0% found this document useful (0 votes)

16 views17 pagesAluminium Certification and Testing Data

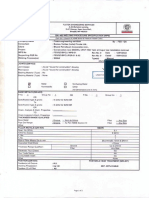

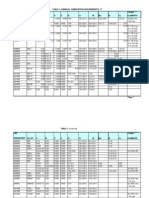

The document provides detailed information on various tests and analyses conducted on materials, including chemical composition, mechanical properties, and electrical characteristics. It includes data on tensile tests, impact tests, and roughness measurements, along with certification details for specific batches. The results are organized by test type and include various metrics for evaluating material quality and performance.

Uploaded by

xallequennoize-3128Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

16 views17 pagesAluminium Certification and Testing Data

The document provides detailed information on various tests and analyses conducted on materials, including chemical composition, mechanical properties, and electrical characteristics. It includes data on tensile tests, impact tests, and roughness measurements, along with certification details for specific batches. The results are organized by test type and include various metrics for evaluating material quality and performance.

Uploaded by

xallequennoize-3128Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd