0% found this document useful (0 votes)

8 views1 pageOHS Task Analysis for Heavy Machinery Use

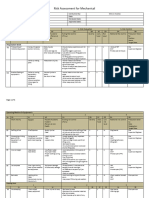

The document outlines a task analysis for construction workers using heavy machinery, detailing steps from pre-operational checks to post-operation inspections. It identifies potential hazards at each stage and suggests risk control measures, assigning responsibilities to various personnel. The focus is on ensuring safety through proper procedures and communication during machinery operation.

Uploaded by

hashirhaider78Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

8 views1 pageOHS Task Analysis for Heavy Machinery Use

The document outlines a task analysis for construction workers using heavy machinery, detailing steps from pre-operational checks to post-operation inspections. It identifies potential hazards at each stage and suggests risk control measures, assigning responsibilities to various personnel. The focus is on ensuring safety through proper procedures and communication during machinery operation.

Uploaded by

hashirhaider78Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd