0% found this document useful (0 votes)

174 views3 pagesGrand Vitara Input & Output Sensor Check

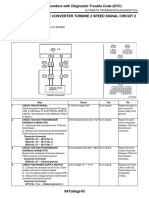

The document outlines diagnostic trouble codes (DTC) related to automatic transmissions, specifically DTC P0717 and P0722, which indicate issues with input and output speed sensor circuits. It provides detailed conditions for detecting these DTCs, confirmation procedures, and troubleshooting steps to identify and resolve sensor malfunctions. Additionally, it mentions DTC P0741 and P0742, which relate to torque converter clutch performance issues, along with their potential causes.

Uploaded by

ido.overathCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

174 views3 pagesGrand Vitara Input & Output Sensor Check

The document outlines diagnostic trouble codes (DTC) related to automatic transmissions, specifically DTC P0717 and P0722, which indicate issues with input and output speed sensor circuits. It provides detailed conditions for detecting these DTCs, confirmation procedures, and troubleshooting steps to identify and resolve sensor malfunctions. Additionally, it mentions DTC P0741 and P0742, which relate to torque converter clutch performance issues, along with their potential causes.

Uploaded by

ido.overathCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd