robots design 8 conquer markets all over the world. precisely and at breathtaking speed in these and many other applications — often

Production philosophy 10 Today, Epson Factory Automation is up to 24 hours a day.

Controllers 11 one of the leading companies pro-

Technical data Epson ProSix C3 12 ducing high-quality robot systems

with branches on all five continents. As one of the pioneers in robotics we know exactly what the main feature of the combination of kinematics and

Technical data Epson ProSix S5 14 intelligent control must be apart from speed and precision: Reliability! That is because the standstill of an installation

Technical data Epson ProSix S5L 16 resulting in a loss of production is expensive, very expensive. Therefore to us, innovation means more than just

Conserving resources 18 • In-house Research and Develop- up-to-date robot technology. Every day, our development engineers strive to make our robot systems even more

Environmental performance 19 ment department for automation economical, flexible and reliable — under all conditions.

processes

• 1984 first freely available Epson Integrated automation

SCARA robot in Japan We offer you a flexibly expandable range of products with different integrated components. Among these are a great

• One of the world’s most com- number of SCARA robots and 6-axis robots for diverse applications as well as controllers and software. Everything

prehensive SCARA model ranges engages perfectly and is easy to operate.

• 1997 first PC-based controller

• Inventor of the Spider:

a unique SCARA robot with

450° envelope

SERVICE AND SUPPORT

Our service and support program helps you to tap the full potential of your Epson robot systems.

Feasibility studies Pre-sales support After-sales support

Instead of theoretical simulations we How can a robot system be efficiently Hotline service, repair service on site,

offer cycle time tests with real robots. integrated into an installation? inspection and individual maintenance

There are many ways in which you How can cycle times be optimised? concepts as well as spare part

benefit from those studies. Prior to How can the robot program be in- packages tailored to your needs are

your investment you are provided tegrated into external software? only some examples of how we do

with optimal robot configuration Our application engineers advise everything to have your production

and installation site as well as precise you during planning as well as during running non-stop.

cycle times. That is how you get implementation.

maximum planning and project Central spare part stocking

security. Training All spare parts are rapidly delivered

Whether you need introductory from our central warehouse in

seminars, or programming, Meerbusch, Germany.

maintenance or operator trainings —

our experts share their knowledge

with you and your employees.

Epson_6Achsroboter_210x297_EN.indd 2-3 30.05.11 13:17

4

MAXIMUM MOBILITY EPSON PROSIX SERIES — 5

IN THE SMALLEST SPACE JUST THE RIGHT TYPE

FOR YOUR APPLICATION

To tap the full potential of your installation, there is one thing you cannot do without: Epson ProSix 6-axis robots convince through high-speed, precise travel.

Robots that are fast, precise and reliable. Epson robots stand for reliability to set Standard cycle times of up to 0.37 seconds at repeatabilities of +/–0.02 mm

the standards. In every respect. All models. Just like the extremely reliable SCARA ensure a high throughput and increase economic viability.

and cartesian robots, Epson ProSix 6-axis robots also combine those features.

Thanks to their spherical work envelope, they are perfectly suitable for spatial

applications such as complex parts handling or assembling. And they require

surprisingly little space.

Compact, free, flexible The Epson philosophy:

Due to the high number of degrees of freedom, Epson Simpler is better is more economical

ProSix 6-axis robots provide for maximum flexibility and You are not going to find any expensive stand-alone

smoothly manage complex operations. Small production solutions at Epson. We rely on a conclusive control

cell? No problem. Our engineers have optimised the concept and 6-axis programming that guarantee you

kinematics-envelope ratio. maximum flexibility. That is why both Epson controllers —

the RC180 slave controller and the Windows-based

The result is a particularly slim robot design with in- RC620 master controller — can be used with all

tegrated media feed-through. The small interference Epson robots.

contours also reduce the risk of collision if several robots

work inside the same cell — that means an increase in Thanks to a modular design, a reduced number of

safety, reliability, flexibility and efficiency. assemblies and the use of some identical components

we also use for our SCARA robots, Epson ProSix 6-axis

Since the elbow radius is smaller and the swivel range robots are particularly robust and easy to maintain.

bigger, the innovative joint geometry, which was exclu-

sively developed by Epson, proves extremely advantageous

in confined envelopes. Or, to put it simply: more per-

formance per area.

Epson ProSix C3 — Epson ProSix S5 — Epson ProSix S5L —

small loads heavy loads heavy loads

short reach medium reach long reach

Reach: 600 mm Reach: 706 mm Reach: 895 mm

Payload: 3 (5*) kg Payload: 5 (7*) kg Payload: 5 (7*) kg

*Possible under special conditions

(see manual).

Epson_6Achsroboter_210x297_EN.indd 4-5 30.05.11 13:17

EPSON PROSIX SERIES

6

SYSTEMATIC SOLUTIONS 7

WITH A FUTURE

Epson ProSix 6-axis robots are made for complex handling and assembling

workpieces. Thanks to the compact design and Epson joint geometry, they are

particularly easily manoeuvred and feel completely at home even in confined

envelopes.

Loading and unloading machines Epson ProSix 6-axis robots Packaging and palletising Cleanroom and IP versions

Loading and unloading of conveyors, pallet systems, plastic injection are just the perfect Up-to-date packagings ask for a high degree of flexibility of the packaging The perfect robot for every environ-

moulding machines or metal foundry machines are just some of the tasks solution for: lines. That is to ensure ever shorter product changeover times and high ment: Epson ProSix 6-axis robots

in this field which Epson ProSix 6-axis robots perform precisely and reliably. process reliability. Epson 6-axis robots have it all under control. They package are available as cleanroom versions

Typical work cells can be converted into fully automatic production cells, • loading and unloading machines and palletise even highly sensitive parts. With Conveyor Tracking, the robot and also with different IP codes.

such as the complete, automated process for plastic injection moulding • assembling and equipping can place parts on moving conveyors or pick them up from there. In that

machines with removal, cooling and deburring in just one operation cycle. • packaging and palletising process, the objects are detected by a camera or sensor. Individual service

• testing, measuring and Please feel free to contact us so we

Assembling and equipping inspecting Testing, measuring and inspecting can find the ideal solution for your

Manual activities during assembly and equipping are not only inefficient, • most diverse automation Quality inspections, test runs prior to series production, data measurement — application, conduct feasibility

but also fault-prone. Another aspect is the naturally limited moveability of applications they all require precise detection. With Epson robots in combination with studies and efficiently integrate the

the human arm. Epson ProSix 6-axis robots feature maximum freedom of • handling tools and workpieces a high-performance integrated vision system, those tasks can even be per- robot system into your installation.

movement, an angle of rotation of +/–135° of joint #5 and the capability to • cutting, grinding, deburring, formed with high clock rates. That way, an Epson 6-axis robot can place Our application engineers advise

flip over of joint #3. Apart from that, even the smallest parts can be precisely polishing (with different IP codes) a part on a storage place and rotate joint #6 in front of the Epson Vision you during planning and implemen-

assembled. Process continuity and reproducibility allow a high savings System so that the camera can detect all relevant surfaces. If the predefined tation.

potential while at the same time improving quality. parameters of the product deviate from the tolerance values, the product is

recognised as defective and sorted out.

Epson_6Achsroboter_210x297_EN.indd 6-7 30.05.11 13:17

EPSON PROSIX SERIES

8

THE EPSON CONCEPT: TO 9

TAKE IT ONE STEP FURTHER

We optimise every detail to improve the performance and at the same time reduce Less interference contours

the robot volume. Compact, powerful, absolutely reliable. That is the Epson robot If more than one robot works in a confined space, the risk of collision increases. That is why all models of the

Epson ProSix 6-axis robot series have considerably less interference contours — thanks to the slim design on the

philosophy which is more than just an empty promise. Try it! one hand and the integrated media feed-through on the other. The advantages: maximum reliability of the installation

and low maintenance costs.

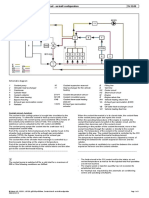

Optimal joint geometry Connections on the Epson ProSix C3 6-axis robot

Thanks to the improved joint geometry,

joint #5 has an angle of rotation of Motor function indicator lamp

+/–135° and has thus a considerably

Connection for brake release unit

greater freedom of movement

.

Connection for user wiring

The elbow radius, that is the distance

(9-pin D-Sub connector)

from the pivotal point of joint #5

to the flange for the hand, is smaller — Four connections for compressed-air

for maximum moveability, supply with pressure plug (2 × Ø 4 mm

even in confined envelopes. and 2 × Ø 6 mm)

Power cable

Joint #3 is considerably smaller — which

is space-saving. Signal cable

Connections on the Epson ProSix S5 and S5L 6-axis robots

Motor function indicator lamp

More flexibility thanks to the capability to flip over of joint #3

The capability to flip over of joint #3 not only helps to flexibly design Connection option for brake release unit

(option)

production cells making full use of the envelope, but also reduces cycle

times.

Connection for user wiring

(15-pin D-Sub connector)

Two connections for compressed-air supply

with pressure plugs (2 × Ø 6 mm)

Power cable

Signal cable

Epson_6Achsroboter_210x297_EN.indd 8-9 30.05.11 13:17

EPSON PROSIX SERIES

10

BECAUSE QUALITY IS THE FLEXIBLE 11

BEST REMEDY CONTROLLER

CONCEPT

Like all Epson robot systems, Epson ProSix 6-axis Economical and future- Central controller or compact slave controller — Epson

robots also feature a series of advantages. High-quality oriented complete solution ProSix 6-axis robots can be optimally controlled with

All important components are Epson

components ensure longevity and high availability. components. They are developed in

the Epson controllers and smoothly integrated into

The design also focuses on reliability — starting from our research centres and produced your production processes. It all depends on what

well-established design principles to easy accessibility in our quality-certified production you need for your application.

of all components. facilities. Hardware and software

match perfectly.

We get to the point fast: Smart Motion Epson RC+ Epson RC180 — the most compact, most lightweight and Epson Smart Camera

Smart Motion is the revolutionary motor management by Epson used in all simulation software fastest controller of its performance class on the market Epson Smart Cameras have an integrated

Machine Vision processor and are therefore

Epson robot systems. At low vibration, Epson robots reach the end position With the Epson simulation software With its compact dimensions, the Epson RC180 is incredibly small. The

separated from the robot controller.

much faster and much more precisely. Optimum positioning, short cycle you can even in the run-up plan your controller was mainly developed to be operated as a stand-alone slave. They can be used as stand-alone cameras

times and increased path accuracy — be on the economical side with robot cell true to the original and or in a network of several cameras.

Smart Motion! simulate different layouts, concepts Epson RC620 — the powerful master controller

and robot tasks fast and easily. Thus for up to 20 axes

you save valuable time and costs in This controller has it all under control: robots, conveyors and other peripheral

all phases — from design to integra- equipment. Due to its open Windows-based system design, it offers endless

tion and operation to maintenance. possibilities and is easy to operate. The RC620 supports Conveyor Tracking

as well as most diverse bus protocols and interface expansions. For even

more demanding system resources, there is the Epson RC620+.

Position For robots with eye contact

The high-performance integrated vision systems reliably detect and position

parts — even in case of manufacturing deviations, part changes or varying

light conditions. Epson Smart Vision: That is perfectly matching software

and hardware. TP1

Monitoring, operation and parametrisation

Target at the portable TP1 Teach Pendant

position Time

Epson robot Common robot

reaches target position reaches target position

Epson robot

Common robot

End position controller

As a result of overshooting, common motor controllers lead to increased deviations.

The result: imprecise positioning, poor interpolation and longer process times. Epson Smart Motion, Epson RC180 Epson RC620 OP1

however, minimises overshooting. Epson robots are more precise and product-conserving and get The slave controller — compact, smart The master for several kinematics and OP1 Operator Pendant for operation and

to the point faster — even if cycle times are extreme. and powerful complex installation control visualisation tasks even in complex installations

Epson controllers brochure in PDF at:

www.epson.de/robots

Epson_6Achsroboter_210x297_EN.indd 10-11 30.05.11 13:17

EPSON PROSIX C3 EPSON PROSIX C3

12

TECHNICAL 13

DATA

Joint 2

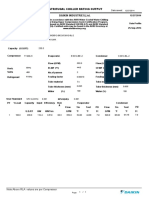

Specifications Scope of delivery Side view 0 pulse position Front view

65 250.0 mm 476.5 mm

EPSON PROSIX C3

• Epson robot and controller J4: –200° J4: +200°

DESIGN vertical articulated arm

• 1 Epson RC+ program CD J6: –360° J6: +360°

PAYLOAD (kg) 3/5* +225° +65° 820.0 mm

including simulation software

REACH (mm) P point 600, 665 max. +135°

• 2 sets of mounting brackets for the

REPEATABILITY (mm) +/–0.02

robot controller (RC180)

ADMISSIBLE (kgm2) J4 0.15

MOMENT OF INERTIA

• 1 set of 3 m power and signal cable -51°

(kgm2) J5 0.15 P point –135° R 191.5 *2 570.0 mm

• 1 emergency stop connector

(kgm2) J6 0.1

• 1 connector for standard I/O

USER WIRING electrical 1 x D-Sub 9-pin

• 1 set of connectors for user wiring Joint 3 5 393.3 mm

pneumatic 4 x tubes (2 x Ø 4 mm and 2 x Ø 6 mm) 0 pulse position

• 2 sets of air connections (4 x R 167 *1

WEIGHT (kg) 27 320.0 mm

straight and 4 x 90° angled each) –160°

CONTROLLER RC180 / RC620 / RC620+ R 500

• 1 back-up disc of the

MANIPULATOR MODEL mounting option floor / wall / ceiling

robot controller (RC180) 209.1 mm

(also skewed or sunk) 154.0 mm

• 1 USB programming cable (RC180)

cleanroom and ESD ISO3

• Manuals on CD

*Possible under special conditions (see manual). • 1 installation/safety manual 156.4 mm Joint 4 6

164.9 mm 0 pulse position

• 1 mouse and 1 keyboard (RC620) Motion range

of P point

Mounting Work envelope related to the pivotal point of joint #5

Manipulator options

The Epson ProSix C3 6-axis robot can be mounted as required for the

application. Apart from floor, wall and ceiling mounting, sunk and skewed • Longer power and signal cables

mounting are also possible. Since there is no base and the cable duct is (5 m/10 m/20 m) Top view

hidden, the work envelope is optimally used. • Brake release unit –180° *3

• Mounting bracket

–170°

P point R 257.4 *4

R 76.8 *5

Joint 1

Floor mounting Wall mounting 0 pulse

position

R 600

reduced height expanded +170°

envelope

+180° *3

This and further information

Ceiling mounting Sunk mounting Skewed mounting as well as CAD data are provided at:

www.epson.de/robots

Epson_6Achsroboter_210x297_EN.indd 12-13 30.05.11 13:17

EPSON PROSIX S5 EPSON PROSIX S5

14

TECHNICAL 15

DATA

Joint 2

Specifications Scope of delivery Side view 0 pulse position Front view

80 305.0 mm 589.0 mm J4: –190° J4: +190°

EPSON PROSIX S5 J6: –360° J6: +360°

• Epson robot and controller

PAYLOAD vertical articulated arm

• 1 Epson RC+ program CD 948.0 mm

TRAGLAST (kg) 5/7*

including simulation software +135°

REACH (mm) P point 706, 786 max.

• 2 sets of mounting brackets for the

REPEATABILITY (mm) +/–0.02

robot controller (RC180)

ADMISSIBLE (kgm2) J4 0.3

MOMENT OF INERTIA

• 1 set of 3 m power and signal cable –135° +65°

(kgm2) J5 0.3 P point

• 1 emergency stop connector

(kgm2) J6 0.1

• 1 connector for standard I/O 752.0 mm

USER WIRING electrical 1 x D-Sub 15-pin Joint 3 5

• 1 set of connectors for user wiring

pneumatic 2 x tubes (Ø) 6 mm 0 pulse position –150°

• 1 set of air connections (2 x straight

WEIGHT (kg) 36

and 2 x 90° angled each) 330.0 mm

CONTROLLER RC180 / RC620 / RC620+

• 1 back-up disc of the

MANIPULATOR MODEL mounting option floor / wall / ceiling 239.0 mm

robot controller (RC180) 156.0 mm

cleanroom ISO4

• 1 USB programming cable (RC180)

IP class IP65

• Manuals on CD Joint 4 6

179.0 mm 0 pulse position

*Possible under special conditions (see manual). • 1 installation/safety manual

246.0 mm

• 1 mouse and 1 keyboard (RC620) Motion range

of P point

Mounting Work envelope related to the pivotal point of joint #5

Manipulator options

Floor, wall or ceiling — you can mount Epson ProSix S5 6-axis robots

on all three. • Longer power and signal cables

(5 m/10 m/20 m) Top view

• Brake release unit

–170°

P point

Floor mounting Wall mounting Ceiling mounting R 235

Joint 1

0 pulse

position

R 706

+170°

This and further information

as well as CAD data are provided at:

www.epson.de/robots

Epson_6Achsroboter_210x297_EN.indd 14-15 30.05.11 13:17

EPSON PROSIX S5L EPSON PROSIX S5L

16

TECHNICAL 17

DATA

Joint 2

Specifications Scope of delivery Side view 0 pulse position Front view

80 405.0 mm 769.0 mm

EPSON PROSIX S5L J4: –190° J4: +190°

• Epson robot and controller

DESIGN vertical articulated arm J6: –360° J6: +360°

• 1 Epson RC+ program CD

PAYLOAD (kg) 5/7* +135° 1,137.0 mm

including simulation software

REACH (mm) P point 895, 975 max.

• 2 sets of mounting brackets for the

REPEATABILITY (mm) +/–0.03

robot controller (RC180)

ADMISSIBLE (kgm2) J4 0.3

MOMENT OF INERTIA

• 1 set of 3 m power and signal cable +65°

(kgm2) J5 0.3 P point –135°

• 1 emergency stop connector

(kgm2) J6 0.1

• 1 connector for standard I/O

USER WIRING electrical 1 x D-Sub 15-pin 842.0 mm

• 1 set of connectors for user wiring Joint 3 5

pneumatic 2 x tubes (Ø) 6 mm 0 pulse position –150°

• 1 set of air connections (2 x straight

WEIGHT (kg) 38

and 2 x 90° angled each)

CONTROLLER RC180 / RC620 / RC620+ 330.0 mm

• 1 back-up disc of the 198.0 mm

MANIPULATOR MODEL mounting option floor / wall / ceiling 97.0 mm

robot controller (RC180)

cleanroom ISO4

• 1 USB programming cable (RC180) Joint 4 6

IP class IP65 317.0 mm

• Manuals on CD 0 pulse position

423.0 mm

*Possible under special conditions (see manual). • 1 installation/safety manual

• 1 mouse and 1 keyboard (RC620) Motion range

of P point

Mounting Work envelope related to the pivotal point of joint #5

Manipulator options

Floor, wall or ceiling — you can mount Epson ProSix S5L 6-axis robots

on all three. • Longer power and signal cables

(5 m/10 m/20 m) Top view

• Brake release unit

–170°

P point

R 267

Floor mounting Wall mounting Ceiling mounting

Joint 1

0 pulse

position

R 895

+170°

This and further information

as well as CAD data are provided at:

www.epson.de/robots

Epson_6Achsroboter_210x297_EN.indd 16-17 30.05.11 13:17

18

EFFICIENTLY USING THE GREEN WAY: 19

RESOURCES ENVIRONMENT AND

SUSTAINABILITY

Saving resources is a holistic approach at Epson. Not only does it mean that we Environmental protection has a long tradition at Epson and is an integral part of

produce environmentally friendly, but that we also focus on sustainable quality. the company philosophy. It is our aim to reduce the environmental impact of our

If strictly implemented, this also considerably increases efficiency, since we can products — from the concept to recycling, from the choice of materials and

reduce the operating and follow-up costs of our robots. components to transport to reuse.

Size and weight are relevant to costs Economical — Saving energy — and costs Life cycle assessment

Size and weight play an important role for the robot design. A slim design also in the long run Energy is money and a real economic factor. Consistently we strive to Since the year 2000, we have been

as well as minimised weight and power consumption lead to savings in All Epson ProSix 6-axis robots stand develop particularly reliable, failsafe products which consume less and less registering the environmental impact

operating costs, since it results in improved performance in minimum space. out for a particularly low power energy. Since 1995, Epson has implemented an environmental management of individual items of our manu-

Dimension and design of the Epson automation solution are tailored to your consumption. The combination of system based on a holistic approach. facturing program. Life cycle assess-

application. maximum reliability and reusability ment gives information about

of the components results in a high Environmental Vision 2050 — our goals how much raw material and energy

Optimum efficiency added value. With our Environmental Vision 2050, we set an example. One of our main a product consumes within the course

related to supplied power and payload intentions is to reduce our CO2 emissions during the complete life cycle of of its production, use and disposal

That is efficiency as required for economical production: Converting electric a product by 90% by 2050. Moreover, we are going to introduce reuse and and what emissions are generated.

energy into kinetic energy so as to achieve high efficiency and short cycle recycling for all of our products and are engaged in protecting biodiversity.

times. Epson RC180 and RC620 controllers are extremely compact, consist

of a smaller number of assemblies and feature low power loss. Thanks to –47% Sustainable and environmentally friendly

that, the total energy consumption of the control system was reduced by interference Within the framework of our sustainability initiative, we have committed

almost 25 %. contour of joint #3 ourselves to high ethical and ecological standards. The annual “Epson

Sustainability Report” documents how we ensure and continuously improve

the good environmental performance of our products and production

processes.

Mass reduced by 26%

Thanks to the reduction of the deadload of the Epson S5 6-axis robot by

13 kg, efficiency related to supplied power and payload was optimised to –13kg

save effective operating costs. weight

–35%

arm width

Epson_6Achsroboter_210x297_EN.indd 18-19 30.05.11 13:17

EPSON PROSIX 6-AXIS ROBOTS

Epson Industry Solutions Center — that’s where we find your solution!

Expertise concentrated on 500 m2: In cooperation with our partners, in our Meerbusch

Industry Solutions Center we present solutions for the most diverse applications in

industry. The fields include large format printing, retail solution and factory automation.

Factory automation: See all Epson robots in action. Our experts help you to set up,

simulate and optimise your automation application in a workshop cell. The cell can be

controlled and networked with all standard fieldbuses. In addition, we provide up-to-date

peripheral equipment such as a Vision and Conveyor Tracking system.

You would like to arrange an appointment?

Call us at +49 2159 5381391 or just e-mail us at:

robot.infos@epson.de

Epson Deutschland GmbH Phone: +49 2159 5381391

Factory Automation Division Fax: +49 2159 5383170

Otto-Hahn-Straße 4 E-mail: robot.infos@epson.de

40670 Meerbusch www.epson.de/robots

Epson America Inc. Phone: +1562290 - 5910

Factory Automation Division Fax: +1562290 - 5999

Printed on LumiArt 150 g/qm, wood-free paper.

18300 Central Avenue E-mail: info@robots.epson.com

Carson, CA 90746 www.robots.epson.com

Seiko Epson Corp Phone: +81 2666 11804

1010 Fujimi, Fujimi-machi, Fax: +81 2666 11846

Suwa gun E-mail: epsonrb@exepson.co.jp

399-0295 Nagano-ken www.epson.jp/fa/e

EPSON® is a registered trademark of SEIKO EPSON® Corporation.

All other product and company names used herein exclusively serve identification purposes and can be trademarks or registered trademarks

of the corresponding rights holders. All specifications can be changed without notice.

Epson_6Achsroboter_210x297_EN.indd 20 30.05.11 13:17

You might also like

- Mlops - Definitions, Tools and Challenges: Elated OrkDocument8 pagesMlops - Definitions, Tools and Challenges: Elated OrkNavendu BrajeshNo ratings yet

- Cooling TowersDocument16 pagesCooling TowersneerajNo ratings yet

- Epson Robots Product Specifications CatalogDocument64 pagesEpson Robots Product Specifications CatalogProduccion TAMNo ratings yet

- CaseStudy Cisco WebDocument2 pagesCaseStudy Cisco WebwwongvgNo ratings yet

- Siemens Distribution Feeder AutomationDocument18 pagesSiemens Distribution Feeder Automationpithoon ungnaparatNo ratings yet

- Siemens MES in Pharma (310118)Document22 pagesSiemens MES in Pharma (310118)krshna999100% (1)

- Janus 2Document6 pagesJanus 2Thoukididis ThoukididouNo ratings yet

- Precise Automation Product CatalogDocument50 pagesPrecise Automation Product CatalogIvan AvramovNo ratings yet

- API 12 X Lesson Transcript v0 2Document37 pagesAPI 12 X Lesson Transcript v0 2luis pinheiroNo ratings yet

- Simulator Portfolio, Underground Mining and TunnellingDocument8 pagesSimulator Portfolio, Underground Mining and TunnellingMikeNo ratings yet

- SAP-MM PowerpointDocument11 pagesSAP-MM PowerpointHimanshu GoyalNo ratings yet

- Epson SCARA Robot BrochureDocument16 pagesEpson SCARA Robot BrochureProduccion TAM100% (1)

- Roboguide EN PDFDocument4 pagesRoboguide EN PDFVelizarNo ratings yet

- Automatic Return of A Double Acting Cylinder Using Roller Lever ValveDocument6 pagesAutomatic Return of A Double Acting Cylinder Using Roller Lever ValveRainwin TamayoNo ratings yet

- AutomationDocument598 pagesAutomationMELVINNo ratings yet

- Design StrategyDocument7 pagesDesign StrategyKholer BurgmanNo ratings yet

- Application Observability with Elastic: Real-time metrics, logs, errors, traces, root cause analysis, and anomaly detectionFrom EverandApplication Observability with Elastic: Real-time metrics, logs, errors, traces, root cause analysis, and anomaly detectionNo ratings yet

- Robotics 6axis Brochure 2017 - 54204 PDFDocument16 pagesRobotics 6axis Brochure 2017 - 54204 PDFJosé Rafael CarvalhoNo ratings yet

- NX CAM Robot ProgrammingDocument2 pagesNX CAM Robot ProgrammingCabinet OrthopédiqueNo ratings yet

- Compumotor Step Motor and Servo Motor SyDocument114 pagesCompumotor Step Motor and Servo Motor SyNawazSatvilkarNo ratings yet

- RoboticDocument5 pagesRoboticNor IrfanNo ratings yet

- 9851 3260 01 - LDocument8 pages9851 3260 01 - LFabian Morquecho100% (1)

- Epson Robots RC PL Brochure 16-Page cpd-59217 FinalDocument8 pagesEpson Robots RC PL Brochure 16-Page cpd-59217 FinalSamritd Suaisa-adNo ratings yet

- ROB0211EN A Palletizing PowerPac Data Sheet FinalDocument2 pagesROB0211EN A Palletizing PowerPac Data Sheet FinalDraghescu DanielNo ratings yet

- Palletpro: Intelligent 3D Simulation For Palletising RobotsDocument2 pagesPalletpro: Intelligent 3D Simulation For Palletising RobotsKristal NewtonNo ratings yet

- Handlingpro: Intelligent 3D Simulation For HandlingDocument2 pagesHandlingpro: Intelligent 3D Simulation For HandlingkiNo ratings yet

- DC-AE Automation-Solution Katalog R999000019Document436 pagesDC-AE Automation-Solution Katalog R999000019Wellington Hiroshi Tani HenriquesNo ratings yet

- iRPickPRO FlyerDocument2 pagesiRPickPRO FlyerLuisito Miguelito ErazoNo ratings yet

- Boomer S1 D Simulator: Play It SafeDocument8 pagesBoomer S1 D Simulator: Play It SafeRonal CórdovaNo ratings yet

- API PRO 9 Installation GuideDocument134 pagesAPI PRO 9 Installation GuideDanielNo ratings yet

- Integrated Design and Test Platform With Ni Multisim, Ultiboard, and LabviewDocument4 pagesIntegrated Design and Test Platform With Ni Multisim, Ultiboard, and LabviewMarcos CayetanoNo ratings yet

- OutSystems Intensiv Workshop Theory SlidesDocument61 pagesOutSystems Intensiv Workshop Theory SlidesJosé Gilson FreitasNo ratings yet

- Bosch Rexroth Factory of The Future ASSEMBLY ShowDocument20 pagesBosch Rexroth Factory of The Future ASSEMBLY ShowmhafizanNo ratings yet

- Alpha Basic Line Value Line enDocument353 pagesAlpha Basic Line Value Line en周小安No ratings yet

- Getting Started With Collaborative RobotsDocument33 pagesGetting Started With Collaborative RobotsHuman Resources DepartmentNo ratings yet

- Robots OmronDocument44 pagesRobots Omronxavier rodriguezNo ratings yet

- Getting Started With ANSYS EKMDocument26 pagesGetting Started With ANSYS EKMtrymybest111No ratings yet

- ABEYAANTRIX ReportDocument7 pagesABEYAANTRIX Reportem1teamdNo ratings yet

- Optimizing Innovation in Machine Design White Paper WP VH 00110Document4 pagesOptimizing Innovation in Machine Design White Paper WP VH 00110Jorge Raul AcostaNo ratings yet

- TimerProPresentation PDFDocument34 pagesTimerProPresentation PDFAliirshad10No ratings yet

- Software Testing Automation Using Appium: Research ArticleDocument4 pagesSoftware Testing Automation Using Appium: Research ArticleabcNo ratings yet

- ABB-EOW-Education and Proposals OptDocument155 pagesABB-EOW-Education and Proposals OptŽeljko Posavec100% (1)

- Esprit Brochure PDFDocument20 pagesEsprit Brochure PDFcamb2270No ratings yet

- Getting Started With ANSYS EKMDocument26 pagesGetting Started With ANSYS EKMSuri Kens MichuaNo ratings yet

- Off-Line Programming Techniques For Multirobot Cooperation SystemDocument17 pagesOff-Line Programming Techniques For Multirobot Cooperation SystemShaw MxNo ratings yet

- Simulator Portfolio EPIROCDocument8 pagesSimulator Portfolio EPIROCioanNo ratings yet

- Brochure Plastics LRDocument8 pagesBrochure Plastics LRmlucian73No ratings yet

- ATZelectronics4 Efficient Basis ETASDocument2 pagesATZelectronics4 Efficient Basis ETASrawannwaheed1No ratings yet

- Tm-I Epos Um e RevjDocument258 pagesTm-I Epos Um e RevjRychlík RadobýlNo ratings yet

- OptiPerformer User ReferenceDocument28 pagesOptiPerformer User ReferencenedjimafaicalNo ratings yet

- Cisco Modeling Labs: Jump-Start Your Netdevops Journey With Network Simulation On Actual Ios ImagesDocument2 pagesCisco Modeling Labs: Jump-Start Your Netdevops Journey With Network Simulation On Actual Ios ImagesArun KNNo ratings yet

- ABBRoboticservicerefurbished LRDocument16 pagesABBRoboticservicerefurbished LRThomas DeponteNo ratings yet

- Aerospace Solutions - Automation in The Aerospace IndustryDocument2 pagesAerospace Solutions - Automation in The Aerospace IndustryalcNo ratings yet

- Next Computing OEMDocument8 pagesNext Computing OEMSiriö AštarötNo ratings yet

- BR Automation enDocument7 pagesBR Automation enJNarigonNo ratings yet

- Aresforti Systems PDFDocument23 pagesAresforti Systems PDFAhmed AlbashirNo ratings yet

- p072 Sysmac Catalogue enDocument418 pagesp072 Sysmac Catalogue enKocsor AttilaNo ratings yet

- SSPL Catalog Regular - Resize PDFDocument25 pagesSSPL Catalog Regular - Resize PDFusman379No ratings yet

- English PRESENTATION - AXELOR v17 ADocument59 pagesEnglish PRESENTATION - AXELOR v17 AOmer Dere100% (1)

- ePOS SDK JavaScript Migration Guide en RevfDocument35 pagesePOS SDK JavaScript Migration Guide en RevfwiriaNo ratings yet

- Process Simulation Using Delmia: Răcăşan Radu, GYÖRKE Gyöngyi Timea, Ghinea Rare Ş, POPIŞTER Florin, NEAMŢU Călin DanDocument10 pagesProcess Simulation Using Delmia: Răcăşan Radu, GYÖRKE Gyöngyi Timea, Ghinea Rare Ş, POPIŞTER Florin, NEAMŢU Călin DanproxxonNo ratings yet

- Eos Plans Feature Comparisons June 2023Document14 pagesEos Plans Feature Comparisons June 2023Javiat Aerospace Pvt LtdNo ratings yet

- CHX - Theta XSPOC Optimization SoftwareDocument6 pagesCHX - Theta XSPOC Optimization Softwaretomas.a.sierraNo ratings yet

- Rethink Robotics Collaborative Robot Buyer's GuideDocument18 pagesRethink Robotics Collaborative Robot Buyer's GuideDuvan TamayoNo ratings yet

- AI Presenation Group 10 FinalDocument26 pagesAI Presenation Group 10 FinalEaindray OoNo ratings yet

- COGNEX In-Sight Product GuideDocument16 pagesCOGNEX In-Sight Product GuidedollareNo ratings yet

- Enviro Product Catalog VCC 2Document1 pageEnviro Product Catalog VCC 2caigaNo ratings yet

- T15-Operation and Maintenance InfoDocument14 pagesT15-Operation and Maintenance Inforoberd_leeNo ratings yet

- Standard Work Rate: Duct Production Per DayDocument2 pagesStandard Work Rate: Duct Production Per Daykali highNo ratings yet

- Rockwell AutomationDocument34 pagesRockwell AutomationMartin RuedaNo ratings yet

- Materials Approval ListDocument4 pagesMaterials Approval ListBala Krishna GallaNo ratings yet

- Automating Sequential Clock Gating With PowerPro CGDocument4 pagesAutomating Sequential Clock Gating With PowerPro CGSriram SeshagiriNo ratings yet

- The Applications of Artificial Intelligence in Logistics and Supply ChainDocument12 pagesThe Applications of Artificial Intelligence in Logistics and Supply ChainSumit BhardwajNo ratings yet

- Selected Engineering ProblemsDocument6 pagesSelected Engineering ProblemsSachin KhandareNo ratings yet

- Forrester TEI GitHub 2022Document32 pagesForrester TEI GitHub 2022Vineedh MathewNo ratings yet

- Contoh WATER COOLED MAGNETIC BEARING CHILLERDocument1 pageContoh WATER COOLED MAGNETIC BEARING CHILLERsitiNo ratings yet

- Compressed Air System Commissioning Part 3 - Testing - Compressed Air Best PracticesDocument7 pagesCompressed Air System Commissioning Part 3 - Testing - Compressed Air Best PracticesmanuNo ratings yet

- Edison Mark I. PilobelloDocument6 pagesEdison Mark I. PilobelloAylie PilobelloNo ratings yet

- Training Curriculum: TIA Portal Module 011Document110 pagesTraining Curriculum: TIA Portal Module 011Hải Nguyễn KhắcNo ratings yet

- C3L1 The Information AgeDocument2 pagesC3L1 The Information Agetouchglory2No ratings yet

- Product Catalog Copeland Scroll ZW Compressor For Heat Pump Water Heating en SG 7200238Document60 pagesProduct Catalog Copeland Scroll ZW Compressor For Heat Pump Water Heating en SG 7200238ThinhNo ratings yet

- Paper Presentation 1Document7 pagesPaper Presentation 1mahakalphotographyspNo ratings yet

- HvacDocument6 pagesHvacIbrahim FarhanNo ratings yet

- DOCU MinAS PCS7 V82 enDocument86 pagesDOCU MinAS PCS7 V82 enRichard BrianNo ratings yet

- Brochures - NEXT LEGACYDocument32 pagesBrochures - NEXT LEGACYkunkzNo ratings yet

- E-Learning Schedule 2015 - V13Document2 pagesE-Learning Schedule 2015 - V13Bhekusizi DlodloNo ratings yet

- Coolant Circuit - As-Built ConfigurationDocument1 pageCoolant Circuit - As-Built ConfigurationviethungNo ratings yet

- 2015-16 PLTW Launch Module DescriptionsDocument4 pages2015-16 PLTW Launch Module Descriptionsapi-264145284No ratings yet

- 09W11Ch08 - Manufacturing SystemsDocument15 pages09W11Ch08 - Manufacturing SystemsNhi HuynhNo ratings yet