Professional Documents

Culture Documents

Welding Welding Procedure Specification (Wps Procedure Specification (WPS) )

Uploaded by

Arijit GhoshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Welding Procedure Specification (Wps Procedure Specification (WPS) )

Uploaded by

Arijit GhoshCopyright:

Available Formats

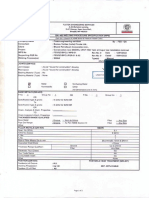

Doc No.

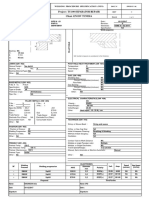

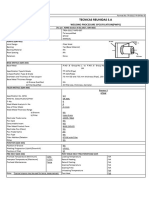

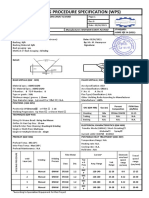

WELDING PROCEDURE SPECIFICATION(WPS)

SPECIFICATION(WPS) Revision :

PIPE 6G Page 1 of 3

WELDING PROCESS: SMAW TYPES: Manual

Client :

Client :

WPS NO. DATE: 09.08.13

Supporting PQR No.

Applicable Code/Spec: ASME Section1X, ANSI B 31.3, AP1 1104

JOINT DETAILS(QW‐402) (See Attached Sketch)

Type: Standard Single Groove Angle:

Groove Angle: 60º‐70º

“V”Bevel

Backing: (YES)_ (NO) X Root Face: 2.0 ± 0.79mm

Root opening:

Root opening: 2.0±1.0mm

BASE METAL (QW‐403)

Material Quality API 5L X 52 to API 5L X 52

Test Piece

Test Piece Dimension 4” Sch 80

Diameter Range ∅2 14”to ∅12 34”

Wall Thickness Range 5.0mm to 14.22mm

Fillet Unlimited

FILLER METAL DETAILS (QW‐ 404)

Parameters Root P

Root Pass Hot P ass Filling and Capping

SFA specification A 5.1 A 5.1 A 5.1

AWS Classification E 6010 E 7010 E 700

F‐ No 3 3 3

A ‐ No 1 1 1

Size 2.5mm 3.2mm 3.2mm

WELDING POSITION (QW‐405)

Welding Position: Groove: 6G Welding Progression: Root

Root Run ‐ Vertic

Vertical

al Up‐hil

Up‐hilll Number of Welders

of Welders

Root Run – 1

Fillet: ALL Second Pass – Vertical Up‐hill Second Pass – 1

Other

Other Passes

Passes – Vertical

Vertical Up‐hill

Up‐hill Other Passes

Passes ‐ 1

PREHEAT (QW‐406)

Preheat temperature: 35º C Interpass temperature: Maximum 250ºC

POST WELD HEAT TREATMENT (QW‐407)

PWHT: NO Method: N/A

Tem

Tempera

peratu

ture

re:: N/A

N/A Hold

Holdin

ingg Tim

Time: N/A

Heating and cooling rate: N/A Loading and unloading temp.: N/A

GAS (QW‐408)

GASES MIXTURE FLOW RATE

Shielding N/A N/A N/A

Trailing N/A N/A N/A

Backing N/A N/A N/A

WPS IN ACCORDANCE WITH ASME IX/ANSI B31.3. WPS PIPE 6G

Doc No. :

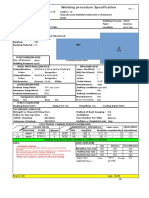

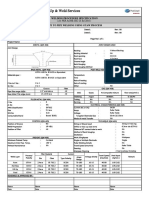

WELDING PROCEDURE SPECIFICATION(WPS)

SPECIFICATION(WPS) Revision :

PIPE 6G Page 2 of 3

WELDING PROCESS: SMAW TYPES: Manual

ELECTRICAL CHARACTERISTICS (QW‐ 409)

Process Weld Pass Amps (Range) Volts (Ran

(Range

ge)) Curr

Curren

ent

t Polarity

SMAW Root pass 50 – 60 20 – 30 Direct El

E lectrode Positive

SMAW Hot Pass 100 – 150 20 – 36 Direct Electrode Positive

SMAW Filling and Capping 100 ‐ 150 20 ‐ 37 Direct Electrode Positive

TECHNIQUE (Q W – 410)

Removal of line –Up Clamp: After at least 65% of the Root Pass.

Bead Characteristics: Root by String bead others by Weave bead

Bead width Restriction: Max 3 times the electrode diameter

Orifice or Gas Cup size: N/A.

Speed of Travel: 2.0 – 4.0”/min

Method of Inter pass cleaning: Grinding/ Mechanical Power Brush.

Time Lapse Between Completion of Root Pass and start of Hot Pass: 5 Minutes Max

Time Lapse Between Completion of Hot Pass and start of Other

5 Minutes Max

Passes:

Minimum Number of passes Before Joint is Allowed to Cool: 3 Passes

Maximum Time Between Commencement and Completion of Weld: 45 minutes

Type of Heater To be Used Propane Gas Torch With Rosebud Nozzle

Peening NO

To maintain the low hydrogen content, electrode shall be baked in accordance with manufacturer’s recommendation

recommendation

and transferred to heat quivers with minimum temperature of 70C

We certify that the statements in this WPS are correct and were prepared, in accordance with the requirements of

section IX of the ASME Code.

o

30 50

2.0 0.79.mm

2.0mm

WPS IN ACCORDANCE WITH ASME IX/ANSI B31.3. WPS PIPE 6G

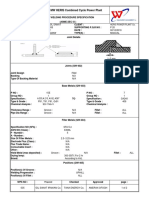

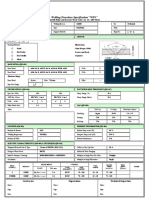

Doc No. :

WELDING PROCEDURE SPECIFICATION(WPS)

SPECIFICATION(WPS) Revision :

PIPE 6G Page 3 of 3

WELDING PROCESS: SMAW TYPES: Manual

STANDARD VEE BEVEL BUTT JOINT

4

3

3

T 2

SEQENCE OF BEAD

WPS IN ACCORDANCE WITH ASME IX/ANSI B31.3. WPS PIPE 6G

You might also like

- Welding Procedure Specification Pipe 6G PDFDocument3 pagesWelding Procedure Specification Pipe 6G PDFchepurthiNo ratings yet

- Welding Procedure Specification (WPS) : WPS-KNM-001 PQR-KNM-001Document4 pagesWelding Procedure Specification (WPS) : WPS-KNM-001 PQR-KNM-001sreejithr86No ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Document2 pagesWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- WDI-WPS-072 Rev.00 SMAW 2Document4 pagesWDI-WPS-072 Rev.00 SMAW 2MohamedNo ratings yet

- Welding Procedure Specification (WPS) : WPS-KNM-001 PQR-KNM-001Document4 pagesWelding Procedure Specification (WPS) : WPS-KNM-001 PQR-KNM-001sreejithr86No ratings yet

- PWPS CS To SS446-3Document5 pagesPWPS CS To SS446-3BIIS QAQC Babu SivaNo ratings yet

- WPS-CS-113 Rev.1Document2 pagesWPS-CS-113 Rev.1Muhammad BilalNo ratings yet

- Project: Ts 100 Separator Repair: Welding Procedure Specification (WPS)Document1 pageProject: Ts 100 Separator Repair: Welding Procedure Specification (WPS)Anonymous 7aUHXY1vWbNo ratings yet

- WPS PQR ProcedureDocument31 pagesWPS PQR Proceduresudeesh kumarNo ratings yet

- WPS PQR Procedure PDFDocument31 pagesWPS PQR Procedure PDFsudeesh kumarNo ratings yet

- Welding Procedure Specification: JOINT (QW-402)Document10 pagesWelding Procedure Specification: JOINT (QW-402)Lipika GayenNo ratings yet

- WPS PQR CompleteDocument49 pagesWPS PQR CompleteGulfam HussainNo ratings yet

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- Welding Procedure Specification FormatDocument3 pagesWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04Document9 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04BIIS QAQC Babu SivaNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- WPS 03 GtawDocument3 pagesWPS 03 GtawBiswajit DeyNo ratings yet

- Tecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)Document2 pagesTecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)BIIS QAQC Babu SivaNo ratings yet

- Welding Procedure Specification (WPS) : Joint Design PositionDocument9 pagesWelding Procedure Specification (WPS) : Joint Design PositionpetermanroelibraryNo ratings yet

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Document2 pagesLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNo ratings yet

- Wps For Steel RodsDocument5 pagesWps For Steel RodsHamid MansouriNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDocument10 pagesWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- Arl-Al - WPS-001 PDFDocument2 pagesArl-Al - WPS-001 PDFrajuajiNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- WPS-035 - (Pno.15e To Pno.7) - 2Document2 pagesWPS-035 - (Pno.15e To Pno.7) - 2Allahyar YekkalamNo ratings yet

- Ce0034-Wps PQR02 E7.62 P01 01 PDFDocument1 pageCe0034-Wps PQR02 E7.62 P01 01 PDFKhaled BouhlelNo ratings yet

- PQR Acero Al CarbonoDocument2 pagesPQR Acero Al CarbonoROBERTO QUESADANo ratings yet

- 347 310 WPSDocument2 pages347 310 WPSBIIS QAQC Babu SivaNo ratings yet

- Astm 537 CL.1 WPSDocument2 pagesAstm 537 CL.1 WPSaudiihussain67% (3)

- Welding Procedure Specification (WPS) : Manufacturer: NAHADIN SANAT ALVANDDocument2 pagesWelding Procedure Specification (WPS) : Manufacturer: NAHADIN SANAT ALVANDvahid mobiniNo ratings yet

- WPS No. ST-CS-02-2Document1 pageWPS No. ST-CS-02-2Hussein JassimNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (5)

- Daewoo E & C: Welding Procedure Specification (WPS)Document2 pagesDaewoo E & C: Welding Procedure Specification (WPS)Jarus YdenapNo ratings yet

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- Mathew Associates Hook Up & Weld Services: Welding Procedure SpecificationDocument1 pageMathew Associates Hook Up & Weld Services: Welding Procedure SpecificationHimanshu SinghNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- Wps For Carbon Steel THK 7.11 GtawDocument1 pageWps For Carbon Steel THK 7.11 GtawAli MoosaviNo ratings yet

- WPS For Carbon Steel THK 7.11 GTAWDocument1 pageWPS For Carbon Steel THK 7.11 GTAWAli Moosavi100% (1)

- Aic Asf PQR 0119Document2 pagesAic Asf PQR 0119AHMED MEDANYNo ratings yet

- Procedure Qualification Record PQRDocument3 pagesProcedure Qualification Record PQRNMBaihakiARNo ratings yet

- WQT Form (ASME) 04-23Document1 pageWQT Form (ASME) 04-23hanz bermejoNo ratings yet

- WPS-PQR RepairDocument16 pagesWPS-PQR RepairmohammedetaNo ratings yet

- Procedure Qualification RecordsDocument2 pagesProcedure Qualification RecordsRM ENTERPRISESNo ratings yet

- Request For Welding Procedure ApprovalDocument13 pagesRequest For Welding Procedure ApprovalecsuperalNo ratings yet

- Draf WPSDocument2 pagesDraf WPSMj EdinNo ratings yet

- WPS and PQRDocument4 pagesWPS and PQRdandiar1No ratings yet

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- Welding Procedure Specification (WPS) : Code: Asme-IxDocument2 pagesWelding Procedure Specification (WPS) : Code: Asme-IxAnonymous 4WzixLwupNo ratings yet

- Procedure Qualification Records (PQR) : KAL.f.009 REV:01 01.07.2002Document2 pagesProcedure Qualification Records (PQR) : KAL.f.009 REV:01 01.07.2002Walid BdeirNo ratings yet

- Joint Detail (Qw-402)Document2 pagesJoint Detail (Qw-402)Nitesh Patel100% (3)

- Welding Procedure Specification: (As Per Asme Sec Ix)Document1 pageWelding Procedure Specification: (As Per Asme Sec Ix)Himanshu SinghNo ratings yet

- WPS PQRDocument126 pagesWPS PQRBuditama ChandranegaraNo ratings yet

- PRN004Document2 pagesPRN004beyNo ratings yet

- QW - 482 Welding Procedure Specification (WPS)Document5 pagesQW - 482 Welding Procedure Specification (WPS)Arijit GhoshNo ratings yet

- Wps-E 6013 - 3G&2GDocument15 pagesWps-E 6013 - 3G&2GArijit GhoshNo ratings yet

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocument6 pagesQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit GhoshNo ratings yet

- RT BPCL WQT 16.06.2022Document3 pagesRT BPCL WQT 16.06.2022Arijit GhoshNo ratings yet

