Professional Documents

Culture Documents

Wps-E 6013 - 3G&2G

Uploaded by

Arijit Ghosh0 ratings0% found this document useful (0 votes)

32 views15 pagesWPS 3G

Original Title

WPS-E 6013 -3G&2G (1)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWPS 3G

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

32 views15 pagesWps-E 6013 - 3G&2G

Uploaded by

Arijit GhoshWPS 3G

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 15

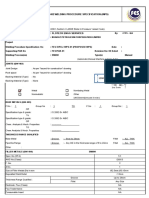

FLOTEX ENGINEERING SERVICES

‘A-63 Mahoksl society,

8 Trilange, Near Aura Mall,

‘Bhopal, MP-462039

[Company Name Flotek engineering services

JConsultant + Bureau Veritas (India) Private Ltd,

Jctient + Bharat Petrolleum Corporation Ltd.,

Project +: Construction new 20000KL CRVT HSD Tank at

wes No FESIQC/BPCLI WPS-01 Rev No:

ISupporting POR No FESIQCIBPCLIPOR-01 & 02 Rev No:

Welding Process(e = SMAW Type(s)

[As per "issued for constuction” drawing

[As por "issued for construction” drawing

Backing Material (Type)

‘GW -482 WELDING PROCEDURE SPECIFICATION (WPS)

{OW-200 | Secton CASE Bole & Preatire Venel Coe)

‘

By :FES-GA

lrugur top installation terminal

© Date: 12/01/2022

© Dated: 08/01/2022

Manu:

(Automatic, Manual Machine or Semi Auto}

coro

a Metal 1 Niortusing Metal

o Nonmettic OD Ober

(A Dimensions.

JP.No Group No 10 PNo Group No:

oR

[Specification type & grade: 182082 Gr E250 BR

To

[specication type & grads: 18 2062 Gr £250 BR

oR

JChem, Analysis & Mech, Properties

TO

[Chom Analysis & Mech. Properties

THICKNESS RANGE QUALIFIED

Bese Metal Groove = Smm to 24mm Filet Anv Size

Pipe Dia Range Groove = As Per ASME Section x! Filet = Anv Size

Spec. No (SFAY oI

AWS No (Glass) E oor

FN. zi

IAN.

7

ze of Flor Metals Dia rm

Bam OS. Tsmm & oom

[Deposited Weld Metal

PALL

Up hit

All

[Postion (S) of Filet

Page of?

a5

a ae

ras Rage tn Ts pain

— i

ase m

Eonunsse aT a

= os

NOT APPLICABLE

[TECHNIQUE (aW-470)

string or weave bead

JOxiice or Gas cup size

IMethord of back Gouging

loscitation

[Contact tube to work dostance

FLOTEK ENGINEERING SERVICES

‘A-63.Mahakal society,

E-8 Trllanga, Near Aura Mal

‘Bhopal, MP-462039

‘GW -482 WELDING PROCEDURE SPECIFICATION (WPS)

TaW200-1 Seaton DCASME Boler& Pressure Vessel Code)

rial & interpass cleaning (Brushing, Grinding etc)

Weaving with shall not exceed 3 imes the core wire diame

“GAS (QW-408)

NOT APPLICABLE

Pataiy :DcEN

Vats (Range) 118-26

: Stringer (Weaving width < 3 times core dia of electrode.)

Not applicable

+ By wire brushing & grinding

Gouging by Grinding

None

Not applicable

Multiple

Single

+ 60 (Approx)

‘Not applicable

Manual

= Not permitted.

Not applicable

None

er Trae] Oar eg os

had tyer voitranoe | peed | comment Hot me

wets Layerte) | Process | ass loin) Tp | Anos. | ans” lrangeimm_ cdo Teehigu

pol 9 Imin) | Torch angle,ete.

suo | Eons | 075 | poEW| 10-100

Root &Subeeq Pass ["SMAW | E eot8 | 0.3.18 | DGEN | 100-140 «

SwaW |e eots [03.48 | BCEN | 10-10

oprved by

sanatre ZEZCORS

x

Itane _ [wawKaKoanT [21 snare

pate | vamvauza oS

Page 2082

Accredited by NABL, Dept. of Science & Technology, Govt. of India.

No. 10A, RMT. Bungalow Road, Sai Nagar 2nd Cross, Opp. Krishnar Temple,

Sidco Industrial Estat, Coimbatore - 641 021. Phone : 0422 - 2674872

E-mail: coimbatore@ microlabchennalcom Web : www.microlabiesting.com

Page tof 1

TEST REPORT

[eastomer TiRTCS89820000000005

M/s. Flotek Engineering Services, |Report No/ Date __ MU/M3868/i/2522/ Du OTOL2022

Pict No. 15, Door Nor 23, Your ref/ Date | Letter Date: 30122021

Selvancgar 2 Cross, Rettaiveikal, OUet/ Date | TOCR: W3865/2-22/ Ox O01, 7022

oo *PNature of test | Tense Test

perRebie Test Method 'ASME Sec IX- 2021

Trichy 620 102. Date Testing | 07.01.2022

Sample Drawn By | Customer

7MS Welded Plate

‘Material Grade: 1s 2062 Gre25088

sero | Maem ee

inion WPS No: BPCL/FES/WPS/WOT-O1/WO1/36 6012

ty: 1 No.

1 : ales

Test Parameters bserved Values Observed

TH 7

Gauge Wich (mm) 1902 1905

Gauge Thickness (mm) 12s 15.08

Area (mm) 231.08 23042 |

Ultimate Tensile Load (kN) 9769 118 |

Urimate Tensile Strength (MPa) 423 a2

Fracture Location Base Metal ase Metal

Remarks: The above Tensile Test Found Satisfactory

Veried by

For MICROLAB N. Balakrishna

-~END OF THE REPORT-

NOTE: Therepe eats ant he parteula eagle eubatedfiest @ Arycnecton nthe report wl nde his reper @ Ary compl about ths ep sheuld be

camemricale wring win 7 days fom Be dal of recep of rept @ Ths repr canal be reproduced except ul @ Sale desciptan sven as cescrbed

by he custo @ Samping ro cared ut byte abr @ Sarl Wl be cestoyed ai 15 day Yom dat of caro fe ures romed byte cstone

(Lateral opr fe Sana corti bala spectator a pt Dein Ru, Non Cova apr Den Rue 4 fo ues 283 cso ove each.

Format No. ML-CBE / QMS /TR/01

% MICROLAB

Accredited by NABL, Dept. of Science & Technology, Govt. of India.

No, 10, RMT. Bungalow Read, Sai Nagar 2nd Cross, Opp. Krishnar Temple,

Sidco industrial Estate, Coimbatore - 681 021. Phone 0422 - 2674872 ee

E-mail coimbatore@ mirolabenennai.com Web : www mierolabtesting.com

Page Loft

TEST REPORT

Customer: ‘ULR-T€584820000000005,

M/s. Flotek Engineering Services., | Report No/ Date _| Mi/H3868/2/21-22/ Dt: 07.01.2022

Plot No. 15, Door No: 23, Your ref/ Date | Letter Date: 30.12.2021

Selvanagar,2” Cross, Rettaivaikal, | Ou'tef/ Date | TOCR: H3868/21-22/ Dt OL 03.2022 |

ecg * [Nature oftest | Bend Test

ye 4 Test Method | ASME Sec X-2021

Trichy — 620 102. Date Testing | 07.03.2022

‘Sample Drawn By | Customer |

MS Welded Plate

Sempl Material Grade: 'S 2062 £250 GrE250BR

are Size: 300 X 300.X 12mm

‘et WPS No: BPCL/FES/WPS/WAT-01/WO1/3G - 6013,

ary: 1 No.

1L.Bend Test:

Nature of | Length Width | Thickness Mandrel_| Angle of

Sample 1D servation

te Bend | (mm) (mm) | (mm) | Dia(mm) | Bend (Deg) a

sai | Sidesend | 250 | 1003 | 12.06 40 180° Nee Siecont ies:

observed

s82_ | Sidesend | 260 © 1901 | 1240 40 180° ala

‘observed

7 > ‘No Open discontinuities

sea | sidesend | 250 1003 | 1208 40 80 observed

No Open discontinuities

ses | sidesend | 250 | 1005 | 1213 40 180° observed

Remarks: Bend Test found satisfactory

verified by

For MICROLAB

(e#=))

jenateshwston

ied Signatory.

~ — ~~~ END OF THE REPORT:

NOTE: This repress ont the patina sample suited forest @ Any coracion nthe repr wilnvaldata his epon © Ary complains abou the repo shoud be

ernmurcated in wing wen nT days ram ne Gate of rece! ep © Ta repr carrt ba reproduced exc él @ Sample descipon ven as descrted

the custome @ Sanping sol aid cu by thelabuatay © Samples wil be destroyed afer 15 days for dal of completion of tts nes formed by he cuter

1 Laterety repr te Sater of eat el spelen es er Decson Rue, Non Cover as pr Dacor Rue 4 ues 283 cstome poe each

Format No. ML-CBE / QMS /TR/01

Accredited by NABL, Dept. of Science & Technology, Govt. of India.

No, 108, RAAT. Bungalow Road, Sai Nagar 2nd Cross, Opp. Krishnar Temple,

Sidco Industrial Estate, Coimbatore - 641 021. Phone : 0422 - 2674872

E-mail: coimbatore@ microlabchennai.com Web : www.microlabtesting com

Page 1of1

TEST REPORT

Customer: ULR-TC584820000005852F

M/s. Flotek Engineering Services., Report No/ Date _| ML/H3868/3/21-22/ Dt 07.03.2022

Plot No. 15, Door No: 23, Your ref/Date | Letter Date: 30.12.2021

Selvanagar,2” Cross, Rettaivaikal, | Ourteh/ Date | TOCR; #3868/21-22/ 04 03.03,2022

; ei * [Nature of test | Impact Test

Valayar Road, Test Method | ASTM A370-2020

Trichy ~ 620 102. Date Testing 07.03.2022

Sample Or Customer

(MS Welded Plate

‘Material Grade: IS 2062 €250 Gré2508R

ee Size: 300 X 300 X 12mm

a WPS No: BPCL/FES/WPS/WAQT-01/WO1/3G - 6013,

ty: 1No.

|Licharpy ‘V’ Notch impact Test:

‘Specimen Size (mm): 55 x 10x 10mm

‘charpy ‘V' Notch

Test Temperature: - RT

Test Parameters | Location | Sample 0:1 SampleD:2| Sample l0:3 | Average

Observed Energy —

aaa Weld nR 62 60 647

Shearee ey, Haz 370 420 204 1647

Verified by:

For MICROLAB N. Balakrishnan

‘Autnorized Signatory.

= END OTHE REPORT: ~

NOTE: This eportreetes cl tthe parla saple submited east @ Any coecon ne report wlth report @ Any complains abou i apr should be

Cmunicelad nwrtng wth n7 days rom te dae cf tecept of report ® This report cannot be repdiced excep ful © Saige dasptons Given as desobas

by be cases Samping so carie ut by abr @ Sans We destroyed at 15 day tom date of conplaton of asus nomad byte cute.

© Lateraty repre sateen of coy rl ypecteaten opt Deon Rue Non Cory spr Deon Rule 8 ues 283 csime Proves eat

Format No. ML-CBE / QMS /TR/01

[Company Name

Jconsunant

cient

Project

Jpar No

[vomers (aw-402)

Supporting WPS No

|Welding Process(es)

‘BASE METALS (W403)

FLOTEK ENGINEERING SERVICES

WELDING PROCEDURE QUALIFICATION RECORD (PQR)

Flotek engineering services Date 0807-2022

'A-63,Mahakai society,

E-8 Trilanga, Near Aura Mall

‘Bhopal, MP-462039

Bureau Veritas (India) Private Ltd,

Bharat Petrolleum Corporation Ltd,

Construction new 20000KL CRVT HSD Tank at irugur top installation terminal

FESIOCIBPCLPOR-O1

FESIOCIBPCLI WPS-01 Rev No: 0

SSMAW (Mana!)

POST WELD HEAT TREATMENT (W407)

ores

ickness of Test Coupon : 12mm

bia of Test Coupon LNA

FILLER METALS (@W-404)

Materials Spee 715.2082 GrE750 BR

Type or Grade 2Gc.6250 BR

P.No

(GAS (QW-408)

Gas (es)

‘Shielding None

Traling

sizeof filer Metal

otners

Postion (S) of Filet

Preheat temp. Min

otners

[Weta Metal thickness

Postion) of Groove

£0019

[SFA Specification iat

Jaws ciassiteation

Fier Metal F. No 2

| Weta metal analysis A no 4

216mm

Welding Progression

PREHEAT (QW-406)

oterpass Temp, Max

20°C

250" ©

Refer welding data sheet

ons Refer welding data sheet

Reler welding data sheet

eter welding ta sheet

string or weave bead : Weave

loscstaven None

Muttple

Single

Page 1of2

FLOTEK ENGINEERING SERVICES Gre

© ‘A-63Mahakal society. @

Tang, et Are a, )

Bhopal, MP-462039 |

WELDING PROCEDURE QUALIFICATION RECORD (PQR)

TERETE

= es [ea eas ewes eran

seni (mm) (mm) wenn, Unset eres 8 OND dina ‘or Mpa) Location

7 ae | on | aoe we a ea

12 19.05 15.08 230.12 101.8 442 —_

‘Guided Bend Test (QW-160)

Sample 0 ‘ages ] wth Tray] ei [Aa observation

sei___[beevera] aso | 1000 | veo | «0 | 100" | NoOpondoainaten ooeves

saz [Sdetera] azo | 1001 | ras [a | 190° | NoOpendsoninies coved

sax__[Sdebera] aeo | 100 | veor | 0 [ 100° | NoOpenasoninesobseved

sea [Severe] 00 | va0s | rare | co | veor | open doranaes cosevee

‘Charpy V. Notch impact test (QW-170)

VechLosaton | Specimen a(n | Test, [_Seerty taered alos n Joie pest Ve) es

ia femp'C | Sample 1[Sample2] Samples | Average

Wels S54 0x10 er | 7 [| e 0 47

HAZ sx10x10 et | io [120 208 1647

Fillet Weld test (QW-160): NA

Result satisfactory: Yes. Now Penetration into Parent metal: Yes. NO

ae

[Fvpe oftest mT

Deposit anaysis NA

orhers

Wwetsers Name JTENDRA RAY ‘Stamp No : FES/QGIBPOLIPGR-O1/SGIE6013,

Hest Conducted by __: Mra. Goimbalore Laboratory tesiNo_: MUH3868/1-321-22 Date 07.01.2022

[Frise Cerify mat ihe Statements n ti record are correct and thal tat welds wore prepared and esled Ih accordance with We

reauements of section X! ofthe ASME Boller & Vesoel code.

