0% found this document useful (0 votes)

13 views20 pagesT102 (1) Updated

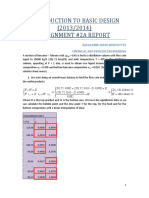

Chapter 6 focuses on the design of a binary distillation column, detailing the necessary calculations for feed, distillate, and bottom conditions, as well as operating parameters like reflux ratio and theoretical stages. It includes hydraulic and process design specifics for a methanol-water distillation column, covering aspects such as column diameter, weeping conditions, pressure drop, and downcomer liquid backup. The chapter provides both empirical data and equations necessary for effective distillation column design.

Uploaded by

ah779612Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

13 views20 pagesT102 (1) Updated

Chapter 6 focuses on the design of a binary distillation column, detailing the necessary calculations for feed, distillate, and bottom conditions, as well as operating parameters like reflux ratio and theoretical stages. It includes hydraulic and process design specifics for a methanol-water distillation column, covering aspects such as column diameter, weeping conditions, pressure drop, and downcomer liquid backup. The chapter provides both empirical data and equations necessary for effective distillation column design.

Uploaded by

ah779612Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd