Professional Documents

Culture Documents

2008-04-10-ERROR List Rose 6k-10

2008-04-10-ERROR List Rose 6k-10

Uploaded by

Christian GaitanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2008-04-10-ERROR List Rose 6k-10

2008-04-10-ERROR List Rose 6k-10

Uploaded by

Christian GaitanCopyright:

Available Formats

sig,rna

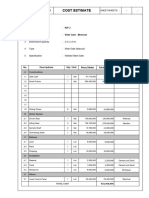

2.2 Error list

Service Manual Centrifuges for Section ServiceInformation 2:

2.2.1 Error list for Rose GontrolUnit

Enor code

1

,la

What happened?

Error in speed interrupt Error in PBM interrupt Error in MPX interrupt Error in polling Overfrequency Stack Overflow HardwareWatchdog PBM Overrun Overvoltage

Effect

User

Service

Exchange EEPROM Exchange EPROM Check hardware

12

1?

14 15 16

- Mainsofflon Reset Erroris indicated duringstandstill Run is continued Operating of centrifugeis blocked slows Centrifuge downand stops Operating of centrifuge is blocked Allow centrifuge to slow downand stoo Mains offlon

40 21

zz

24 28

Speedsignaldefective Oversoeed Rotorblocked stiff or 2 1 . . . 3 5 Severalof these errors occurred simultaneouslv Speedoverrun 41 42 MPX overrun 50...59 Incorrectdata from the EEPROMare usedfor calculations Insutficient backupvoltage after reset used is not suitable Software for centrifuge

Checkregulator and relay Checkspeed sensor Check rotor

- Error message untilnextkeyis Dresseo

Operating of centrifuge is blocked Fast stop

Pressany key

- Erase EEPROM

60

o9

- Faststopis carried out

- Operating of is centrifuge blocked - Operatingof centilfuge is blocked

Allow centrifuge to slow downand stoD Presslid kev Exchange E P R O Mo r eraseEEPROM type code lnsertEEPROM

71

m EEPROM issing

72 73

/c

writeerror EEPROM dataset Errorin program Errorin dataset of characteristic curyes dataset Errorin backup

during Interruption programmrng program Incorrect No.is displayed lncorrect of No. characteristic curveis displayed Errormessage untilnextkeyis oressed

- Operatingof centrifuge is blocked - Faststop

Press keyto any datain the erase EEPROM

- Erase EEPROM datasets - Exchange if EEPROM erroroccurs repeatedly

76

memory cell EEPROM defective

'Lid open'detected while is centrifuge running Prooram runtimeerror

- Exchange EEPROM

to Allow centrifuge slow down and stop Closelid Allow centrifuge to slow down and stop Press lid kev Check lid switch

A1

Faststop

Faststop

82

lssue07/96

Seaion Pege 10 2

Service Manual for Centrifuges

sil=',mra @

Section 2: Service lnformation

83

84 85 86

Keyboard defective heat sink Overtemperature Overtemperaturerotor chamber system does not Refrigeration cool to pre-settemperature

Operating of is centrituge blocked Faststop Faststop Faststop

- Check keyboard Allow to cool down Allow to cool down Raisesetpoint temperature - Checkheatsink - Check rotor chamber switch - Check temperature sensorsano refrigeration svstem - Check temperature gensors Check rotor identification

sensor defective 9 0 . . . 9 7 Temperature (shortcircuitor broken) 98 No rotor identification but Rotoridentified, incorrect tvoe of rotor

Fast stop P r e s s ' l i dk e y ' Insertselectedrotor P r e s s ' l i dk e v '

Faststop Fast stop

pulses. and externalinterference can be causedboth by internal Errormessages simplyby a 'reset'= mainsoff/onor by pressing special Thesecan be eliminated 4.1,3). of combinationskeys(seesection The measures listed under 2.1 conceming interferencesuppression must alwaysbe carried out to ensure maximumprotectionagainst inteference. poorly of interference sourcesin the vicinity the centrifuge, instance for However, etc. disturbances, cause may microwave equipment as wellas atmospheric shielded unjustified error messages.In these cases remove or shield the source of interference. lf such a fault cannot be removed,pleasecontactour service. subsections numerical in in order. are The errormessages described the following page. Seealsothe errorslist on the previous

ERROR _ 16 + 40 10 2.2.1.1

and can usually be These error messagesare caused by radio interference eliminated carrying a reset(mains by out off/on). on lf the erroroccursrepeatedly afterswitching the mains,it is causedby a memory The may in EEPROM or malfunction. malfunction haveoccurred the RAM,EPROM, mustbe exchanged one after ln components microprocessor. this case all memory board. to the the otherby trialand error.lt maybe advisable replace microcontroller

21, circuit 2.2.1.2ERROR Oveloltage in the intermediate

See section 5.3.2.2 intermediate circuit.

circuit occurs the mainsvoltageexceeds if 27OV in An overvoltage the intermediate circuit. The centrifuge not designed is in or 385V DC are exceeded the intermediate

lssue07/98 Section 2Page 11

sicg,ma @

ServiceManual Centrifuges for 2: Section ServiceInformation

voltage meansof suitable by the In for suchovervoltages. suchcasesreduce mains transformer. if R87 or the can exceed385 V duringbraking the brakingresistor The DC voltage of V85 are defective.Malfunctions the braking chopper, see brakingtransistor this 5.3.2.5 brakingchopper,canalsoGtuse errormessage. section

22, 2.2.1.3ERROR Speedsensordefective

See section7.3. speed sensor. The distancebetweenmagnet and Hall sensoron the speed sensor board must be 1 + 0 . 5m m . Check the magnet on the motor. The Hall sensor must generate six pulses per for Use test board No. 70236,if available, testing. revolution. Slippageof the rotor on the drive shaftcan also causethis error. Checkwiringand plug connections.

24, 2.2.1.4ERROR Overspeed

The speed exceedsthe setpointvalue by more than 15%. This can happen when very light rotors are accelerated to their final speed with maximum acceleration. curve,e.g. No.8, will solvethis problem. of Selection a sloweracceleration This error can also occur if the setpointspeed is altered repeatedlyduring a run setpointspeeds. withoutwaitingfor the speed controlto reachthe previous

28, 2.2.1.5ERROR Rotor blockedor stiff

This error occurs if the microcontrollerstarts up the motor and supplies voltage but motor speed. receivesno feedbackor no plausiblefeedbackconcerning . Checkwhether motor or rotor are in fact blockedor stiff. . Checkthe rotor chamberfor foreignobjects. in All malfunctions the power supplywhich preventthe motorfrom startingup lead to this error message. o Checkrectifiers, F1. and microfuse relays, power transistors o Checkwiring of motor. particularly there is a weak if The speed sensor can also use this error message, magnetsegmentor the distancebetweenthe magnetsegmentand the hall sensor is too large.See section7.3 speed sensor. 07/98 lssue

Section 2Page 12

sftg,mra @

for Manual Centrifuges Service 2: Section ServiceInformation

41 2.2.1.6ERROR - 42,Speedoverrun/ MPX'overrun

Gluses a softwareerror.The run can be resumedby interference An undefined pressing keyon the keYPad. any by it on afterswitching the mains, is caused a fault in the regularly lf the erroroccurs Observe component. defective Replace microprocessor. or EEPROM RAM,EPROM, 4.3. in instructions section

50 ERROR - 59 2.2.1.7

The EEPROM datafromthe EEPROM. havebeenmadewith incorrect Calculations - input of offset values. 4.3 Seesection servicemode mustbe erased.

powerbackupvoltage 60, 2.2.1.8ERROR Insufficient

run is resumedafter a brief mainsfailure(ca. 30 sec). This, however, The centrifuge only occursif the rotor is still turningwhen the mainsvoltagereturnsand the voltage at C5 of the voltage supply does not fall below 2.5 V. This voltage is required to storethe data of a run which is in progress. lf the voltagehas fallen below 2.5 V, the data of the run are lost and the centrifuge coasts freely.After the mains voltage returns and an additionalmains off/on reset has been carriedout, a new run can be startedduringcoasting. lf ERROR60 occursfrequently,check the circuitfor the power backupvoltage in the powersupply.See section5.3.2.

for 69, 2.2.1.9ERROR Softwareunsuitable centrifuge

(EPROM)is in fact the software This errormayoccurafter a repair.Checkwhether unsuitable. aftera repair.Erasesystem may be incorrect The systemstringin the EEPROM 4.3 servicemode- input of offset values. see stringin the EEPROM, section must the string, EEPROM the by 69 lf ERROR cannotbe eliminated erasing system section4.3 service mode - input of offset values and section See be replaced. of 4.5 - exchange memorycomponents. Caution: e.9. when using a an ERROR69 occurs on exchanging EPROM, erasedthe system string new special type of rotor without having in the EEPROM.

is centrifuge running 81, 10 2.2.L ERROR 'Lid Open'while

This error occurs if the emergency lock release is actuatedduring a centrifuge run. A fast stop follows automaticalty.The centrifuge can be restarted after the rotor has

lssue 07/98

2 Section Page13

=iema

for ServiceManual Centrifuges 2: Section ServiceInformation

come to a standstill,the lid has been closed and a mains offlon reset has taken place. and wiring. lf the lid was not in fact open, check lid locks,switches

runtimeerror 82, ERROR Program 2.2.1.11

'lid' by of erroroccurs,resetafter standstill centrifuge actuating Whenthis software key.

83, 2.2.L12 ERROR Keyboarddefective

Replacefoil keyboard The messageappearsafter switchingon the centrifuge. platein frontpanel. button separate respectively on duringthe switching of by if alsoappears a key is pressed mistake The message error. lt the mains. is in thiscaseonlyan operating a whether key in the frontpanelis jammed. Check andplugconnections. wiring Check 2 . 2 . 1 . 1 3E R R O R 8 4 - 8 6 of heat 84, ERROR Overtemperature sink 2.2.1.13.1 Allowheat sink to cool down.Checkfan of powerboard.Lowerroomtemperature sensoron Checkthe wiringand temperature to and avoiddirectexposure sunlight. 7.1 theheatsink(seesection .2). in rotor 85, ERROR Overtemperature chamber 2.2.1.13.2 'C if the off the switchswitches centrifuge at approx.70 temperature A mechanical control unit fails. See section7.1.3 safety thermostat and section temperature 9.2 refrigerationof centrifuge. temperature. to does 86, ERROR Refrigeration notcool pre-set 2.2.1.13.3 if This error occurs predominantly the starting temperatureis close to room is and the selected overtemperature set relativelyfar below room temperature temperature. is The error also occurs if the oveftemperature set so low that under normal cannotfall belowthe setpoint. the conditions temperature operating 86. etc.)also leadsto ERROR lf or system fan (leakage A defectin the refrigeration engineer. thisis the case,call a refrigeration to directexposure sunlightor other of Contamination the coolingagentcondensor, systemand can of also diminishthe performance the refrigeration heat sources

lssue07/98

Section 2Page14

siemre

for ServiceManual Centrifuges 2: Seclion ServiceInformation

the or g6. agentcondensor removing source of causeERROR Cleaning the coOling of heathelpsto solvethis problem.

90 ERROR - 97 2.2.1.14

defective chamber in sensor rotor 90, ERROR Temperature 2.2.1,14.1 The temperature sensor in the rotor chamber does not provide plausible measurementvalues. Check if the sensor has short circuited or broken and, if necessary,replace the sensor. See section7.1 temperature sensor. which are not connectedat the for 2.2.1.14.2ERROR91 - 94. Enor message sensors time. sink' sensor'heat defective 95, ERROR Temperature 2.2.1.14.3 See ERROR90. 9 E 2 . 2 . 1 . 1 4 .4 R R OR 6 - 9 7 See ERROR91 - 94.

2.2.L15 ERROR98, No rotor identification

reasons: for a does Themicrocontroller not identify rotor oneof the following o on andthe codingmagnet the rotoris too the between Hallsensor The distance of of mustbe a minimum 0.8 mm and a maximum 2.0 mm. great.The distance a pieceof puttyof morethan 2 leasrre by using a pieceof puttyor wax.Stick mmto the Hall sJnsor,put the rotorin placeandthentake it off again.Measure pieceof puttyby meansof a slidegaugeor similar of the thickness the flattened the undemeath U-washers by can be reduced placing The instrument. distance for Hallsensor, examPle. See sectiorr-7.4 wiringor plug connections. Defectin the sensorelectronics, rotor identification. The test board (part No. 70236) is useful for these investigations.

but 2.2.1.16ERROR99, Rotor identified, incorrecttype of rotor

if of with preselected number number rotorusedandalternumber, rotor Compare necessary.

are in The instructions section2.2.1.15 alsoapplicable.

lssue07/98

2 Section Page15

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Freight Broker Training ManualDocument9 pagesFreight Broker Training ManualTigranuhi MantashyanNo ratings yet

- Lions Mane Ultimate Guide 00Document1 pageLions Mane Ultimate Guide 00János JuhászNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- PLSQL 4 PraticeDocument20 pagesPLSQL 4 PraticeClayton FerreiraNo ratings yet

- 4 - Spanning Tree Protocol (STP) PDFDocument27 pages4 - Spanning Tree Protocol (STP) PDFmcclaink06No ratings yet

- Linguistic Theories of HumorDocument5 pagesLinguistic Theories of HumorNilmalvila Blue Lilies PondNo ratings yet

- Old English Part 8Document5 pagesOld English Part 8eliseo_dNo ratings yet

- Jinko 250WDocument1 pageJinko 250WCruz López MargaritoNo ratings yet

- Unit Plan: Short Stories: For: Grade 7 and 8 Students in The English Classroom TitleDocument49 pagesUnit Plan: Short Stories: For: Grade 7 and 8 Students in The English Classroom Titleste100% (1)

- Quality AwardsDocument9 pagesQuality AwardsCalton MungofaNo ratings yet

- General Drilling PracticeDocument35 pagesGeneral Drilling PracticeNW ArselanNo ratings yet

- Interdisciplinary Approaches To Nonlinear Complex SystemsDocument243 pagesInterdisciplinary Approaches To Nonlinear Complex SystemsBolaybalamNo ratings yet

- ISBN Information SheetDocument1 pageISBN Information Sheetshintaroniko50% (2)

- Rab Execution LTEDocument6 pagesRab Execution LTEvindyasharmaNo ratings yet

- AVE Experiment No. 4Document5 pagesAVE Experiment No. 421EC006 Utkarsh AswarNo ratings yet

- Cage (Lecture On Nothing)Document13 pagesCage (Lecture On Nothing)Sebastián Diez Cáceres100% (3)

- Market Research ProposalDocument23 pagesMarket Research ProposalLachlan Ross100% (4)

- ECA Clean Rooms HVAC Systems 2023 Live Online TrainingDocument4 pagesECA Clean Rooms HVAC Systems 2023 Live Online TrainingRahul RajNo ratings yet

- MaterialismDocument3 pagesMaterialismAce AceNo ratings yet

- Holiday Homework (Summer 2015) - Maths-S-IB HL FormDocument5 pagesHoliday Homework (Summer 2015) - Maths-S-IB HL Formatharva234No ratings yet

- Rss Grad Diploma Module4 2015Document16 pagesRss Grad Diploma Module4 2015S.L.L.CNo ratings yet

- Public Spanish 2 Course Map - Spanish 2Document2 pagesPublic Spanish 2 Course Map - Spanish 2api-534094065No ratings yet

- Module 8Document8 pagesModule 8Dethzaida AsebuqueNo ratings yet

- 01.00 - CE - Slide Gate 2.0 X 2.0m - MotorizeDocument8 pages01.00 - CE - Slide Gate 2.0 X 2.0m - MotorizeJonesNo ratings yet

- Unit 1 Leisure Activities Lesson 6 Skills 2Document16 pagesUnit 1 Leisure Activities Lesson 6 Skills 2ScentCandleNo ratings yet

- Fracture Resistance and Marginal Discrepancy of Porcelain Laminate Veneers Influenced by Preparation Design and Restorative Material in Vitro PDFDocument8 pagesFracture Resistance and Marginal Discrepancy of Porcelain Laminate Veneers Influenced by Preparation Design and Restorative Material in Vitro PDFLuis Alberto Carpio MorenoNo ratings yet

- Success Comes in Many Different Shapes and FormsDocument7 pagesSuccess Comes in Many Different Shapes and FormsRagunathan srinivasan100% (1)

- Chungbuk Product Show & Trade Fair 2014: Myanmar Business MatchingDocument11 pagesChungbuk Product Show & Trade Fair 2014: Myanmar Business Matchingapi-241660673No ratings yet

- Robotic AspectsDocument2 pagesRobotic AspectsmanulalsNo ratings yet

- ZXXXDocument1 pageZXXXleaves_pebblesNo ratings yet

- Lesson PlanDocument5 pagesLesson PlanPrincess Kylah Chua TorresNo ratings yet