Signature [signature ABE

name [mawwanbant

vziow022,

Page 2of2

WELDING PROCEDURE QUALIFICATION RECORD (WPOR)

Welding Data Shoot

‘ompany Name]; Flotek engineering services [welder Name |: Jnendra Ray [Fest Date 2ayia02t

Bureau Veritas (india) Private Lid, lwatNo [01 Etec. itor Make GEE Wnitod

: Bharat Petrolleum Corporation Ltd, WPSNo | FESIOGIBPCL WPS-01 [Elect Filer Class E0013

Construction of New 20000KL GRVT HSD Tank at Irugur

top installation terminal

ase Materia [1S 2082 Gr E250 BR [Welding Process |: SMAW

lrarNo |: FesiacrpPcUPaR.01 |EtectiFiler Batch No |; 1210090095

36,

eat Temperature |: NA [doit Type Single V wold metal

Fi [Dimension Oftest =

interpass Temperature |: 250" e 412 Thk x 3008M x 300MM NA

Weiaing Progression |: Uphi NA

‘Current

ate Volts Range | Travel Speed Range

Potaty,| amp. Rangets) | (Vd

oor | Saaw Deen Tex

FUL up| suaw GEN 7228

a poe | 9 war

loPr or eackcn Accor

FLLUP Deen [Toss 7a

FINAL een | e107 Bar

[Root Pass Acsoptaie Rateane ForRT I

Raut nspeaion —:Accopable

Isicnarure :

kc MICROLAB

Accredited by NABL, Dept. of Science & Technology, Govt. of India.

No. 10A, RMIT. Bungalow Road, Sai Nagar 2nd Cross, Opp. Krishnar Temple,

SidcoIndustial Estate, Coimbatore - 641 021. Phone : 0422 - 2674872 a

E-mail coimbatore@ microlabchennal com Web: www microlabesting.com

Page 1 of.

‘TEST REPORT

Customer: ‘ULR-T¢84820000000005

M/s. Flotek Engineering Services., | Report No/ Date | MI/H3868/4/21-22/ Dt: 07.01 2022

Plot No. 15, Door No: 23, Yourref/Date | Letter Date: 30.12.2021

Selvanagar.2" Cross, Rettaivaikal, | Ovreef/ Date | TOCR: H3868/21-22/ Dt: 01.01.2022

iene * [Nature of test | Tensile Test

cil : TTest Method | ASME Sec x: 2021

Trichy ~ 620 102. Date Testing | 07.01.2022

‘Sample Drawn By | Customer

(Ms Welded Plate

— ‘Material Grade: 1S 2062 £250 GrE250R

Fevpibe ‘Size: 300 X 300 X 12mm

oi WPS No: BPCL/FES/WPS/WQT-05/WO1/2G - 6013

| Qty: 1 No.

‘LTensile Test:

ee Observed Values Observed Values

Tm cc]

Gauge Width (mm) 19.03 19.08

(Gauge Thickness (mm) | 1209 1203

area (mm) | 230.37 22953 |

Uitimate Tensile Load (KN) 105.7 1076

Ultimate Tensile Strength (MPa) 459 469 |

Fracture Location Base Metal ‘Base Metal

Remarks: The above Tensile Test Found Satisfactory.

Verified by:

For

rized Signatory.

- -END OF THE REPORT —

NOTE: Ths repo relatos ont the parka sample submited forts @ Any.

Command n wring hn ays rom eda of recat rpen @ This part carn be reprodoadexcpl nfl @ Sample deszpn is ven a eszbed

2) th catomer © Samping rtrd uty aber @ Sari wl be decroyed at 15 as Fm cae compen oss uss vomed by re cusomer

1 Laat rapt ie Sacer crm mel speceain ae er Deco ue Non Confort apr Dacison ue 4 for ues 28 cso poe ebck

Format No. ML-CBE / QMS /TR/01

willie hig opr @ Any complaints abou his repr shoud be

* MICROLAB

Accredited by NABL, Dept. of Science & Technology, Govt. of India.

No. 108, R.M.T. Bungalow

1a, Sai Nagar 2nd Cross, Opp. Krishnar Temple,

Sideo industil Estate, Coimbatore - 641 021_ Phone : 0422 - 2674872 me

E-mail: coimbatore@ microlabchennal com Web : wivw.microlabtesting com

Page 1 of 1

‘TEST REPORT

Customer: ‘uiR-T¢584820000000005

M/s. Flotek Engineering Services., | Report No/ Date _| ML/H3868/5/21-22/ t:07.01.2022

Plot No. 15, Door No: 23, Yourref/Date | Letter Date: 30.12.2021

Selvanagar,2” Cross, Rettaivoikal, | Ourtet Date | TOCR: H3868/21-22/ D1 04.03.2092,

VatgerReM, * [Nature oftest | Bend Test

y , Test Method | ASME Sec IX- 2021

| Trichy ~ 620 102. Date Testing (07.01.2022

‘Sample Drawn By | Customer

(MS Welded Plate

— Material Grade: 'S 2062 £250 GrE250BR

teen Size: 300 X 300 X 12mm

WPS No: BPCL/FES/WPS/WOT-05/W01/2G - 6013

ty: 1 No.

4.Bend Test:

Nature of | Length Width Thickness | Mandrel | Angle of

Sample | pend (mm) | (mm) | (mm) | dia(mm) | send (Oe8) Shei

3 e ‘No Open discontinuities

sei | Sidepend | 260 | 1008 | 1207 40 180' canal

‘i ‘No Open discontinuities,

sez Side Bend 260 10.02 12.10 40 180° ‘sbaee

‘No Open discontinuities

$83 Side Bend 260 10.04 12.08 40 180° observed

|

| | ‘No Open discontinuities,

se4 | sidesend | 260 | 1005 | 1206 0 380° observed

Remarks: Bend Test found satisfactory

Verified by:

For MICROLAB N. Balakrishna

forized Signatory.

NOTE: Therap ates ony toe partculrsarpl submited fer tst Any carecon in the eport wl invite his report @ Any complains abou this opr should be

camunicata nwrang wth n 7 das fom te dle of ea otra @ This repr canot be reproduced excep infu @ Sale descriptions gen as desorbed

be castamer © Sanping roca oye abrir @ Same wl be ostoyed ater 15 ays tom cate of carole oes ues domed byte cuore.

1 Labret Saeris ol com marl pecan at pe Don ule Nan Clr as er econ ue fr ules 2 3 caster odes eth

Format No. ML-CBE/ MS /TR/01

x MICROLAB

Accredited by NABL, Dept. of Science & Technology, Govt. of India.

No. 108, R.M.T. Bungalow Road, Si Nagar 2nd Cross, Opp. Krishnar Temple,

Sideo Industral Estate, Coimbatore - 631 021. Phone: 0822 - 2674872 mee

E-mail: coimbatore@ microlabchennal.com Web : www microlabtesting.com

‘TESTREPORT

Customer: ULR-T€584820000000005

M/s. Flotek Engineering Services., Report No/ Date _| ML/H3866/6/21-22/ Dt: 07.01.2022

Plot No. 15, Door No: 23, Your ref/Date | Letter Date: 30.12 2021

Selvanager,2" Cross, Rettaivaikal, | Ourtet./ Date | TOCR: H3868/21-22/ Dt 01.01.2022

peri al Nature of test | Impact Test

Hl i Test Method | ASTM A370:2020

Trichy ~ 620 102. Date Testing | 07.01.2022

‘Sample Drawn By | Customer

(Ms Welded Plate

“Moterial Grade: 1S 2062 £250 Gré2508R

ae Size: 300 X 300 X 12mm

ba WPS No: BPCL/FES/WPS/WAT-05/W01/2G - 6013

Qty: 1 No.

|L.Gharpy ‘V’ Notch impact Test:

‘Specimen Size (mm): 55 x 10 x 10mm

Charpy “V' Notch

Test Temperature: - RT

Test Parameters | Location | Samplel0:1 | Sample 10:2 | SampleD:3 Average

Observed Energy~ |

pa Weld 66 “8 567

Sbseres Ener | yay a || am | ss ay

Verified by:

For MICROLAB N. Balakrishnan

icateervaran

ized Signatory.

- a END OF THE REPORT:

NOTE: Ths report relates any tothe prada sarpe submited forest @ Any conection inne repo wil vale ts report @ Any compas about is report shoul be

mma im web wh n days te dao recep report ©. Ths fepot cannot be reprodued excep! nfl @ Sample deszpén is ue a sorbed

by he customer © Sarping nc caria ut by ha abr @ Sales wi be destroyed ar TS doys fom data of compton ls ress rfored bye cstovar

‘© Lorn reponse sates lena marl pecan arp Dcson ul, Nan Cefn) as pe Deco ul 8 x Ras 28 3 casomer oes io

Format No. ML-CBE / MS /TR/01

© fea ©

Bhopal, MP-462039 ESE

WELDING PROCEDURE QUALIFICATION RECORD (PQR)

— SR ae

= ed ttt iiavhhenersntqrore

a ‘oe on

Rain. ae en

—

RTE Fe ST

SS

[Type or Grade .GLE250 BR |Time range: NAL

oe crtencavnn te Se) Sa rw

Tae | re

= = +e

ae eee

Eisen tn Sn, ee

=

[——rosmron(awas)_——~i| SCTE TOTO) CS

Sn

PREHEAT (awe ut cr ero Pa le

Prenat np. in we Mute rae sate

ee

age Lof2

FLOTEK ENGINEERING SERVICES "

‘Aeauenkaleoooty @

Bhopal, MP-462039

WELDING PROCEDURE QUALIFICATION RECORD (PAR)

TENSILE TEST (aW-150)

wats | Ticks Rese svengn] Type o Fare &

ier ea (rnz) | Utiate eu

sont wan [ices | pranmmay)_| timate tnt nao [ Trae Seer Te of Fa

7 vem | 200 | moar 087 wo | mabe

1 woos | 200 | aanss ware veo | Deamon

Told Bond Tost GATT

=a Tea] We Tr gra] Manda [Angi ot ena eae

Seni Bend (mm) (eum) [T*C™™ ia am) (Deg)

Sei [Banton] — 200 | 100s | zor | «| — tar | No Open acorn opened

sez [eben] 260 | 1002 [21] ao | 1a] No Open accrues obered

sua [Siete] 200 | 1000 | 1208 | | tar | No Open decors obered

S54 [Sitetond] 260 | 1008 [1208 | 0 | 19 | No Open dcosres observed

Charpy ¥ Notch impact et (OWT)

Toscano sec pemy] Tost | _Everay sorbed valves Joules pact Vate) |

Notch Lecaton | Spedinen Sze remarks

ipecimen Size (mm) | Toimp ‘Sample 1] Sample 2] Sample 3. ‘Average

We coono | er | | [oe “7

vane sexo ev] 12 | 106_[ 208 7

aE ee a

ra —=|

=

SS

ueN fuecve

(foam) OOTY NOULWOISIT¥ND 34NGIOOd ONITTIM

ywous Beg BUIpIOM,

Institute of Inspection Technology

&

NDT Resources

1.0: #2 Navaladiyan Arcade, Pugal Nagar, Kattur, Trichy 620 019 Tamilnadu

Fee: AGFAD7 Technique: sWSt

{Exposure Time: 3Ci Min

[Procedure Neo: HTNOT/RT 003 Rev. 01

BPCL FES WPS WOT 01 WO1 36 6013,

'BPCL FES WPS WOT 07 WO1 26 7018

Bureau Veritas,

India Pvt. Ltd,

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- QW - 482 Welding Procedure Specification (WPS)Document5 pagesQW - 482 Welding Procedure Specification (WPS)Arijit GhoshNo ratings yet

- Welding Welding Procedure Specification (Wps Procedure Specification (WPS) )Document3 pagesWelding Welding Procedure Specification (Wps Procedure Specification (WPS) )Arijit GhoshNo ratings yet

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocument6 pagesQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit GhoshNo ratings yet

- RT BPCL WQT 16.06.2022Document3 pagesRT BPCL WQT 16.06.2022Arijit GhoshNo ratings yet