- Astm E1975 - 1 (En)Document17 pagesAstm E1975 - 1 (En)Dinesh Sai100% (1)

- 2022 Specimen Paper 1 Mark Scheme 1Document4 pages2022 Specimen Paper 1 Mark Scheme 1Herman HermanNo ratings yet

- CE-401CE 2.0 Network Diagrams 2015Document83 pagesCE-401CE 2.0 Network Diagrams 2015Shubham BansalNo ratings yet

- Ground Investigation ReportDocument49 pagesGround Investigation Reportjoemacx6624No ratings yet

- Craig - 4353 TX CobraDocument3 pagesCraig - 4353 TX CobraJorge ContrerasNo ratings yet

- CPower Product Training.09.2016.EnDocument70 pagesCPower Product Training.09.2016.Enerdinc100% (1)

- INERT-SIEX 200-300 IG-100: Design ManualDocument54 pagesINERT-SIEX 200-300 IG-100: Design ManualSaleh Mohamed0% (1)

- Previous Years Questions (2020-1983) Segment-Wise: Ordinary Differential EquationsDocument16 pagesPrevious Years Questions (2020-1983) Segment-Wise: Ordinary Differential EquationsAniket bhaiNo ratings yet

- Warm and Humid GREEN BUILDING CASE STUDYDocument8 pagesWarm and Humid GREEN BUILDING CASE STUDYPooja PrakashNo ratings yet

- Taenia SoliumDocument40 pagesTaenia SoliumBio SciencesNo ratings yet

- Ebp Cedera Kepala - The Effect of Giving Oxygenation With Simple Oxygen Mask andDocument6 pagesEbp Cedera Kepala - The Effect of Giving Oxygenation With Simple Oxygen Mask andNindy kusuma wardaniNo ratings yet

- Formula 1638 Collagen Eye CreamDocument2 pagesFormula 1638 Collagen Eye CreamLinh Sa LaNo ratings yet

- Exercises PDFDocument39 pagesExercises PDF910220No ratings yet

- Balance Diet and NutritionDocument9 pagesBalance Diet and NutritionEuniceNo ratings yet

- Cosmetic-Regulations, Research & Marketing Challenges and Global Compliance: An OverviewDocument19 pagesCosmetic-Regulations, Research & Marketing Challenges and Global Compliance: An Overviewmaria sepulvedaNo ratings yet

- Crane Inspection ChecklistDocument1 pageCrane Inspection ChecklistsudhakarNo ratings yet

- Provisional Restorations in Fixed ProsthodonticsDocument4 pagesProvisional Restorations in Fixed ProsthodonticsPhoebe David100% (1)

- Op Amp AssignmentDocument10 pagesOp Amp AssignmentJuan-Wian CoetzerNo ratings yet

- Our School Broke Up For The Winter VacationsDocument7 pagesOur School Broke Up For The Winter VacationsprinceNo ratings yet

- High Risk Neonatal Nursing CareDocument40 pagesHigh Risk Neonatal Nursing Carecarol_cezar100% (2)

- Chm130 Test Batch-2Document3 pagesChm130 Test Batch-2misakisuki7No ratings yet

- Theories of DissolutionDocument17 pagesTheories of DissolutionsubhamNo ratings yet

- Whitepaper - Loadspreading and SeafasteningDocument3 pagesWhitepaper - Loadspreading and SeafasteningtyuNo ratings yet

- Project Sanjay YadavDocument51 pagesProject Sanjay YadavriyacomputerNo ratings yet

- Lover Album LyricsDocument34 pagesLover Album LyricsMichael PlanasNo ratings yet

- 002-679e-08.19 v1.6.x KLDocument523 pages002-679e-08.19 v1.6.x KLChanon OnramoonNo ratings yet

- Final ExamDocument5 pagesFinal Examirtiza200No ratings yet

- Cross Border Pack 2 SumDocument35 pagesCross Border Pack 2 SumYến Như100% (1)

- HVT DS HAEFELY RIC 422 Reference Impulse Calibrator V2004Document4 pagesHVT DS HAEFELY RIC 422 Reference Impulse Calibrator V2004leivajNo ratings yet

- The Book of JonahDocument2 pagesThe Book of JonahJames Hampton BeltonNo ratings yet