0% found this document useful (0 votes)

43 views6 pagesIBRAHIM

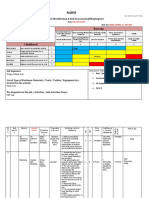

The report assesses workplace safety in a chemical manufacturing facility, identifying key hazards including chemical exposure and work-related stress as the highest risks. Proposed control measures emphasize engineering solutions and administrative changes over reliance on personal protective equipment (PPE). Recommendations include investing in safer chemical alternatives, improving mental health support, and enhancing training on chemical hazards.

Uploaded by

godstimemonday4Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

43 views6 pagesIBRAHIM

The report assesses workplace safety in a chemical manufacturing facility, identifying key hazards including chemical exposure and work-related stress as the highest risks. Proposed control measures emphasize engineering solutions and administrative changes over reliance on personal protective equipment (PPE). Recommendations include investing in safer chemical alternatives, improving mental health support, and enhancing training on chemical hazards.

Uploaded by

godstimemonday4Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd